Electric vacuum cleaner

A vacuum cleaner and electric technology, used in vacuum cleaners, household appliances, cleaning equipment, etc., can solve the problems of metal plate obstruction, shortened battery life, temperature imbalance, etc., and achieve the effect of prolonging life and improving usability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

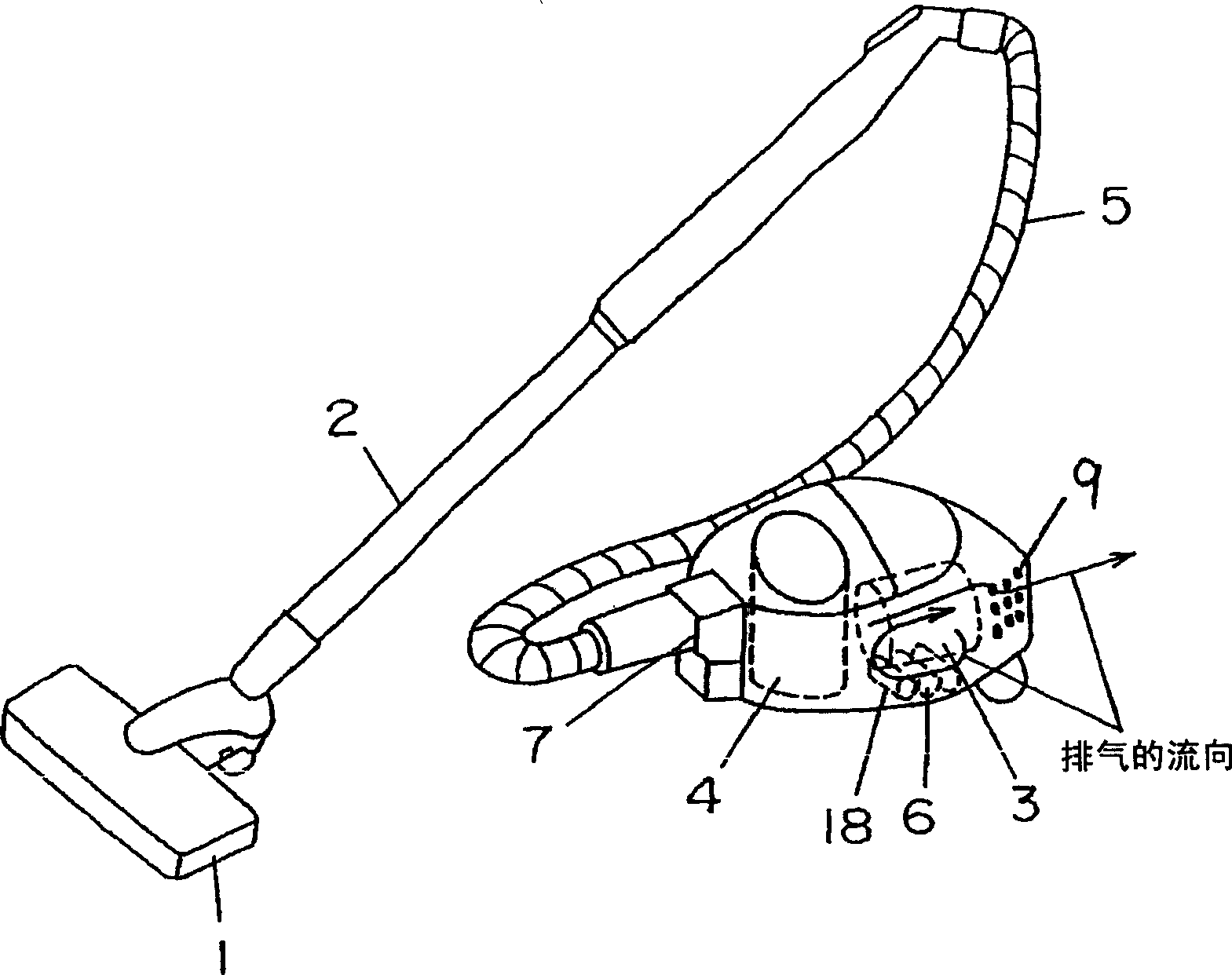

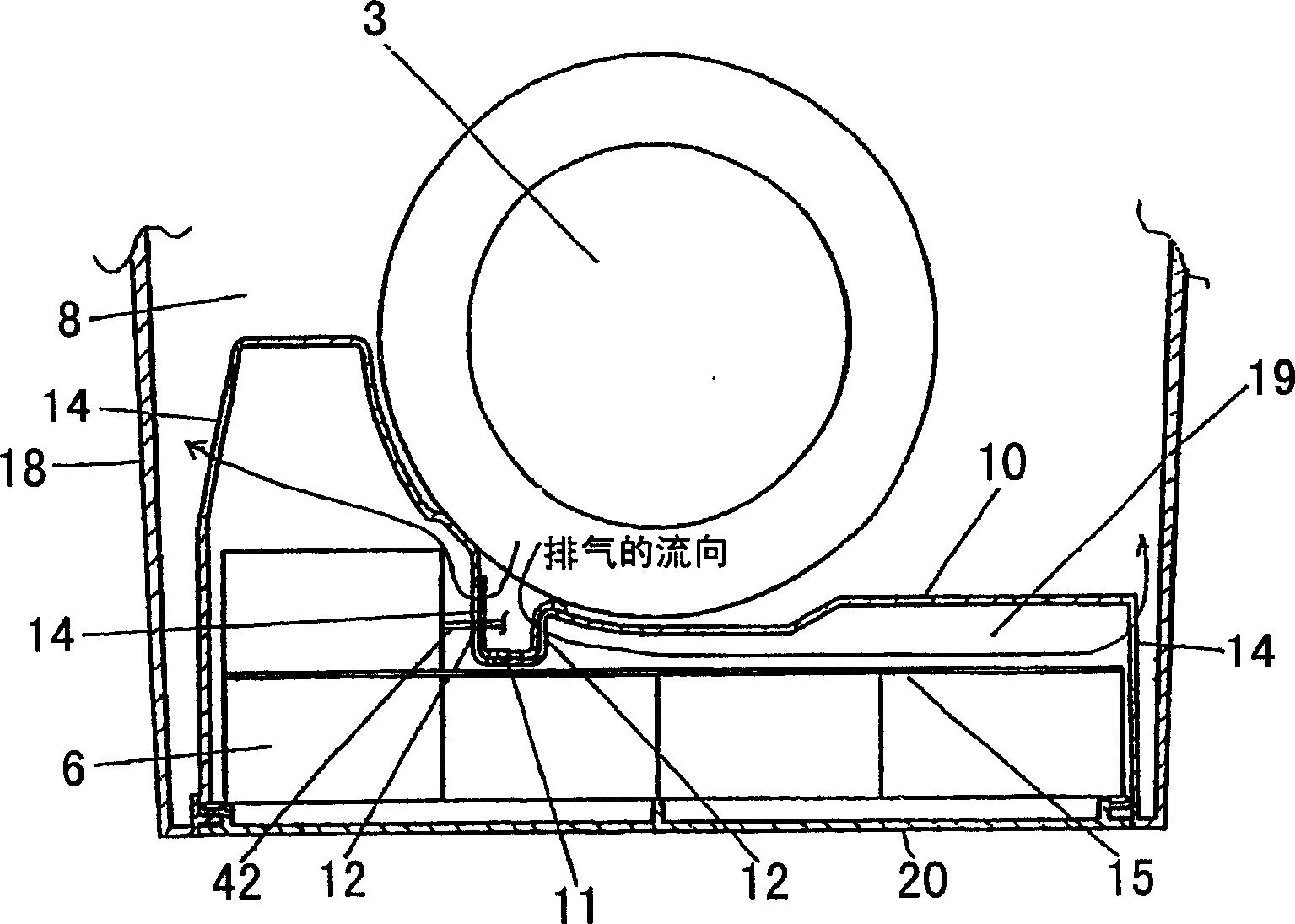

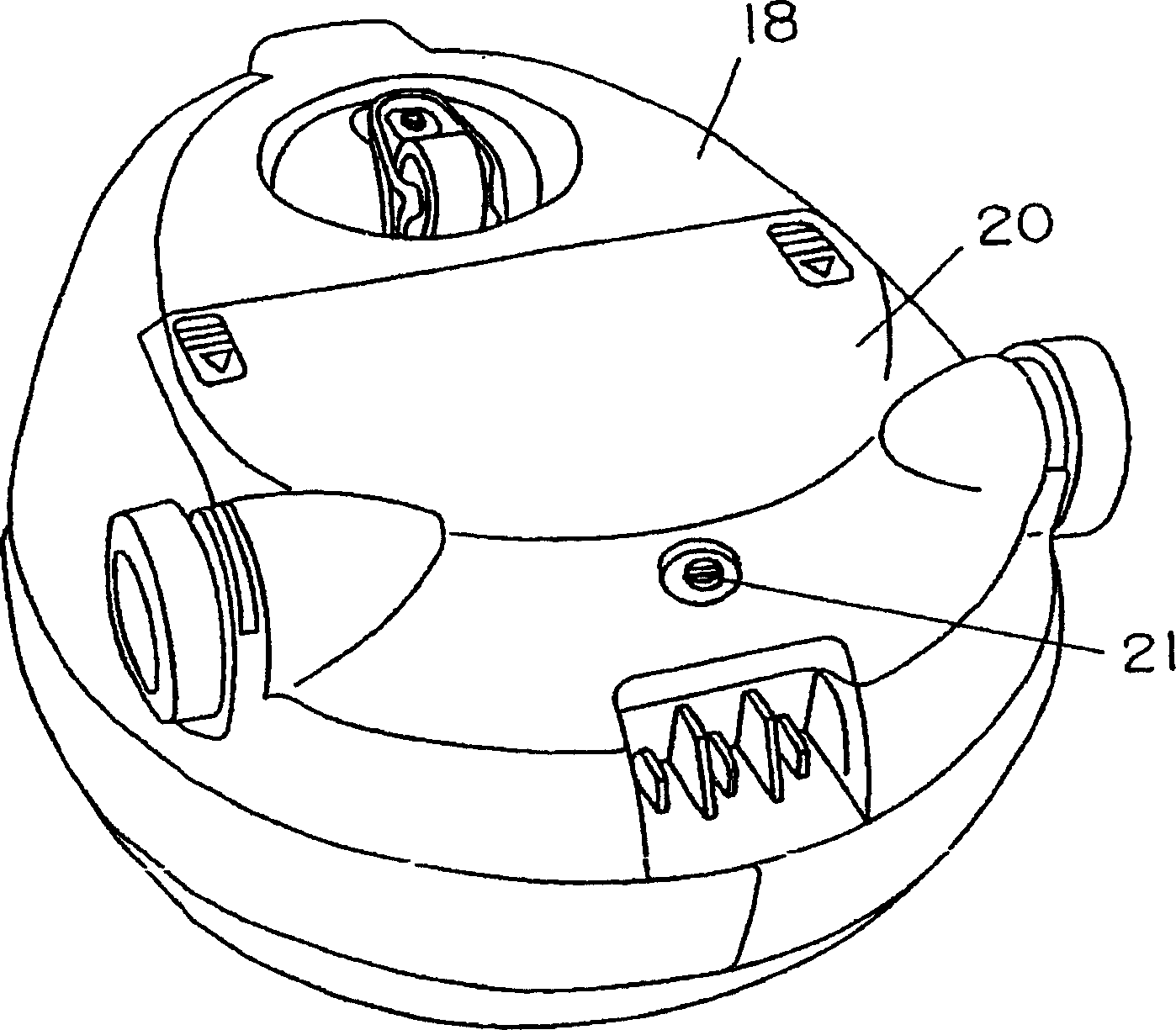

[0057] First, with the help of Figure 1 to Figure 8 The first embodiment of the present invention will be described.

[0058] As shown in the figure, the main body 18 of the vacuum cleaner is provided with: an electric blower chamber 8 which is an electric blower for generating a dust-absorbing airflow inside, that is, an electric blower chamber 8 of the frequency converter motor 3; The battery 6, and the secondary battery compartment 19 in which the secondary battery 6 is arranged below the frequency converter motor 3; In addition, one end of the hose 5 is connected to the upstream side of the dust collecting box 4 in the main body 18 of the vacuum cleaner, and the other end is connected to the floor suction head 1 through the extension pipe 2 .

[0059] When the frequency converter motor 3 is working, it will generate a dust suction airflow, and the dust and the dust suction airflow will be sucked from the ground suction head 1 together. The dust box 4 in the main body 18...

Embodiment 2

[0073] pass below Figure 9 The second embodiment of the present invention will be described. Wherein, the parts that are the same as those in the previous embodiment are given the same symbols, and repeated description thereof will be omitted.

[0074] In this embodiment, an outlet B41 communicating with the electric blower chamber 8 and the secondary battery compartment 19 and a soundproof tube 16 covering the outer periphery of the exhaust side of the inverter motor 3 are provided. Wherein, the discharge port B41 for releasing the exhaust gas of the inverter motor 3 into the secondary battery compartment 19 is provided on the soundproof tube 16 .

[0075] The operation and action of the electric vacuum cleaner having the above construction will be described below.

[0076] Due to the formation of a passage for the exhaust gas to forcibly flow into the secondary battery compartment 19 , all the exhaust gas from the inverter motor 3 can be used for cooling the secondary bat...

Embodiment 3

[0078] Use below Figure 10 ~ Figure 15 A third embodiment of the present invention will be described.

[0079] Figure 10 The main body 118 of the vacuum cleaner includes an electric blower 103 for generating dust suction airflow, and its lower part is provided with a power supply for driving the electric blower 103, that is, a secondary battery composed of a plurality of slightly cylindrical secondary batteries 106 bundled together. Group. The dust collecting box 104 is provided on the upstream side of the dust suction air flow of the electric blower 103 . In addition, the upstream side of the dust box 104 in the main body 118 is connected with one end of the hose 105 , and the other end of the hose 105 is connected with the floor suction head 101 through the extension tube 102 . When the electric blower 103 works, it will generate a dust suction airflow, and the dust will be sucked from the floor suction head 101 together with the dust suction airflow. The dust collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com