Grain refiner for magnesium alloy and preparation method thereof

A grain refiner and a technology for magnesium alloys, applied in the field of grain refiner for magnesium alloys and their preparation, can solve the problems of high reaction temperature, cannot be used in industrial production, and have not been widely used, and can reduce the reaction temperature. , Enlarge the production scale, and refine the effect with remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Aluminum powder, carbon powder, MgCO with a particle size of 50-400 mesh 3 Mix the powder and magnesium alloy No. 2 flux uniformly with a ball mill, and then dry it at 100°C for 5 hours to make a prefabricated powder. The weight percentage of each component is 30% of aluminum powder, 20% of carbon powder, MgCO 3 5% powder, and the balance is magnesium alloy No. 2 flux.

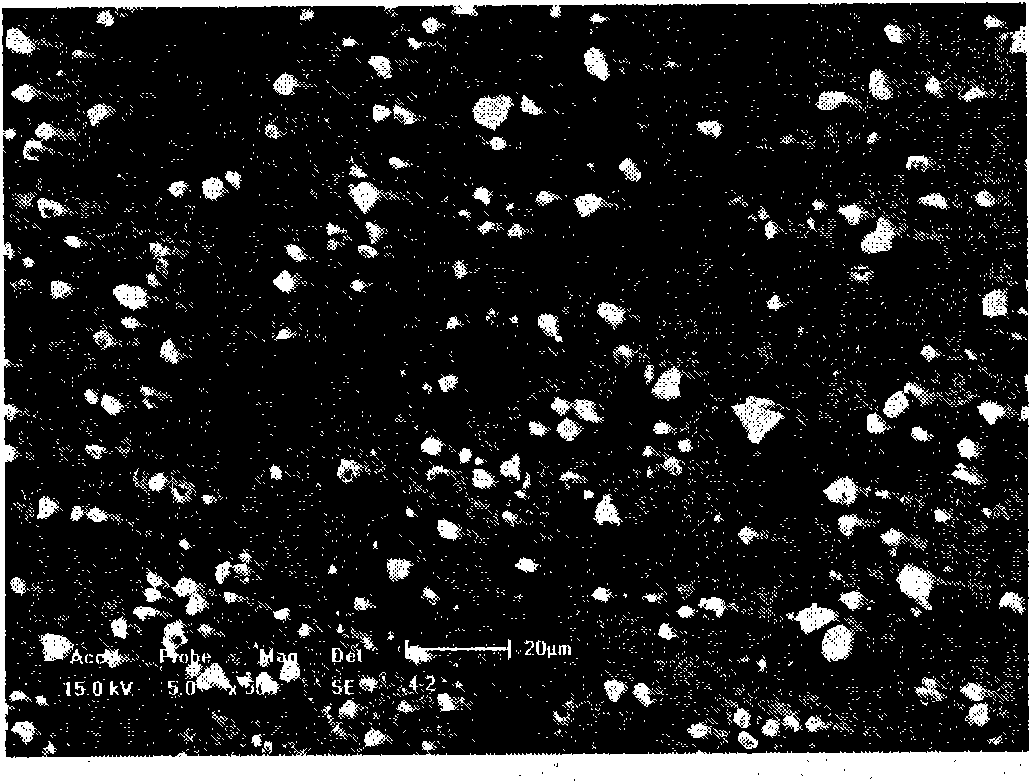

[0036] Wrap the preformed powder with aluminum foil, place it in an intermediate frequency furnace preheated to 750±10°C, pour aluminum melt at a temperature of 750°C into the intermediate frequency furnace to cover the preformed powder, and the preformed powder accounts for 10% of the total weight of the aluminum melt ; Apply an intermediate frequency magnetic field to the prefabricated powder and aluminum solution through an intermediate frequency furnace, and heat it at 950°C for 30 minutes. After the heat preservation, the reaction material is poured into an ingot to prepare a magnesium alloy grain re...

Embodiment 2

[0041] Aluminum powder, carbon powder, MgCO with a particle size of 50-400 mesh 3 Mix the powder and magnesium alloy No. 2 flux uniformly with a ball mill, and then dry it at 300°C for 1 hour to make a prefabricated powder. The weight percentage of each component is 45% of aluminum powder, 5% of carbon powder, MgCO 3 Powder 15%, the balance is magnesium alloy No. 2 flux.

[0042] Wrap the preformed powder with aluminum foil, place it in an intermediate frequency furnace preheated to 750±10°C, pour aluminum melt at a temperature of 800°C into the intermediate frequency furnace to cover the preformed powder, and the preformed powder accounts for 2% of the total weight of the aluminum melt ; Apply an intermediate frequency magnetic field to the prefabricated powder and aluminum solution through an intermediate frequency furnace, and heat it at 900 ° C for 50 minutes. After the heat preservation, the reaction material is poured into an ingot to prepare a magnesium alloy grain refi...

Embodiment 3

[0046] Aluminum powder, carbon powder, MgCO with a particle size of 50-400 mesh 3 Mix the powder and magnesium alloy No. 2 flux evenly with a ball mill, and then dry it at 200°C for 3 hours to make a prefabricated powder. The weight percentage of each component is 40% aluminum powder, 10% carbon powder, MgCO 3 10% powder, and the balance is magnesium alloy No. 2 flux.

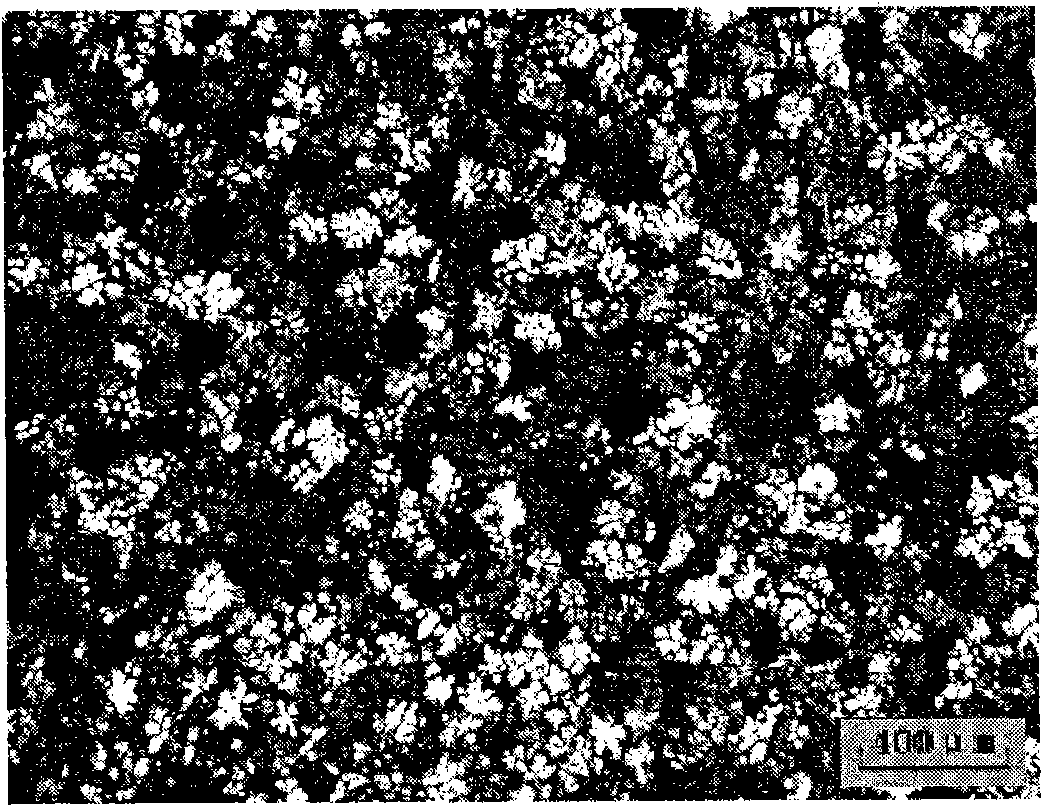

[0047] Wrap the preformed powder with aluminum foil, place it in an intermediate frequency furnace preheated to 750±10°C, pour aluminum melt at a temperature of 850°C into the intermediate frequency furnace to cover the preformed powder, and the preformed powder accounts for 5% of the total weight of the aluminum melt ; Apply an intermediate frequency magnetic field to the prefabricated powder and aluminum solution through an intermediate frequency furnace, and keep it warm at 850°C for 40 minutes. After the heat preservation, the reaction material is poured into an ingot to prepare a magnesium alloy grain refi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com