Roaster for roasting whole lamb

A technology for ovens and furnace bodies, applied in the field of ovens, can solve problems such as lack of good solutions, labor and time-consuming construction, food pollution, etc., and achieve the effects of reducing smoking time, convenient use, and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

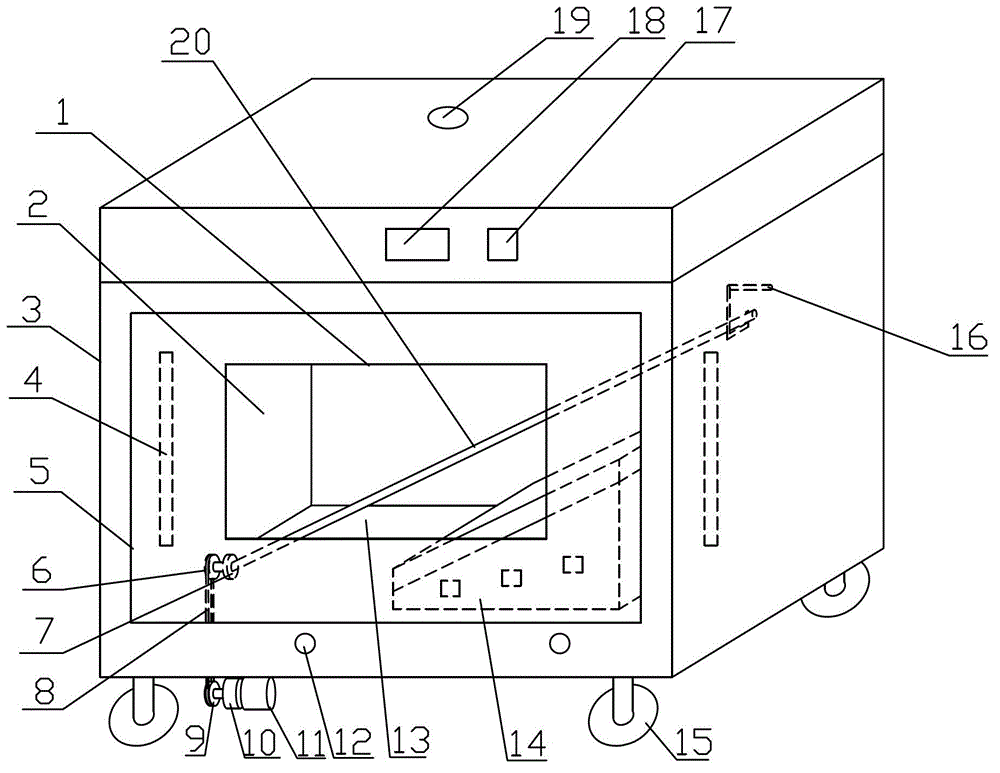

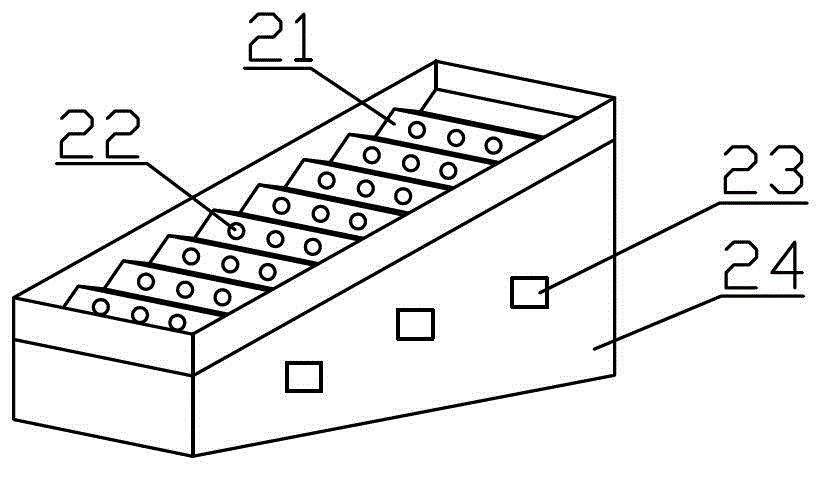

[0017] Refer to the attached figure 1 And attached figure 2 An oven for roasting whole lamb of the present invention will be described in detail below.

[0018] A roasting whole sheep oven of the present invention has a structure comprising a furnace body 3, an electric heating tube 4, an insertion rod 20, an insertion rod detection hook 16, an insertion rod rotation driving device and a baking pan 14. The furnace body 3 The front side is provided with a front door 5, the front door 5 is provided with an observation window 1, the top is provided with an air outlet 19, the side of the lower part is provided with an air inlet 12, and the furnace body 3 on the top of the front door 5 is provided with an electric controller 18 and a display 17. The furnace body 3 is provided with an electric heating tube 4, the electric heating tube 4 is electrically connected to the electric controller 18 and the display 17, and a layer of refractory bricks is respectively arranged on the top s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com