Aerosol product, preparation method and application

An aerosol generation and aerosol technology, applied in the field of tobacco, can solve the problems of reducing the cooling surface area, high flue gas temperature, adhesion and collapse, etc., and achieve the effect of good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

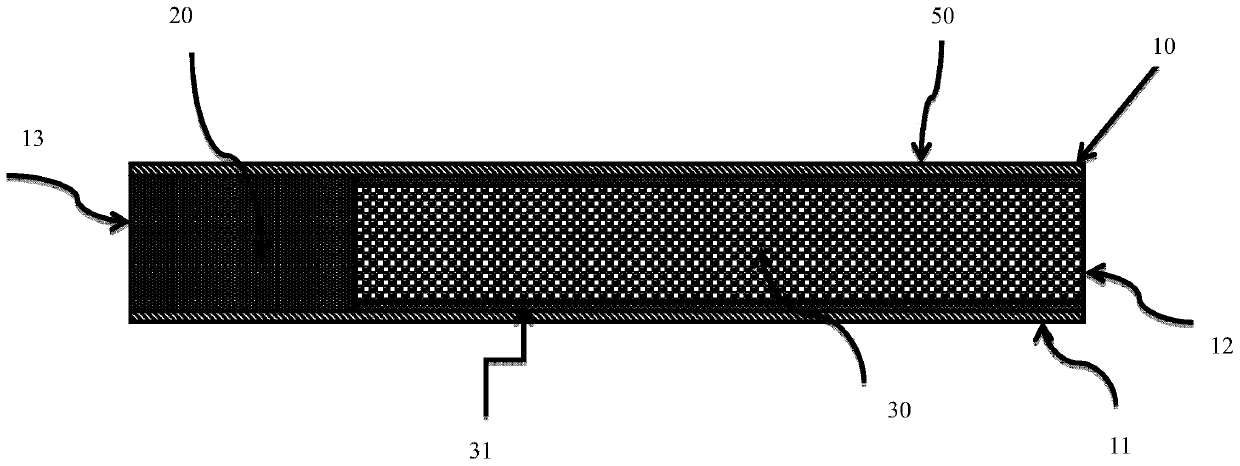

[0045] Such as figure 1 , the present invention is a two-stage aerosol generating product 10 with a unit for reducing the temperature of flue gas, comprising two units: an aerosol atomization unit 20 and a flue gas cooling unit 30 . These two units are sequentially coaxially assembled into a rod 11 with the cigarette paper 50 using a rod composite forming machine. The aerosol atomization unit 20 is located at the farthest end 13 of the bar; the smoke cooling unit 30 is located downstream of the aerosol atomization unit, and the bar 11 has a mouth end 12 . When compositely assembled by the forming machine, the rod 11 has a length of approximately 45 mm, an outer diameter of approximately 7.2 mm, and an internal diameter of approximately 6.9 mm.

[0046] The aerosol atomizing unit 20 comprises filamentary or crimped tobacco material, rolled by a cigarette making device, wrapped in filter paper (not shown) to form a rod. The tobacco material includes additives including aerosol...

Embodiment 2

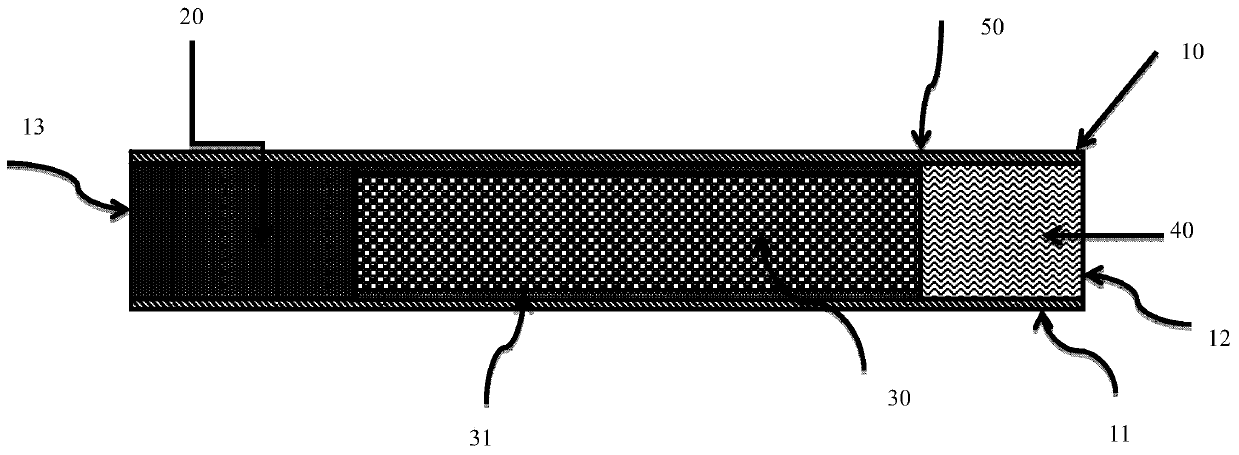

[0054] Such as figure 2 As shown, the present invention is a three-stage aerosol generating product 10 with a unit for reducing the temperature of smoke, including three units: an aerosol atomization unit 20 , a smoke cooling unit 30 and a filter 40 . The aerosol atomization unit 20 is located at the farthest end 13 of the bar; the smoke cooling unit 30 is located downstream of the aerosol atomization unit; the filter 40 is located downstream of the smoke cooling unit, and the bar 11 has a mouth end 12 . The three units are sequentially and coaxially wrapped tightly with cigarette paper 50 and assembled into a rod 11 . When compositely assembled, the bar 11 has a length of approximately 45 mm, an outer diameter of approximately 7.2 mm, and an internal diameter of approximately 6.9 mm.

[0055] The aerosol atomizing unit 20 comprises filamentary or crimped tobacco material, rolled by a cigarette making device, wrapped in filter paper (not shown) to form a rod. The tobacco ma...

Embodiment 3

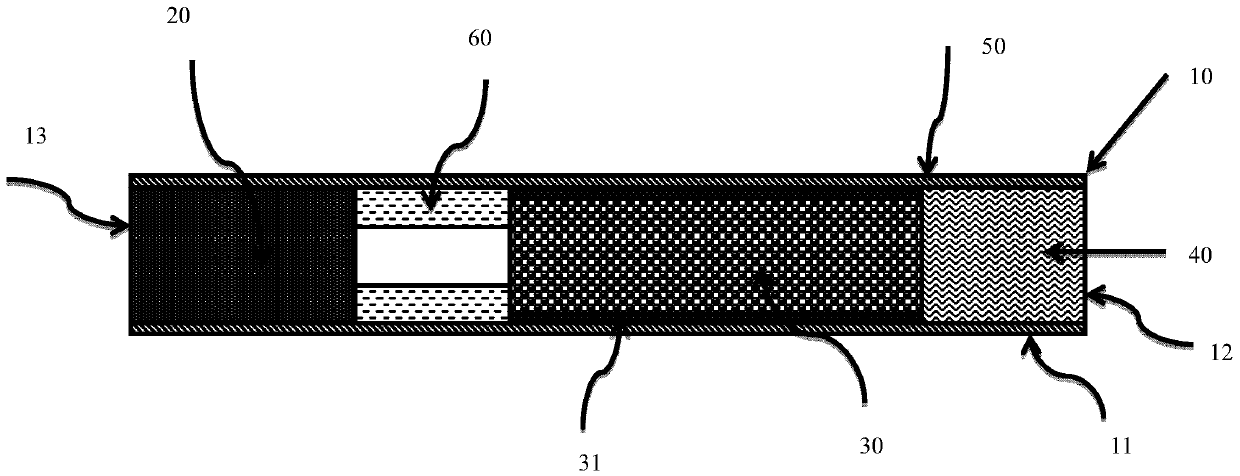

[0067] Such as image 3 As shown, a four-stage aerosol generating product 10 with a unit for reducing the temperature of smoke includes four units: an aerosol atomization unit 20 , a hollow cellulose acetate tube 60 , a smoke cooling unit 30 and a filter 40 . These four units are coaxially wrapped tightly with cigarette paper 50 in sequence and assembled into a rod 11 . The aerosol atomization unit 20 is located at the farthest end 13 of the bar; the hollow cellulose acetate tube 60 is downstream of the aerosol atomization unit; the smoke cooling unit 30 is downstream of the hollow cellulose acetate tube; Downstream of the air cooling unit, the bar 11 has a mouth end 12 . When assembled by a cigarette maker, the rod 11 has a length of approximately 45 mm, an outer diameter of approximately 7.2 mm and an internal diameter of approximately 6.9 mm. The aerosol atomizing unit 20 comprises filamentary or crimped tobacco material, rolled by a cigarette making device, wrapped in fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com