Ring rib pin tenon connection structure of concrete member and construction method thereof

A technology for connecting structures and concrete, applied in the direction of building structure, construction, etc., can solve the problems of raising the overall cost of concrete prefabricated components, unfavorable promotion and popularization of prefabricated buildings, and high bolt connection costs, and achieves convenient detection and application scope. Wide and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

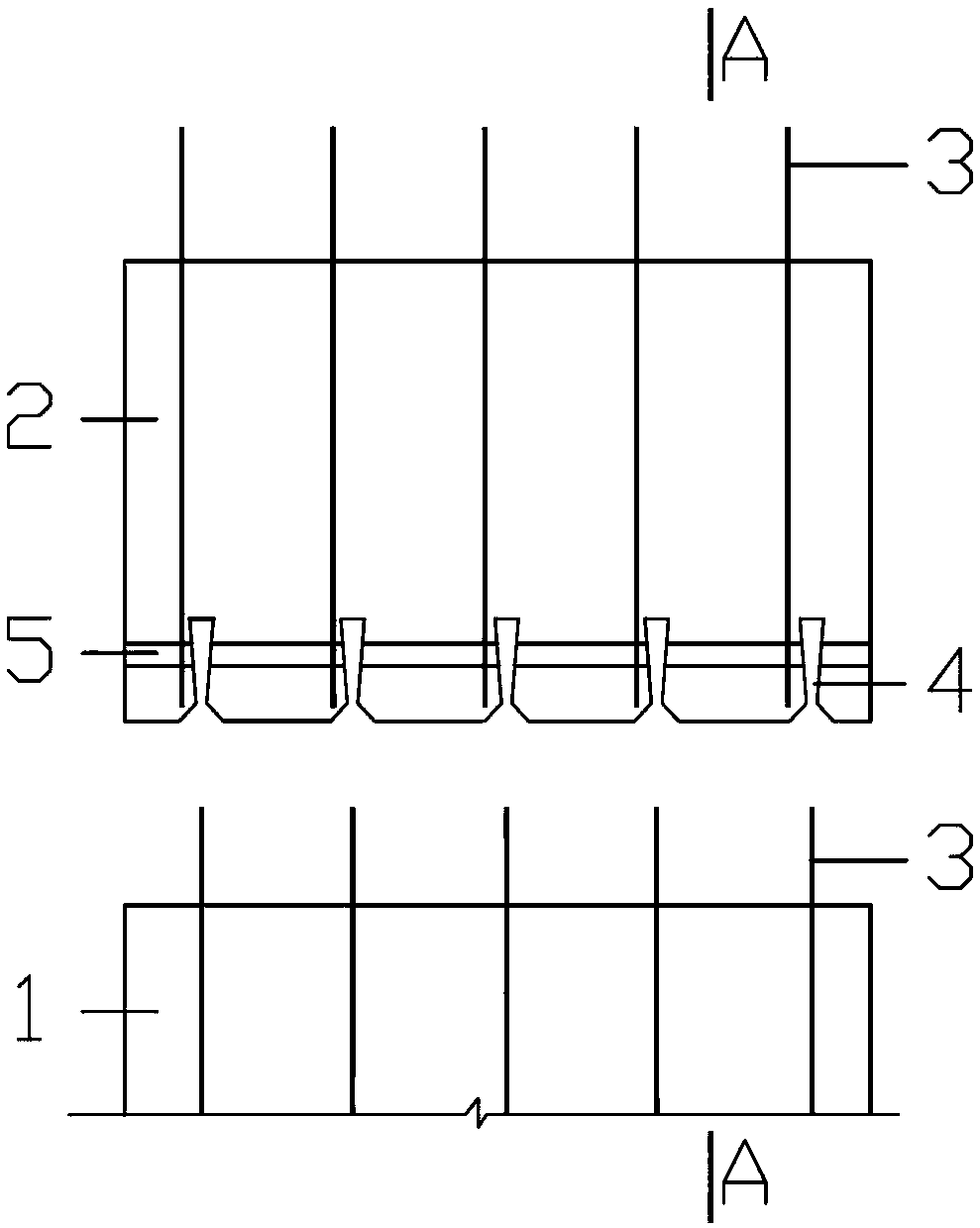

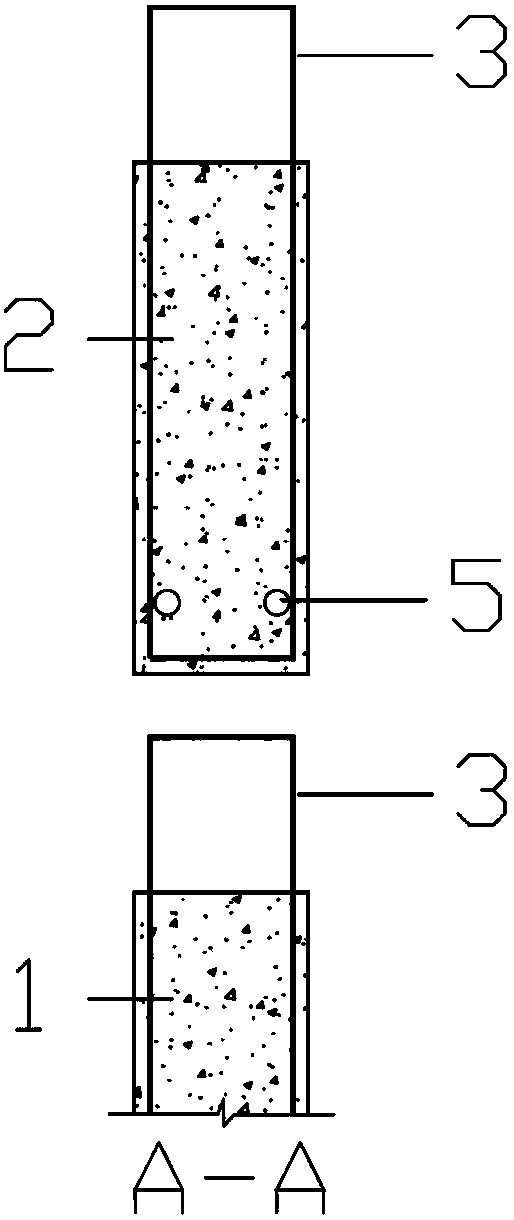

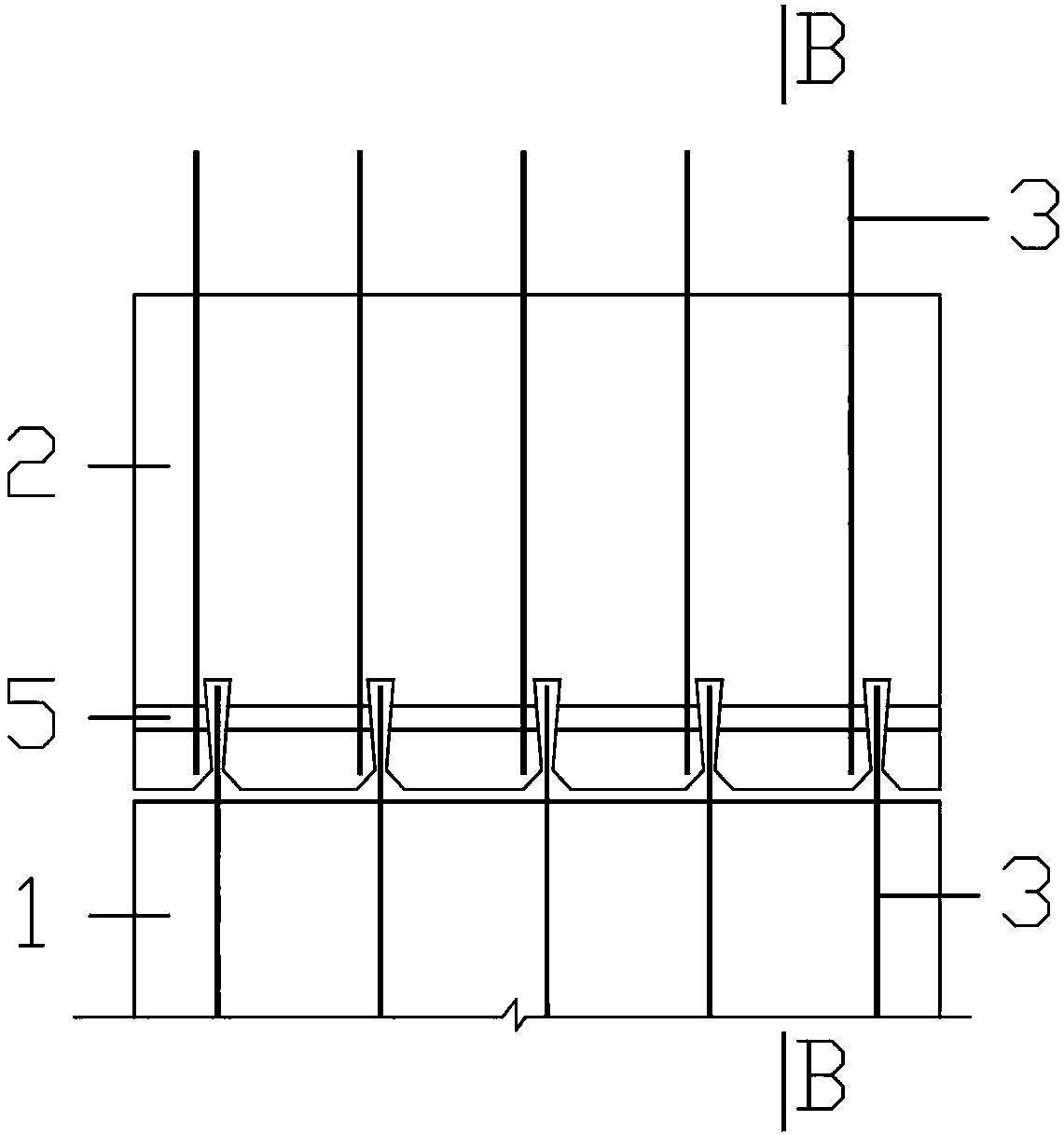

[0070] The first step: processing pre-embedded ring reinforcement 3;

[0071] The second step: constructing the concrete member 1 including the pre-embedded ring reinforcement 3;

[0072] The third step: constructing the concrete member 2 including the reserved tenon and groove 4 and the reserved pin hole 5;

[0073] Part 4: Lift the concrete member 2 containing the reserved tenon groove 4 and the reserved pin hole 5 to the position of the concrete member 1 containing the pre-embedded ring reinforcement 3, move and insert the pre-embedded ring reinforcement 3 into the reserved tenon groove 4 ;

[0074] Step 5: Insert the pin 6 into the reserved pin hole 5;

[0075] Step 6: Clamp and seal the periphery of the concrete member 2 including the reserved mortise 4 and the reserved pin hole 5 with a splint, and pour the glue into the reserved mortise 4 and the reserved pin hole 5 The grout is formed to form the joint grout 7.

Embodiment 2

[0077] The first step: processing pre-embedded ring reinforcement 3;

[0078] The second step: constructing the concrete member 1 including the concrete tenon 8 and the embedded ring reinforcement 3;

[0079] The third step: constructing the concrete member 2 including the reserved tenon and groove 4 and the reserved pin hole 5;

[0080] Part 4: Lift the concrete member 2 containing the reserved tenon groove 4 and the reserved pin hole 5 to the position of the concrete member 1 containing the concrete tenon 8 and the embedded ring reinforcement 3, move and insert the concrete tenon 8 into the reserved Tenon and groove 4;

[0081] Step 5: Insert the pin 6 into the reserved pin hole 5;

[0082] Step 6: Clamp and seal the periphery of the concrete member 2 including the reserved mortise 4 and the reserved pin hole 5 with a splint, and pour the glue into the reserved mortise 4 and the reserved pin hole 5 The grout is formed to form the joint grout 7.

[0083] The ring reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com