Method for processing steamed and baked bread and special-purpose equipment stove for steaming and baking

A processing method and special equipment technology, which is applied in the field of steaming and steaming ovens for noodle food, can solve the problems of insufficient steam generation, loose combination, and reduced thermal efficiency, so as to reduce heat loss and achieve a mellow and strong taste. , the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

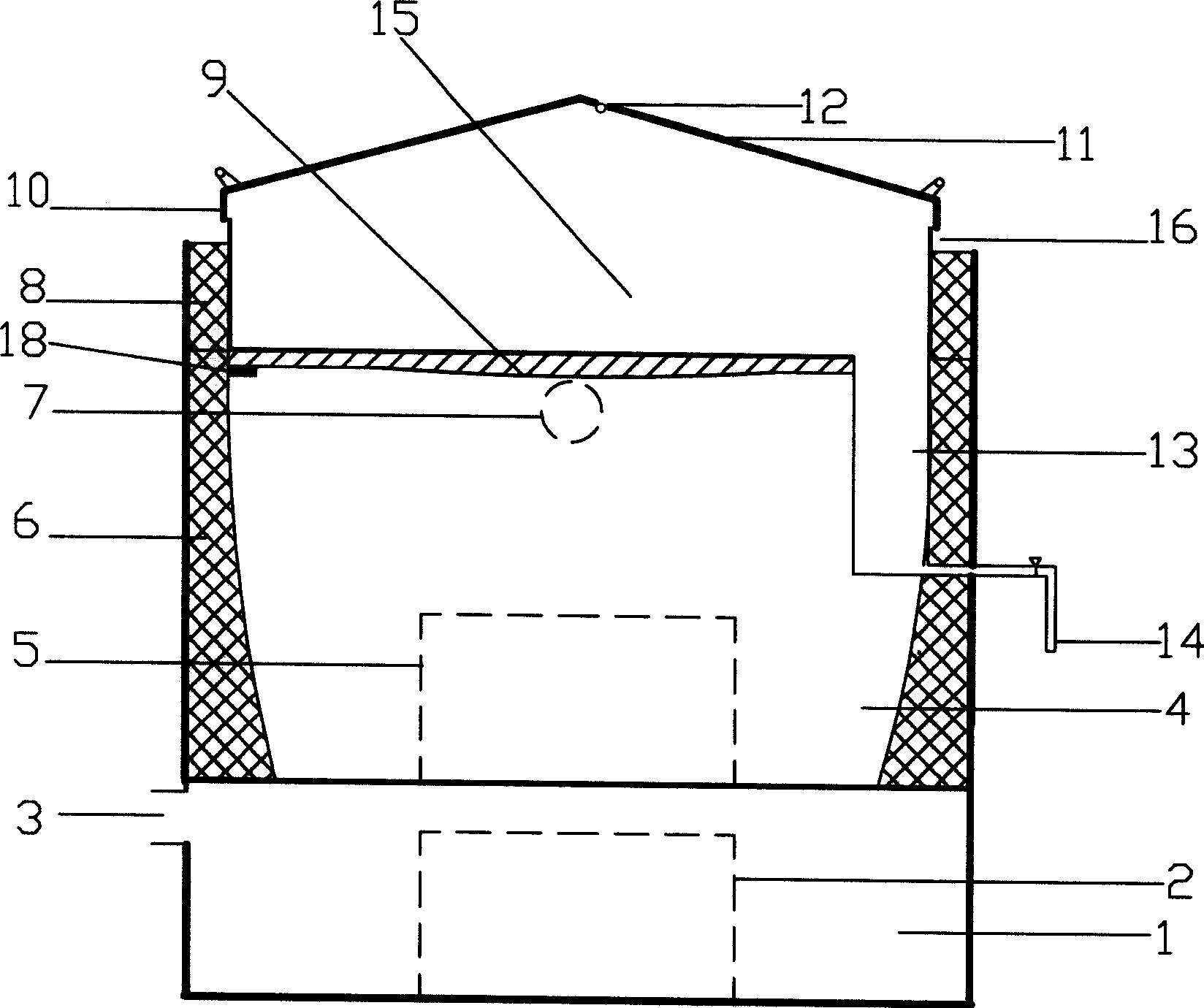

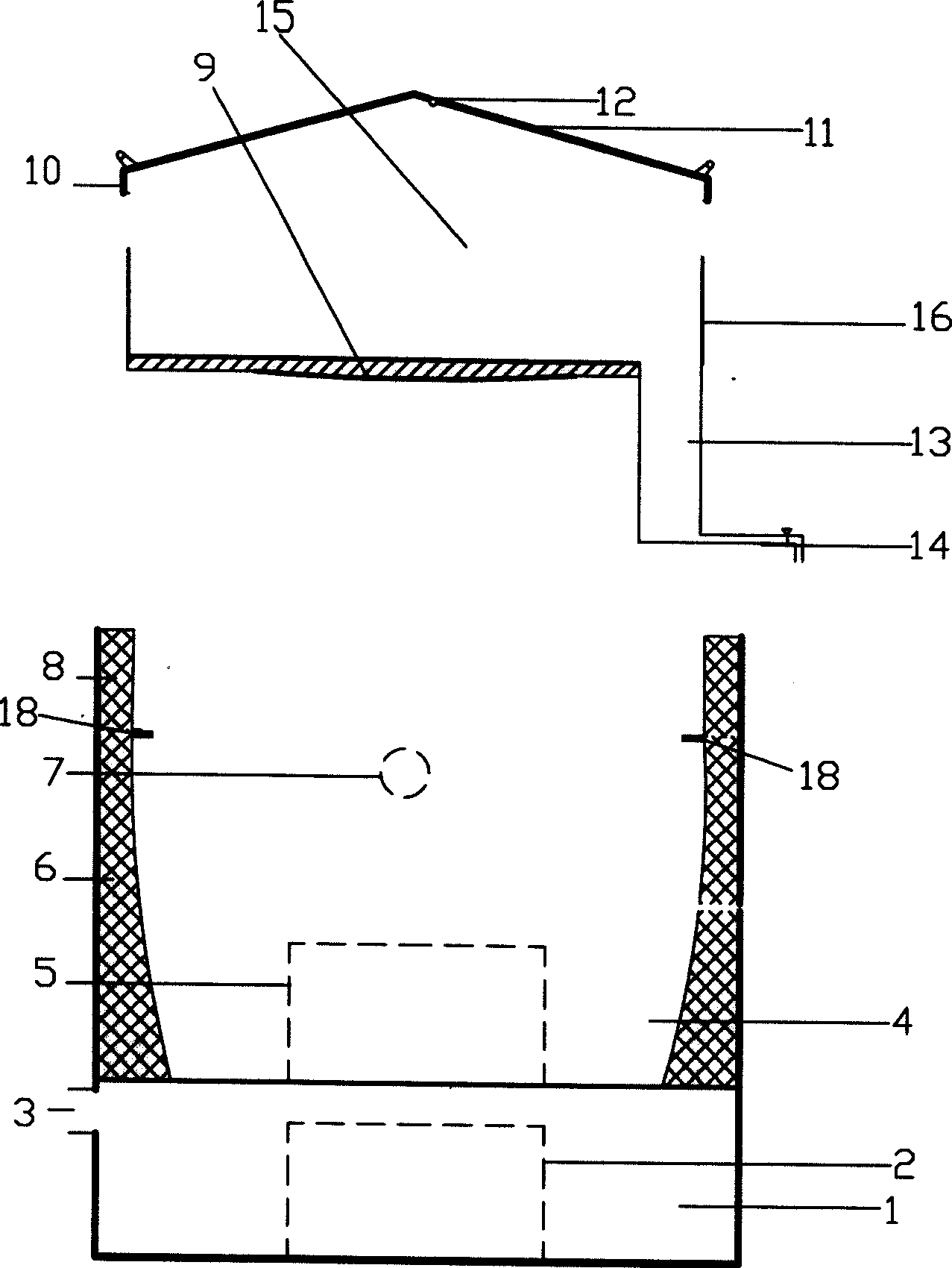

[0034] Embodiment 1: The overall shape of the firewood and coal steaming furnace is a cylinder or a cube, and from bottom to top it consists of an ash chamber 1, a furnace tooth, a stove chamber 4, a steam griddle holder 18, a steam griddle insulation ring 8, a steam griddle 15 and Pan cover 11 constitutes. Ash chamber is 20 centimeters high, is provided with ash outlet and ash outlet door 2. A blower air inlet 3 with a diameter of 5 to 10 centimeters is arranged on the top of the ash chamber on the upper left side of the ash outlet, and an opening and closing device is arranged. The hearth is 40 cm high. Kitchen chamber wall 6 is steel plate, heat insulation material, refractory material structure from outside to inside, and the top is thick 4 centimetres, and middle and lower part is thick 5~10 centimetres. Fuel operation port and operation port door 5 are established on the vertical line between the bottom of the stove chamber and the ash outlet. A smoke outlet 7 is arra...

Embodiment 2

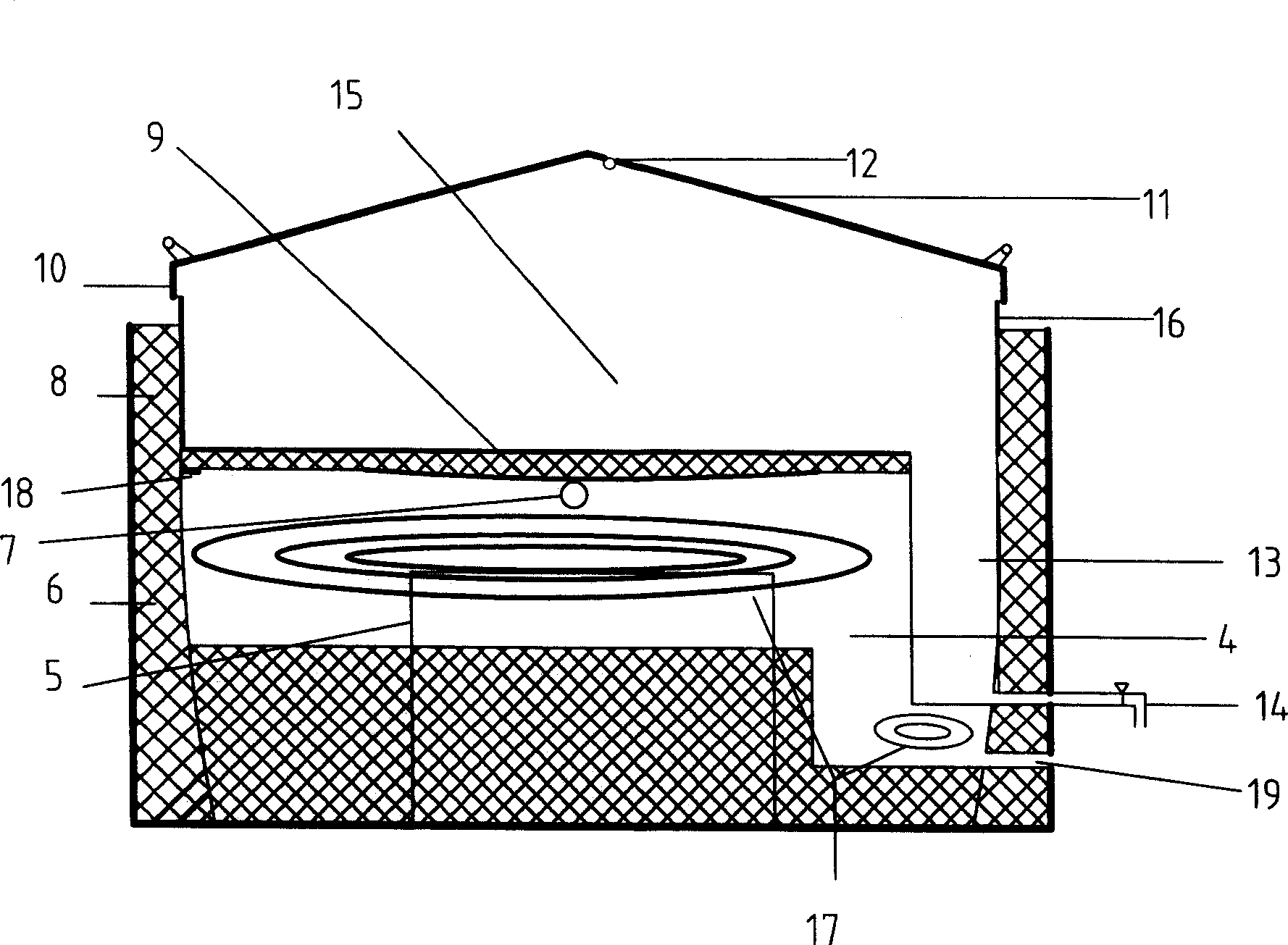

[0035]Embodiment 2: The overall shape of the gas steamer is a cylinder or a cube, and it is composed of a stove chamber 4, a stove head 17, a steam grill holder 18, a steam grill insulation ring 8, a steam grill 15 and a grill cover 11 from bottom to top. The hearth is 34 cm high. Kitchen chamber wall 6 is steel plate, heat insulation material, refractory material structure from outside to inside, and the top is thick 4 centimetres, and middle and lower part is thick 5~10 centimetres. The kitchen range is provided with the operation door 5 that can enter and exit the range head, and the door is provided with an observation window. One side of the kitchen range is provided with a gas pipeline port 19, which is also used as an air inlet. A smoke outlet 7 is arranged at the center position of the top, rear portion of the kitchen range. There are 4 supporting handles 18 in order to take advantage of the steam grid with 4 lengths of 5 cm and a width of 3 cm welded on the inner ci...

Embodiment 3

[0036] Embodiment 3: The overall shape of the electric steamer is a cylinder or a cube, and it consists of a hearth 4, a heating device 17, a steam griddle holder 18, a steam griddle insulation ring 8, a steam griddle 15 and a griddle cover 11 from bottom to top . The hearth is 34 cm high. Kitchen chamber wall 6 is steel plate, heat insulation material, refractory material structure from outside to inside, and the top is thick 4 centimetres, and middle and lower part is thick 5~10 centimetres. The kitchen range is provided with the operation door 5 that can open and close, and the door is provided with observation window. A cable inlet 19 is provided at the bottom of one side of the stove. There are 4 supporting handles 18 in order to take advantage of the steam grid with 4 lengths of 5 cm and a width of 3 cm welded on the inner circumference or four corners of the stove top. 8 high 7~17 centimetres of steam boiler insulation ring. The steam griddle is made of a griddle bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com