Kiln for melting high-alkali aluminosilicate glass

A technology for silicate glass and melting glass, applied in the field of glass kilns and special equipment, can solve the problems of low melting quality, thermal efficiency and low energy consumption, and achieve the effects of improving heat transfer, reducing combustion intensity, and being beneficial to environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

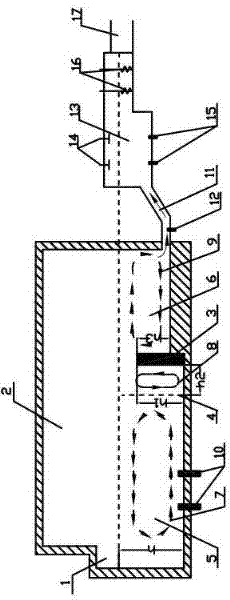

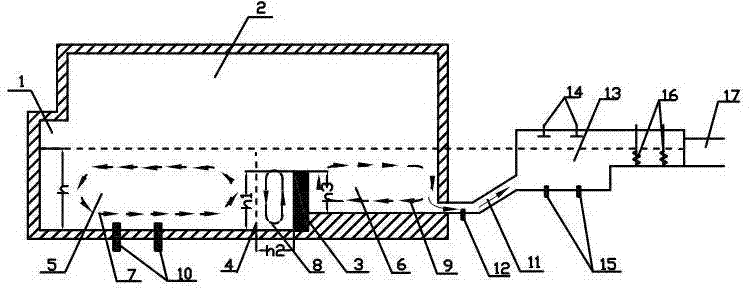

[0022] Such as figure 1 As shown, the present invention is a furnace for melting high-alkali aluminosilicate glass, the furnace includes a heating system matched with the furnace, and the structure of the furnace includes: a pre-melting pool 1 for melting glass and a A cross-flame melting pool 2 connected to it, in which a kiln ridge 3 for separating the molten glass flow into a melting zone 5 and a clarifying zone 6 is provided. The liquid hole 11 connecting the melting pool 2 and the feeding channel 13 is provided with a stirring unit 16 .

[0023] In the kiln for melting high alkali aluminosilicate glass, bubbles 4 are arranged in front of kiln ridge 3; in the kiln for melting high alkali aluminosilicate glass, kiln ridge 3 and bubbling 4 meet the following requirements:

[0024] h 1 =0.7~0.8H

[0025] h 2 =1.0~1.5H

[0026] h 3 =0.5~0.6H

[0027] Where H is the depth of glass liquid, H 1 is the kiln ridge height, H 2 is the distance from the kiln sill to the bubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com