Fire door of microwave baking box

A technology for oven doors and ovens, applied in oven doors/flap gates, oven/stove doors, household ovens/stoves, etc., which can solve problems such as excessive microwave leakage, easy deformation, and oven door structures that cannot be used directly. Achieve the effect of simple structure and process and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

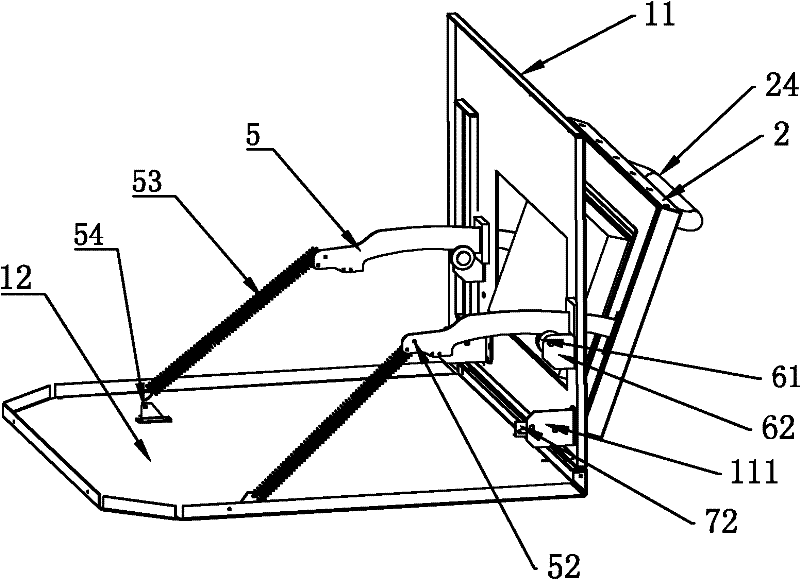

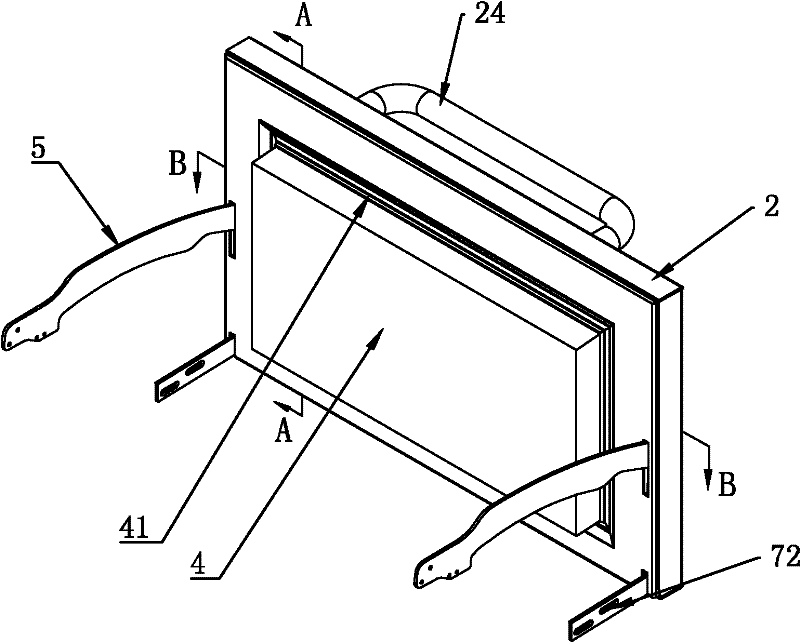

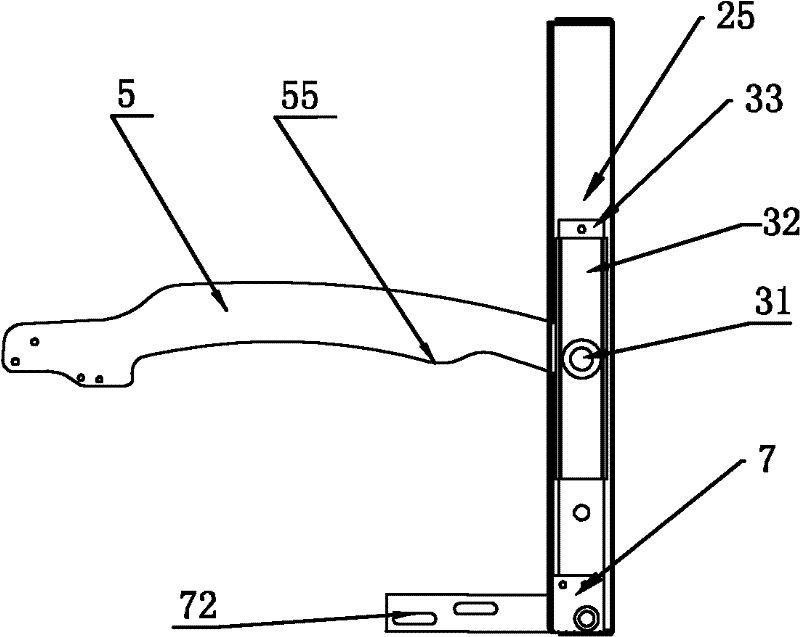

[0030] Such as Figure 1 to Figure 8 As shown, a microwave oven door includes a furnace body front plate 11 and a furnace body bottom plate 12 arranged in an "L" shape. The two plates are fixedly connected together and are the installation base of the oven door. There is a rectangular furnace door opening on the top. A door casing 2 is installed at the furnace door opening of the body of furnace front plate 11, and an automatic reset system is designed between the door casing 2 and the body of furnace front plate and the body of furnace bottom plate.

[0031] The door casing 2 is a hollow structure composed of an outer shell 21, an inner lining plate 22 and a blocking plate 23 formed by recessing on the inner lining plate, and a door handle 24 is fixedly installed on the outside of the door casing.

[0032] The inner liner 22 wherein opens inwardly at the center to form a rectangular groove with flanging around. The bottom surface of the rectangular groove is a blocking plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com