Oscillatory scanning laser beam-electric arc hybrid welding method and system

A hybrid welding and laser beam technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inability to meet the welding requirements of light alloy structures, difficulty in implementing laser beam scanning movement, and single laser beam scanning path. problems, achieve excellent technical capabilities, improve welding characteristics and welding quality, and reduce welding spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

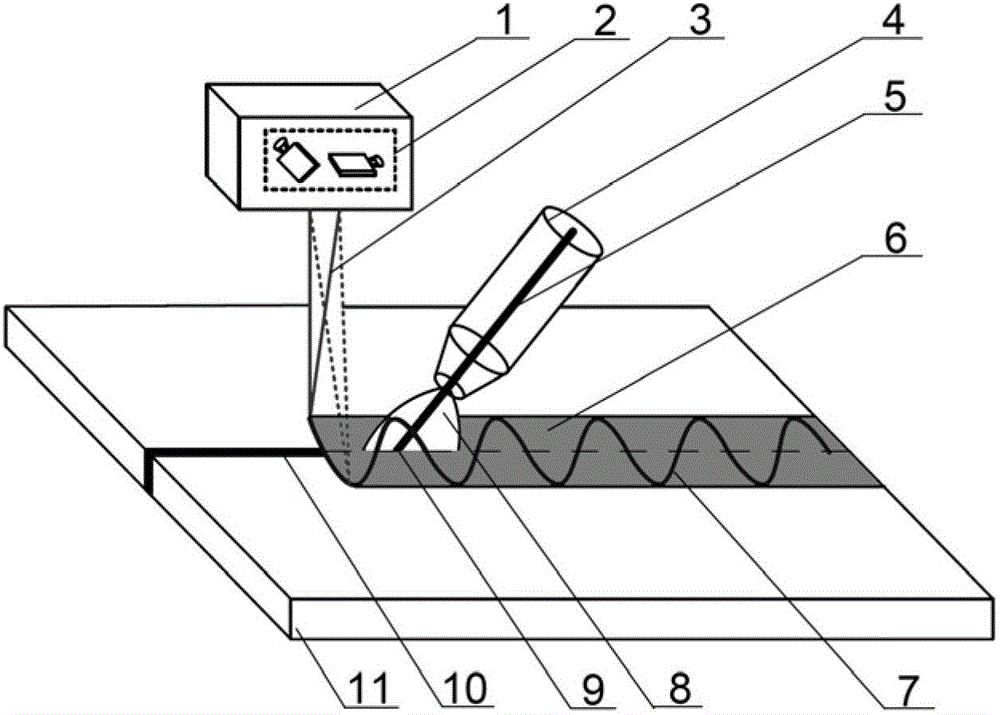

[0040] The workpiece material is 6082-T6 deformed aluminum alloy with a thickness of 8mm, and the welding method is flat welding.

[0041] In this embodiment, the operating platform is a six-axis robot system, the laser light source is a 10,000W fiber laser, the arc heat source is a 500A pulse digitally controlled fusion inert gas welder, the laser beam is transmitted to the vibrating mirror through an optical fiber, and the focal length of the vibrating mirror is 300mm.

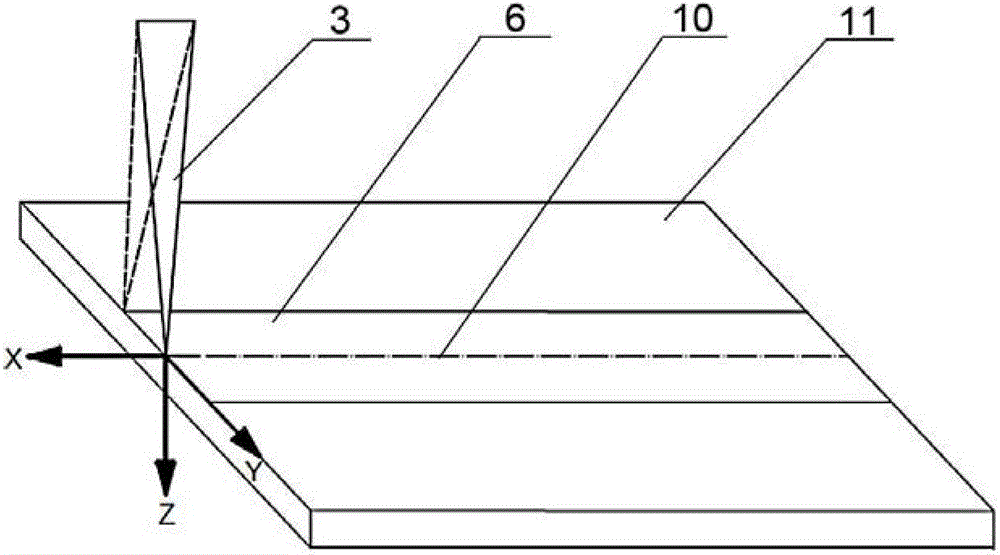

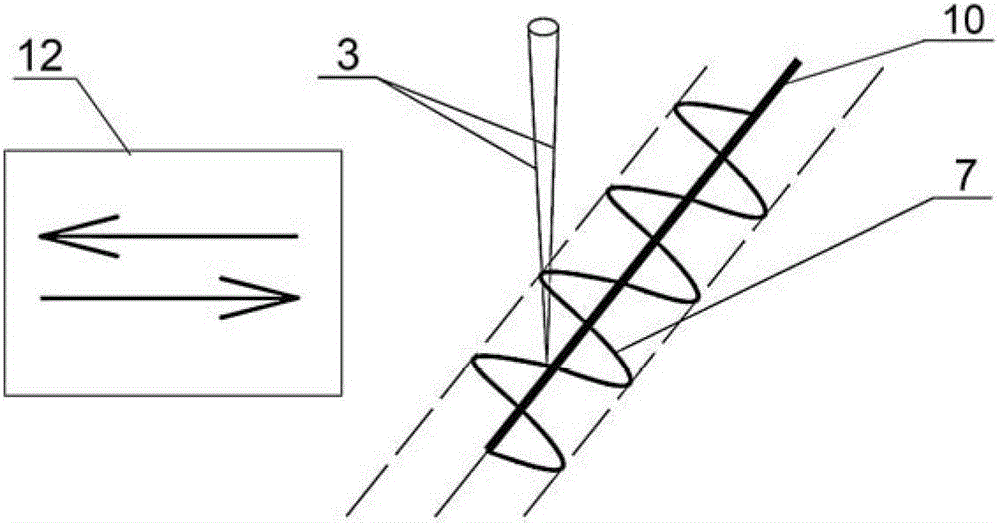

[0042] The technical parameters of the oscillating laser beam-arc hybrid welding in this embodiment are: the angle between the laser beam and the arc torch is 30°, the laser-arc distance is 4mm, the defocus of the laser beam is -2mm, the laser power is 10000W, and the arc current The welding speed is 320A, the welding speed is 6m / min; the scanning displacement range of the laser beam in the X direction is -2-3mm, the scanning displacement in the Y axis direction is -5-5mm, and the scanning displacement in the...

Embodiment 2

[0045] The workpiece material is AZ31B wrought magnesium alloy with a thickness of 2mm, and the welding method is flat welding.

[0046] In this embodiment, the operating platform is a six-axis robot system, the laser light source is a 2000W DISC laser, the arc heat source is a 200A tungsten argon arc welding machine, the laser beam is transmitted to the vibrating mirror through an optical fiber, and the focal length of the vibrating mirror is 250mm.

[0047] The technical parameters of the oscillating laser beam-arc hybrid welding in this embodiment are: the angle between the laser beam and the arc torch is 40°, the laser-arc distance is 1mm, the defocus of the laser beam is 2mm, the laser power is 500W, and the arc current is 150A, the welding speed is 2m / min, the scanning displacement of the laser beam in the X direction is -1-2mm, the scanning displacement in the Y axis direction is -3-3mm, and the scanning displacement in the Z axis direction is -1-1mm, The oscillation fr...

Embodiment 3

[0050] The workpiece material is a TC4 titanium alloy cylinder with a thickness of 5mm, and the welding method is circular seam splicing.

[0051] In this embodiment, the operating platform is a three-axis CNC machining platform, and the laser light source is an 8000W CO 2 The slab laser, the arc heat source is a 500A pulse digital control fusion inert gas welding machine, the laser beam is transmitted to the vibrating mirror through the optical transmission mirror group, and the focal length of the vibrating mirror is 400mm.

[0052] The specific process parameters of the oscillating laser beam-arc hybrid welding in this embodiment are: the angle between the laser beam and the arc welding torch is 35°, the laser-arc distance is 2.5mm, the defocus of the laser beam is 0, the laser power is 4000W, the arc The current is 200A, the welding speed is 2.5m / min, the scanning displacement of the laser beam in the X direction is -1-1mm, the scanning displacement in the Y axis direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com