Method for cooling turbine stators and cooling system for implementing said method

A technology of cooling system and cooling method, which is applied in the direction of stator, blade support element, machine/engine, etc., and can solve the problem of air-conditioning performance cost and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

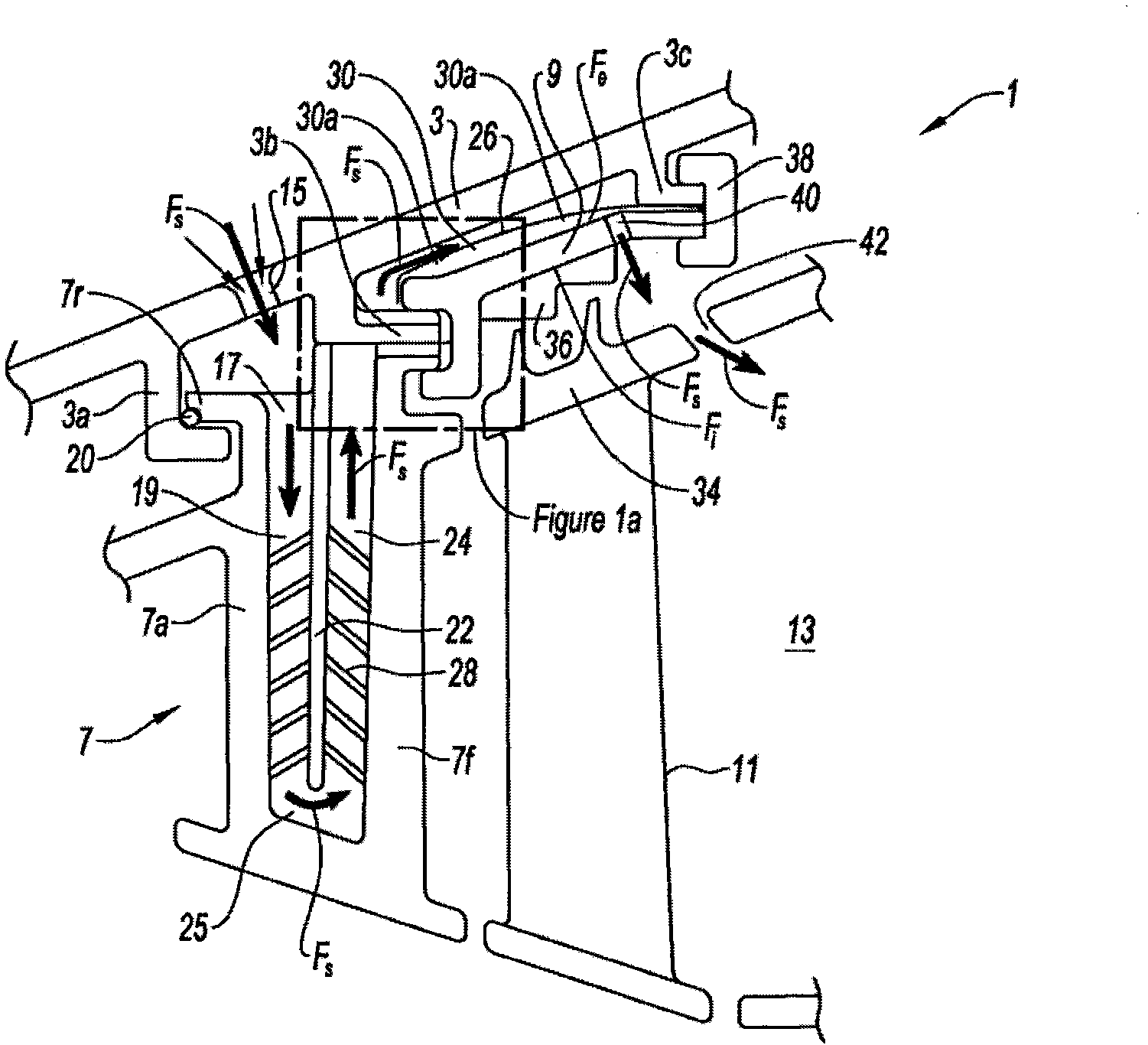

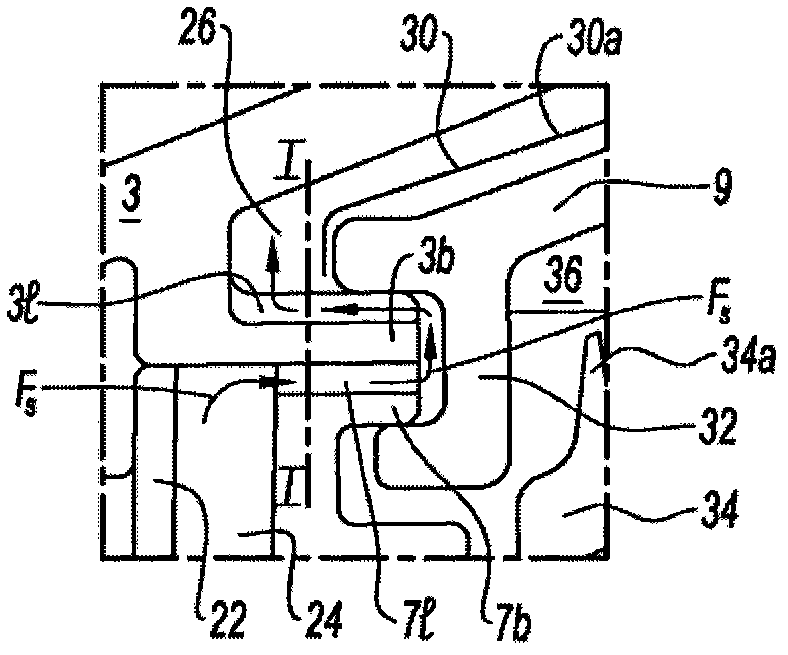

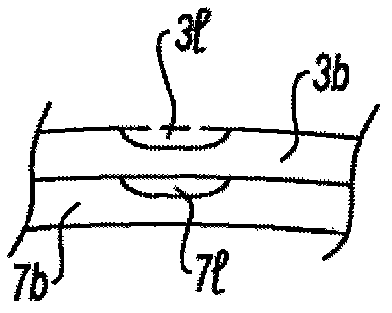

[0035] The terms "inner" and "outer" define components viewed from one side of the axis of rotation of the turbine or from the opposite side of this axis. Furthermore, the same reference numerals in the drawings denote the same or equivalent components.

[0036] With reference to 1, the turbine 1 consists in particular in a housing 3 of an air distribution stator or distributor with fixed vanes 7, a seal ring support 9 for the movable vanes 11, and a nozzle (not shown) for reaching the The exit path 13 is composed. The housing 3 fixes the position of the dispenser and ring support with support arms 3a, 3b and 3c. Air under the cowling is drawn in at low pressure in the form of an airflow Fs, across the inlet aperture 15 of the housing 3 and up through the distributor 7 and ring support 9 to the outlet path 13 .

[0037] The holes 15 are arranged facing an air inlet 17 provided at one end of a first radial circulation channel 19 inside the distributor 7 . The upstream seal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com