Liner with connecting structure from beginning to end

A head-to-tail connection and gasket technology, applied in baking, oven door/flap gate, food science, etc., can solve the problem that the airtightness of the oven cannot be guaranteed, the male head and the female head are easy to separate, and it is inconvenient to install To the furnace door and other problems, to achieve the effect of ensuring air tightness, simple structure and ensuring elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

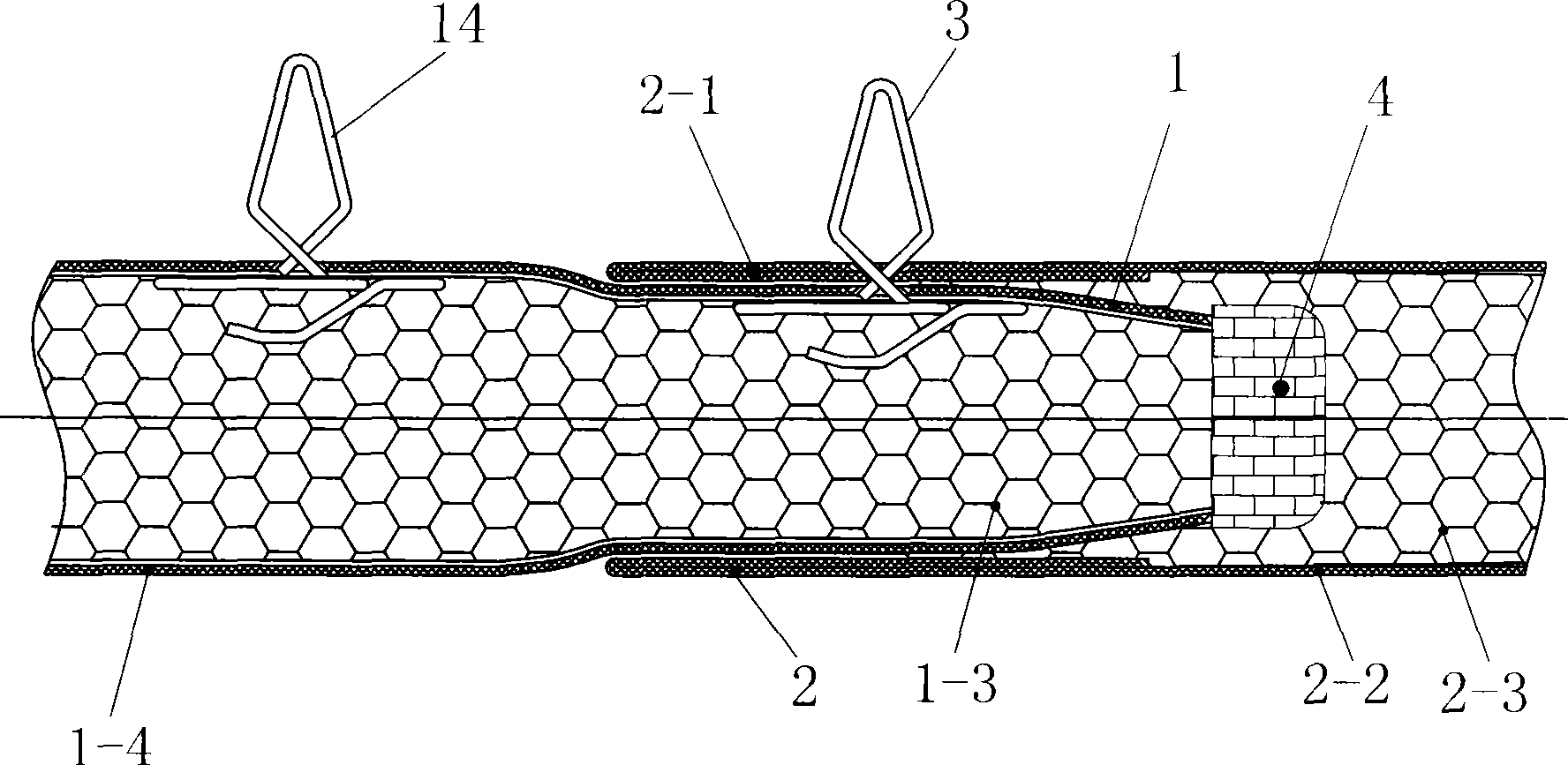

[0022] See figure 1 , 3 , 4 and 6, the gasket with head-to-tail connection structure in this embodiment includes: a female head 2 and a male head 1, and the male head 1 extends into the female head 2.

[0023] The edge of the open glass fiber tube of the female head 2 is rolled inwards to form the first double-layer part 2-1.

[0024] The male head 1 includes: a glass fiber tube 1-4, and a network tube-shaped skeleton 1-3 located in the glass fiber tube 1-4; the female head 2 includes: a glass fiber tube 2-2, and a fiberglass tube 2-2 2 is composed of a net tube-shaped skeleton 2-3; and the first double-layer part 2-1 of the female head 2 is sandwiched with a net tube-shaped skeleton 2-3.

[0025] The spring clip 3 is composed of a clip-shaped horizontal base 3-1 and a diamond-shaped engaging clip 3-2 vertically arranged on the horizontal base 3-1, and the horizontal base 3-1 has a free end 3-1-1.

[0026] The horizontal base 3-1 passes through the free end 3-1-1 from the s...

Embodiment 2

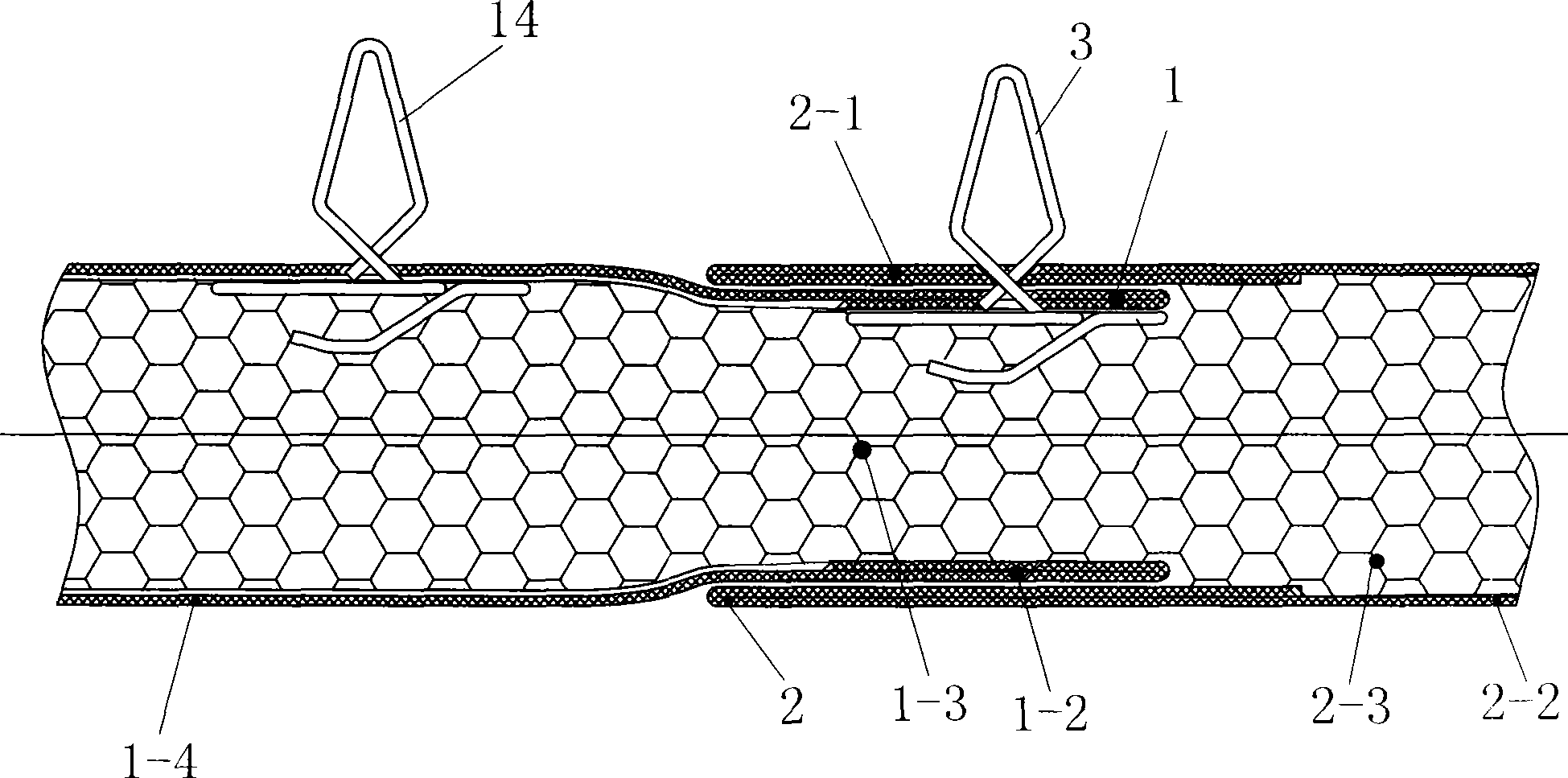

[0031] On the basis of Embodiment 1, the liner of this embodiment has the following deformations:

[0032] See figure 2 and 6 The edge of the glass fiber tube opening of the female head 2 is turned inward to form a first double-layer part 2-1; the edge of the glass fiber tube opening of the male head 1 is turned inward to form a second double-layer part 1-2 .

[0033] The first double-layer part 2-1 of the female head 2 is sandwiched with a net tube-shaped skeleton 2-3 and / or the second double-layer part 1-2 of the male head 1 is sandwiched with a net tube-shaped skeleton 1-3.

[0034] The spring clip 3 is composed of a clip-shaped horizontal base 3-1 and a diamond-shaped engaging clip 3-2 vertically arranged on the horizontal base 3-1, and the horizontal base 3-1 has a free end 3-1-1.

[0035] The horizontal base 3-1 passes through the first double-layer part 2-1 of the female head 2 and the second double-layer part 1-2 of the male head 1 from the surface to the inside th...

Embodiment 3

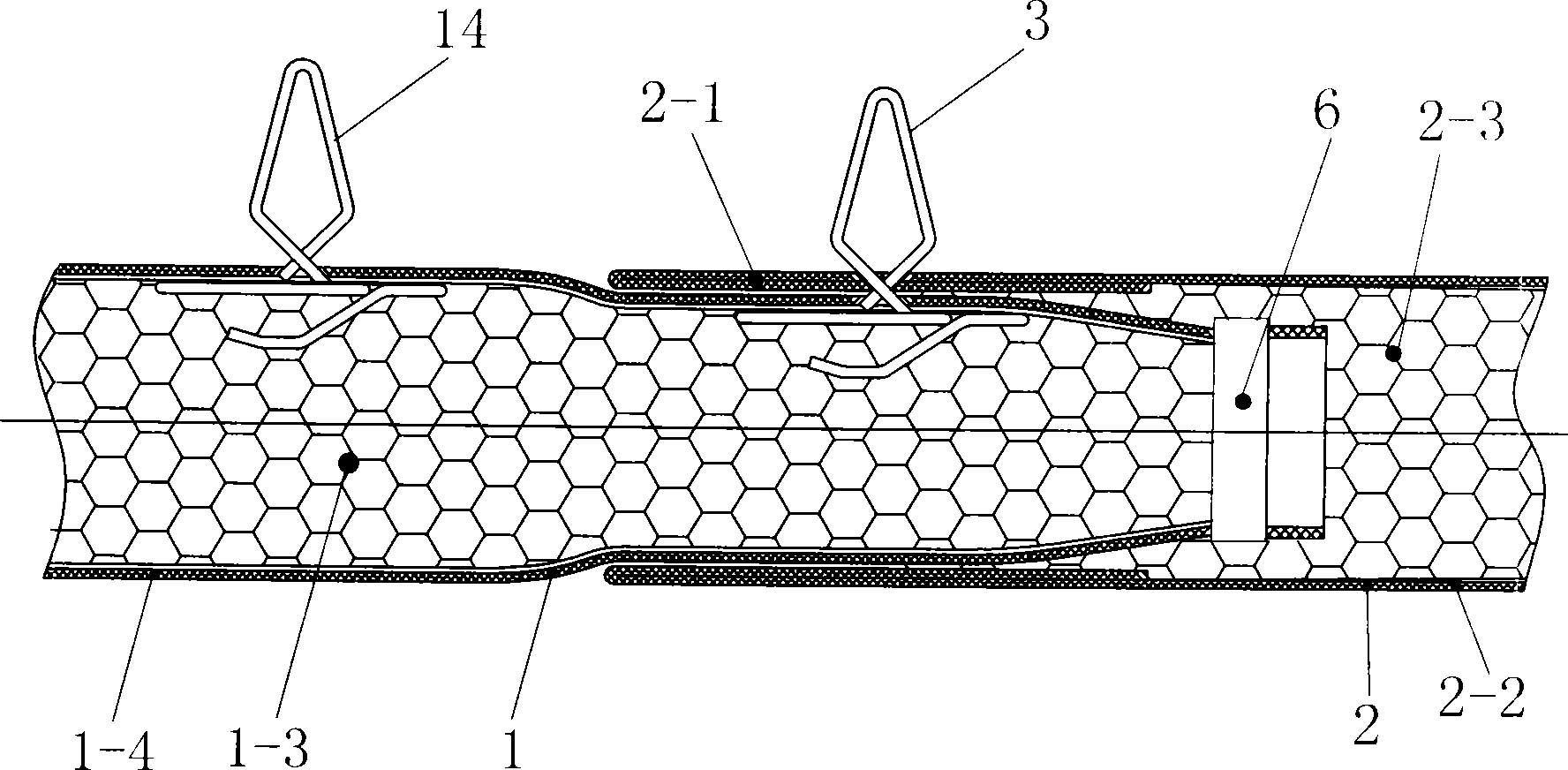

[0038] On the basis of the foregoing embodiments, the gasket of this embodiment has the following deformations:

[0039] See Figure 5 and 6 , the walls around the opening of the female head 2 are coated with glue; the male head 1 is either tied with high temperature resistant tape 4, or fixed with a metal beam opening 6, or coated with glue, so that the male head 1 is tapered and closed end.

[0040] The spring clip 3 is composed of a clip-shaped horizontal base 3-1 and a diamond-shaped engaging clip 3-2 vertically arranged on the horizontal base 3-1, the horizontal base 3-1 has a free end 3-1-1, The horizontal base 3-1 passes through the side walls of the female head 2 and the male head 1 sequentially from the surface to the inside through the free end 3-1-1, and places the horizontal base 3-1 of the spring clip 3 on the side wall of the male head 1. Inside the network tube-shaped frame 1-3, the rhombic engaging clip 3-2 of the spring clip 3 is held to protrude outward fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com