Coiled tubing cable sealing and fixing device

A cable sealing and fixing device technology, which is applied to the parts of the connecting device, the device for joining/disconnecting the connecting parts, the coupling device, etc., can solve the problems of cable insulation, etc., and achieve the effect of improving the sealing and preventing the entry of mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

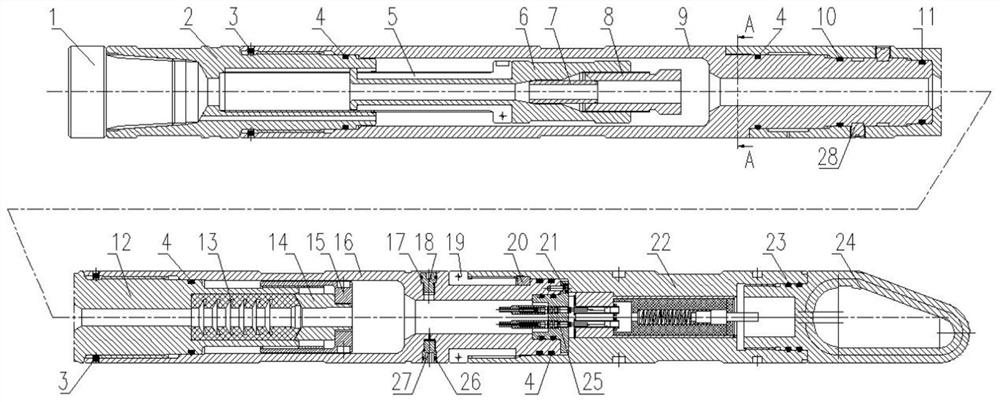

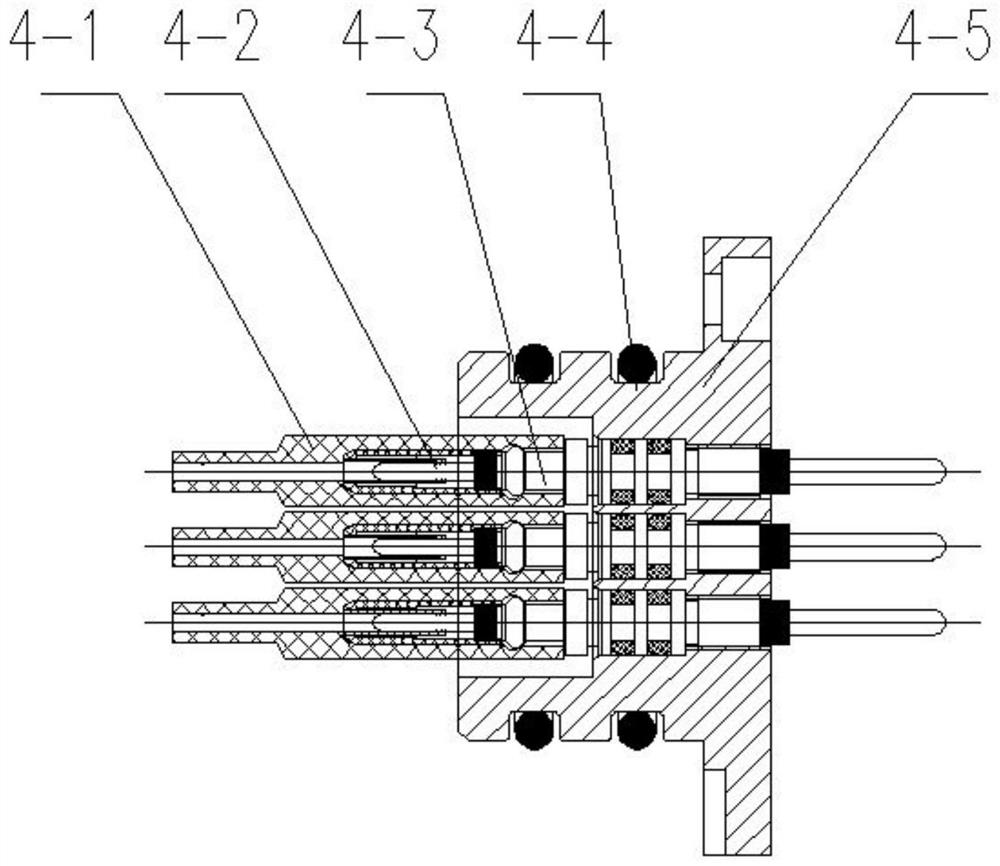

[0038] Specifically, according to figure 1 As shown, the coiled tubing cable sealing and fixing device includes a cable fixing assembly, a mechanical throwing assembly, a connecting shell 16 and an electrical transformation assembly; wherein, the cable fixing assembly, the mechanical throwing assembly, the connecting casing 16 and the electrical transformation assembly are coaxial Setting; one end of the cable fixing assembly is threaded in one end of the mechanical throwing assembly for pressing and fixing the cable; the other end of the mechanical throwing assembly is threaded in one end of the connecting shell 16, and in one end of the connecting shell 16 A cable sealing assembly is provided on the mechanical throwing assembly; the other end of the connecting shell 16 is threadedly connected to the electrical conversion assembly.

[0039] according to figure 1 As shown, the cable fixing assembly includes an upper joint body 2, a positioning split screw ring 5, a clamp seat...

Embodiment 2

[0049] Specifically, according to Figure 5 As shown, the coiled tubing cable sealing and fixing device includes a cable fixing assembly, a mechanical release assembly, a connecting shell 16 and an electrical conversion assembly; one end of the cable fixing assembly is threaded into one end of the mechanical release assembly for compression Fix the cable; the other end of the mechanical drop assembly is threaded in one end of the connecting shell 16, and a cable sealing assembly is provided on the mechanical drop assembly in one end of the connecting shell 16; the other end of the connecting shell 16 is screwed into the electrical conversion components.

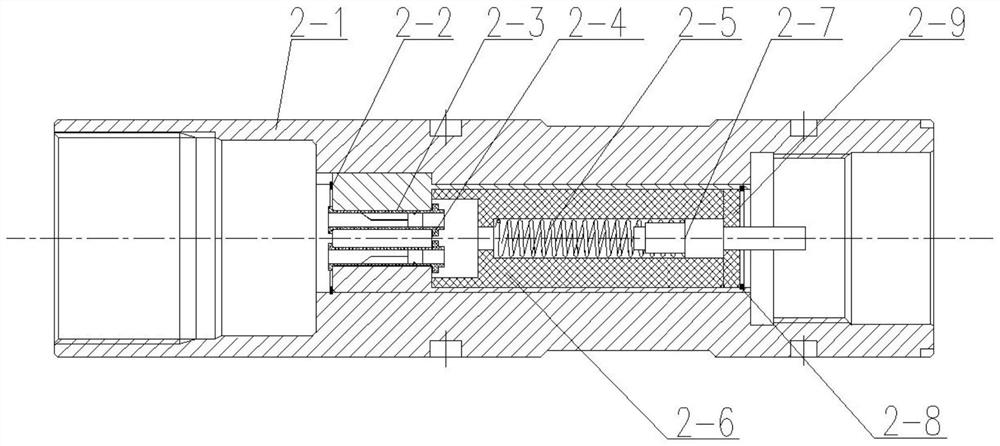

[0050] Specifically, according to Figure 5As shown, the cable fixing assembly includes slip upper connector 1-1, slip 1-2, slip shell 1-3, backing ring 1-4 and compression nut 1-5; one end of slip upper connector 1-1 Assemble the protective cap 1, the other end of the joint 1-1 on the slip is threaded to one end of the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com