Preparation method of specially-shaped cigarettes with naturally endowed aroma

A flavoring and special-shaped technology, which is applied in the preparation of tobacco, tobacco, application, etc., can solve the problems of unstable quality, unstable quality of cigarette products, incision shedding, etc., and achieve the effect of improving sensory quality, high cost, and avoiding empty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

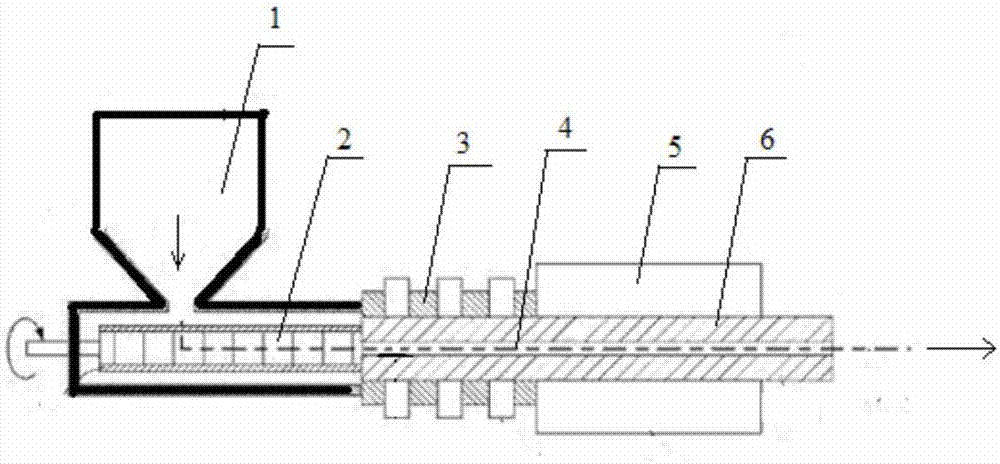

Method used

Image

Examples

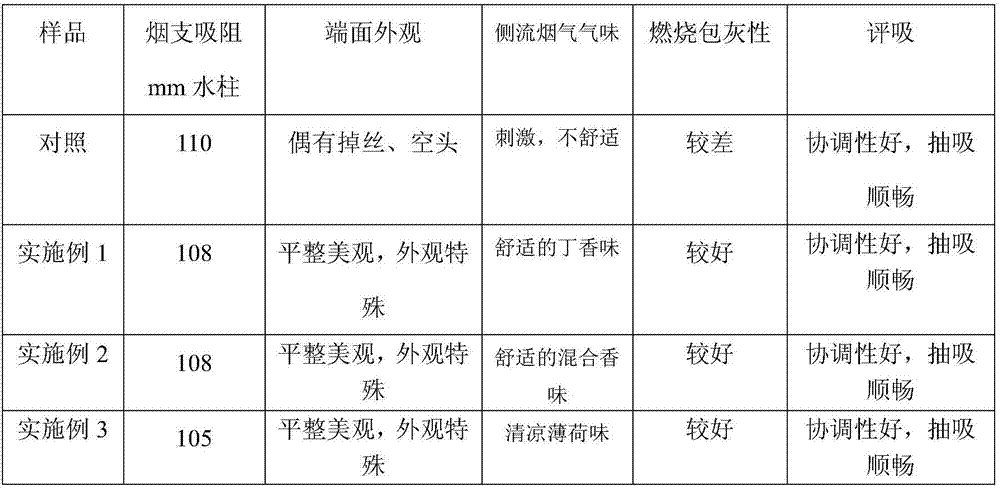

Embodiment 1

[0049] 1) Grinding tobacco raw materials such as tobacco leaves and tobacco stems into 100-150 mesh tobacco powder at 40°C; 2) Grinding clove dried flowers into 100-150 mesh clove powder at 15°C; 3) mixing the above tobacco powder and clove powder 100 parts and 0.5 parts by mass are uniformly mixed, and the resulting mixed powder is set aside; 4) Potassium citrate, 10% carboxymethyl cellulose aqueous solution and propylene glycol are uniformly stirred according to 0.2 parts, 8 parts and 0.2 parts by mass to obtain Mixed solution; 5) granulate the above-mentioned tobacco / flavor mixture powder and the mixed solution in one step, dry and air-select the tobacco particles with a particle size of 20-80 mesh for subsequent use; 6) weigh 10% white latex for tobacco by weight of the tobacco particles , and spray it evenly on the surface of the above-mentioned tobacco particles, use a continuous feeding device to press it from one end of a cylindrical mold with a diameter of 7.5mm (the i...

Embodiment 2

[0051] 1) Grinding tobacco raw materials such as tobacco leaves and tobacco stems at 40°C into 100-150 mesh tobacco powder; 2) Grinding cloves and cardamom according to 1 and 5 parts by mass at 20°C into 100-120 mesh mixed spice powder ; 3) mix the above-mentioned tobacco powder and mixed spice powder according to 100 parts by mass and 1.5 parts evenly, and the resulting mixed powder is set aside; 4) mix potassium citrate, 15% modified starch aqueous solution and honey according to 0.1 part by mass, 10 parts and 0.3 parts were stirred evenly to obtain a mixed solution; 5) The above-mentioned tobacco powder and the mixed solution were granulated in one step, dried and air-selected to obtain tobacco particles with a particle size of 20-80 mesh for subsequent use; 6) Weighing 15% of the weight of the tobacco particles Polyethylene hot-melt adhesive is sprayed evenly on the surface of the above-mentioned tobacco particles after it is melted, and it is pressed in from one end of a c...

Embodiment 3

[0053] 1) Grinding tobacco raw materials such as tobacco leaves and tobacco stems into 100-150 mesh tobacco powder at 40°C; 2) Grinding mint and Angelica dahurica into 100-120 mesh mixed spice powder at 40°C according to 4 parts by mass and 1 part by mass ; 3) mix the above-mentioned tobacco powder and mixed spice powder according to 100 parts by mass and 4 parts evenly, and the resulting mixed powder is for later use; 4) mix sodium citrate, 10% modified starch aqueous solution and glycerin material according to 0.3 parts by mass , 8 parts and 1 part were stirred evenly to obtain a mixed solution; 5) the above-mentioned mixed powder and mixed solution were granulated in one step, dried and air-selected to take a particle diameter of 20-80 mesh tobacco particles for subsequent use; 6) weigh the tobacco particle weight 15% polymerized rosin hot-melt glue, after it is melted, spray evenly on the surface of the above-mentioned tobacco particles, use a continuous feeding device to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com