Anisotropic conductive adhesive

A conductive adhesive, anisotropic technology, used in conductive adhesives, adhesives, conductive materials, etc., can solve problems such as poor connection reliability, and achieve the effect of high heat release and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

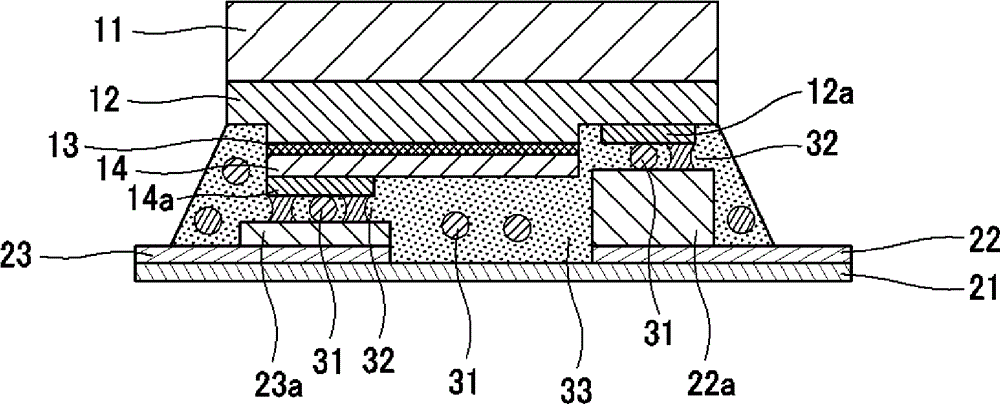

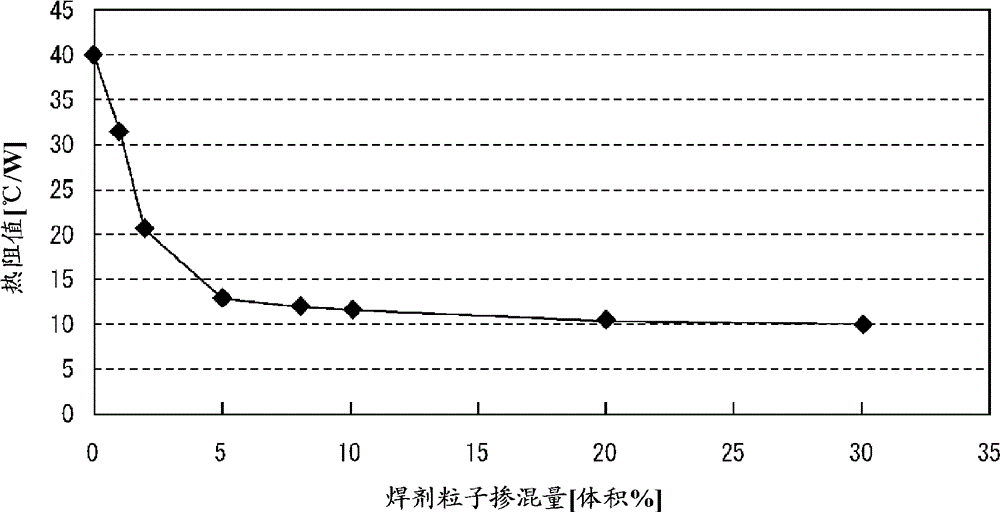

Embodiment 1

[0093] 8 volume % of conductive particles and 2 volume % of solder particles were mixed with the aforementioned resin composition to prepare an anisotropic conductive adhesive having thermal conductivity. The thermal resistance measurement result of the LED package produced using this anisotropic conductive adhesive was 21.0° C. / W, and the chip shear strength was 26 N / chip. In addition, the evaluation results of the high-temperature and high-humidity test for electrical characteristics are ○ at the initial stage and ○ after the test; and the evaluation results of the thermal shock test for electrical characteristics are ○ at the initial stage and ○ after the test. .

Embodiment 2

[0095] 5% by volume of conductive particles and 5% by volume of solder particles were mixed with the aforementioned resin composition to prepare an anisotropic conductive adhesive having thermal conductivity. The thermal resistance measurement result of the LED package produced using this anisotropic conductive adhesive was 13.2° C. / W, and the chip shear strength was 37 N / chip. In addition, the evaluation results of the high-temperature and high-humidity test for electrical characteristics are ○ at the initial stage and ○ after the test; and the evaluation results of the thermal shock test for electrical characteristics are ○ at the initial stage and ○ after the test. .

Embodiment 3

[0097] 2% by volume of conductive particles and 8% by volume of solder particles were mixed with the aforementioned resin composition to prepare an anisotropic conductive adhesive having thermal conductivity. The thermal resistance measurement result of the LED package prepared using this anisotropic conductive adhesive was 12.2° C. / W, and the chip shear strength was 45 N / chip. In addition, the evaluation results of the high-temperature and high-humidity test for electrical characteristics are ○ at the initial stage and ○ after the test; and the evaluation results of the thermal shock test for electrical characteristics are ○ at the initial stage and ○ after the test. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com