Self-resetting assembled pier column system with seismic mitigation and isolation functions

A seismic isolation and self-reset technology, applied in protection devices, buildings, bridges, etc., can solve the problems of plastic hinge transfer, large residual displacement, cracking at joints, etc., to achieve simple structure, good joint durability, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach example 1

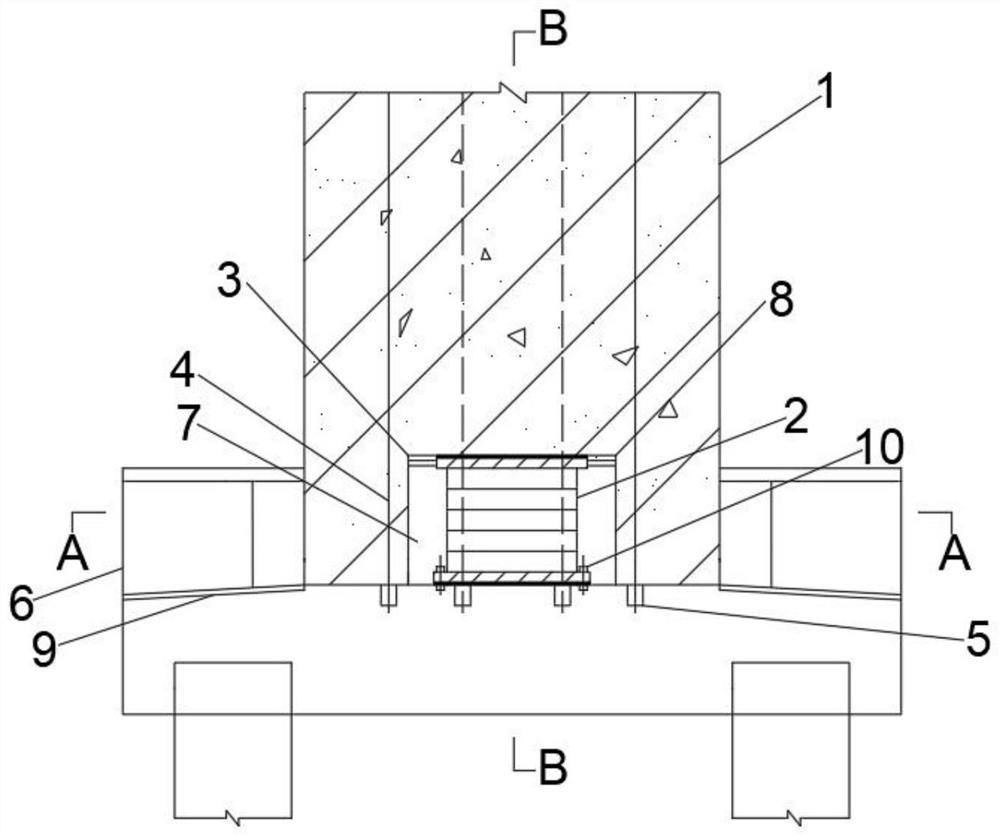

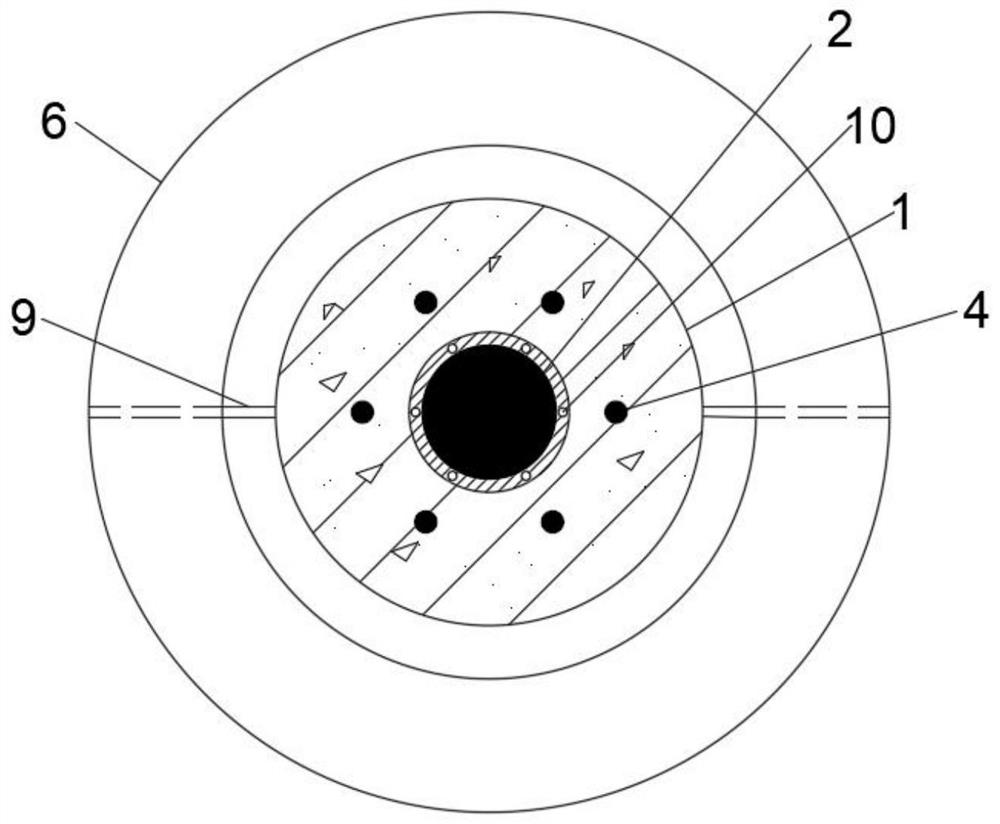

[0024] Such as figure 1 , figure 2 , image 3 The self-resetting assembled pier system with the function of shock absorption and isolation connected by epoxy resin is mainly used in areas with medium and low intensity to play the role of shock absorption and isolation. Including prefabricated reinforced concrete pier column section 1, shock-absorbing and isolating rubber bearing 2, epoxy resin glue 3, shape memory alloy (SMA) rod 4, grouting sleeve 5, cap 6, reserved notch 7, water stop Belt 8, drainage groove 9, high-strength bolt 10. The diameter of the prefabricated reinforced concrete pier section 1 is 160cm; the vibration-absorbing and isolating rubber bearing 2 is a laminated rubber bearing with a diameter of 50cm and a height of 70cm. The steel plates above and below the bearing have a diameter of 60cm and a thickness of 5cm; epoxy resin The thickness of the glue 3 is 1cm; the diameter of the shape memory alloy (SMA) steel bar 4 is 1.6cm, and the number is 6; the di...

Embodiment approach example 2

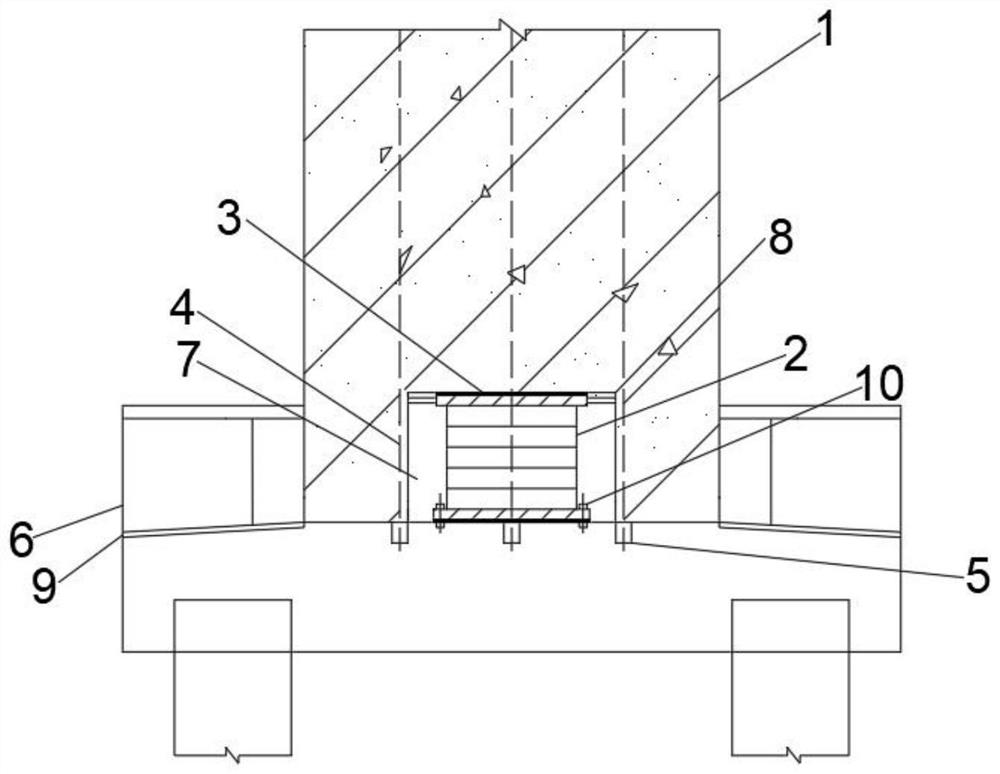

[0027] Such as Figure 4 , Figure 5 , Figure 6 The shown self-resetting assembled pier system connected by high-strength bolts 10 with the function of shock absorption and isolation is mainly used in areas with medium and high intensity to play the role of shock absorption and isolation. Including prefabricated reinforced concrete pier column section 1, shock-absorbing and isolating rubber bearing 2, epoxy resin glue 3, shape memory alloy (SMA) rod reinforcement 5, grouting sleeve 6, cap 7, reserved notch 7, stop Hose belt 8, drainage groove 9, high-strength bolt 10. The prefabricated reinforced concrete pier section 1 has a diameter of 180cm; the vibration-absorbing and isolating rubber bearing is a lead rubber bearing, the diameter 2 is 50cm in diameter, and the height is 70cm. The steel plates above and below the bearing have a diameter of 70cm and a thickness of 5cm; The thickness of the epoxy resin glue 3 is 1cm; the diameter of the shape memory alloy (SMA) rod 4 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com