Heating atomization electronic cigarette using capacitances to supply power

A technology of heating atomization and electronic cigarettes, which is applied in the field of electronic cigarettes. It can solve the problems that ex-smokers are not easy to control the amount of smoking, reduce the overall weight of electronic cigarettes, and the weight of rechargeable batteries, etc., and achieve light weight, enhanced atomization effect, charging and discharging. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

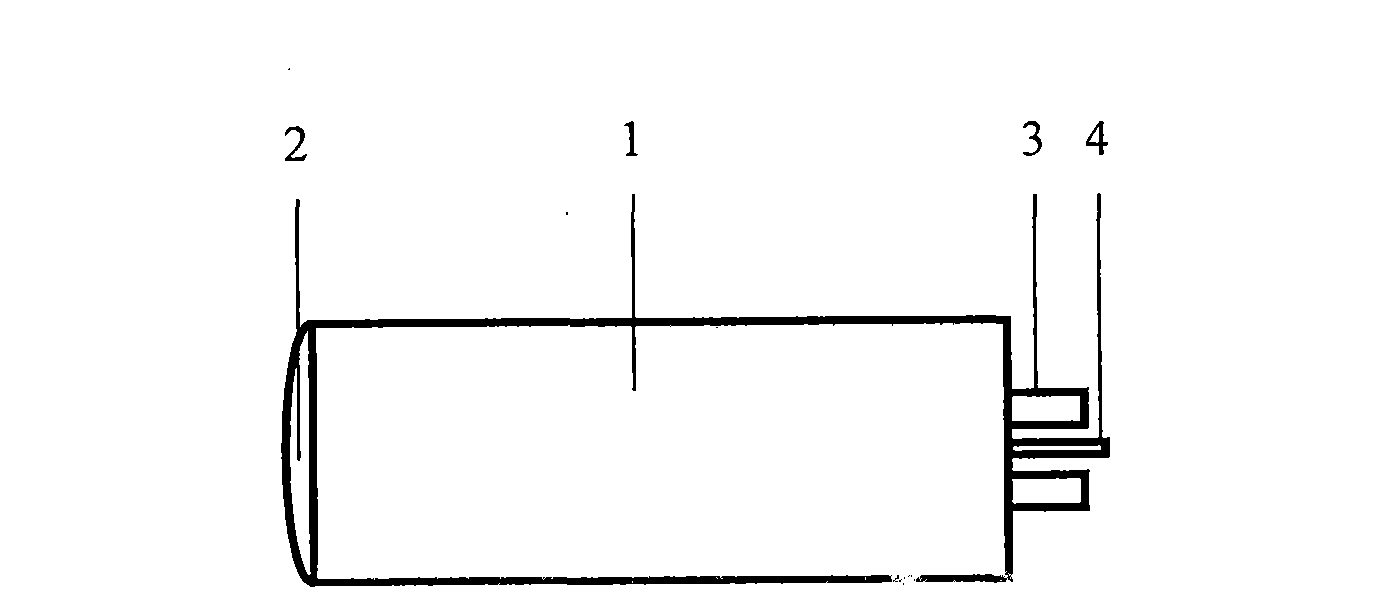

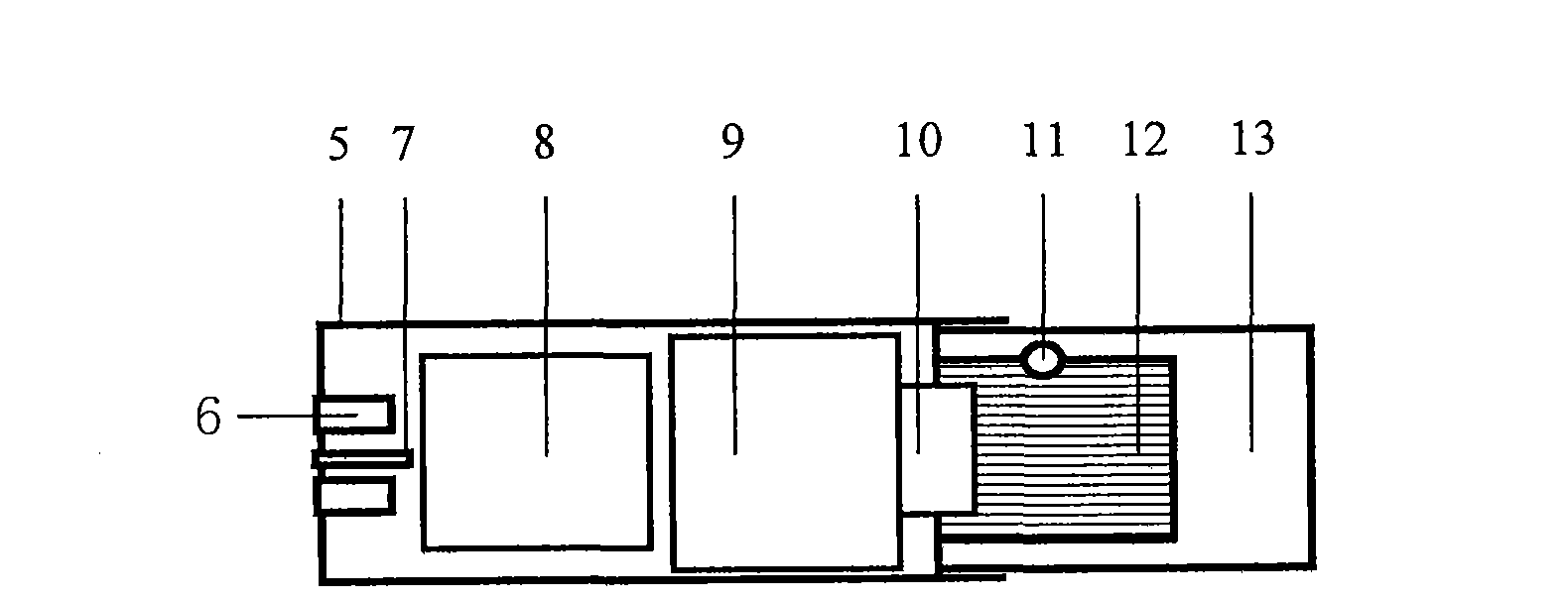

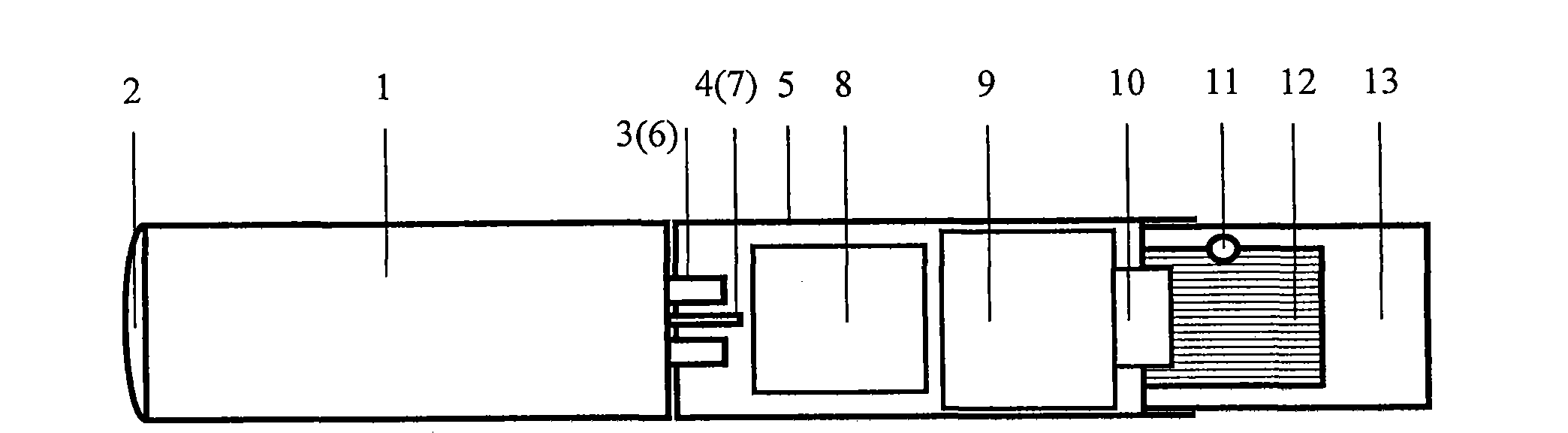

[0061] In this embodiment, the outer diameter of the power supply 1 and the hollow tobacco rod 5 are the same, about 8 mm, which is equivalent to the size of a conventional cigarette; For capacitors, the capacitor parameters can be 2.7V (voltage), 5F (capacitance), Φ8.2mm (outer diameter) × 25.8mm (length), this type of capacitor is available in the market (Samsung Capacitor). In addition to this capacitor product, capacitors with other parameters that meet the requirements can also be selected.

[0062] In this embodiment, the casing of the power supply 1 can be directly used as the casing of the power supply part, so as to ensure that the power supply capacity per unit mass of the electronic cigarette is improved. It should be noted that this embodiment does not rule out that a housing for the power supply part is additionally provided as required. The indicator light 2 is located at the rear end of the power supply 1, and the electrode plug joint 3 and the lead wire plug...

Embodiment 2

[0067] The difference between this embodiment and Embodiment 1 is that in this embodiment, the electric heater of the heating and atomizing device 9 is made of porous ceramic resistors, and the resistance value range is still 0.5Ω-10Ω.

[0068] In this embodiment, all other components have been thoroughly explained in Embodiment 1, so no detailed description will be given in this embodiment.

Embodiment 3

[0070] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that in this embodiment, the electric heater of the heating atomization device 9 is made of metal fibers (such as stainless steel metal fibers) or resistance wires, and its resistance value range is still 0.5Ω~10Ω.

[0071] In this embodiment, all other components have been thoroughly explained in Embodiment 1, so no detailed description will be given in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com