Fan-shaped insulated wire core cabling anti-turnover device

A technology of insulated wire cores and wire cores, which is applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of inconvenient operation, inability to pre-twist the fan-shaped cores, affecting production efficiency, etc., so as to reduce pressure injuries and avoid distortion. Deformation, avoid crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

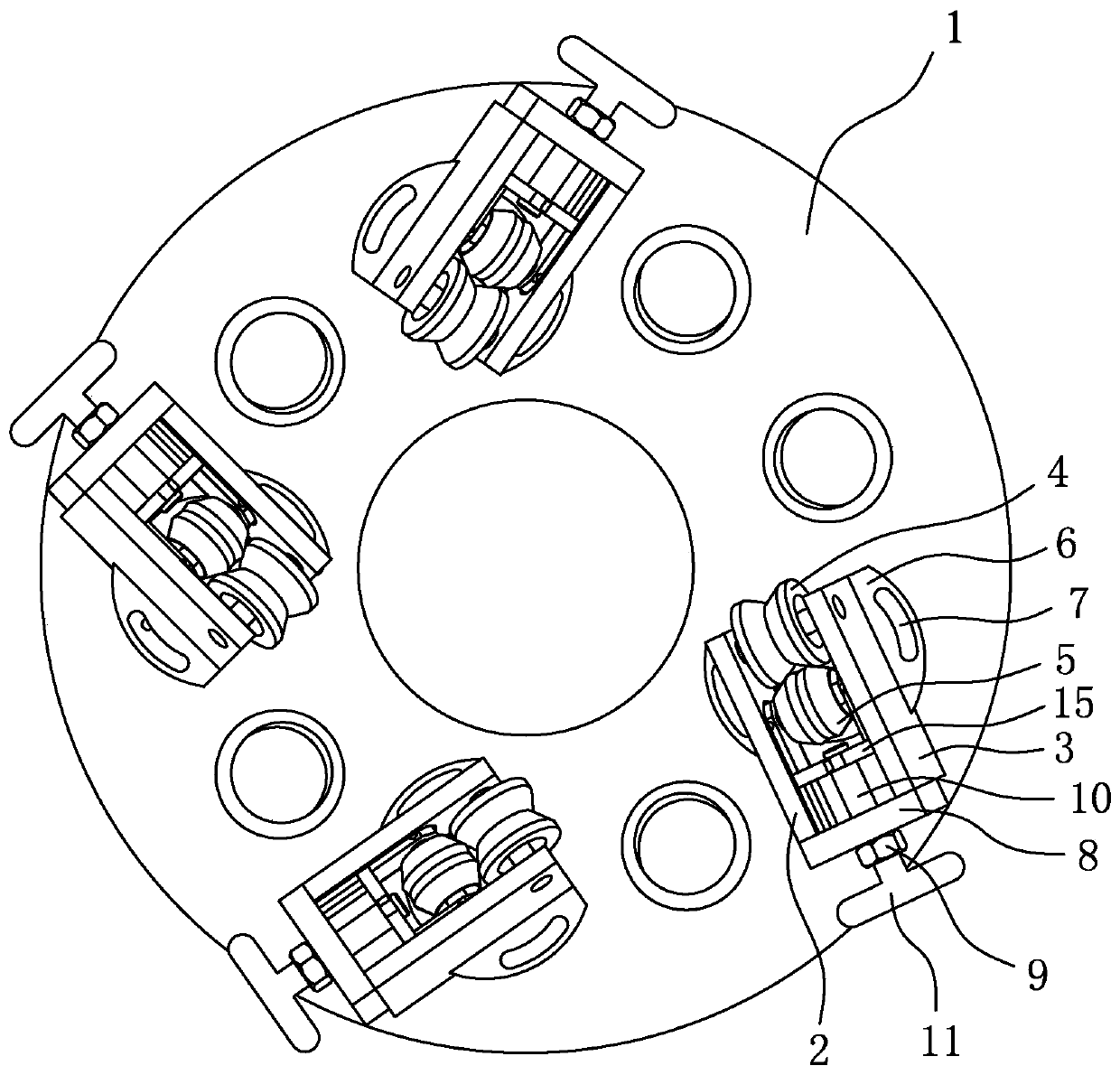

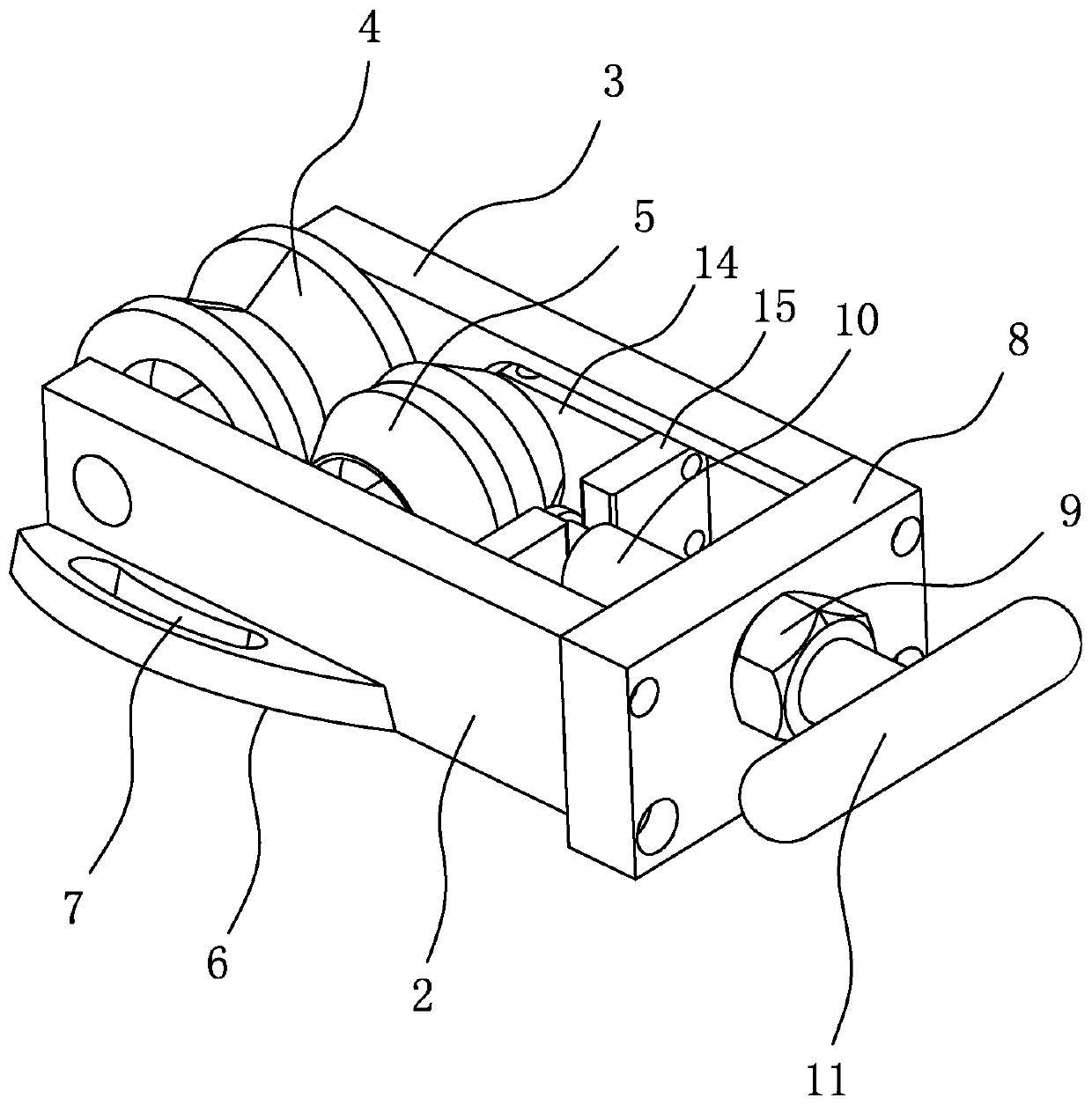

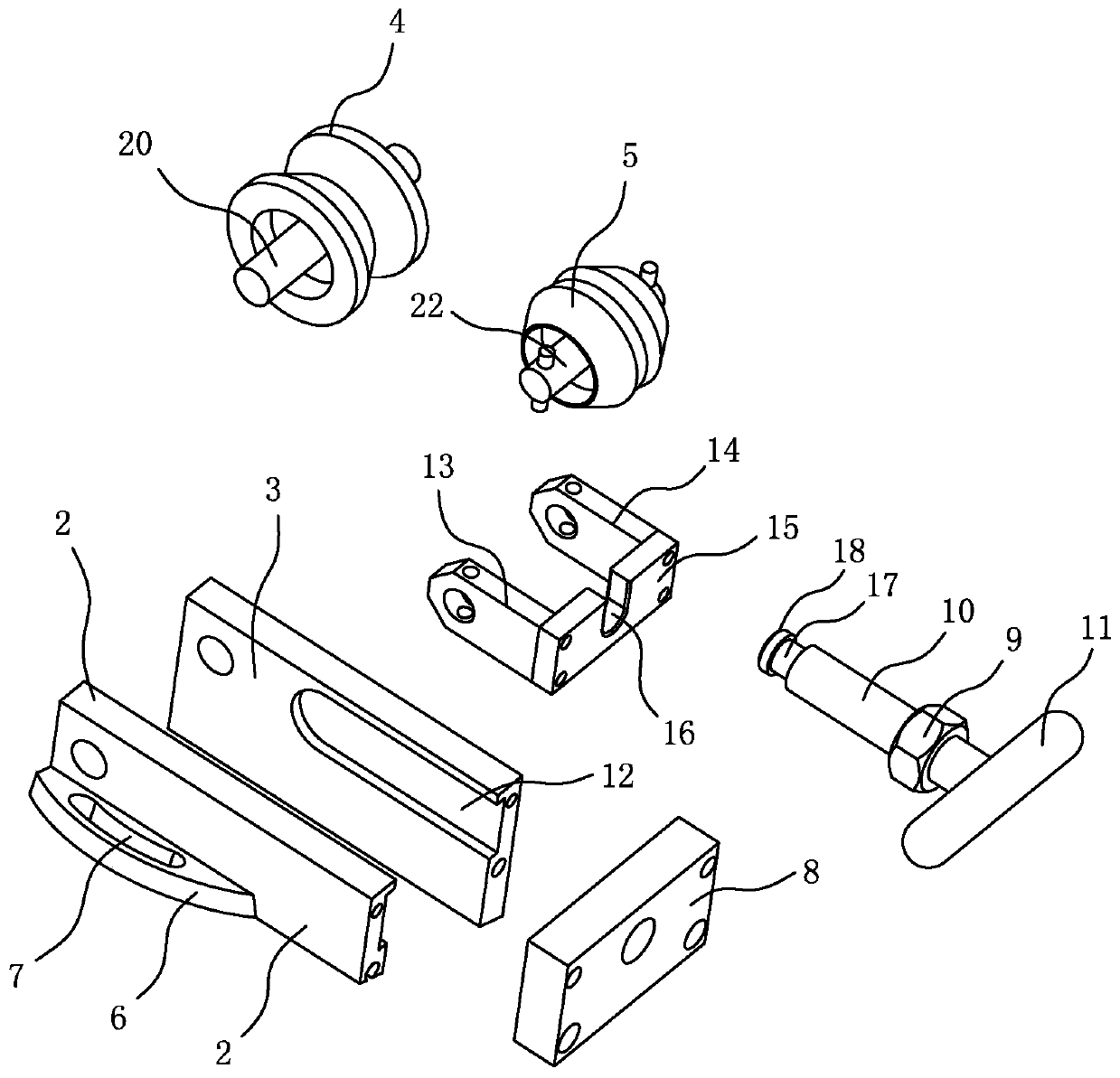

[0032] Such as figure 1 A fan-shaped insulated core cabling anti-turning device is shown, which includes a line distribution tray 1 with a threading hole (not shown in the figure) and four pressure roller devices opened at the corresponding positions of the threading hole on the line distribution tray. , the four pressure roller devices are arranged circumferentially on the line distribution plate, and the threading holes are opened on the line distribution plate below the pressure wheel device (the threading holes are blocked by the pressure wheel device and are not shown in the figure); the pressure wheel device includes a left Side plate 2, right side plate 3, wire core angle wheel 4 and wire core arc wheel 5 (as figure 2 , image 3 shown), the left side panel and the right side panel are parallel to each other and arranged obliquely on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com