Cookie filling molding and roasting machine

A baking machine and cookie technology, which is applied in baking, special product baking, food forming, etc., can solve the problems of low work efficiency and long time for taking out the cookie filling, and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

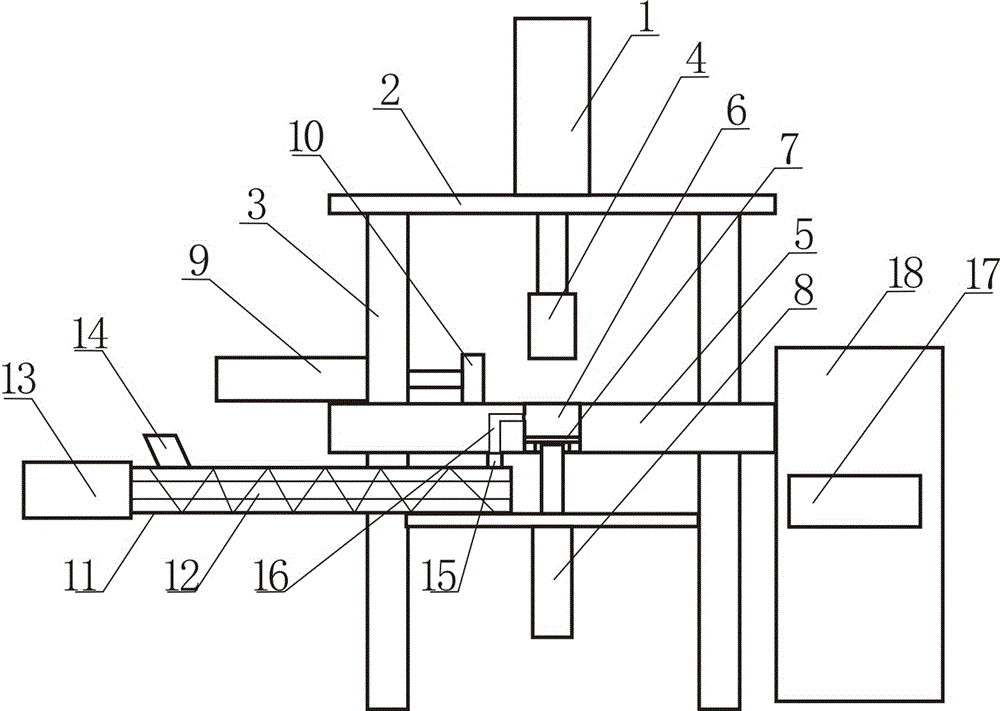

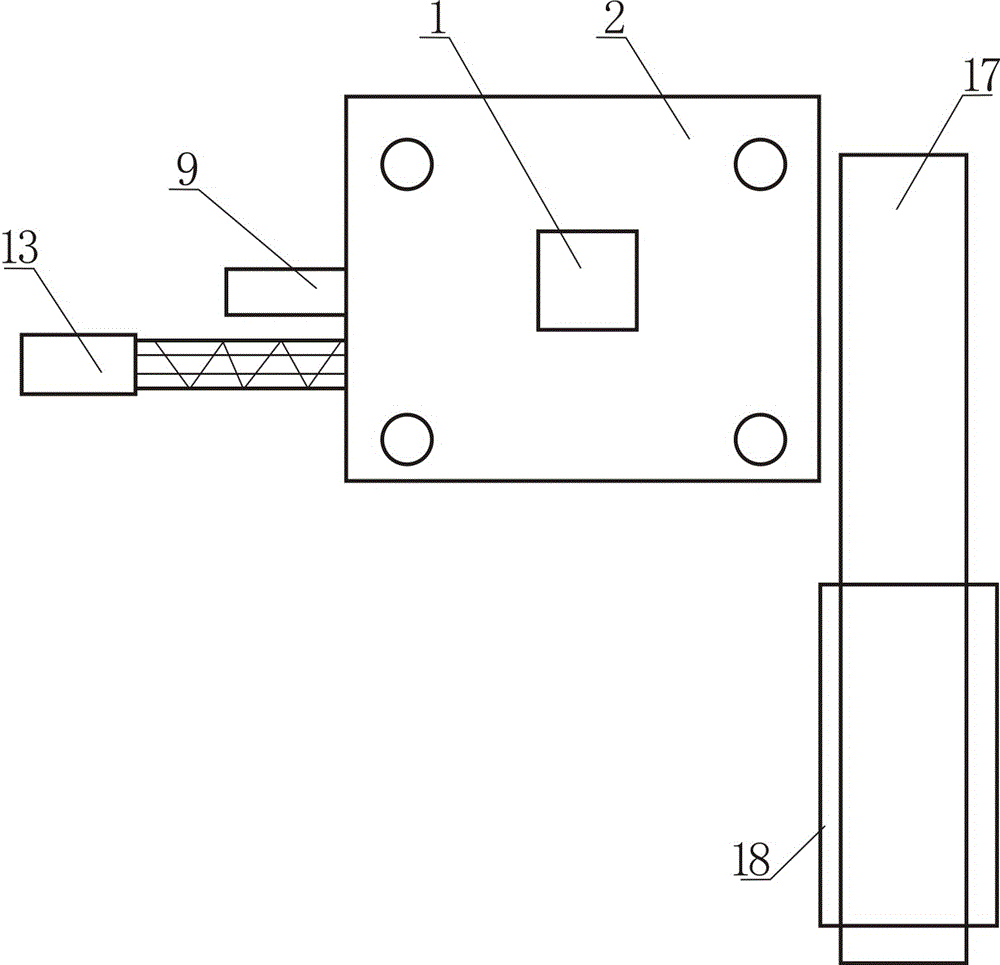

[0022] Such as figure 1 , 2 As shown, the cake filling forming baking machine includes a support frame, a lower pressure cylinder 1, a mold head 4, a mold barrel 6, a movable template 7, an upper cylinder 8 and a shaping support workbench 5, and the support frame includes four support feet 3 and the horizontal fixed plate 2 located on the top of the supporting feet 3, the shaping supporting workbench 5 is arranged on the four supporting feet 3 and is parallel to the horizontal fixing plate 2, the mold cylinder 6 is fixed on the shaping supporting workbench 5, and the movable template 7 Be located in the mold barrel 6, press down the cylinder 1 verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com