Microwave drying method and device adopted by same

A microwave drying and drying technology, applied in the direction of drying gas arrangement, heating device, drying solid materials, etc., can solve the problems of hot air loss temperature, slow heating speed, large heat loss, etc., and achieve the goal of accelerating the drying process and raising the average temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

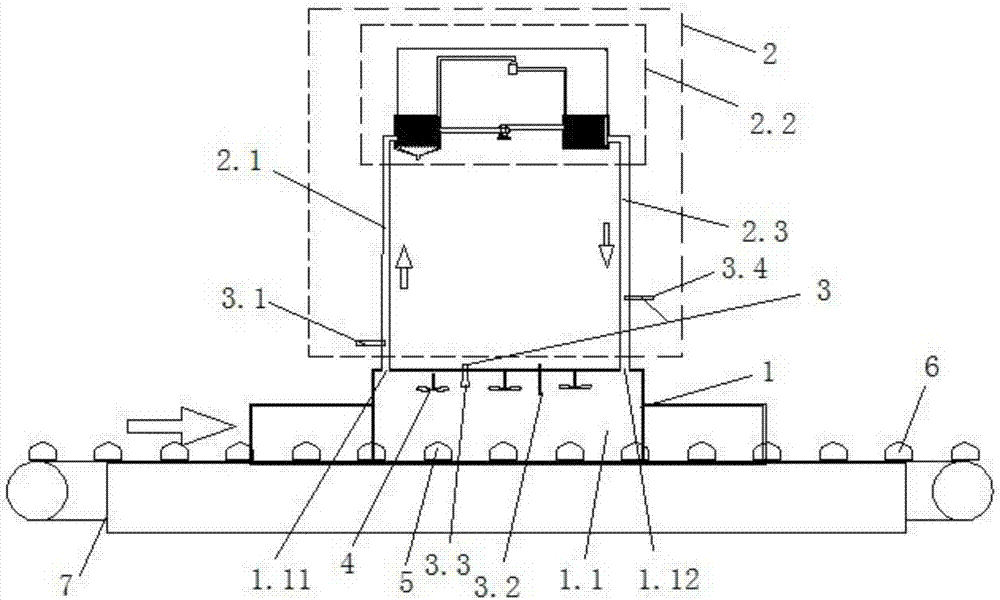

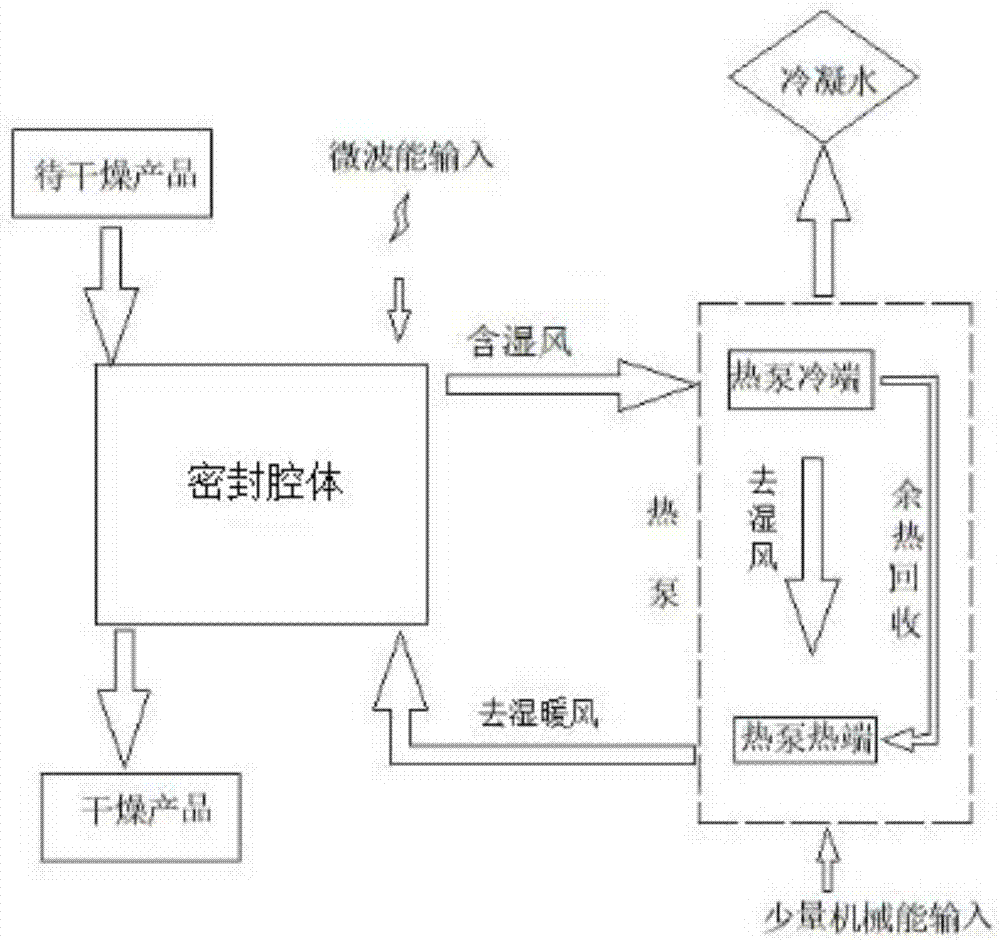

[0054] A microwave drying method (taking the drying of building blocks with a maximum size of 30mm as an example, with a moisture content of 21.5% to 2%), the device used is detailed in figure 1 , specifically including microwave drying equipment 1, a circulating air control system 2 that provides circulating hot air for the microwave drying equipment 1, a temperature sensor group 3 and an auxiliary circulation device 4, the details are as follows:

[0055] The microwave drying equipment 1 includes a sealed chamber 1.1 provided with an insulating layer, and the sealed chamber 1.1 is provided with an outlet 1.11 containing humid air and an inlet 1.12 for dehumidifying warm air.

[0056] The circulation control system 2 includes a wet air flow pipe 2.1, a processing part 2.2 for post-processing the wet air, and a dehumidified warm air flow pipe 2.3. The air outlet is connected, and the outlet end of the processing part is connected with the dehumidifying warm air inlet through t...

Embodiment 2

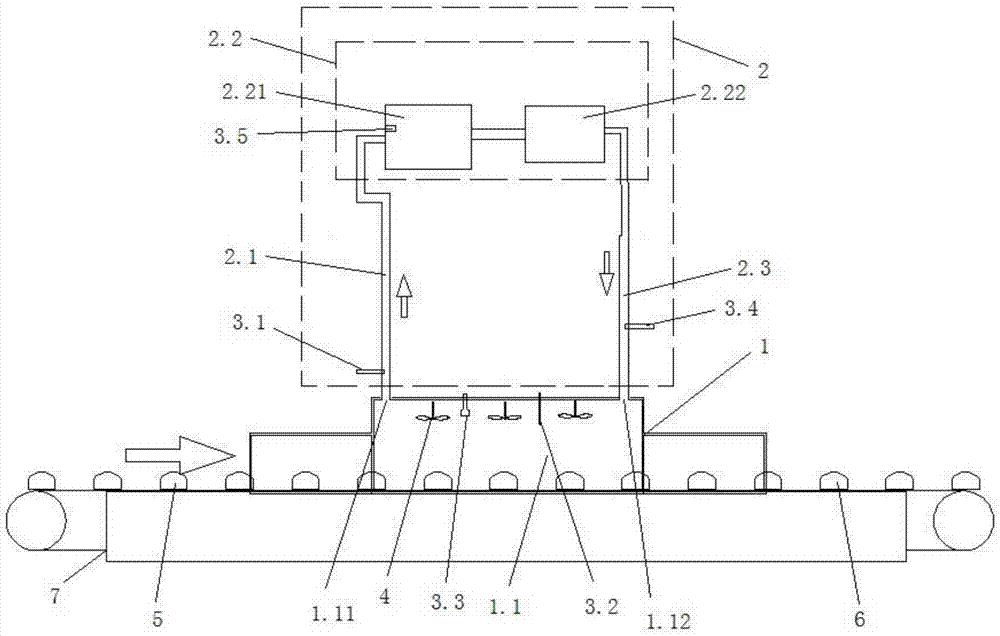

[0075] The specific scheme of this embodiment is detailed in image 3 and Figure 4 , which differs from Example 1 in the following two aspects:

[0076] The device structures are different, specifically: (1) the processing unit includes a condenser 2.21 and a heater 2.22, the condenser 2.21 is used for cooling and dehumidification of the humid wind, and the heater 2.22 is used for Carry out heat treatment to described dehumidification wind (heater can be the parts that can be heated such as heat exchanger, heat pump, when adopting heat pump, specifically: the cold end of heat pump is from atmosphere, industrial flue gas, natural water body, water body containing geothermal heat The heat is obtained from the heat pump and transferred to the hot end, and the hot end of the heat pump is used as a heater); the air inlet of the condenser is connected with the outlet of the wet air through the wet air flow pipe, and the air outlet of the condenser is connected with the The air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com