Method for processing waste gas treating ultraviolet lamp and waste gas treating method

A technology for waste gas treatment and production method, which is applied in separation methods, chemical instruments and methods, chemical/physical/physical-chemical processes of energy application, etc. With desorption effect, the effect of keeping the air clean

Inactive Publication Date: 2005-04-20

NAT CHUNG SHAN INST SCI & TECH +1

View PDF22 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The above-mentioned patent originally came from exhaust gas treatment, so basically in a closed reactor, whether it is a granular catalyst or a coated catalyst particle, complex equipment is required for use or operation.

[0007] The above shortcomings make photocatalysts unable to effectively treat waste gas, and the only photocatalyst reactor that uses fiber

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

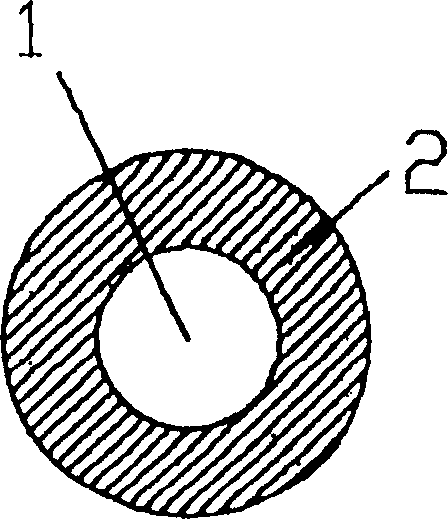

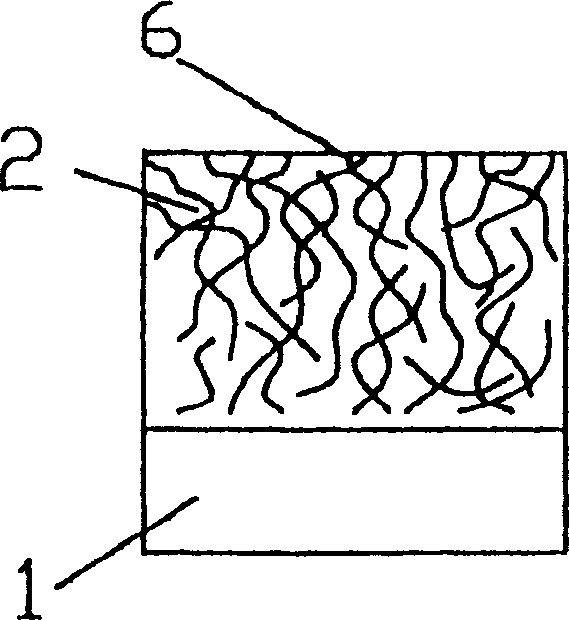

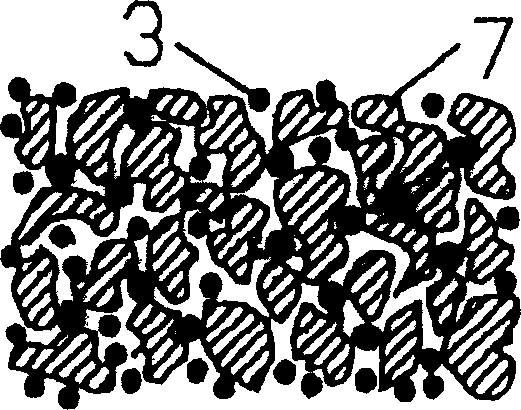

The method for making ultraviolet lamp and method of waste gas processing by same utilize dissolved gel filming technology, which is a photocatalyst filming on glass fiber fabric, the light ultraviolet lamp irradiates the coated film by covering glass fiber fabric on lamp tube to generate electronic hole pair for decomposing waste gas in air. The photocatalyst film is made of by TiO#-[2] dissolved gel added with WO#-[3],ZnO,SnO#-[2] and Fe#-[2]O#-[3], some noble metal such as Au,Pd,Pt or Ag, and transition metal salt Mo, Nb, V, Ce or C etc can be used for raising photocatalyst decomposition ability. The lamp tube is normal 154,312 or 365 nm, natural convection and forced convection is adopted for decomposing various organic and inorganic gas into oxide such as CO#-[2],H#-[2]O etc harmless air.

Description

technical field [0001] The invention relates to a method for manufacturing an ultraviolet lamp for exhaust gas treatment and a method for treating exhaust gas, in particular to a method for manufacturing an ultraviolet lamp for exhaust gas treatment by using a sol-gel coating technology and a method for treating exhaust gas. Background technique [0002] Sol-gel technology is currently being valued by countries with advanced technology. The main reason is that when the development of traditional chemical and physical technologies encounters bottlenecks, especially when inorganic materials can no longer meet the needs of traditional technologies, especially materials with multi-component special structures, Materials that cannot be prepared by traditional hot-melt method and precipitation method, and when traditional evaporation technology cannot coat irregular surfaces, sol-gel coating can easily obtain metal oxide coating, and catalyst coating requires porous crystalline par...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A61L9/20B01D53/86B01J19/12B01J35/00B01J37/00C03C17/00C03C17/25

Inventor 王伟洪游敏锋

Owner NAT CHUNG SHAN INST SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com