Thermite for hypergravity-assisted combustion synthesis of copper-based composite material

A copper-based composite material and assisted combustion technology, applied in thermite field, can solve the problems of reaction stability, combustion rate and temperature controllable product purity that are difficult to meet the high-gravity assisted combustion synthesis process, and achieve high heat release, Effect of low splatter rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

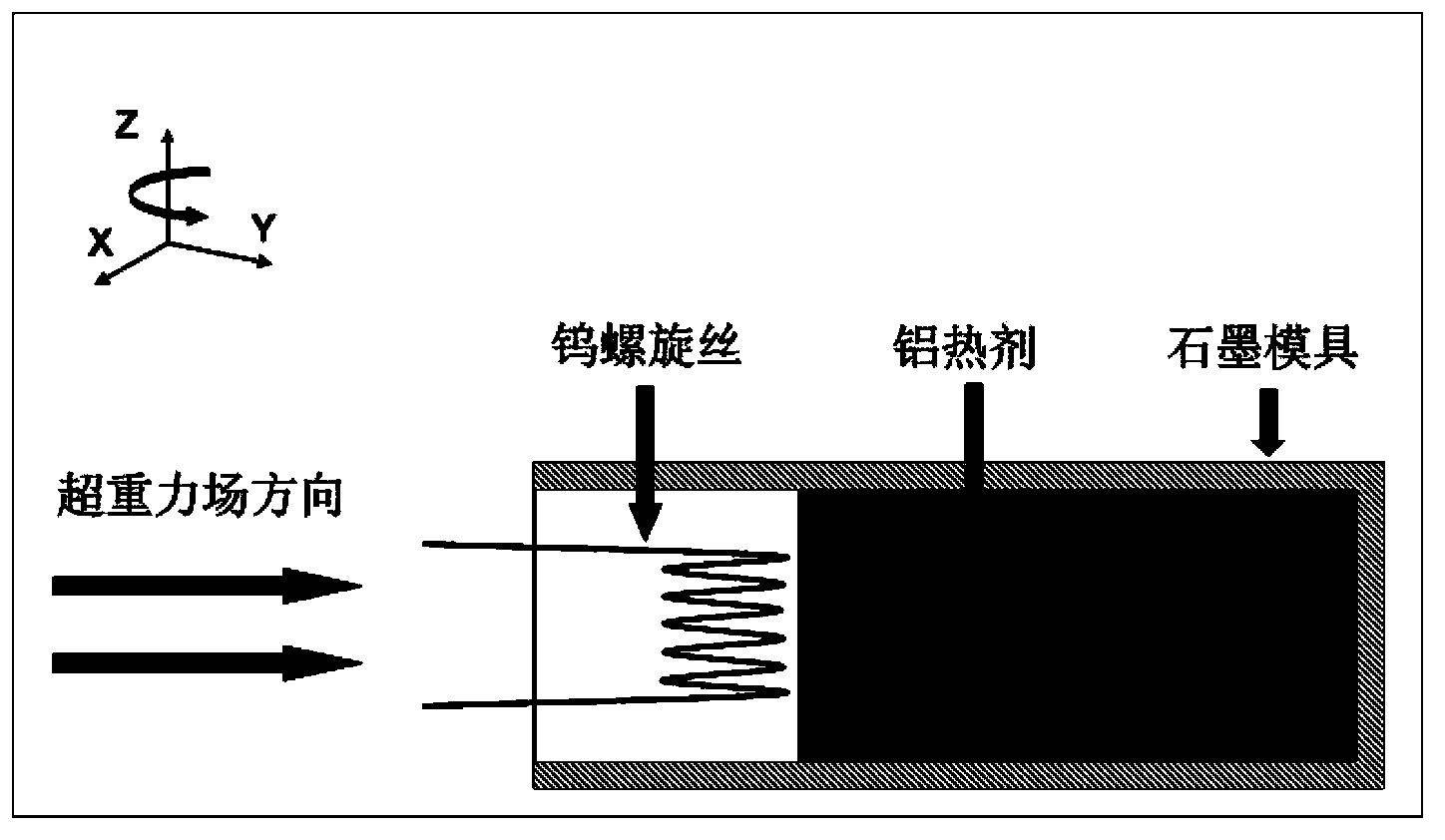

Method used

Image

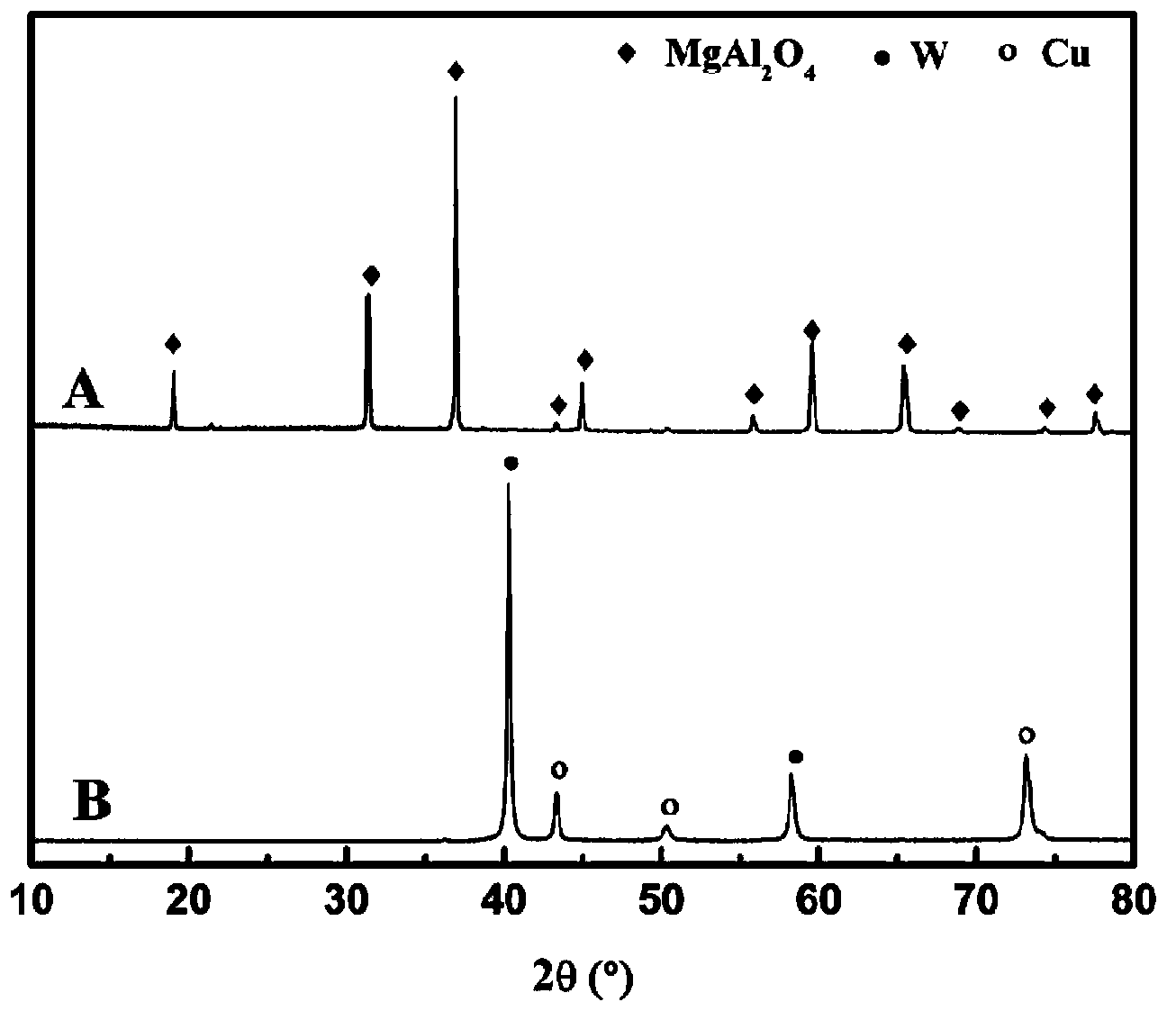

Examples

Embodiment 1

[0030] The thermite used for high-gravity assisted combustion synthesis of copper-based composites is composed of CuO powder with a gradient of particle size and Al powder with a gradient of particle size, and added Cu 2 O powder, MgO powder and CaF 2 The powder is obtained after mixing; the composition and formulation of the thermite are shown in Table 1.

[0031] Table 1

[0032]

[0033] The copper-based composite material is prepared by using the above-mentioned thermite used for high-gravity assisted combustion synthesis of copper-based composite materials:

[0034] (1) Preparation of raw materials: Weigh 200g of various raw materials according to the formula of the thermite in the selected table 1, and mix the various raw materials for 60 minutes at 50 revolutions per minute using a ball mill to obtain the thermite;

[0035] (2) Batch forming: the thermite obtained by mixing uniformly in step (1) is pressed into a thermite body with a diameter of 40 mm under 10 MPa;

[0036] (3) L...

Embodiment 2

[0039] The thermite used for high-gravity assisted combustion synthesis of copper-based composites is composed of CuO powder with a gradient of particle size and Al powder with a gradient of particle size, and added Cu 2 O powder, Cu powder, MgO powder and CaF 2 The powder is obtained after mixing; the composition and formulation of the thermite are shown in Table 2.

[0040] Table 2

[0041]

[0042] The copper-based composite material is prepared by using the above-mentioned thermite used for high-gravity assisted combustion synthesis of copper-based composite materials:

[0043] (1) Preparation of raw materials: Weigh 200g of various raw materials according to the formula of the thermite in the selected table 2, and mix the various raw materials for 60 minutes at 50 revolutions per minute using a ball mill to obtain the thermite;

[0044] (2) Batch forming: the thermite obtained by mixing uniformly in step (1) is pressed into a thermite body with a diameter of 40 mm under 10 MPa;

[...

Embodiment 3

[0048] The thermite used for high-gravity assisted combustion synthesis of copper-based composites is composed of CuO powder with a gradient of particle size and Al powder with a gradient of particle size, and added Cu 2 O powder, Cu powder, MgO powder and CaF 2 The powder is obtained after mixing; the composition and formulation of the thermite are shown in Table 3.

[0049] table 3

[0050]

[0051] The copper-based composite material is prepared by using the above-mentioned thermite used for high-gravity assisted combustion synthesis of copper-based composite materials:

[0052] (1) Preparation of raw materials: Weigh 200g of various raw materials according to the formula of the thermite in the selected table 3, and mix the various raw materials for 30 minutes at 100 revolutions per minute using a ball mill to obtain the thermite;

[0053] (2) Batching molding: the thermite obtained by mixing uniformly in step (1) is pressed into a thermite body with a diameter of 40 mm under 15 MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com