Heat storage phase change heat exchanger and method for promoting crystallization of sugar alcohol phase change material and reducing degree of supercooling

A technology of phase-change heat exchanger and phase-change material, which is applied in heat storage phase-change heat exchangers, promotes the crystallization of sugar alcohol phase change materials and reduces the degree of subcooling, and can solve problems such as difficulty in sugar alcohol crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings. However, the embodiments of the present invention are not limited thereto, and any technical concepts defined in the claims of the present invention and other simple transformations based on them are within the protection scope of the present invention.

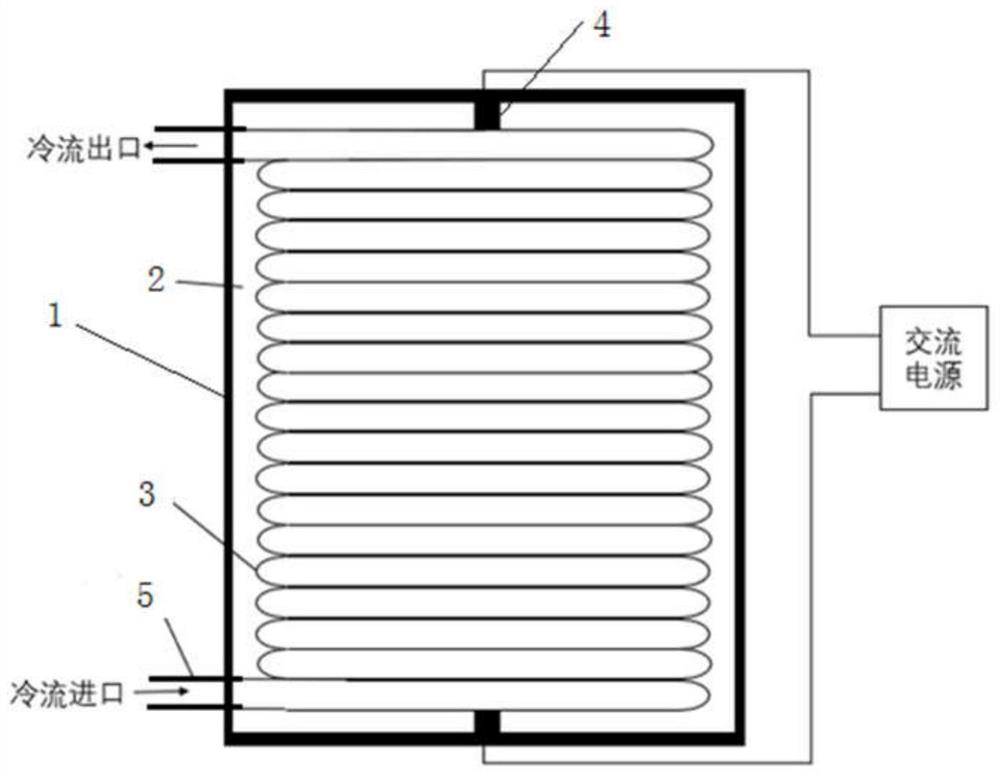

[0022] Such as figure 1 As shown, the thermal storage phase change heat exchanger that can promote the crystallization of sugar alcohol phase change materials and reduce the degree of subcooling includes a heat exchanger body 1, and the outer shell of the heat exchanger body is composed of a metal shell, heat preservation layer and an insulating plastic cavity; the insulating plastic cavity is filled with sugar alcohol phase change heat storage material 2, and the insulating plastic cavity is also provided with an annular coil 3 as a working medium flow channel, and the annular coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com