Double-roller RAP crushing machine and crushing method thereof

An asphalt pavement and crusher technology, which is applied in the field of asphalt production equipment, can solve the problems of inability to meet the requirements of gradation, the limited effect of asphalt pavement milling materials, and the destruction of the original gradation of RAP, so as to improve the crushing efficiency and crushing effect. , the effect of resolving variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details. Known components, methods and processes will not be described in detail below.

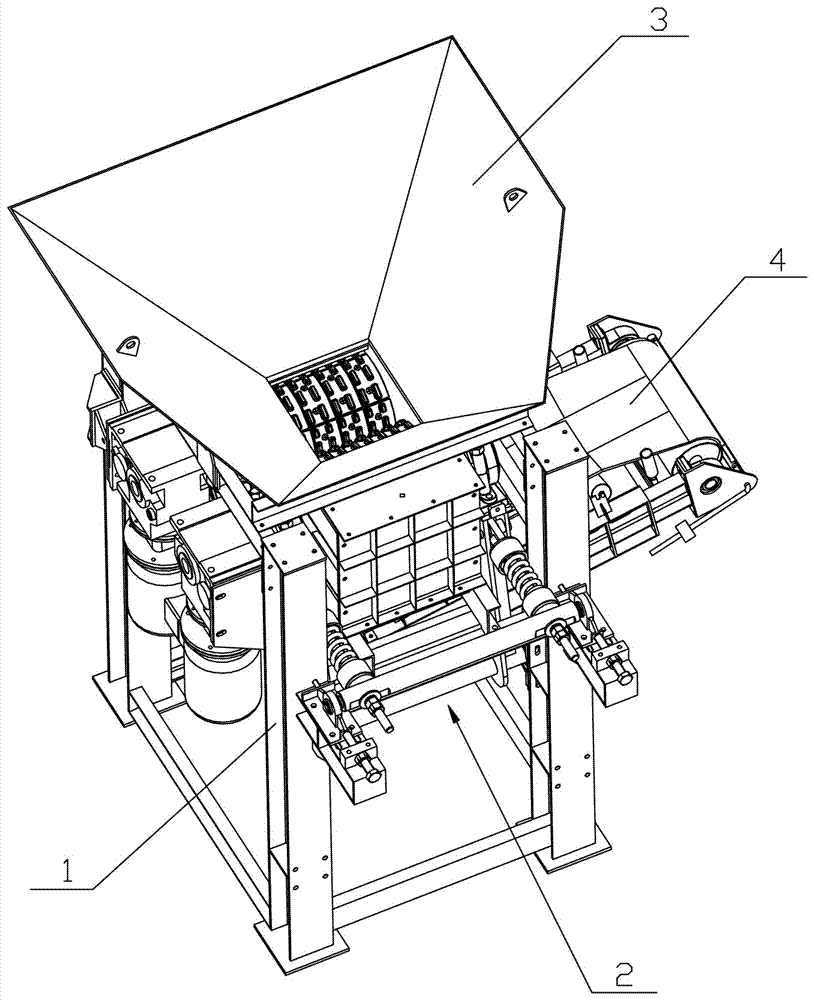

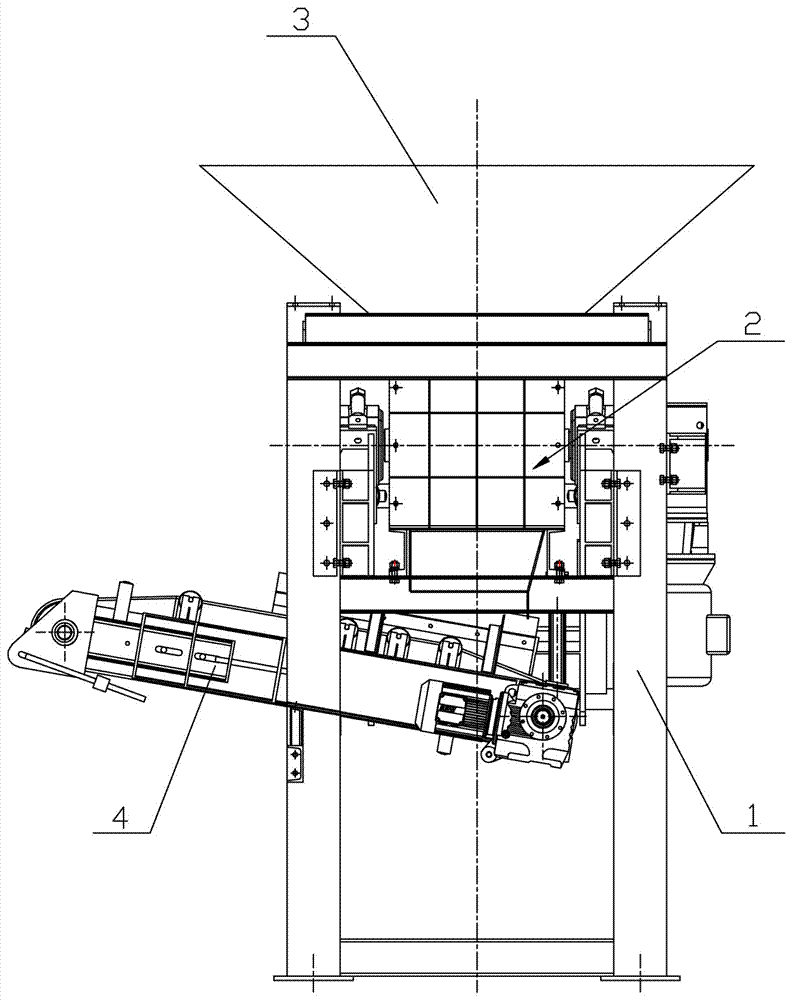

[0038] A double-roller asphalt pavement milling material crusher, refer to Figure 1 to Figure 3 , including a frame 1, a crusher body 2, a collection hopper 3 and a belt conveyor 4, the collection hopper 3 is arranged directly above the crusher body 2, the crusher body 2 is arranged inside the frame 1, and the belt The conveyor 4 is located directly below the crusher body 2 .

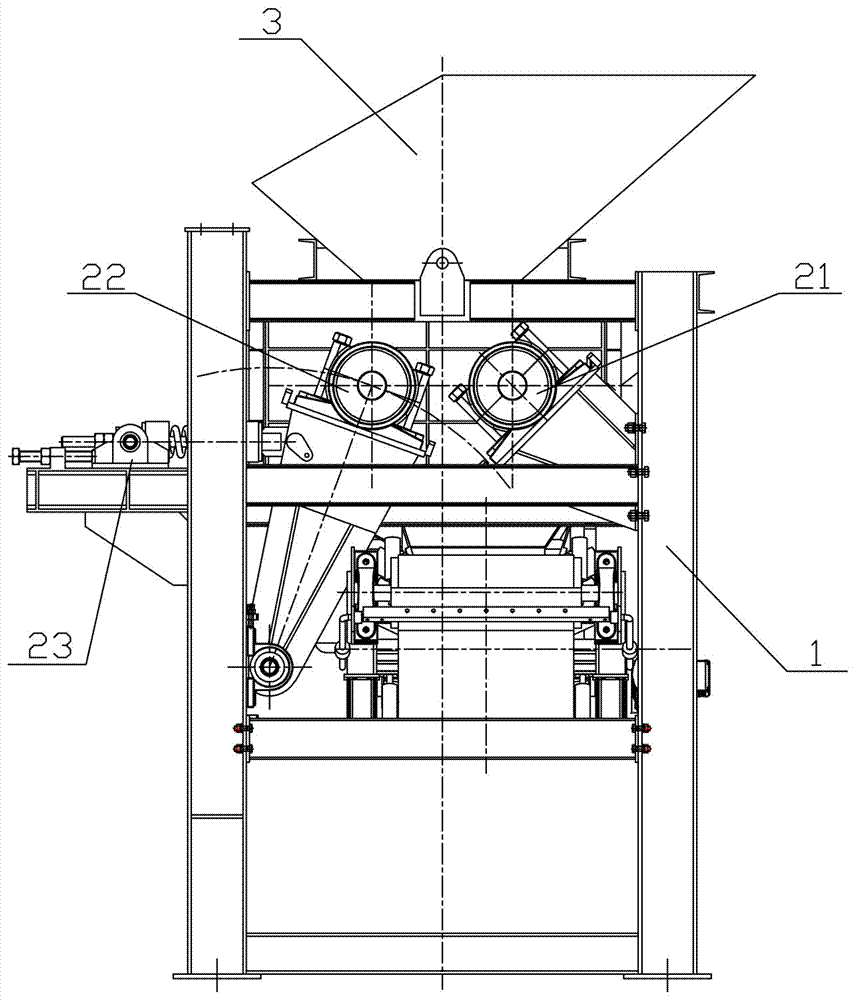

[0039] refer to Figure 4 to Figure 8The above-mentioned crusher body 2 includes a crusher box 20, a crushing device one 21, a crushing device two 22 and a tension buffer dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com