Low height lead frame for LED device and the manufacturing method thereof

A technology for LED devices and lead frames, which is applied in the field of lead frames for small-sized LED devices, and can solve problems such as resin cracks, epoxy resin leakage, lead frames and resin peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

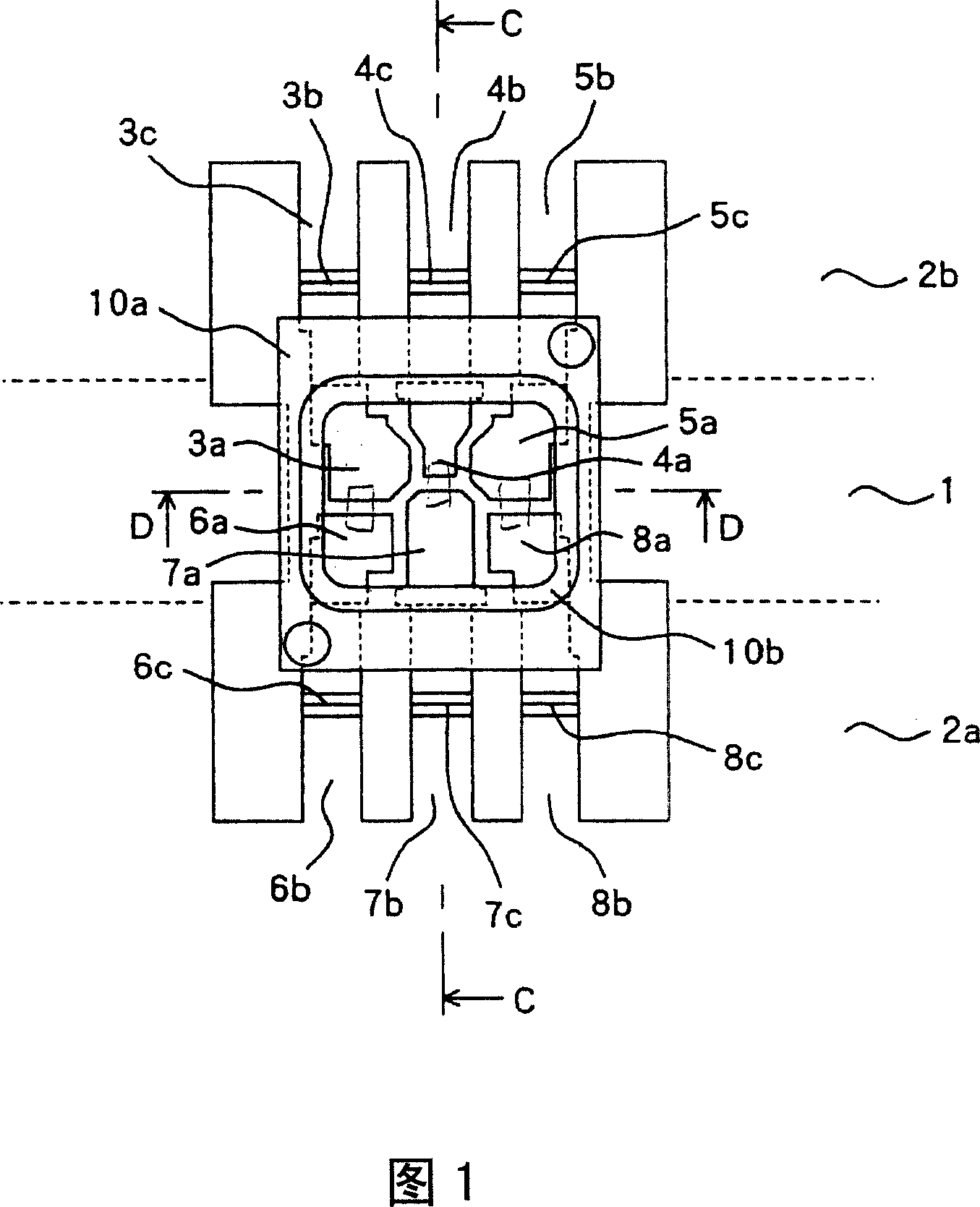

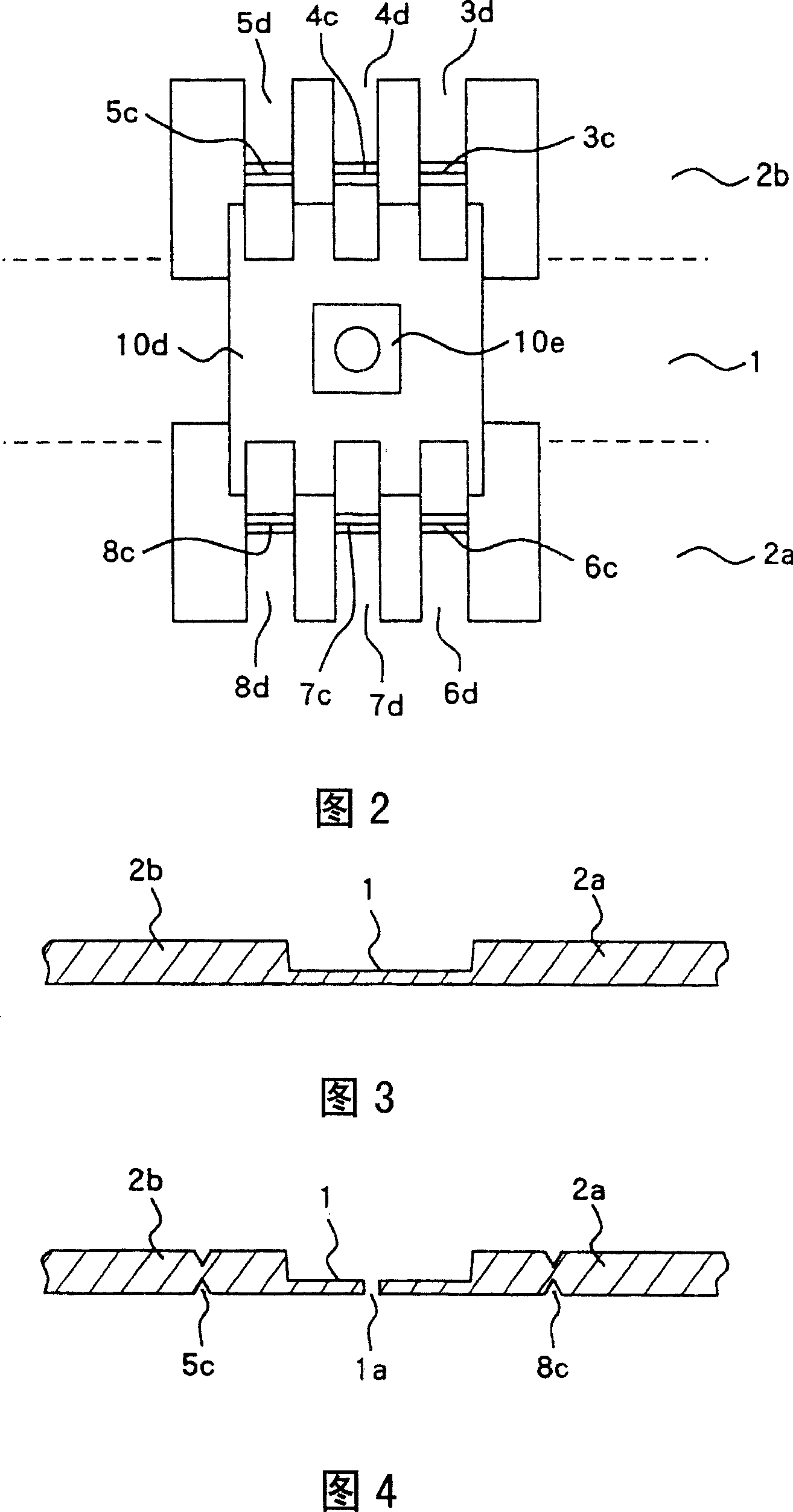

[0049] Hereinafter, a lead frame for a small-sized LED device according to an embodiment of the present invention will be described in detail with reference to the attached drawings.

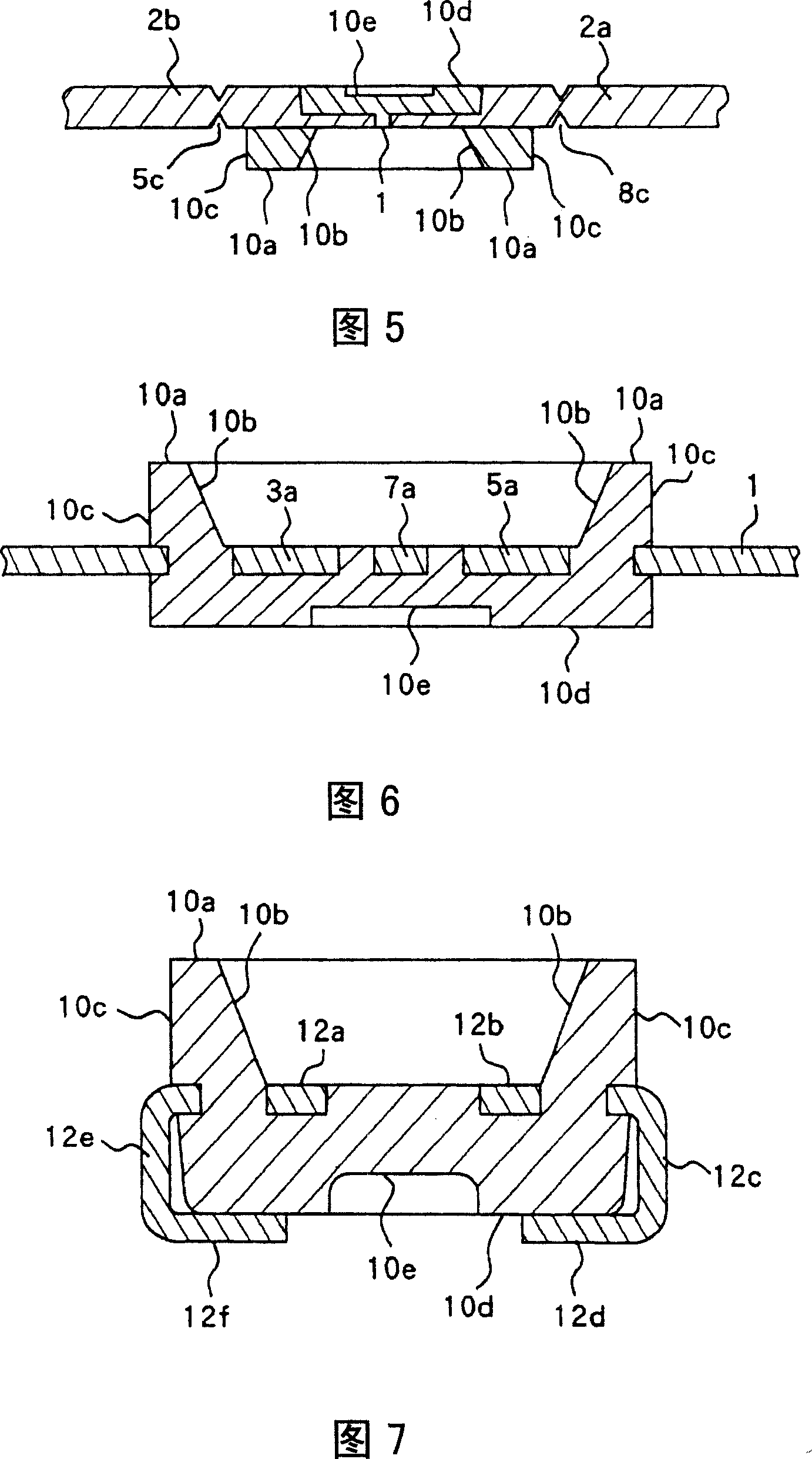

[0050] 3 is a cross-sectional view of a long irregular-shaped metal material used to manufacture a lead frame for a small-sized LED device according to an embodiment of the present invention, and is a cross-sectional view perpendicular to the longitudinal direction.

[0051] Both sides of the thin part 1 with a thickness of about 0.15 to 0.25 mm are sandwiched by normal parts 2a and 2b with a thickness of about 0.4 to 0.5 mm in parallel. Considering the electrical conductivity and price, copper alloy and stainless steel can be used as the material.

[0052] Fig. 4 is a cross-sectional view of a state in which a V-shaped groove is formed by drilling the long irregular-shaped metal material shown in Fig. 3 through a multi-station press (multi-stage sequential transfer press group). The drilled po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com