End-to-end connected lining cushion and production method thereof

A head-to-tail connection and gasket technology, which is used in baking, oven door/flap gate, food science, etc. Good reliability, easy operation, improved sealing and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

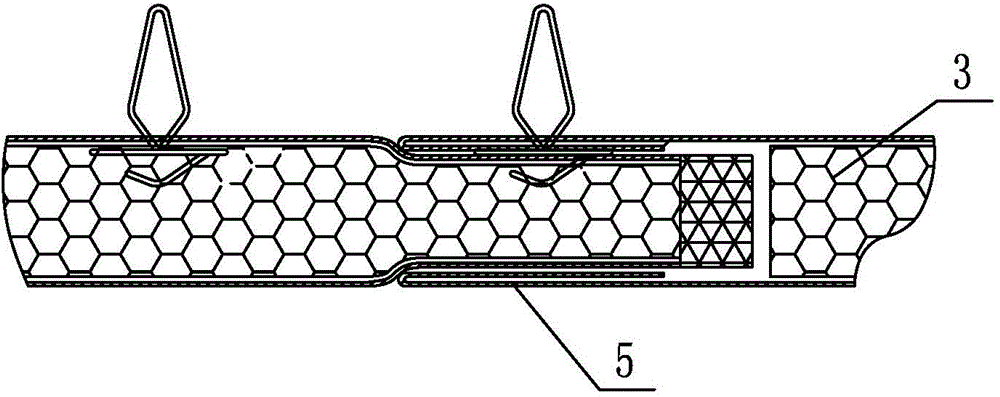

[0047] See Figure 6 , the end-to-end gasket of this embodiment includes: an elastic net tube 3, a glass fiber cloth tube 5 sleeved on the elastic net tube 3; a high temperature resistant yarn or metal wire or a resistant High-temperature elastic thread or spring 14, the glass fiber cloth at the head end of the glass fiber cloth tube 5 is folded toward its inner hole to form a female head 51 with a double layer, and the tail end of the glass fiber cloth pipe is a male head 52; After connecting the high temperature resistant yarn or metal wire or high temperature resistant elastic wire or spring 14 end to end, insert the male connector 52 into the female connector 51 . The pad joint with this structure is easy to operate and is beneficial to improve production efficiency. The change of the pipe diameter at the joint of the gasket is small, so the sealing performance of the gasket is better.

[0048] The end-to-end high-temperature-resistant yarns or metal wires or high-temper...

Embodiment 2

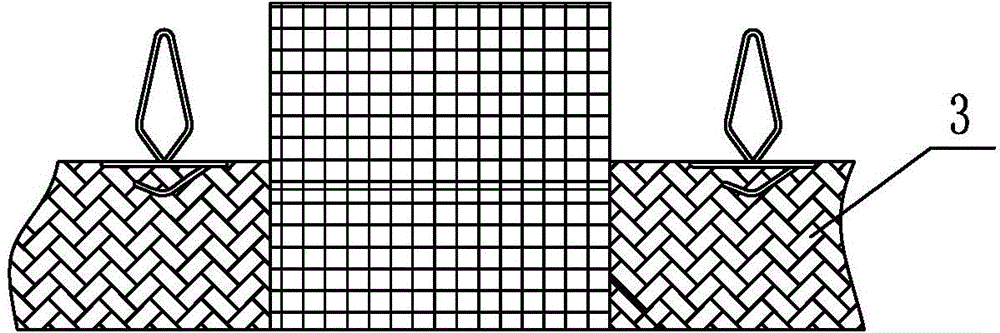

[0052] Compared with the above-mentioned embodiment 1, the structure of the head-to-tail connection type gasket in this embodiment of this embodiment has the following modifications:

[0053] The glass fiber cloths at the first and last ends of the glass fiber cloth pipe 5 are folded towards the respective inner holes to form double-layer parts at the first and last ends respectively, (the double-layer parts may be at the first and last ends of the elastic network pipe. outside the two ends, or the ends of the elastic mesh tube are in the corresponding double-layer parts), the two ends of the staple 8 pass through the double-layer parts of the first and last ends respectively and connect the first and last ends (The preferred solution is: the two ends of the staple 8 are also connected to the first and last ends of the elastic network pipe 3 at the same time, so as to ensure that the joint has corresponding elasticity, so as to improve the sealing of the gasket and the quality ...

Embodiment 3

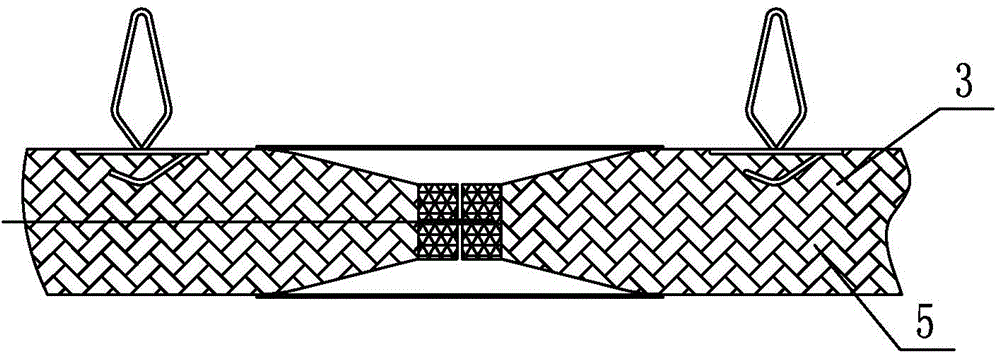

[0056] Compared with the above-mentioned embodiment 2, there are the following modifications in the structure of the head-to-tail connection type gasket in this embodiment:

[0057] Such as Figure 11 , the glass fiber cloths at the first and last ends of the fiberglass cloth pipe 5 are folded toward their respective inner holes to form double-layer parts at the first and last ends respectively, (the double-layer parts may be at the first and second ends of the elastic network pipe Outside the two ends of the tail, or the end of the elastic net tube is in the corresponding double-layer part), a pair of metal buckles 9 are used to connect the double-layer parts at the two ends of the head and tail.

[0058] Such as Figure 12 , the metal buckle 9 is a scroll spring buckle, and the inner and outer ends of the buckle have hook parts; the outer end hook part 91 of the buckle passes through the double-layer part and is embedded in the outer layer of glass fiber In the cloth, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com