Patents

Literature

49results about How to "Low labor intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

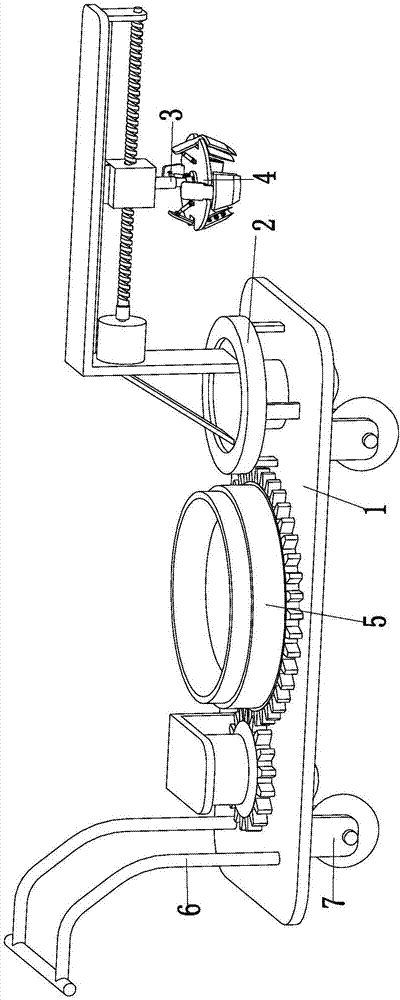

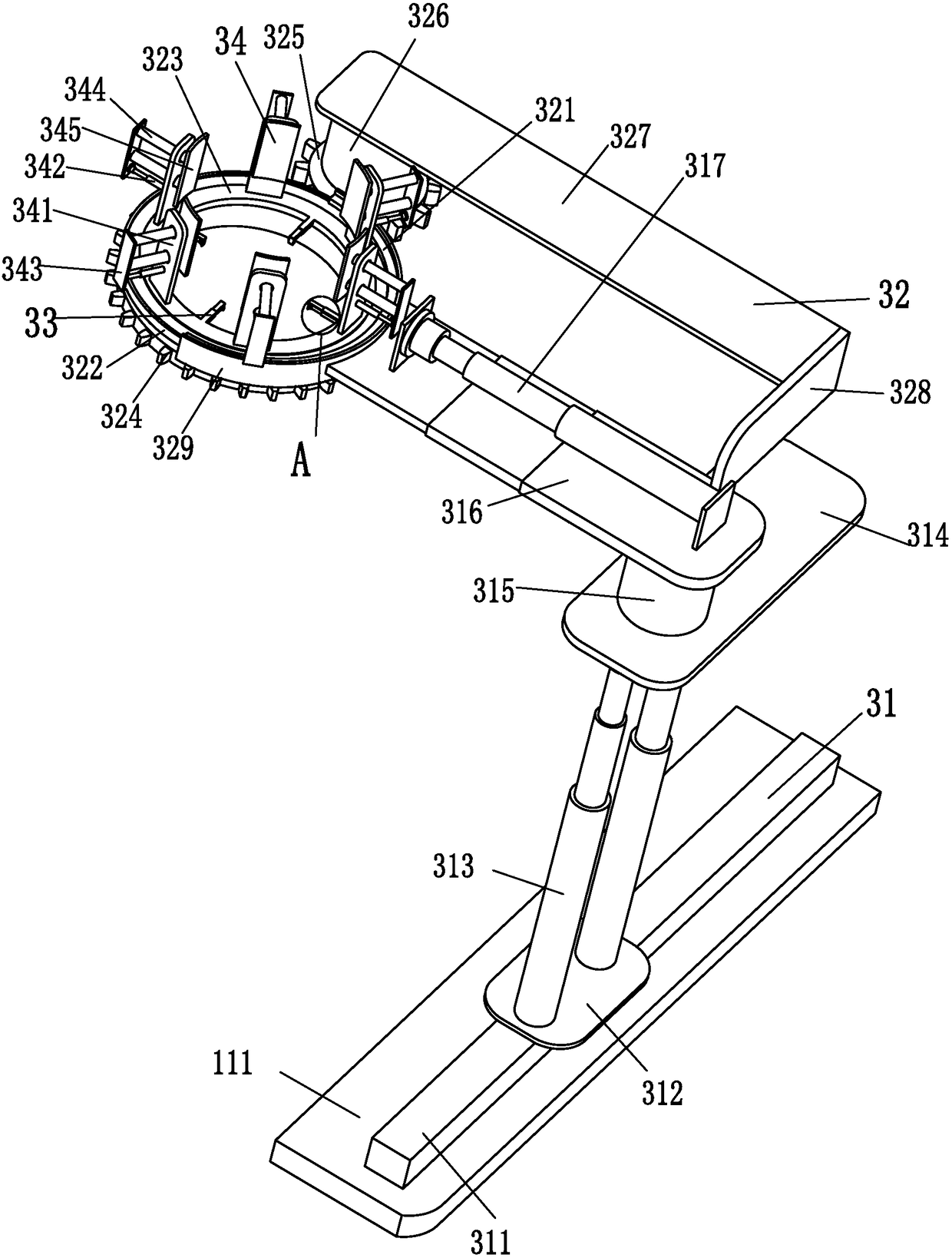

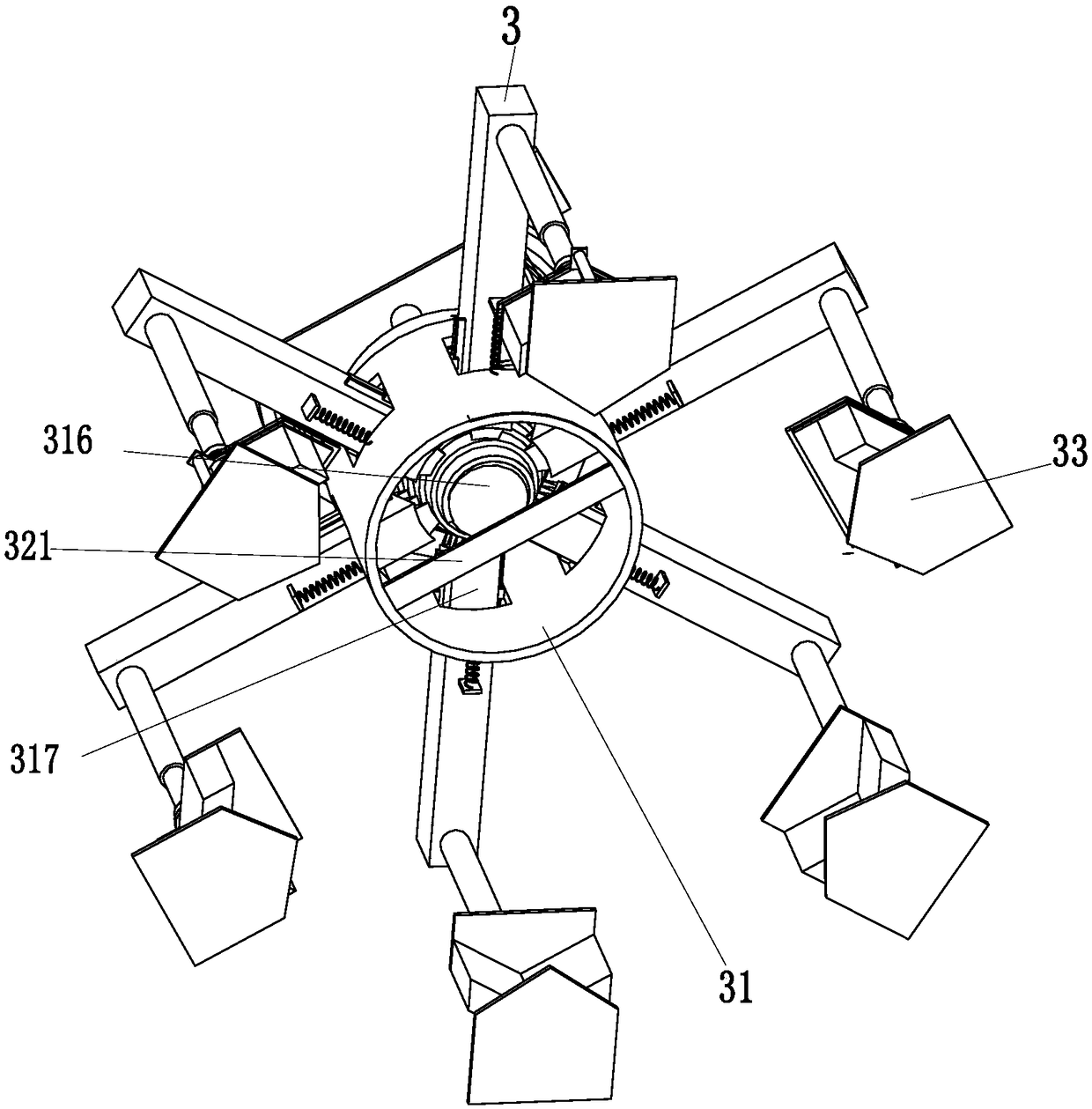

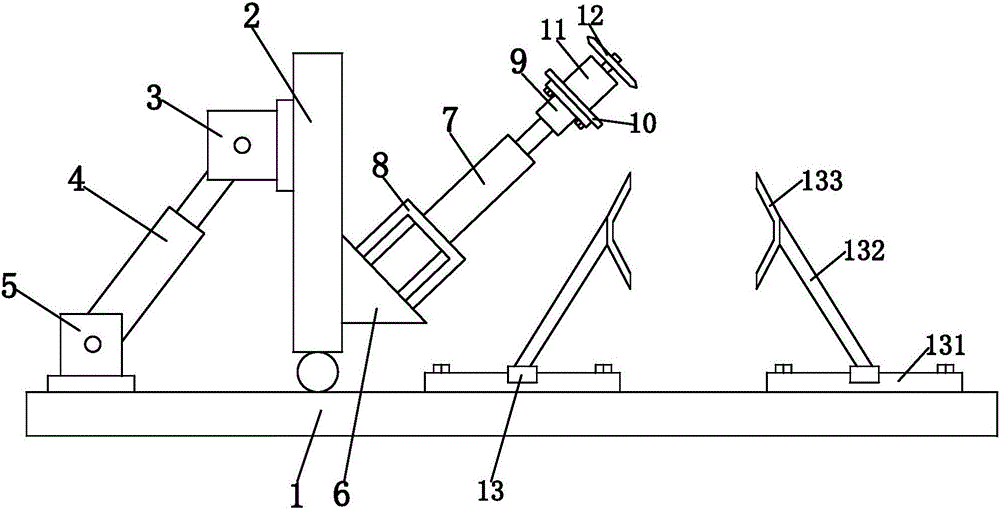

Efficient automatic fruit sorting robot

ActiveCN106976102AGrasp firmlyReduce labor intensityGripping headsConveyor partsHydraulic cylinderEngineering

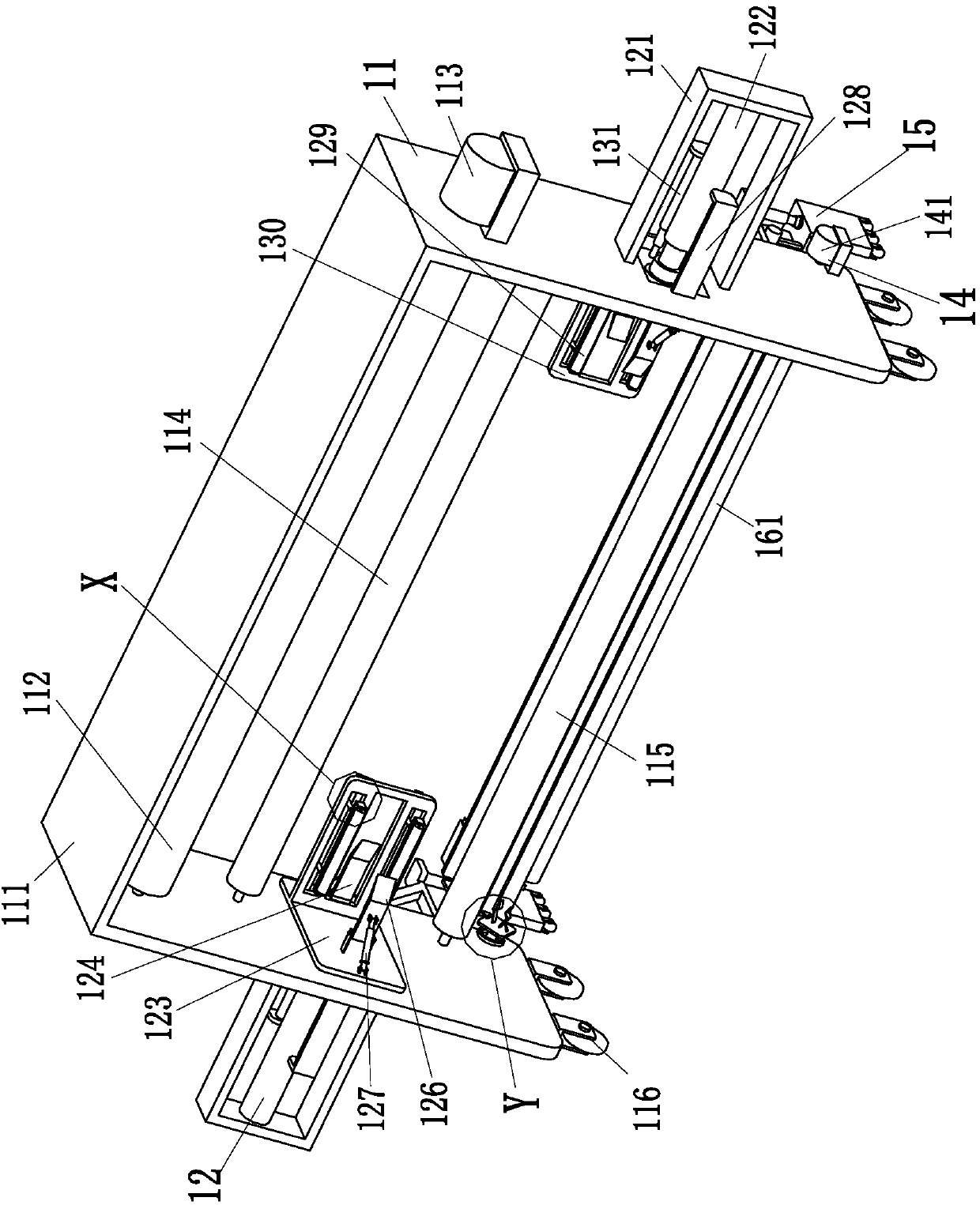

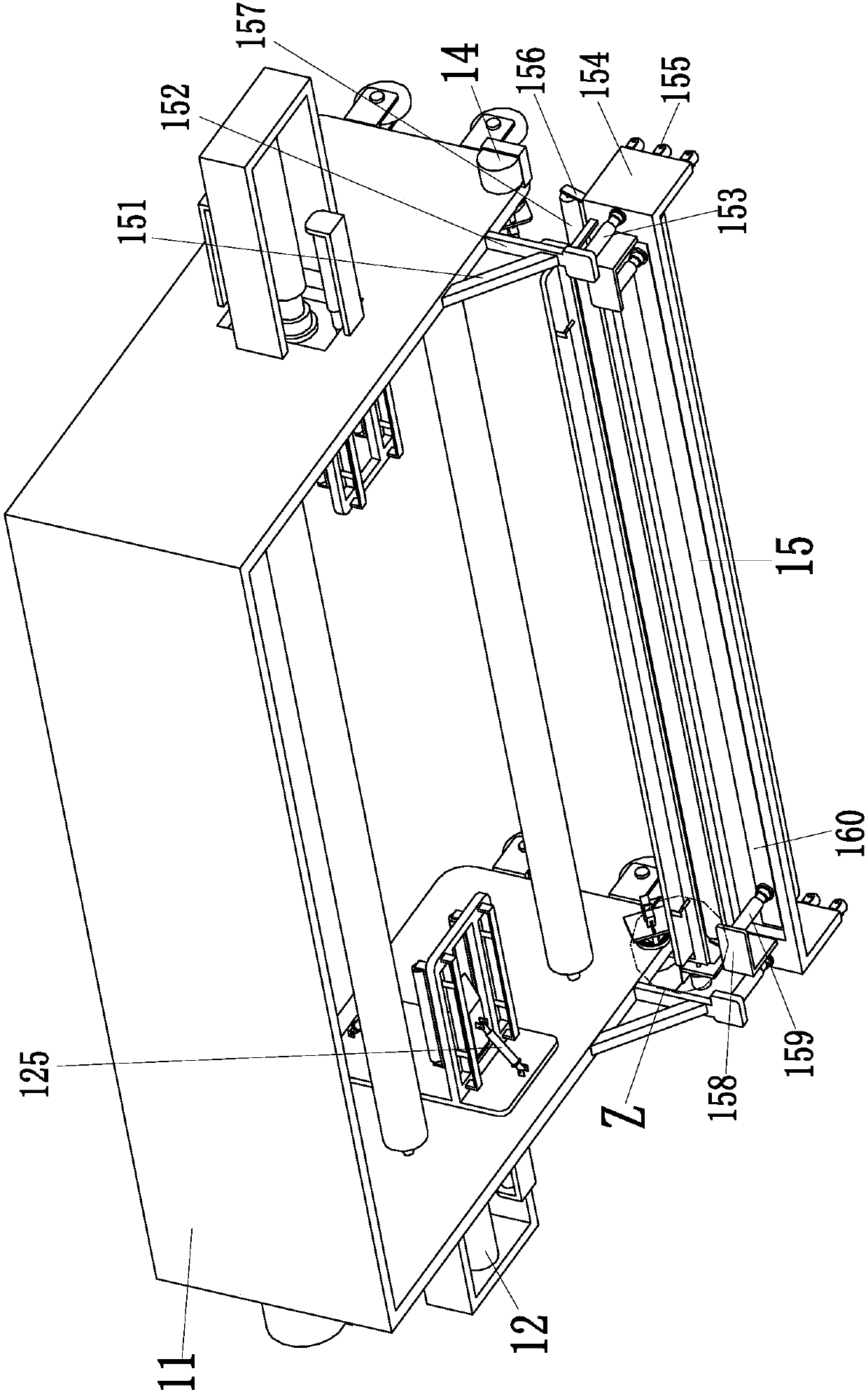

The invention relates to an efficient automatic fruit sorting robot comprising a base plate. An adjusting mechanism is mounted at the front end of the base plate. A lifting hydraulic cylinder is mounted at the lower end of the adjusting mechanism. The bottom end of the lifting hydraulic cylinder is mounted on a hard-shell fruit grabbing mechanism through a flange. A collecting mechanism is mounted in the middle of the base plate, and a pushing handle is mounted at the rear end of the base plate. Four universal wheels are mounted symmetrically at the lower end of the base plate. The adjusting mechanism can drive the hard-shell fruit grabbing mechanism to conduct position adjusting. The adjusting mechanism, the hard-shell fruit grabbing mechanism and the collecting mechanism are mutually matched to complete the process of fruit sorting. The problems that in the existing fruit sorting process, soft-shell fruit and hard-shell fruit need to be carried through labor, the surface of the soft-shell fruit is prone to damaging, fruit selling is affected, and carrying of the hard-shell fruit through the labor is large in labor intensity and low in working efficiency can be solved, and the function of efficient fruit sorting can be achieved.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

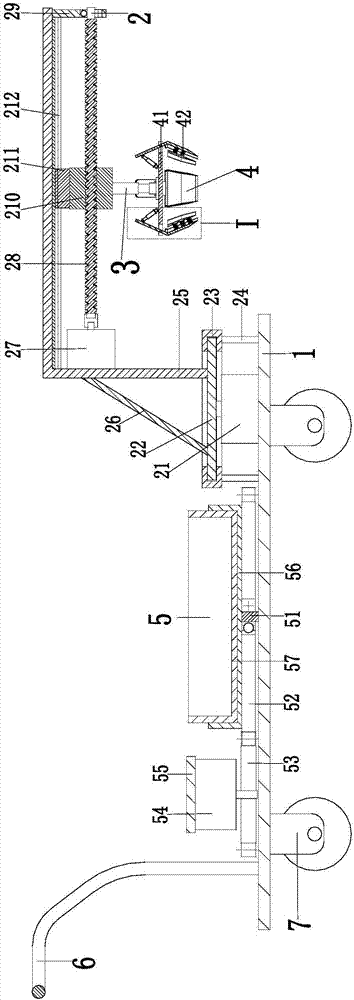

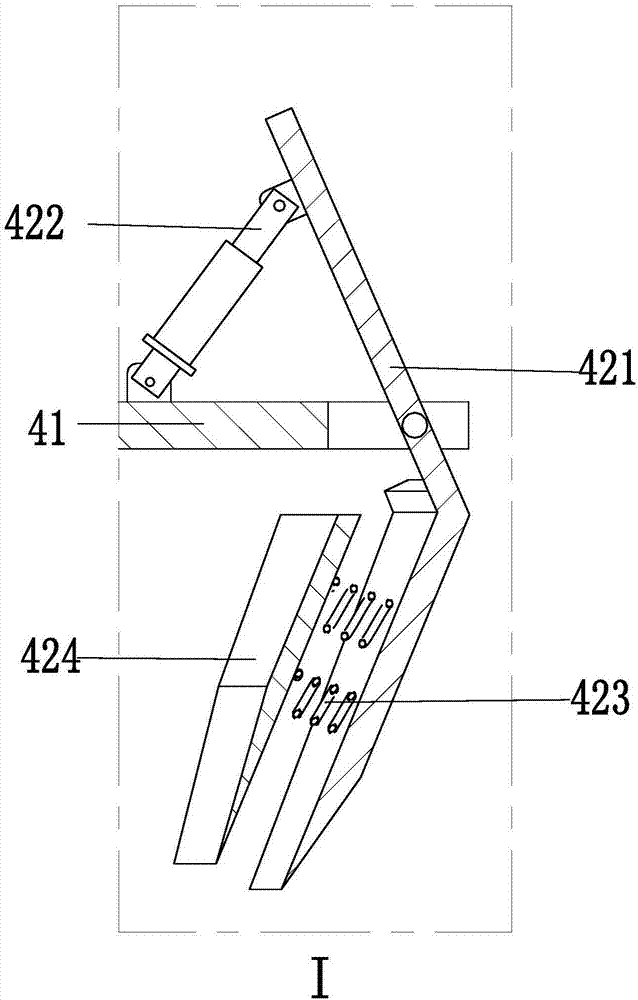

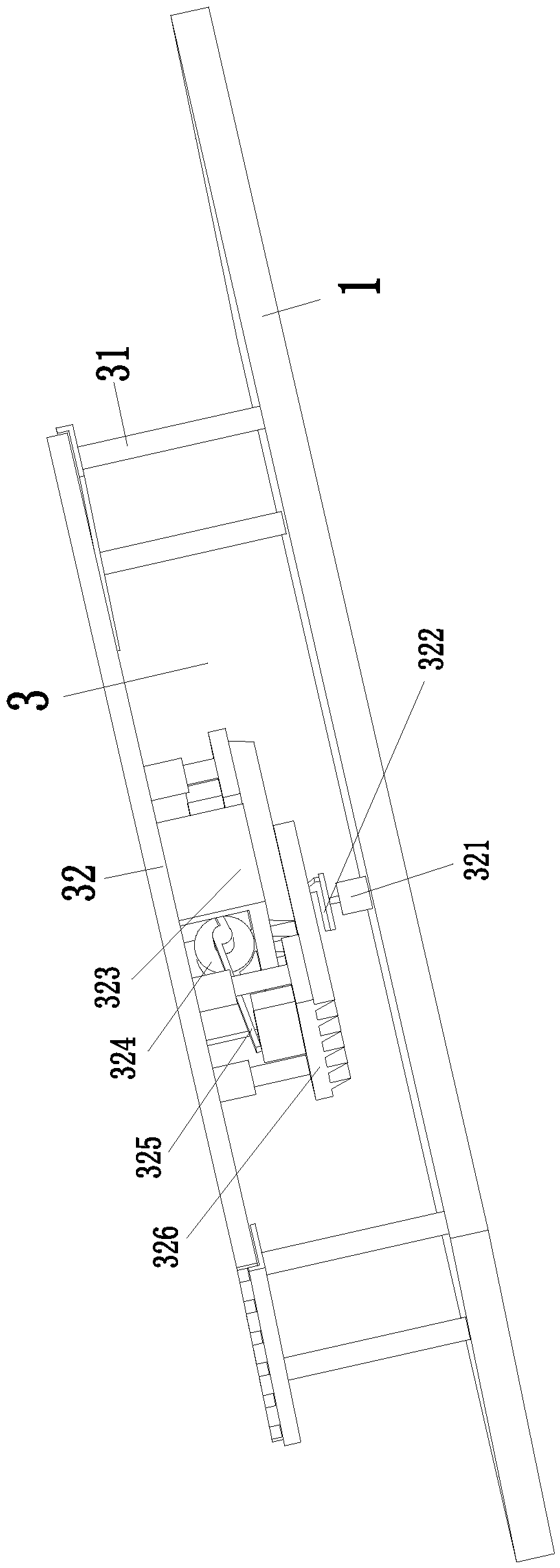

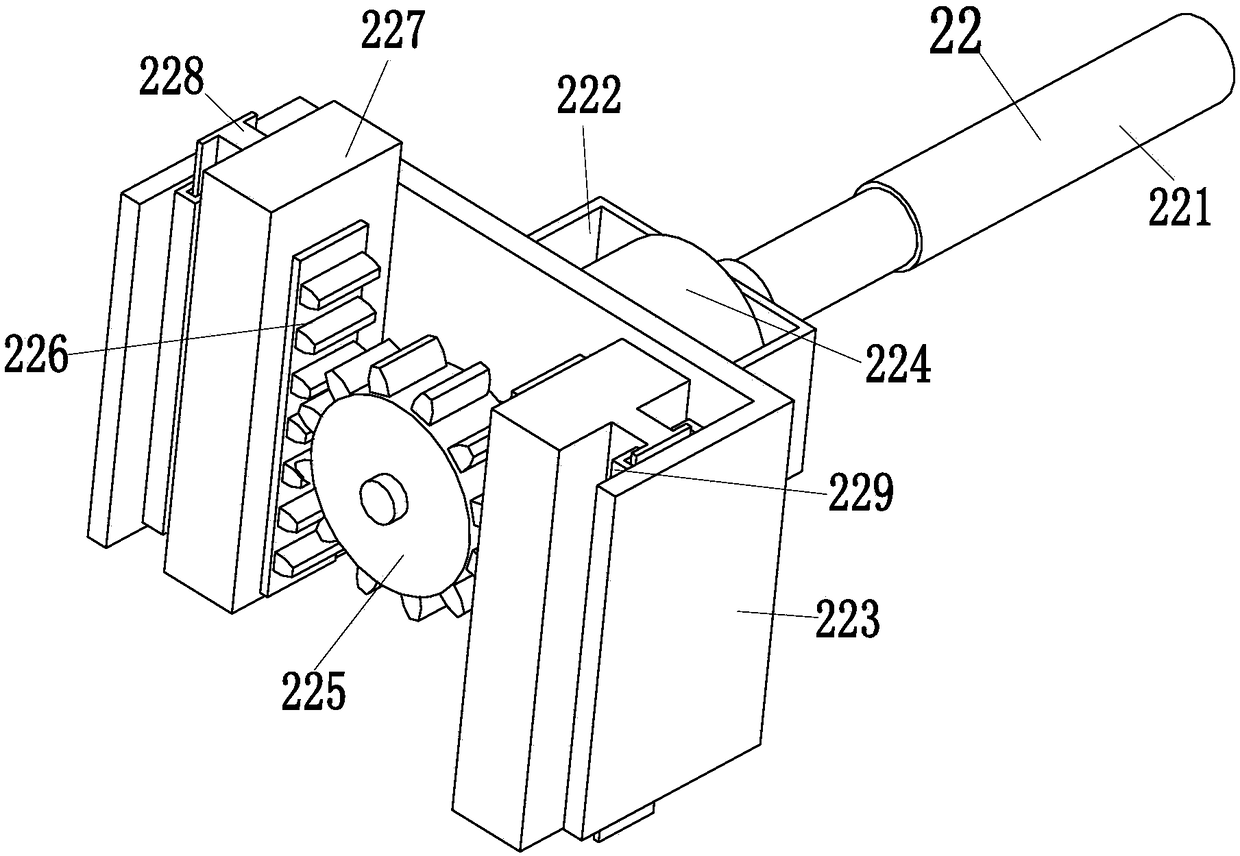

Cutting robot for processing communication cable

ActiveCN108406881ANo manual operationEasy to operateEdge grinding machinesMetal working apparatusMachining processProcess communication

The invention relates to a cutting robot for processing a communication cable. The cutting robot comprises a main board, a cutting and deburring device and a middle limiting device, wherein the frontend of the main board is provided with the cutting and deburring device, and the middle of the main board is provided with the middle limiting device. The cutting robot can solve the problems that inthe existing communication cable sleeve processing process, a communication cable sleeve needs to be limited by a worker and then be cut, the communication cable sleeves with different structures needto be grabbed in different ways by the worker when the communication cable sleeves are limited, and during cutting, pipe openings are not flat due to the fact the position is deviated easily during manual cutting, burrs are generated after the communication cable sleeve is cut, the consumed time of the process is long, the labor intensity is large and the efficiency is low. The cutting robot hasthe advantages that the communication cable sleeves can be limited and cut stably, the communication cable sleeves with different structures are limited targetedly, automatic cutting can be realized,the pipe openings are cut flatly, the burrs are automatically removed, manual operation is not needed, the consumed time is short, the operation is simple, the labor intensity is low, and the workingefficiency is high.

Owner:徐州海德力工业机械有限公司

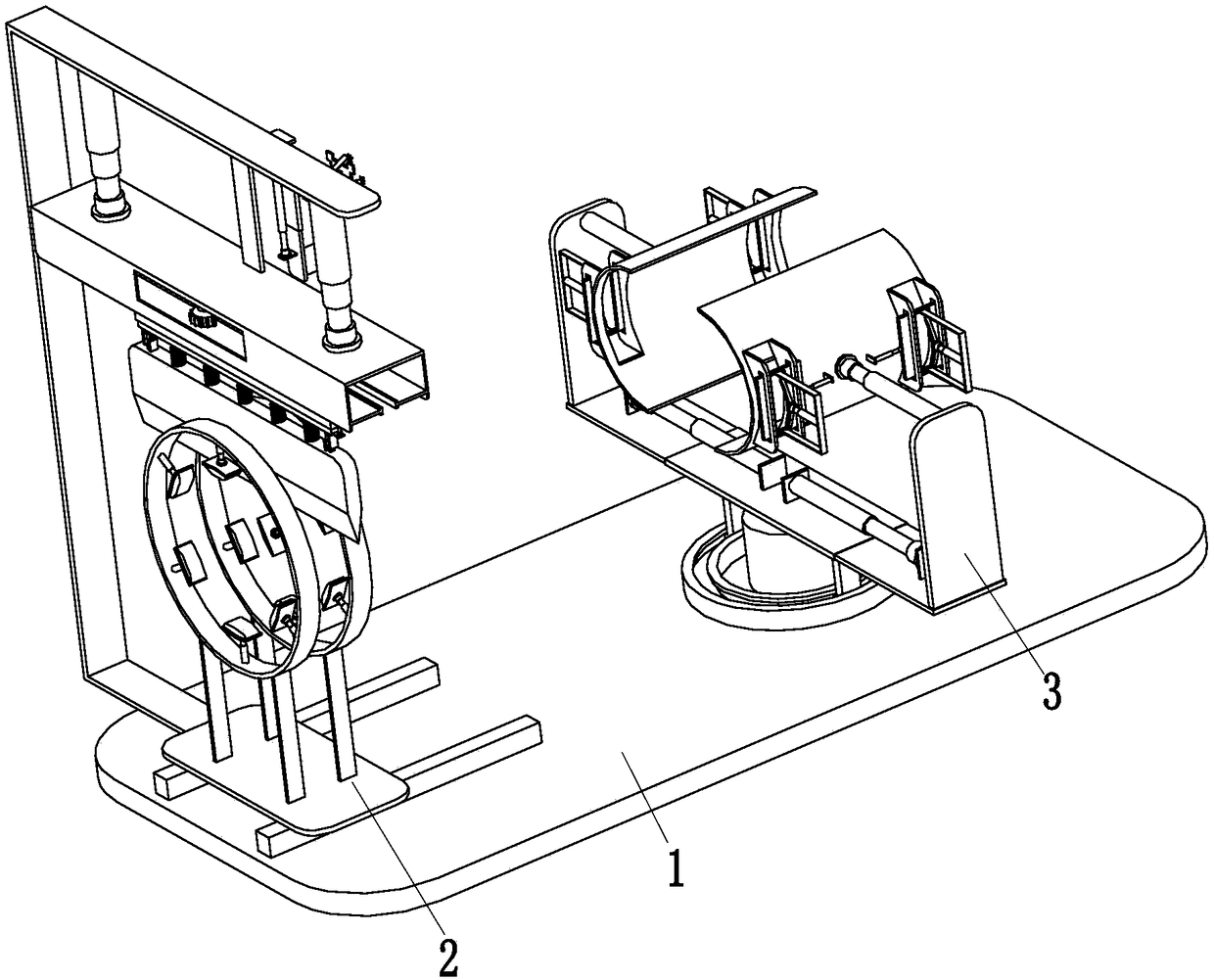

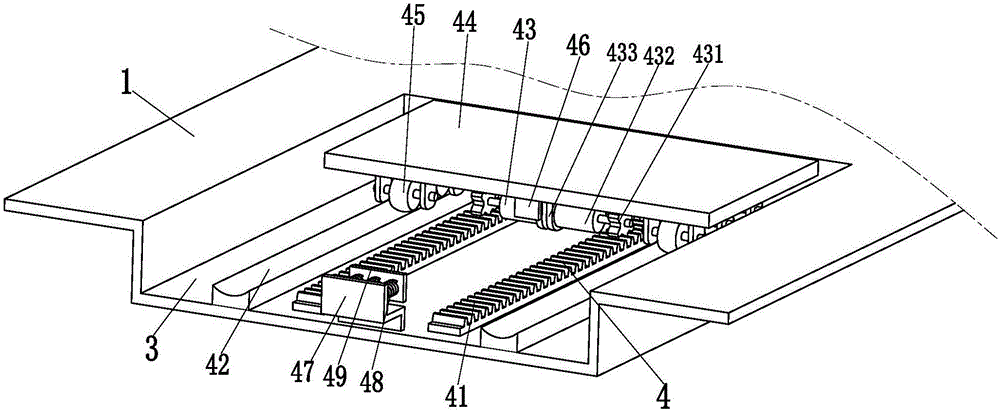

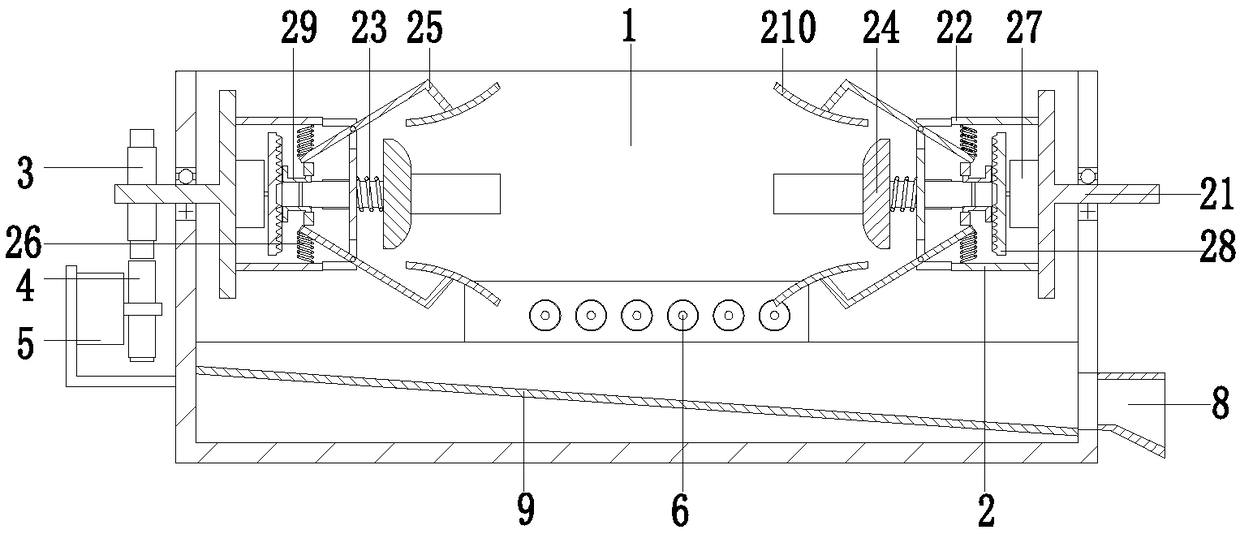

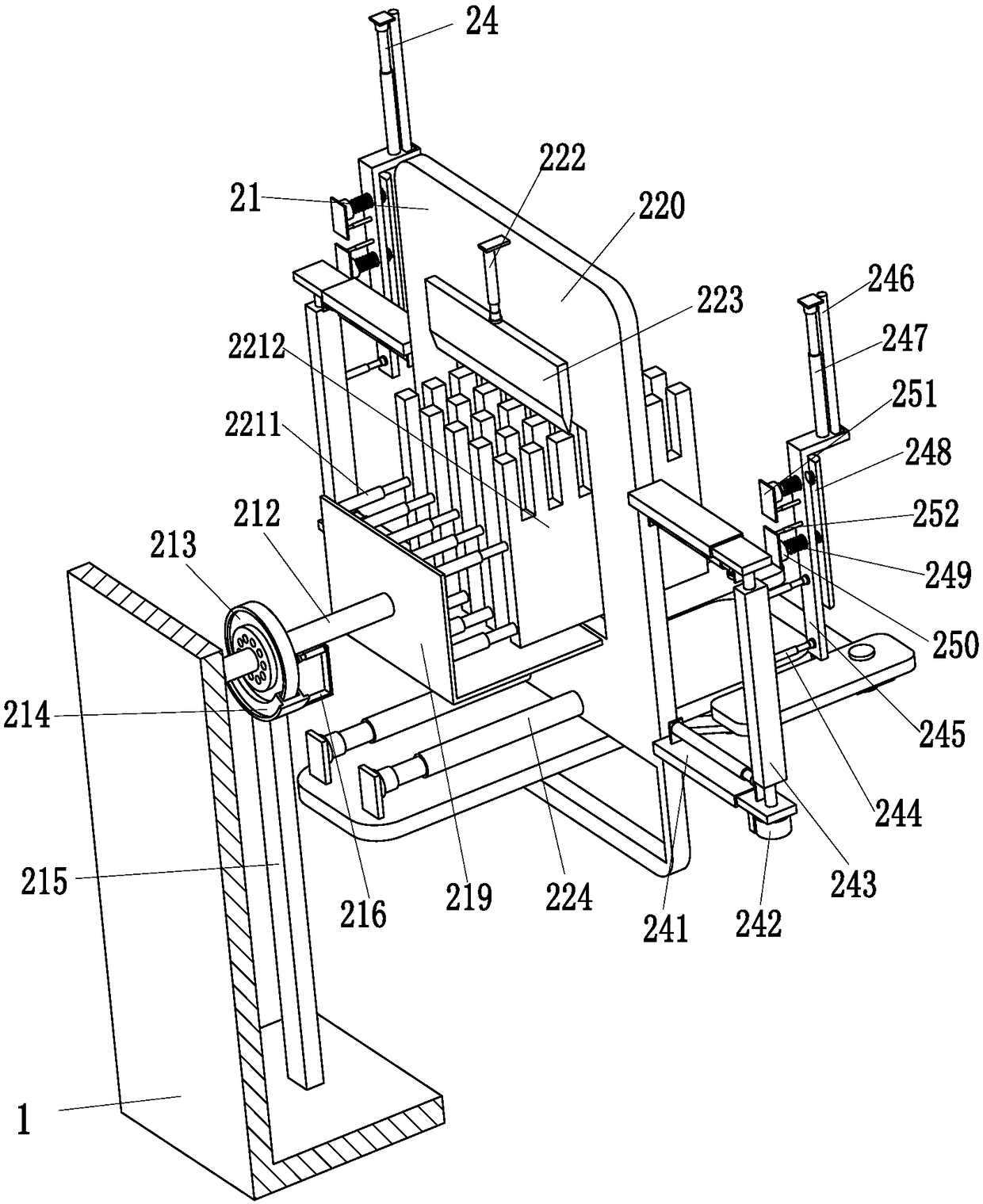

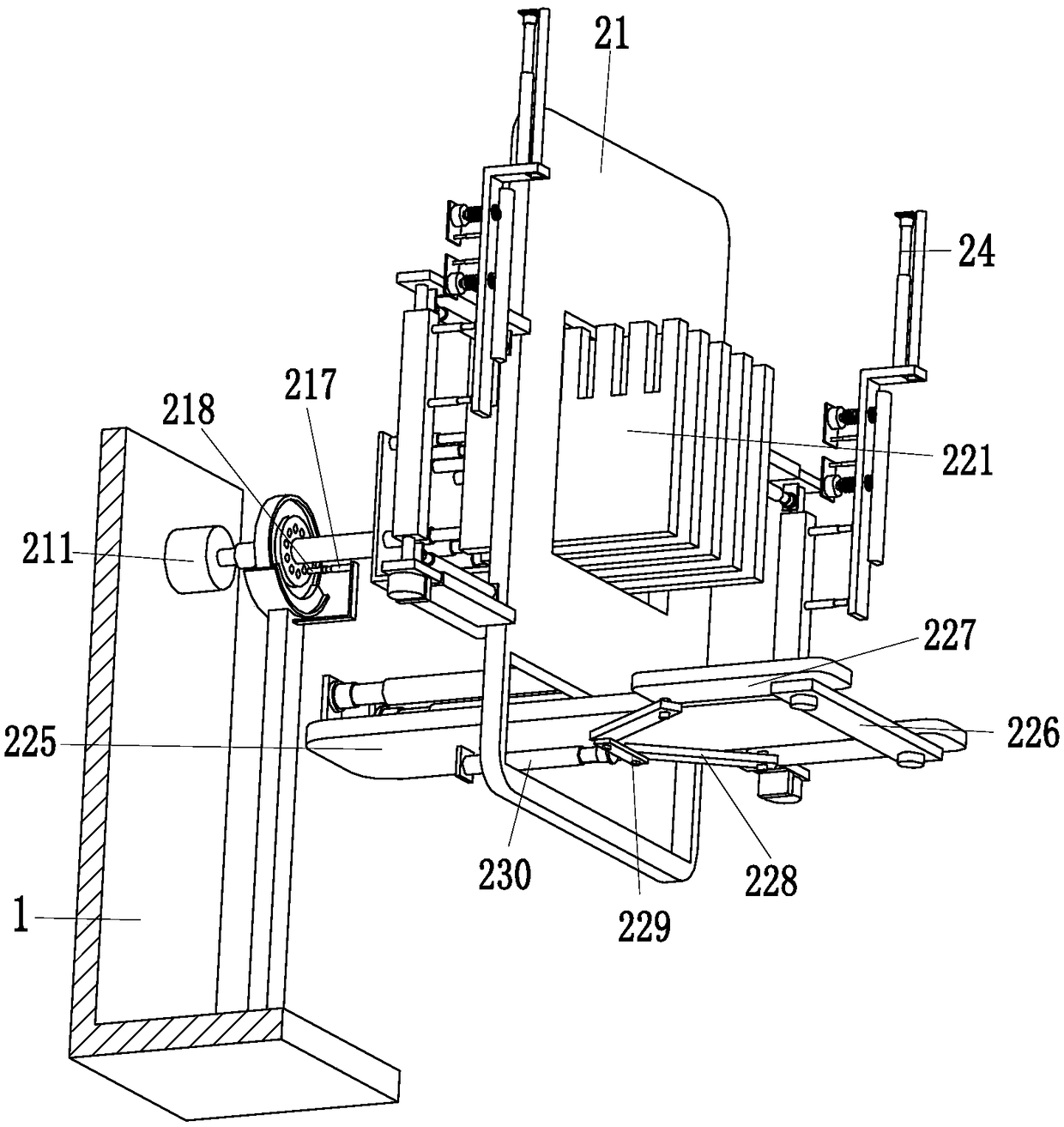

Upper clamp assembly and disassembly device with automatic carrying function for dry-type transformer

ActiveCN106548862ASmooth transmissionGood transmission effectInductances/transformers/magnets manufactureConveyor partsTransformerEngineering

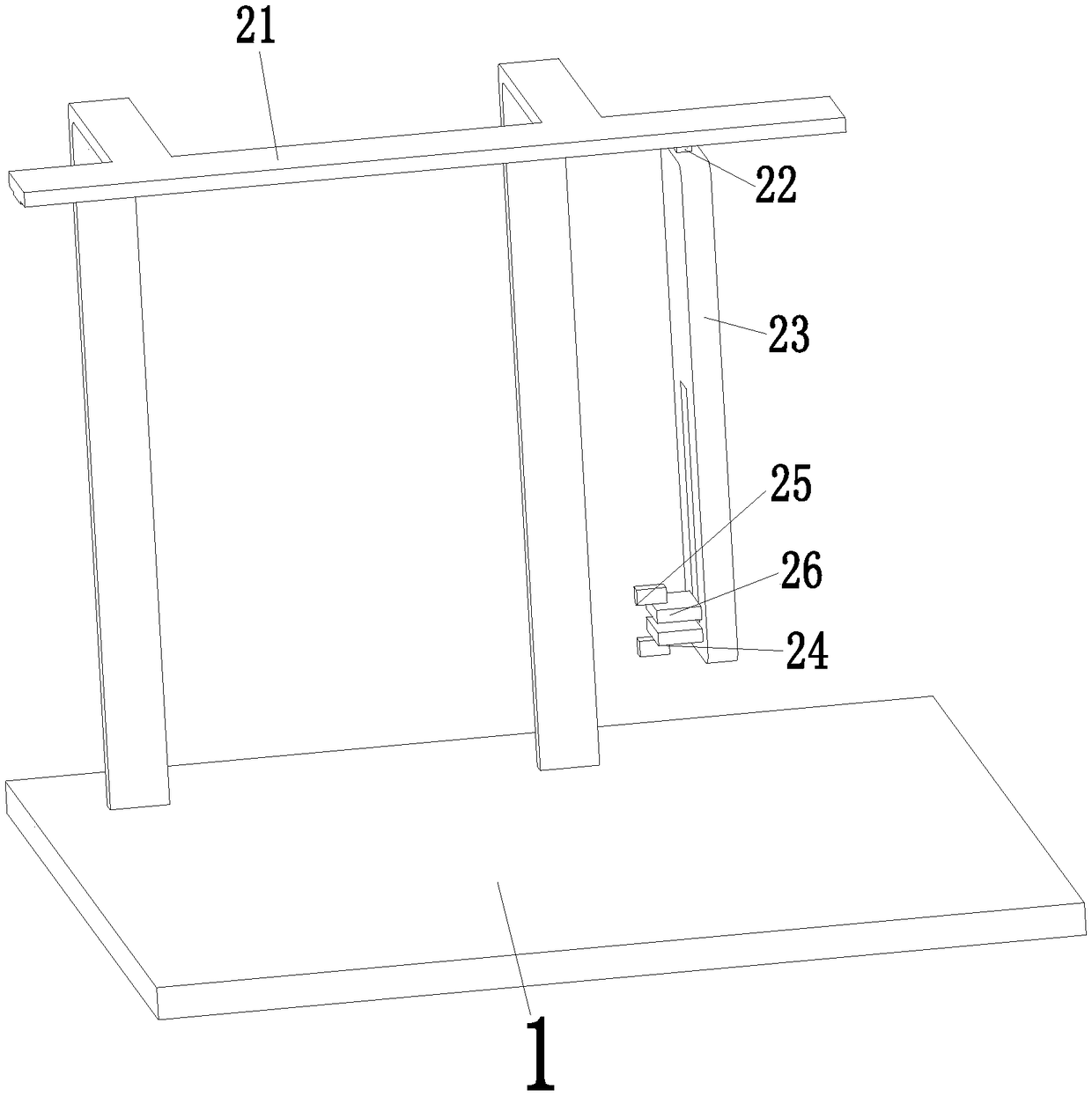

The invention relates to an upper clamp assembly and disassembly device with an automatic carrying function for a dry-type transformer. The upper clamp assembly and disassembly device comprises a bottom plate and an iron core, wherein a concave installation groove is arranged in the front side of the upper end surface of the bottom plate; a sliding carrying mechanism is arranged on the upper end surface of the installation groove; the iron core is put on the upper end of the sliding carrying mechanism and a limiting mechanism is arranged in the middle of the bottom plate; after the sliding carrying mechanism automatically carries the iron core to a specified position, the iron core is locked through the limiting mechanism, so that the iron core does not move when the transformer is manufactured, and the condition that the iron core moves to affect the manufacturing efficiency of the transformer is avoided; two power mechanisms are symmetrically arranged at the left side and the right side of the upper end surface of the bottom plate; each power mechanism is provided with a clamping branch chain for clamping an upper clamp; and the two clamping branch chains are driven to move back and forth through the two power mechanisms. According to the upper clamp assembly and disassembly device, automatic carrying of the iron core of the transformer and the automatic assembly and disassembly function on the upper clamp can be achieved and manual operation is not needed.

Owner:HENGSHUI POWER SUPPLY BRANCH OF STATE GRID HEBEI ELECTRIC POWER

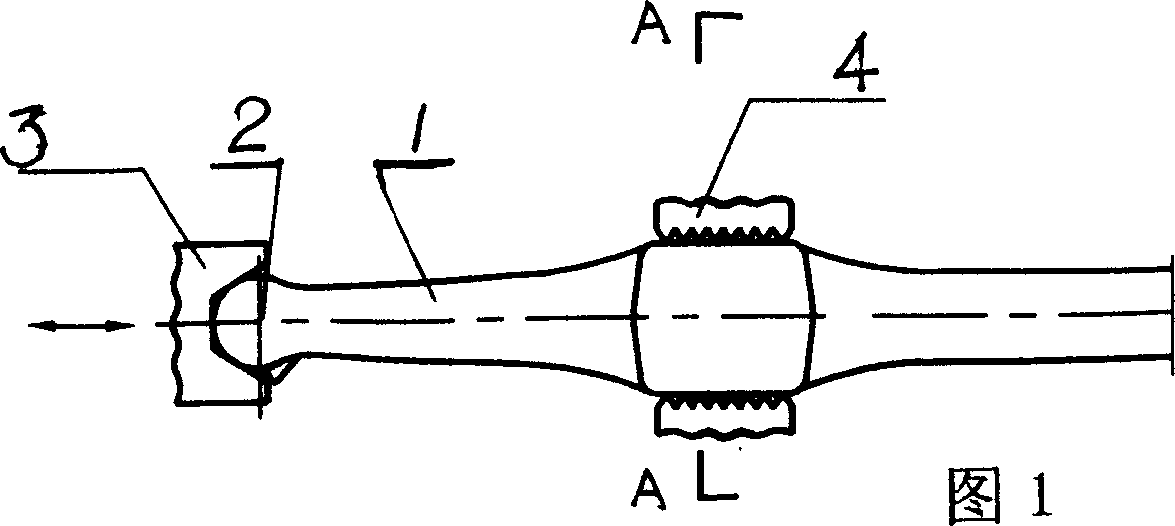

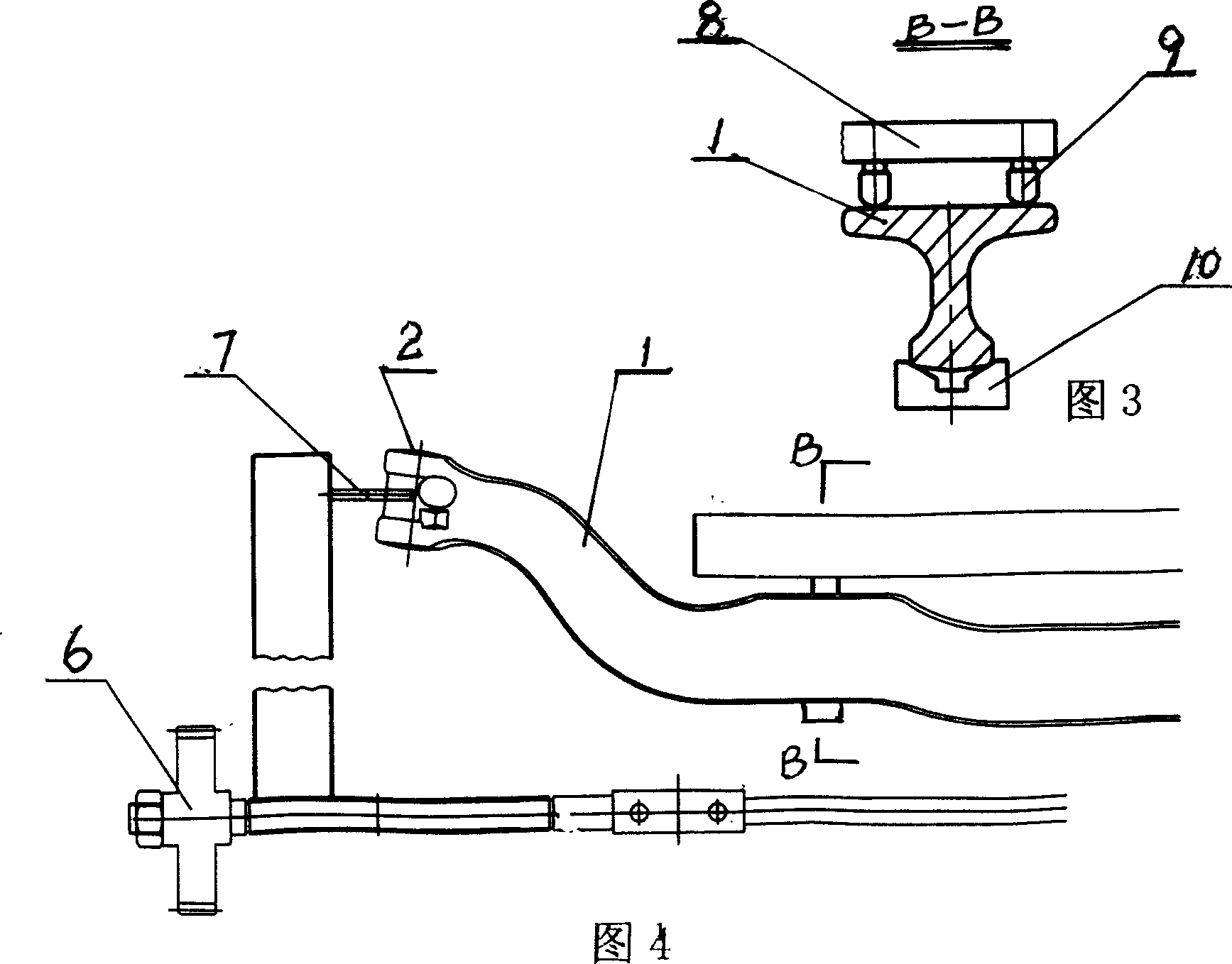

Cold-working boring and milling composite technology for automobile front axle

ActiveCN1593841AGuaranteed Aperture SizeGuaranteed surface roughnessOther manufacturing equipments/toolsEngineeringSpring steel

The invention relates to a kind of cold boring and milling technique to process the foreside axis of the car. The main technique is: locate the two spring steel seats, drill ten holes in each steel board, and drill the holes again with U drilling technology to finish the primary process. Fine the holes and corner, the upper and the under board faces with the boring bed. Only one setting and clumping step is needed to finish the holes process. The invention overcomes the excursion phenomenon by combining the boring and milling technology with three work position machine bed to take the drill-bore-drill-hinge procedure. It limits the warp between the chief pin hole and the locking pin hole. The technology is simple and has high processing precision. So the product is high quality, and needs few device and cost. The production efficiency is high and the work steam intensity between the procedures is low. In addition, it can make sure clean working circumstance.

Owner:HUBEI TRI RING AXLE

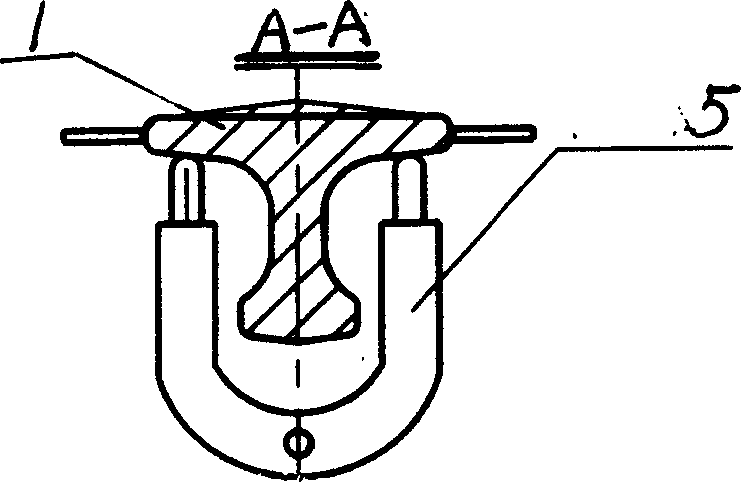

Intelligent manipulator for grinding edges of aluminium plastic plate

InactiveCN108972205ARealize the function of automatic edgingSmooth edgingEdge grinding machinesManipulatorEngineeringManipulator

The invention relates to an intelligent manipulator for grinding the edges of an aluminium plastic plate. The intelligent manipulator comprises a U-shaped frame, two auxiliary moving mechanisms, two compaction regulating mechanisms and a targeted edge grinding mechanism; the front and rear sides of the left end of the U-shaped frame are provided with the two auxiliary moving mechanisms, and the two compaction regulating mechanisms are arranged between the two auxiliary moving mechanisms, and installed at the upper and lower ends of the U-shaped frame; and the right end of the U-shaped frame isprovided with the targeted edge grinding mechanism. The intelligent manipulator is capable of solving the problems that the edges of an existing aluminium plastic plate need to be ground manually, and the process is complicated; during edge grinding, manual edge grinding is slow and uneven, and burrs are generated; different tools are required for grinding straight edges and corners, and the replacement is complex; during corner grinding, persons need to grind the corners for a long time in a reciprocating manner, the time consumption and the labor intensity are high, the efficiency is low and the like; and the automatic edge grinding function for the aluminium plastic plate can be achieved.

Owner:合肥集知网信息技术有限公司

Electrical intelligent construction equipment

InactiveCN108193682ARealize the limit functionRealize the installation functionBulkheads/pilesSignsArchitectural engineeringElectric power

Owner:李猛

Intelligent processing robot of stainless steel tube

ActiveCN109128364AEnsure safetyRealize automatic cutting productionMetal sawing devicesMetal sawing accessoriesAgricultural engineeringSteel tube

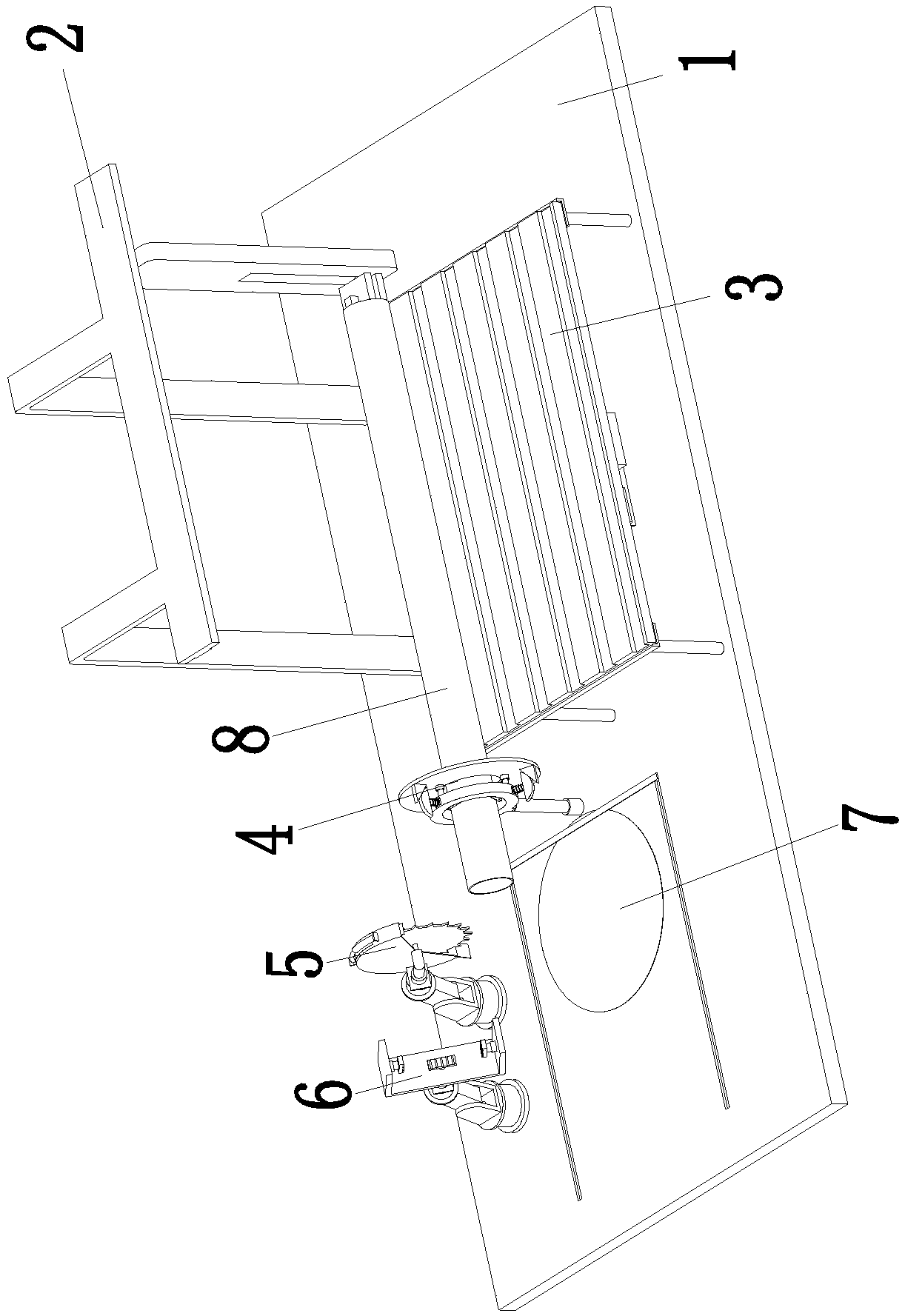

The invention relates to an intelligent processing robot of a stainless steel tube. The intelligent processing robot comprises a bottom plate, a conveying device, a cutting and feeding device, a sleeve type fixing device, a cutting device, a clamping device, an adsorption and cleaning device and a stainless steel hollow tube body, wherein the conveying device, the cutting and feeding device, the sleeve type fixing device, the cutting device and the clamping device are installed on the bottom plate in sequence from left to right, and the adsorption and cleaning device is installed on the bottomplate. According to the intelligent processing robot, the problems that a multi-caliber stainless steel hollow tube cannot be preferably clamped and fixed when the stainless steel hollow tube is cutin the prior art, sweeps which are generated when the stainless steel hollow tube is cut cannot be preferably prevented from splashing and hurting people, people need to wear protective equipment forprotection, the sweeps which are generated in a cutting process need to be manually cleaned and collected so as to be recycled and the people are easy to hurt by the sweeps which are generated when the stainless steel hollow tube is manually cut can be solved.

Owner:泰州市银杏舞台机械工程有限公司

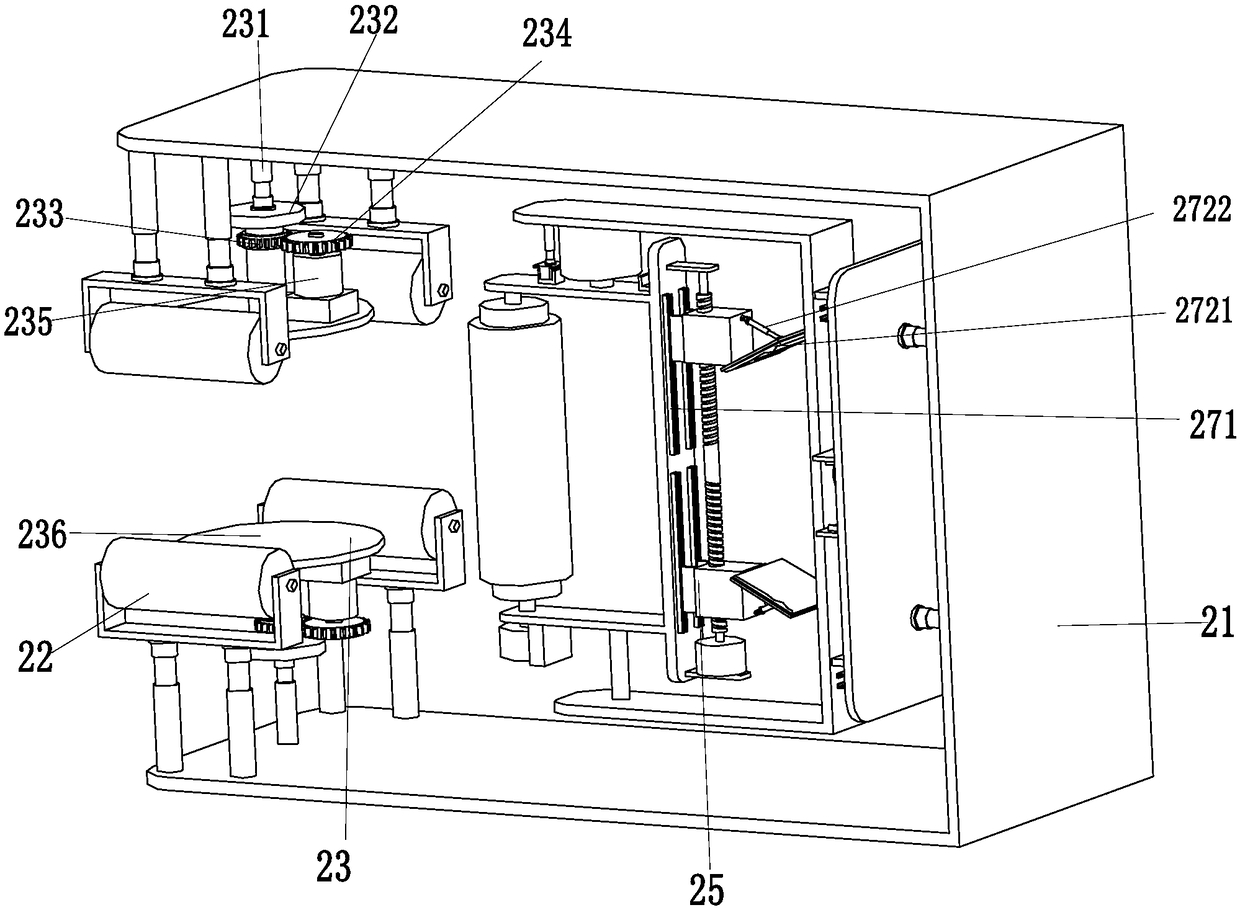

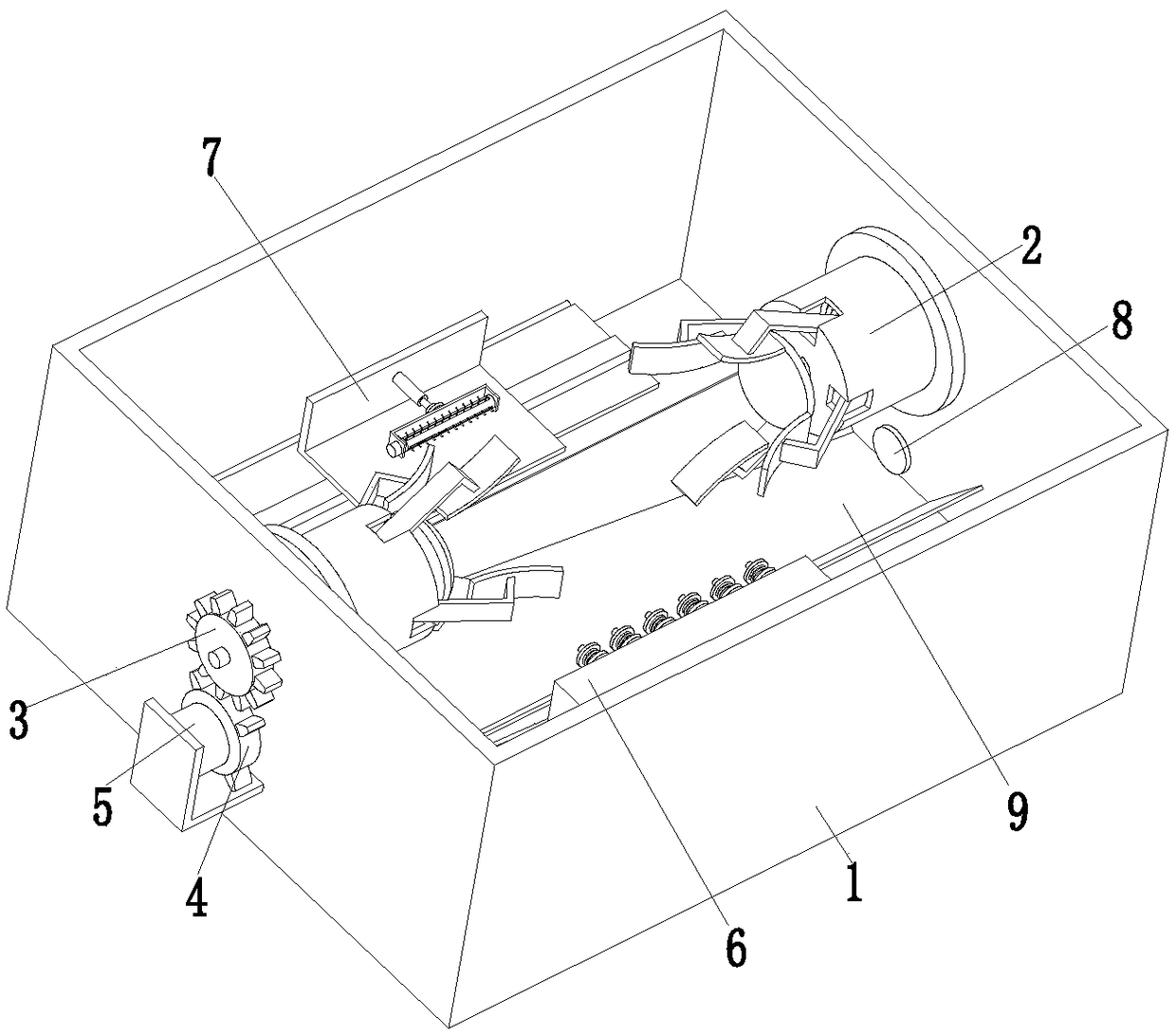

An automatic toner processing system special for laser printer toner cartridge

ActiveCN109188877ARealize the function of automatic cleaningEasy to operateElectrography/magnetographyHuman bodyHand held

The invention mainly relates to an automatic toner processing system special for a laser printer toner cartridge, comprising a working frame, wherein a fixed rotating device is arranged on the inner walls of the front and rear ends of the working frame through bearings, a vibration auxiliary device is arranged on the lower side of the left end of the working frame, and a cleaning device is arranged on the lower side of the right end of the working frame. The invention can solve the problem that the ink cartridge of the prior laser printer needs manual hand-held toner cartridge to pour out toner in the cleaning process, the toner in the cartridge needs to be cleaned manually, toner is harmful to human body, manual hand-held ink cartridges affect the health of workers, artificially simply flipping the toner cartridge can not effectively discharge the toner in the toner cartridge, manual cleaning toner cartridge, easy to cause toner diffusion in the air, affect human health, and pollutionof the environment, manual cleaning operation is complex, time-consuming, labor intensity and low efficiency and other problems.

Owner:北京辰光融信技术有限公司

Intelligent pork processing machine capable of automatically removing and grabbing head and feet

InactiveCN108029732AEnsure safetyNo off-cutsSlaughterhouse arrangementsSlaughtering accessoriesEngineeringPotential risk

The invention relates to an intelligent pork processing machine capable of automatically removing and grabbing head and feet. The intelligent pork processing machine capable of automatically removingand grabbing head and feet comprises a bottom plate, two auxiliary mechanisms, a connecting plate, a foot removing mechanism, a head removing mechanism and two grabbing mechanisms, wherein the two auxiliary mechanisms are mounted in symmetry on the bottom plate, and the upper ends of the two auxiliary mechanisms are mounted on the connecting plate; the lower end of the connecting plate is providedwith the foot removing mechanism, and the upper end of the connecting plate is provided with a head removing mechanism; each auxiliary mechanism is provided with one grabbing mechanism. The intelligent pork processing machine capable of automatically removing and grabbing head and feet can solve the problems such as that traditional pork processing operation requires manual head and foot removal;during head removal, workers need to cut pigs with cutters to result in potential risks of possible accidental cut injury; during pig foot cutting, the workers need to hold pig feet tightly for cutting, and due to the fact that head cutting requires multiple operations which are prone to leading to inaccurate cutting; pigs with head and feet cut need carrying by multiple workers. The intelligentpork processing machine capable of automatically removing and grabbing head and feet can achieve the function of automatically removing and grabbing off head and feet of pigs.

Owner:吴露露

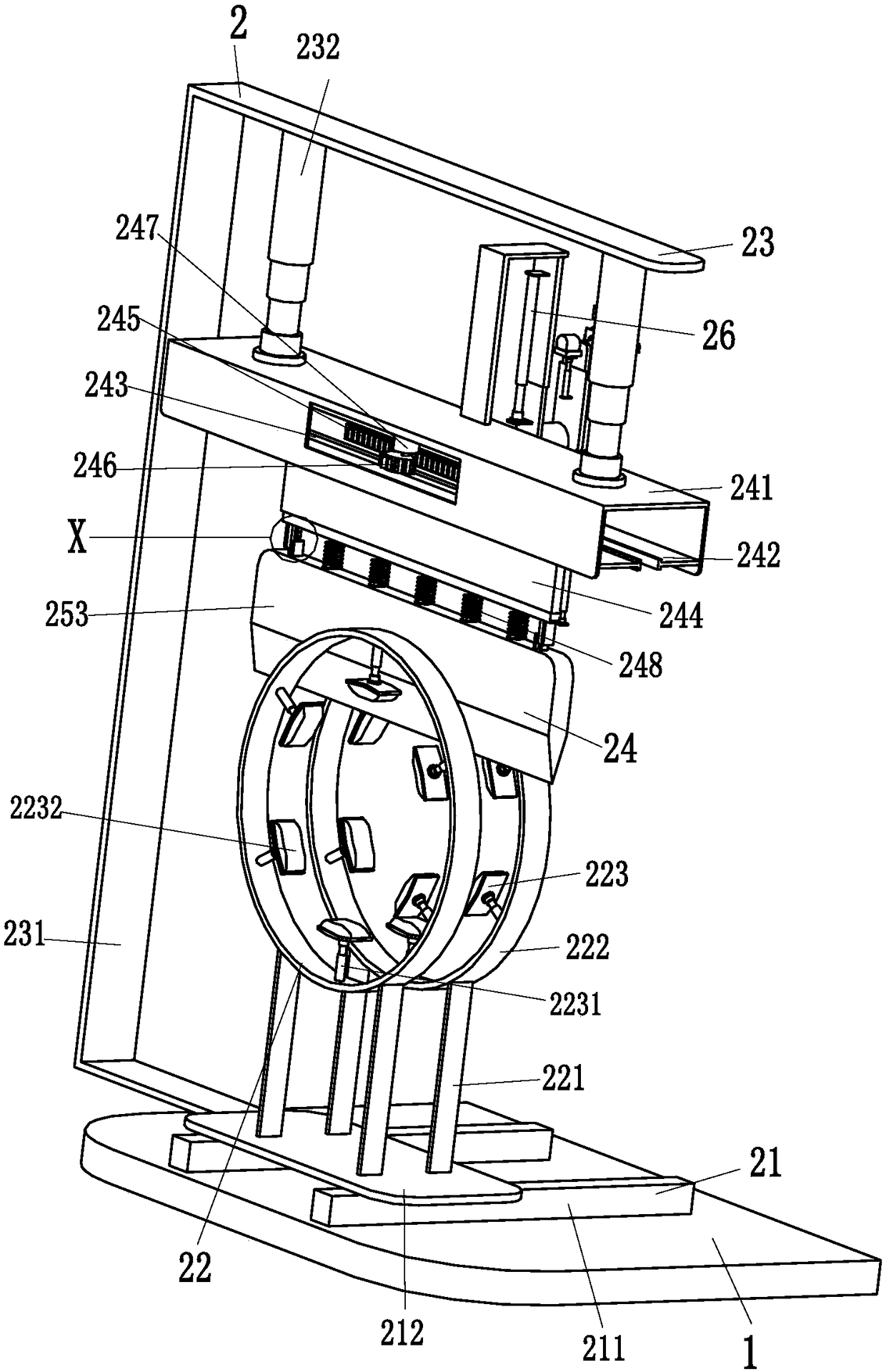

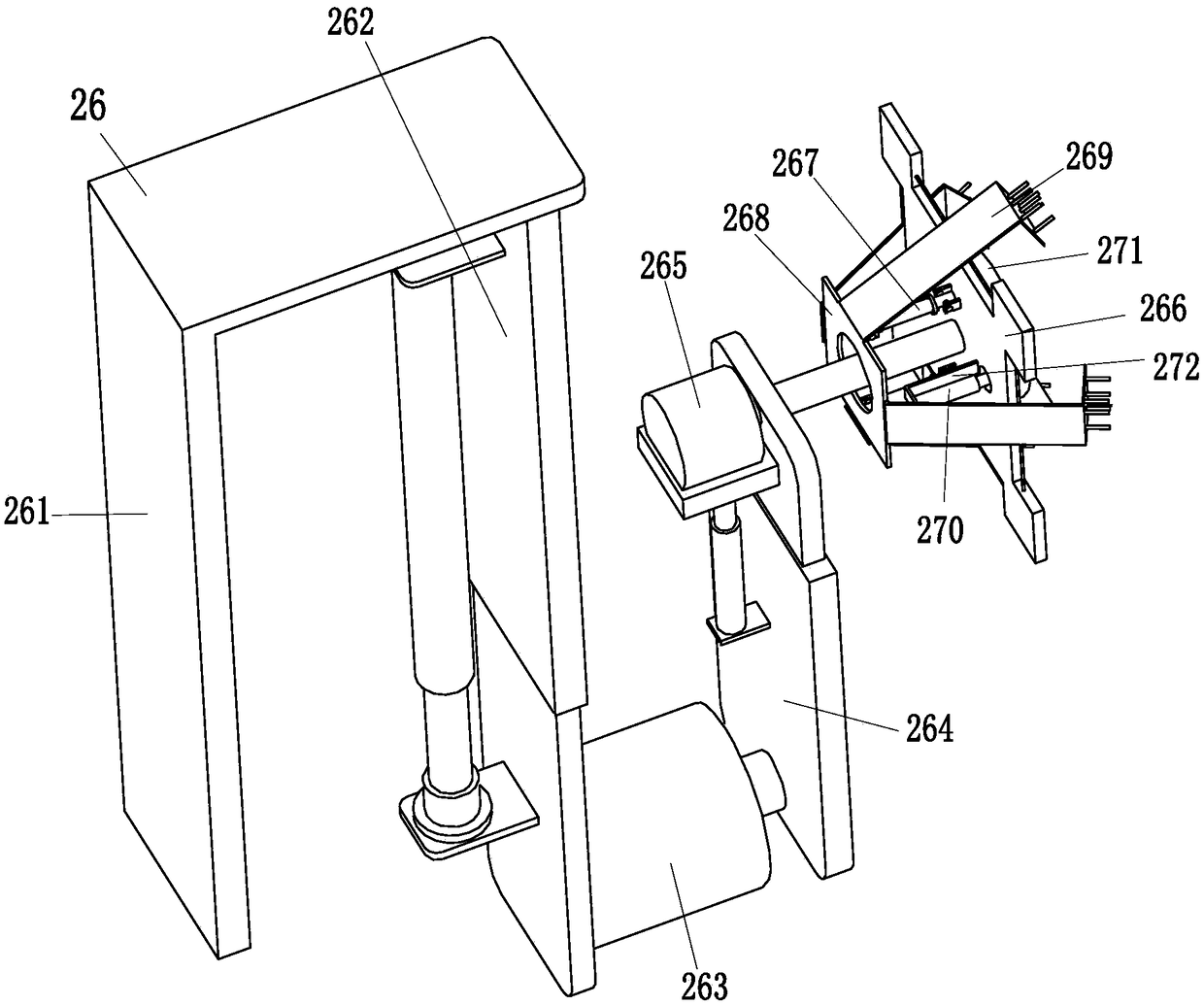

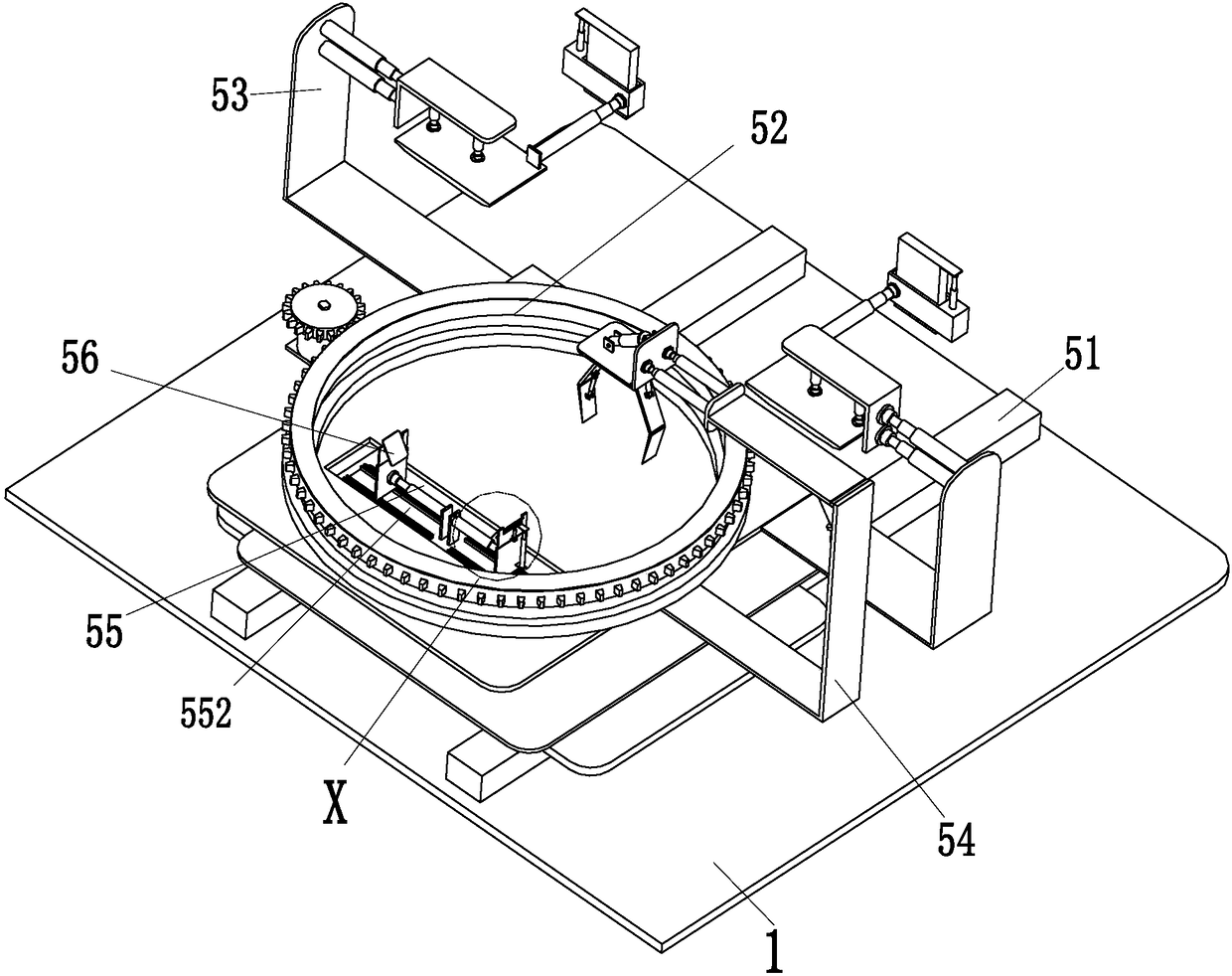

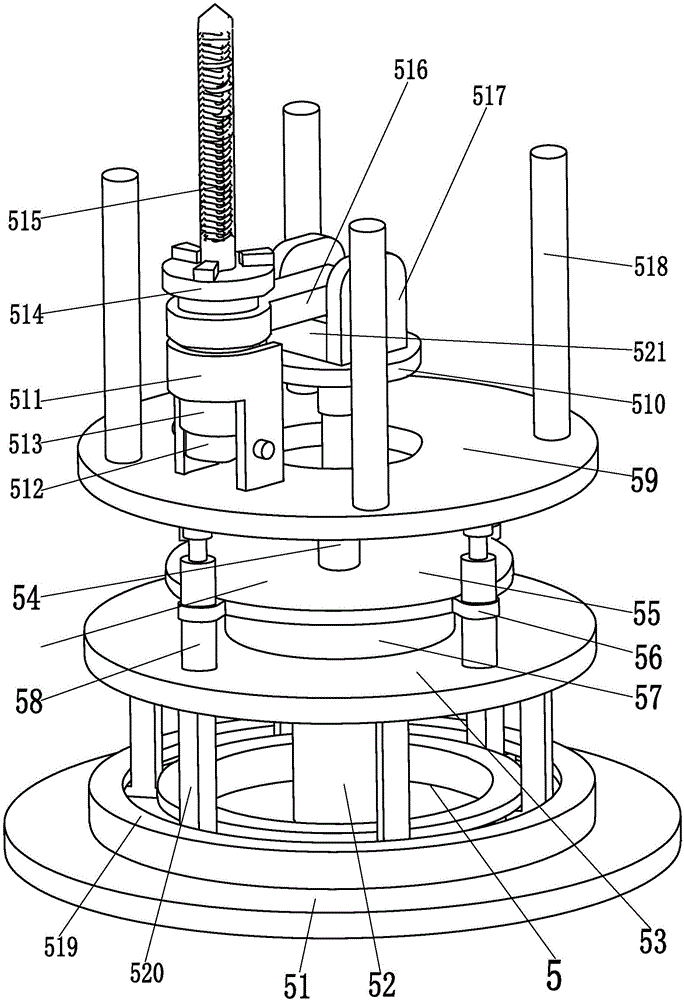

Automatic installing machine

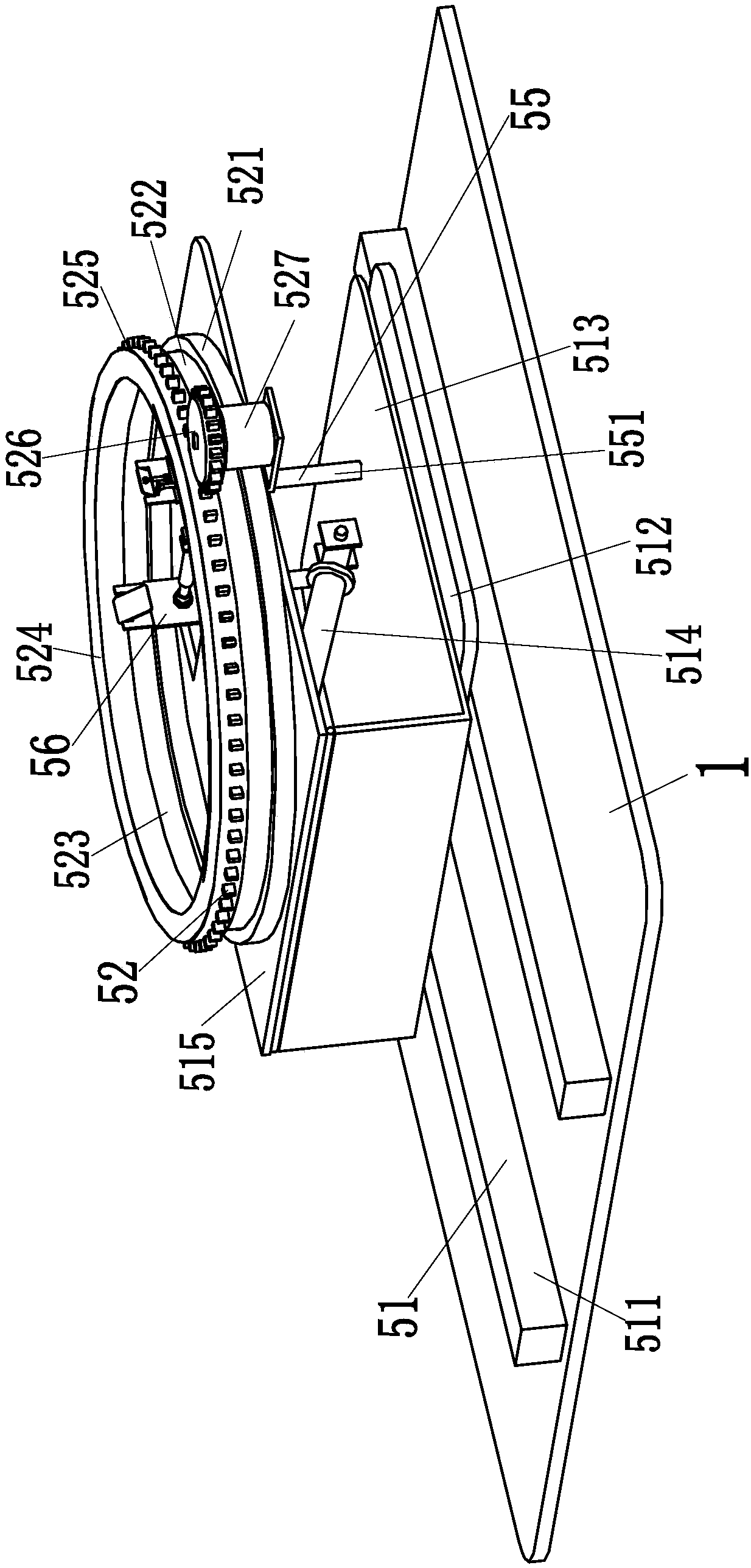

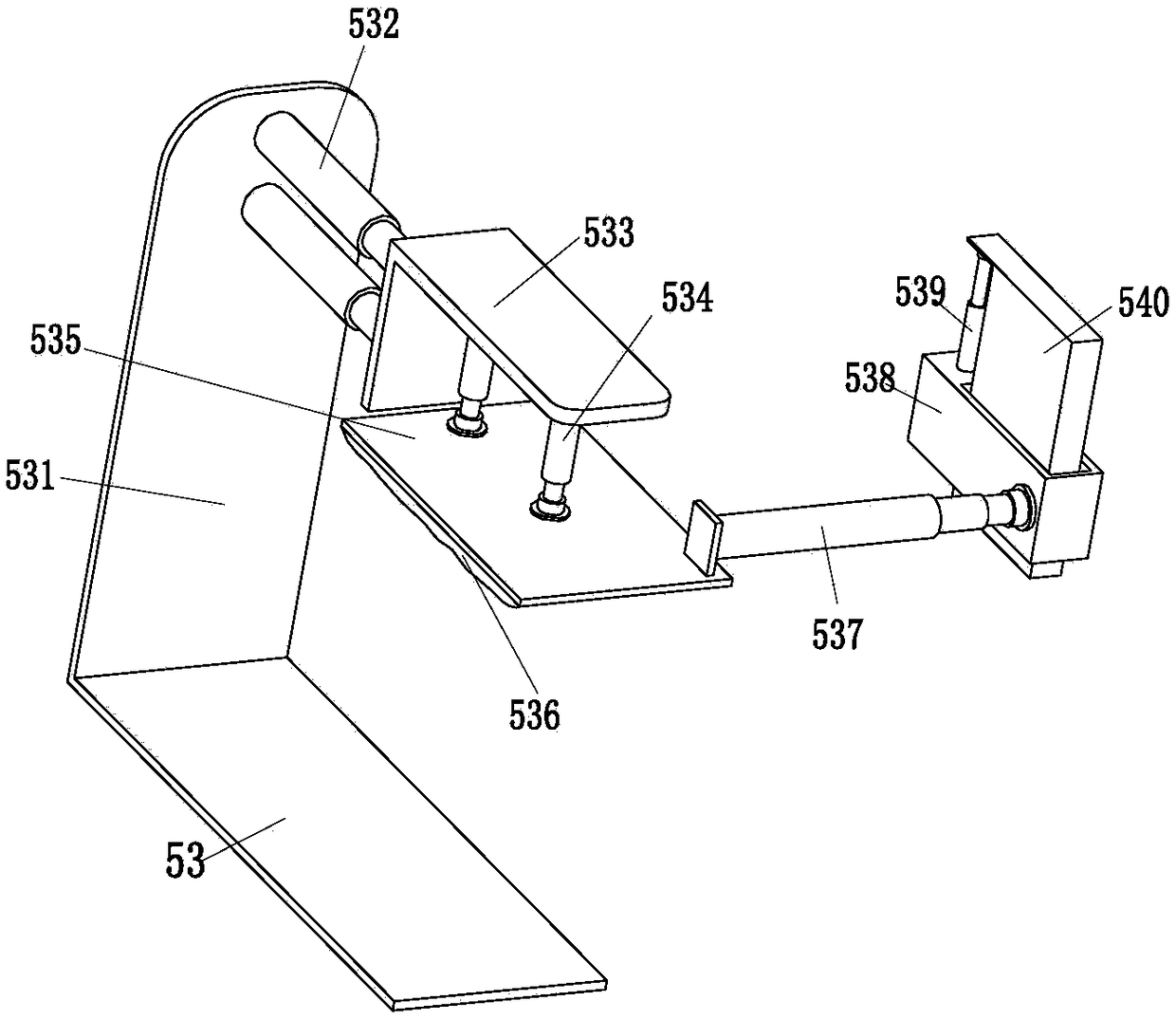

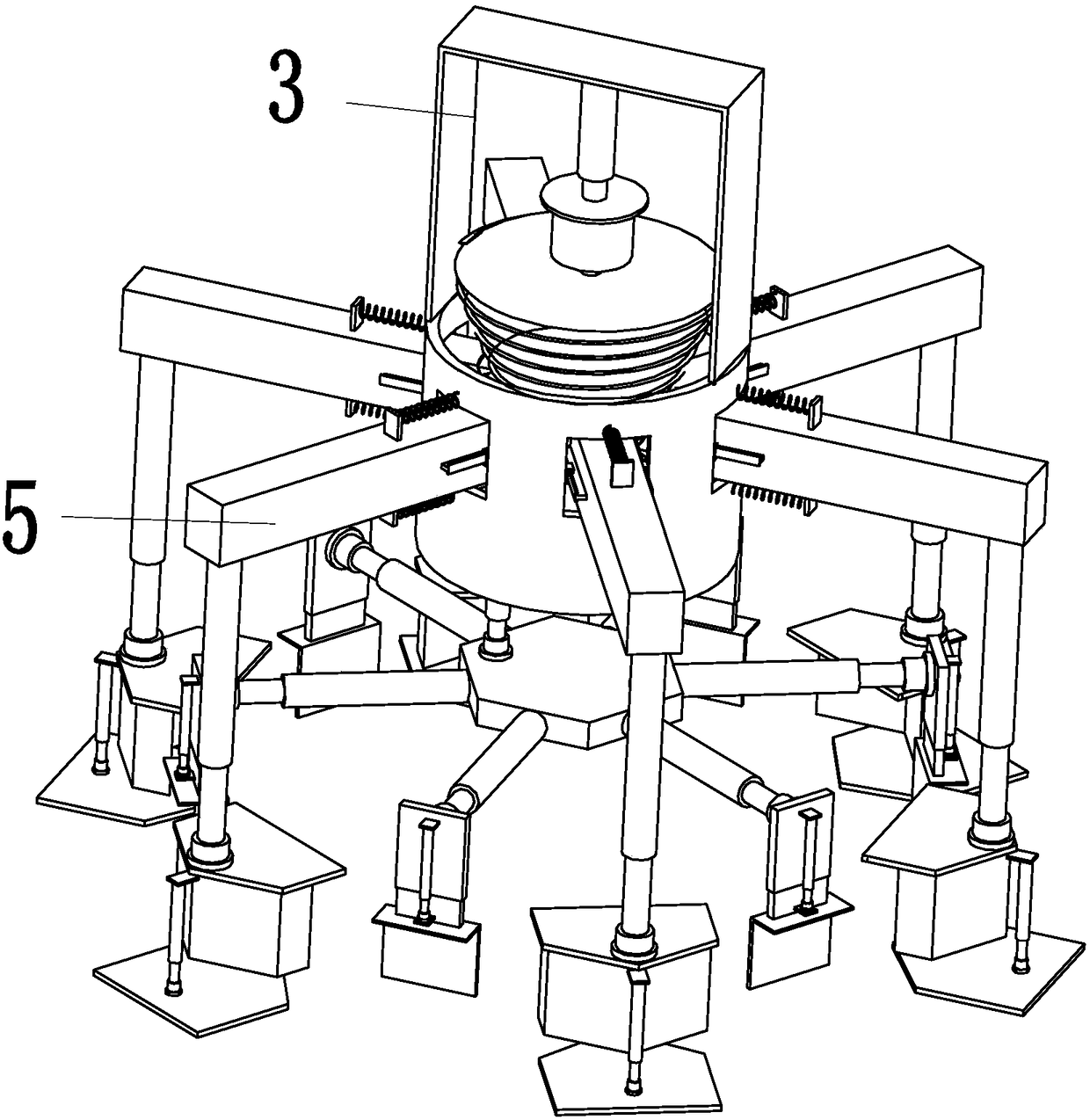

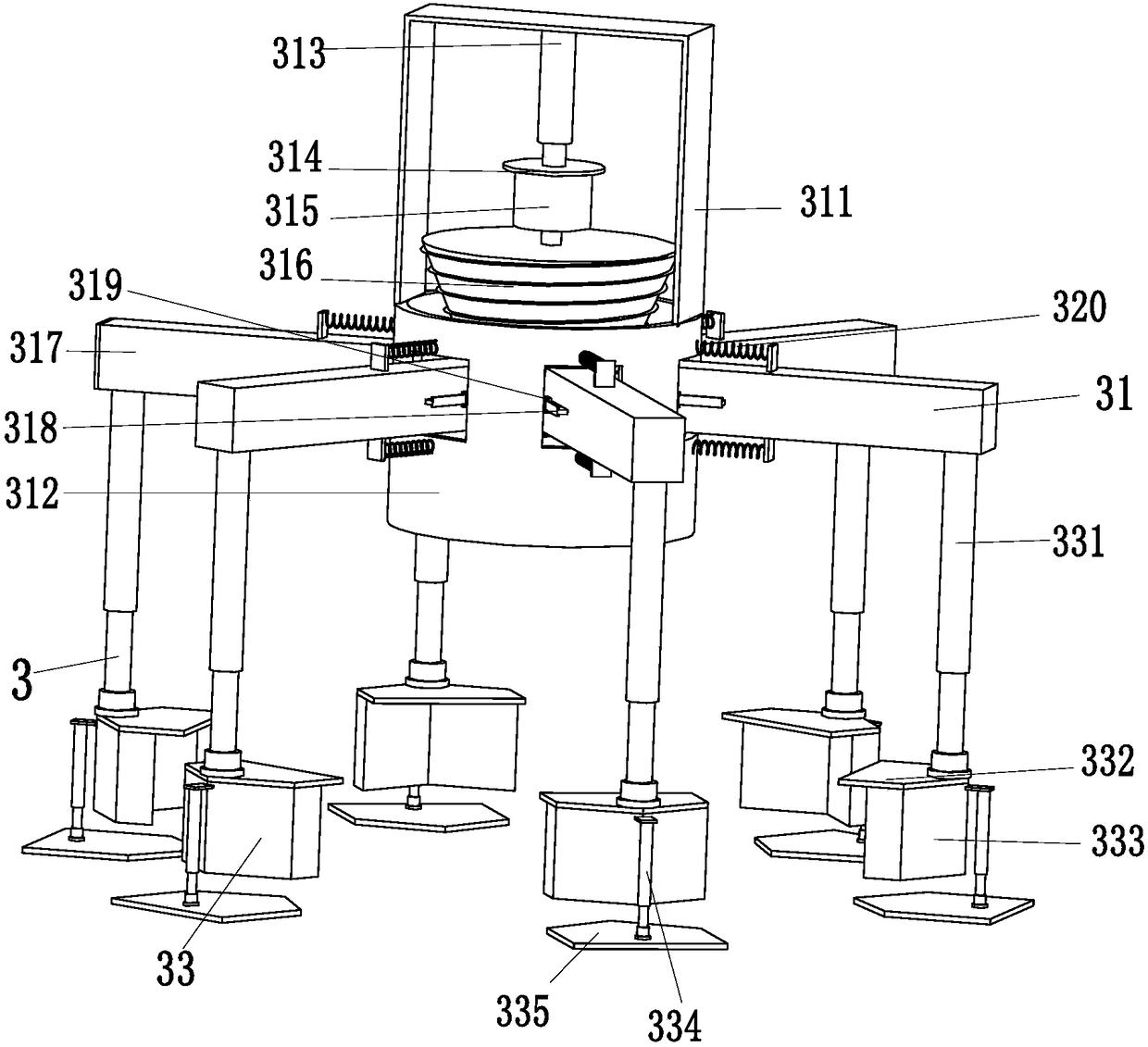

The invention relates to an automatic installing machine. The automatic installing machine comprises a U-shaped main board, a position adjusting mechanism, a rotating mechanism, four bottom supportingmechanisms and six fixing mechanisms, wherein the position adjusting mechanism is installed on the U-shaped main board, the upper end of the position adjusting mechanism is provided with the rotatingmechanism, the middle of the rotating mechanism is uniformly provided with the four bottom supporting mechanisms, the six fixing mechanisms are uniformly installed at the upper end of the rotating mechanism, the position adjusting mechanism drives the rotating mechanism to be adjusted to a working position, the four bottom supporting mechanisms cooperate with the six fixing mechanisms to fix a fixing ring for a plurality of times, the rotating mechanism drives the fixing ring to rotate away from a lamp head under the assistance of the position adjusting mechanism, and the fixing ring is automatically taken down. According to the automatic installing machine, the function of automatically taking away the fixing ring of a table lamp can be achieved, the fixing ring is automatically taken down, the loss of the fixing ring is not caused, and manual operation is not needed; and the advantages of being easy to operate, low in labor intensity, high in working efficiency and the like are achieved.

Owner:浙江小易智能家居有限公司

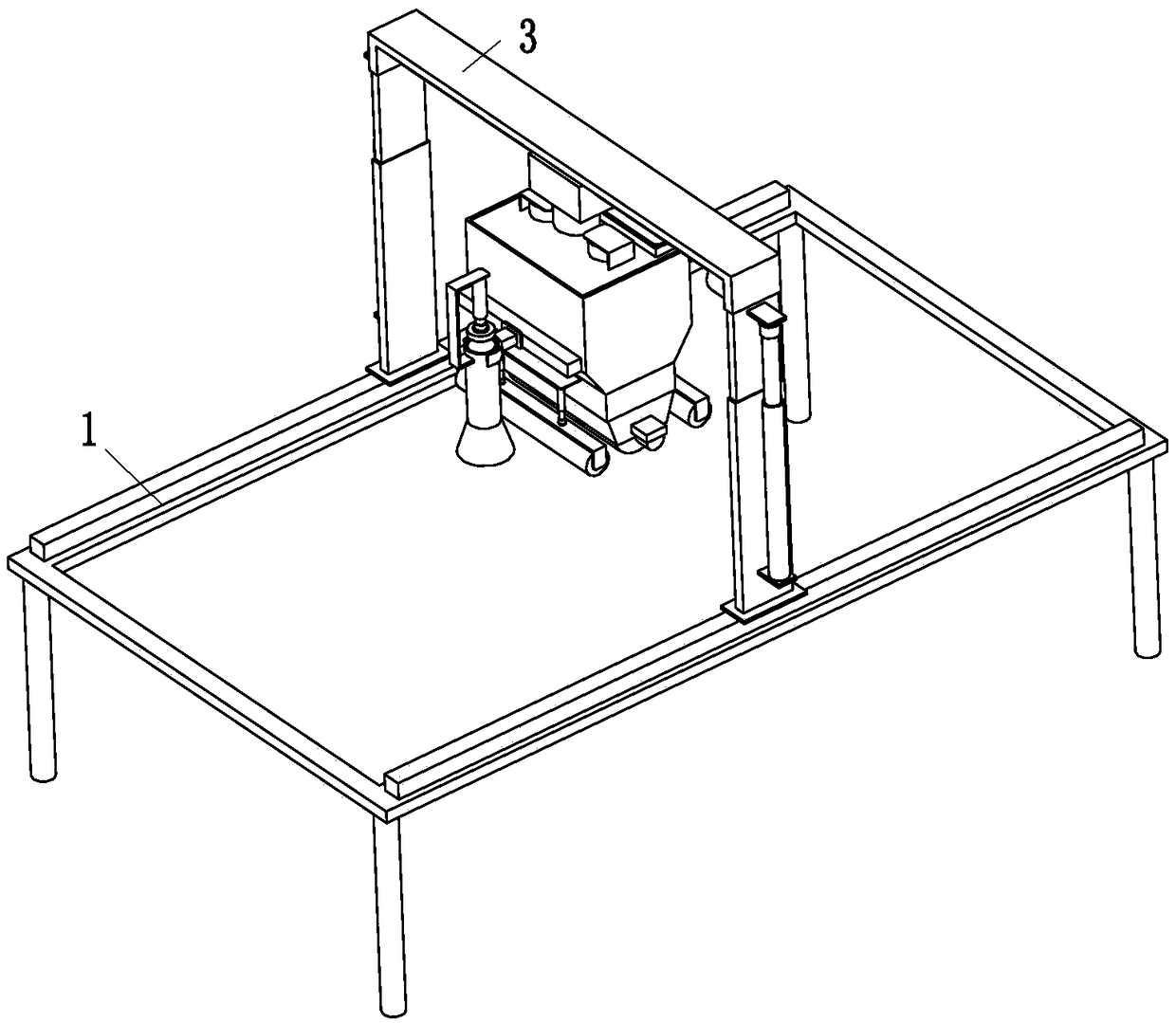

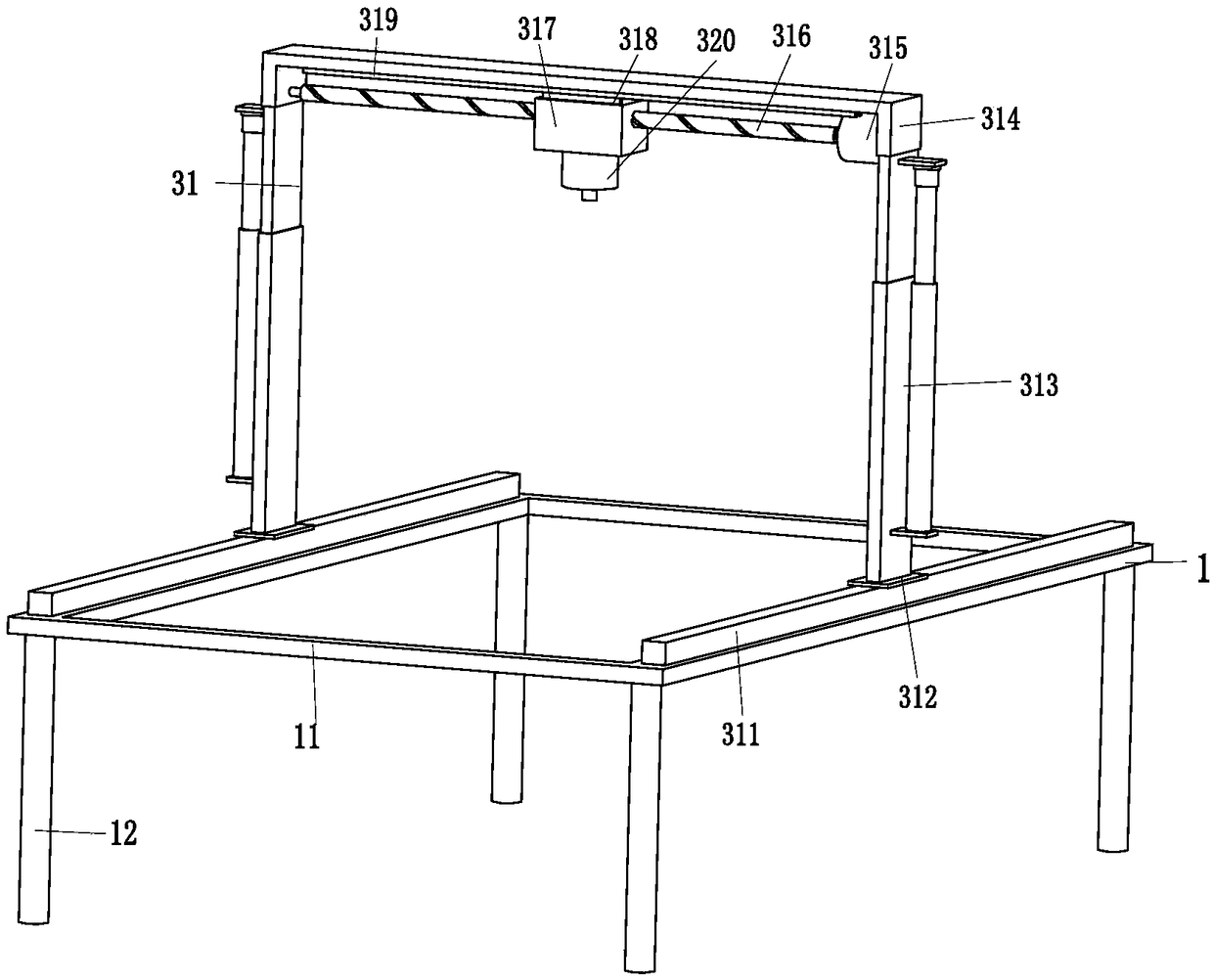

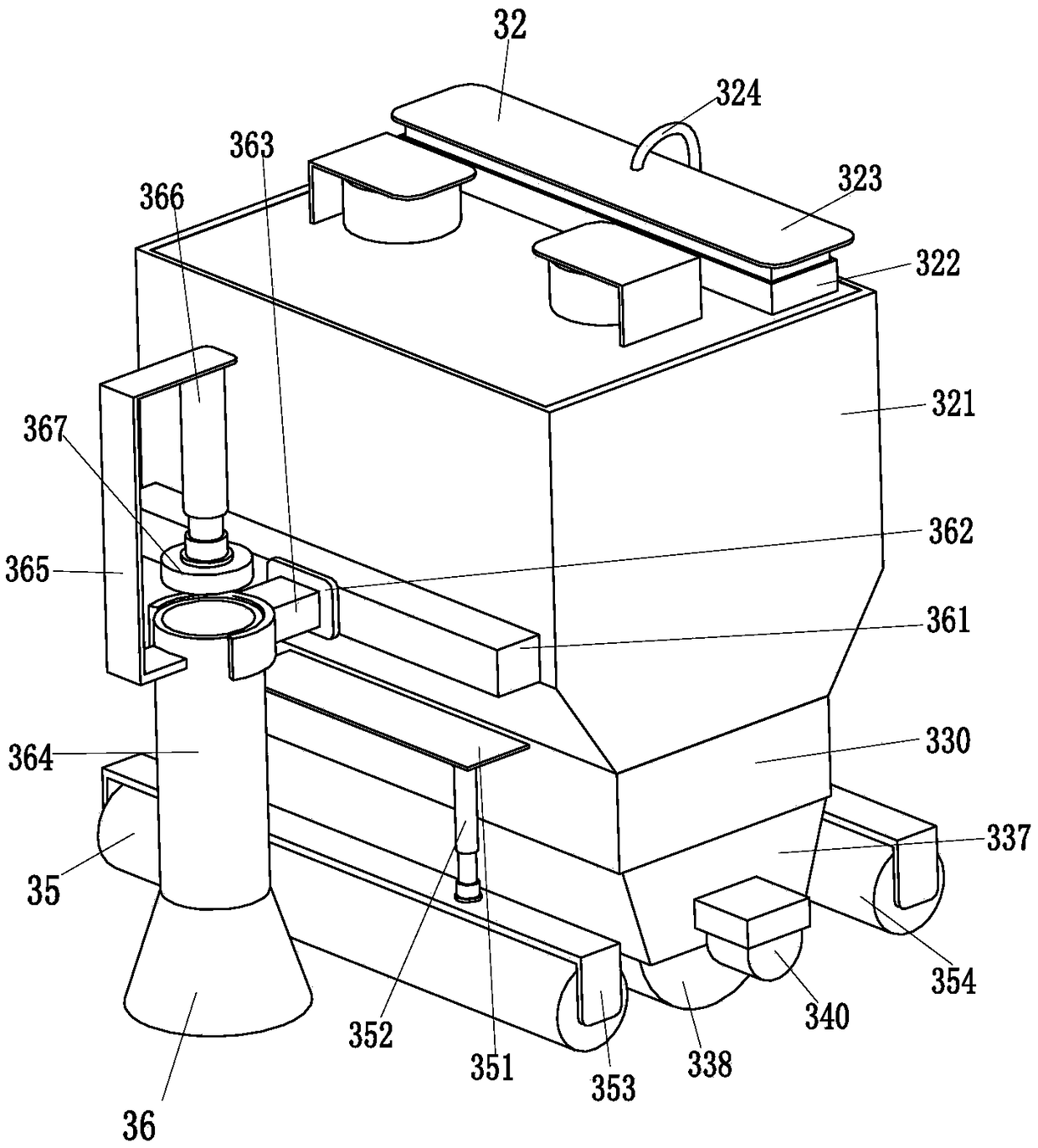

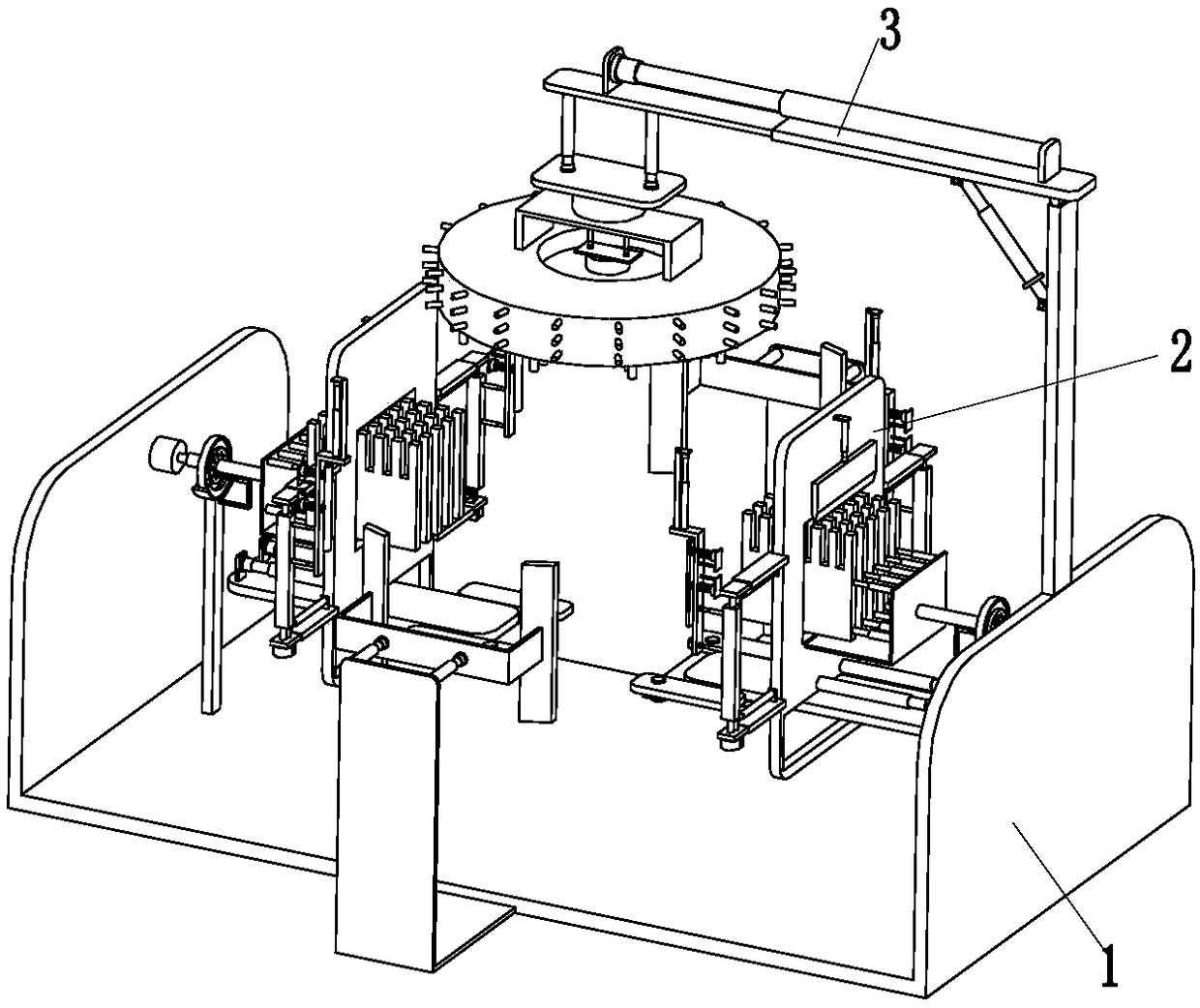

Automatic machining production line for aluminum plastic plate

ActiveCN109013181AShort time consumingEasy to operateLiquid surface applicatorsLiquid spraying apparatusIntelligent lightingProduction line

The invention relates to an automatic machining production line for an aluminum plastic plate. The automatic machining production line comprises a support and a coating device, wherein the coating device is arranged at the upper end of the support. According to the automatic machining production line, the problems that manual coating needs to be carried out in the existing coating process, the process is tedious and complex, each coating needs to be coated with a corresponding thickness during coating, the coating is not uniform in the manual coating process, redundant coating cannot be recycled in time, the concave part of the coating cannot be leveled in time, the consumed time is long, the labor intensity is large, the efficiency is low and the like can be solved, the function of carrying out intelligent coating on aluminum coil can be realized, the dynamic coating is carried out, coating is uniform, the concave part is filled up and leveled up, the redundant coating is discharged in time, the coating layer is flat, and the production line has the advantages of being simple to operate, low in labor intensity, high in working efficiency and the like.

Owner:JIANGSU KAIHUA ALUMINUM

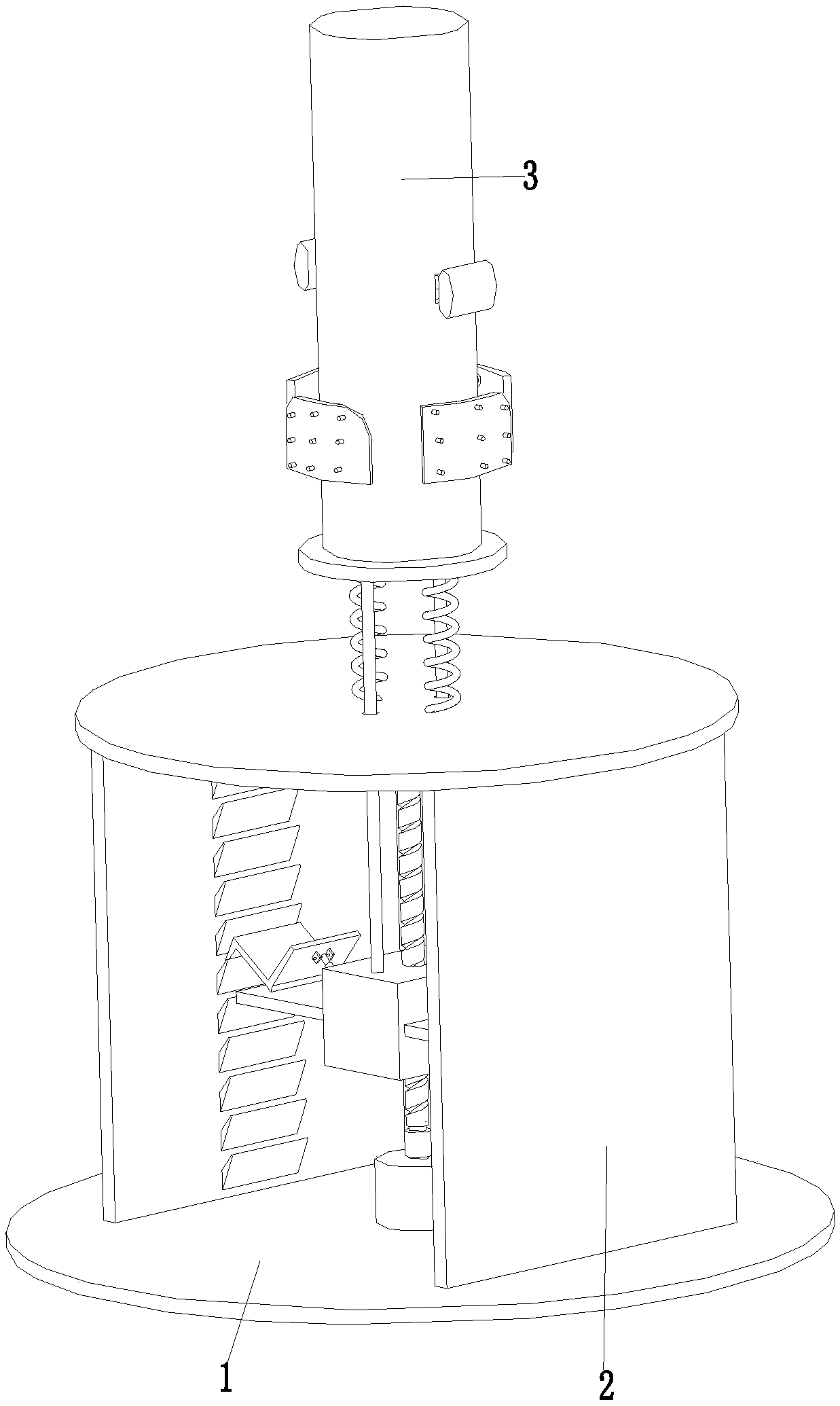

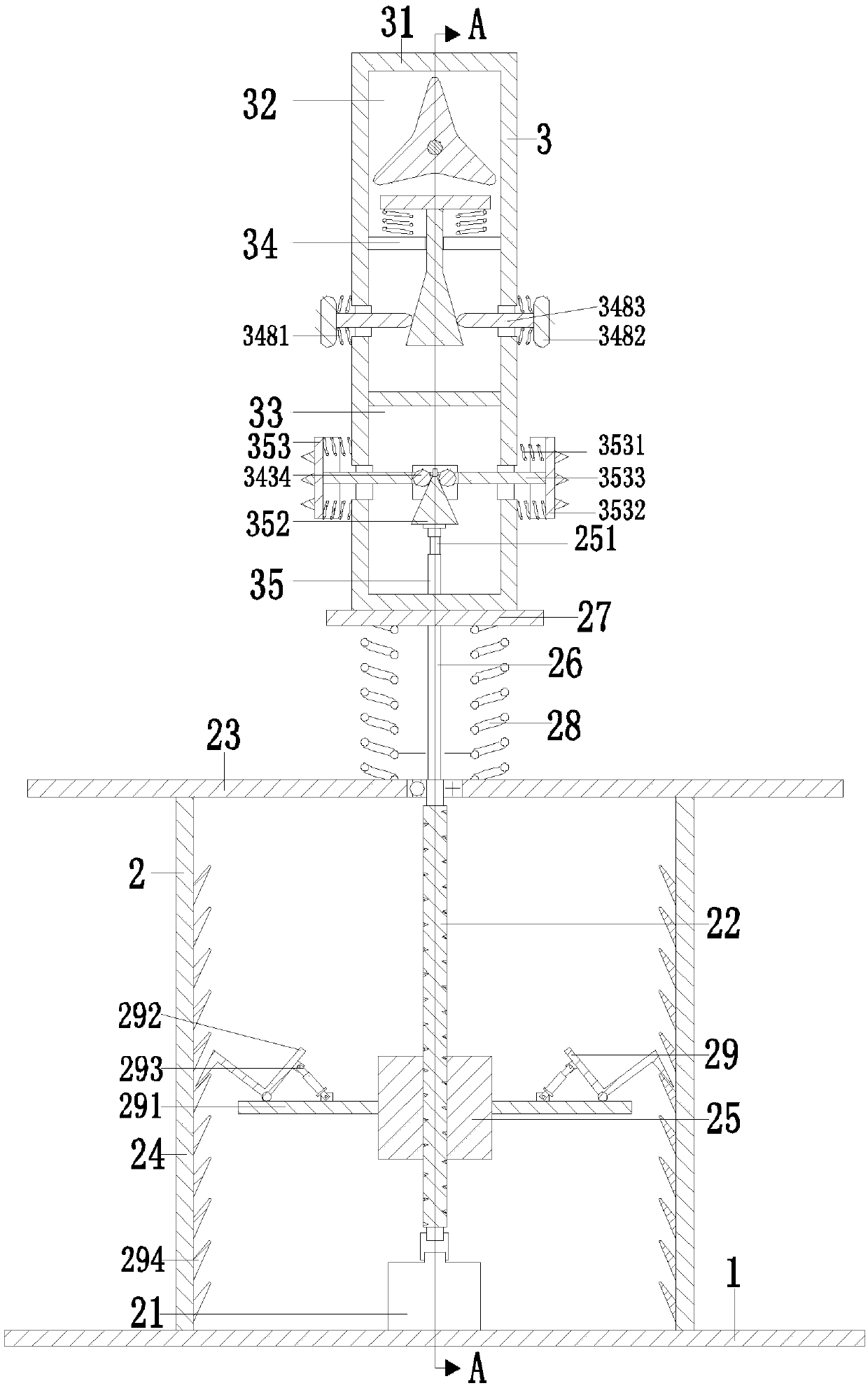

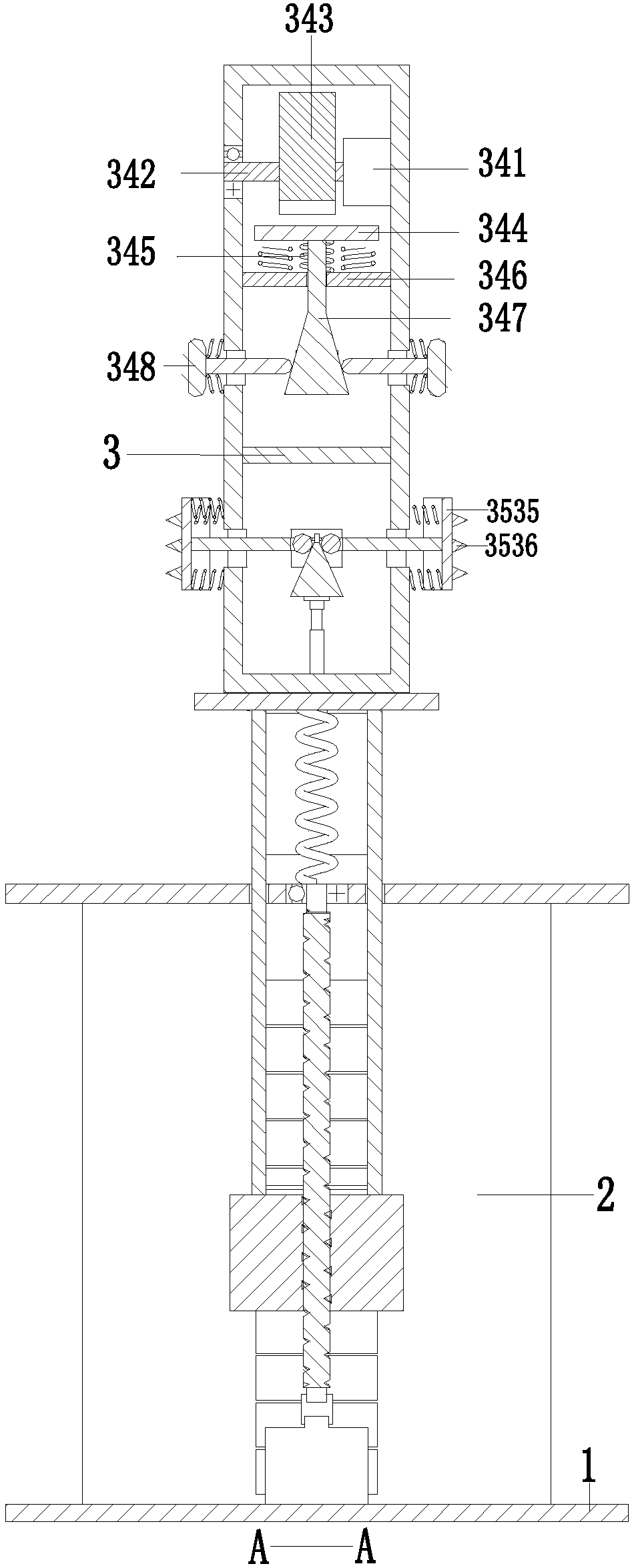

Round steel pipe quick recovering equipment

InactiveCN107838234AImprove stabilityReduce labor intensityMetal-working feeding devicesPositioning devicesEngineeringUltimate tensile strength

The invention relates to a round steel pipe rapid recovery device, which comprises a bottom plate, a lifting adjustment device is installed on the bottom plate, and a beating recovery device is installed on the upper end of the lifting adjustment device. The present invention can solve the problems existing in the restoration process of the existing deformed circular steel pipes that the steel pipes need to be manually fixed, and the baked steel pipes need to be manually restored with the help of tools, and the fixing of steel pipes of different specifications requires manual adjustment of the clamp position, the operation Complicated, artificial restoration of high-temperature baked steel pipes is easy to be scalded, and there are potential safety hazards. Manual restoration of steel pipes with tools is limited and the special structure of steel pipes. Manual restoration of steel pipes is cumbersome, labor-intensive and low-efficiency. Realize the function of quick recovery of round steel pipe.

Owner:储田生

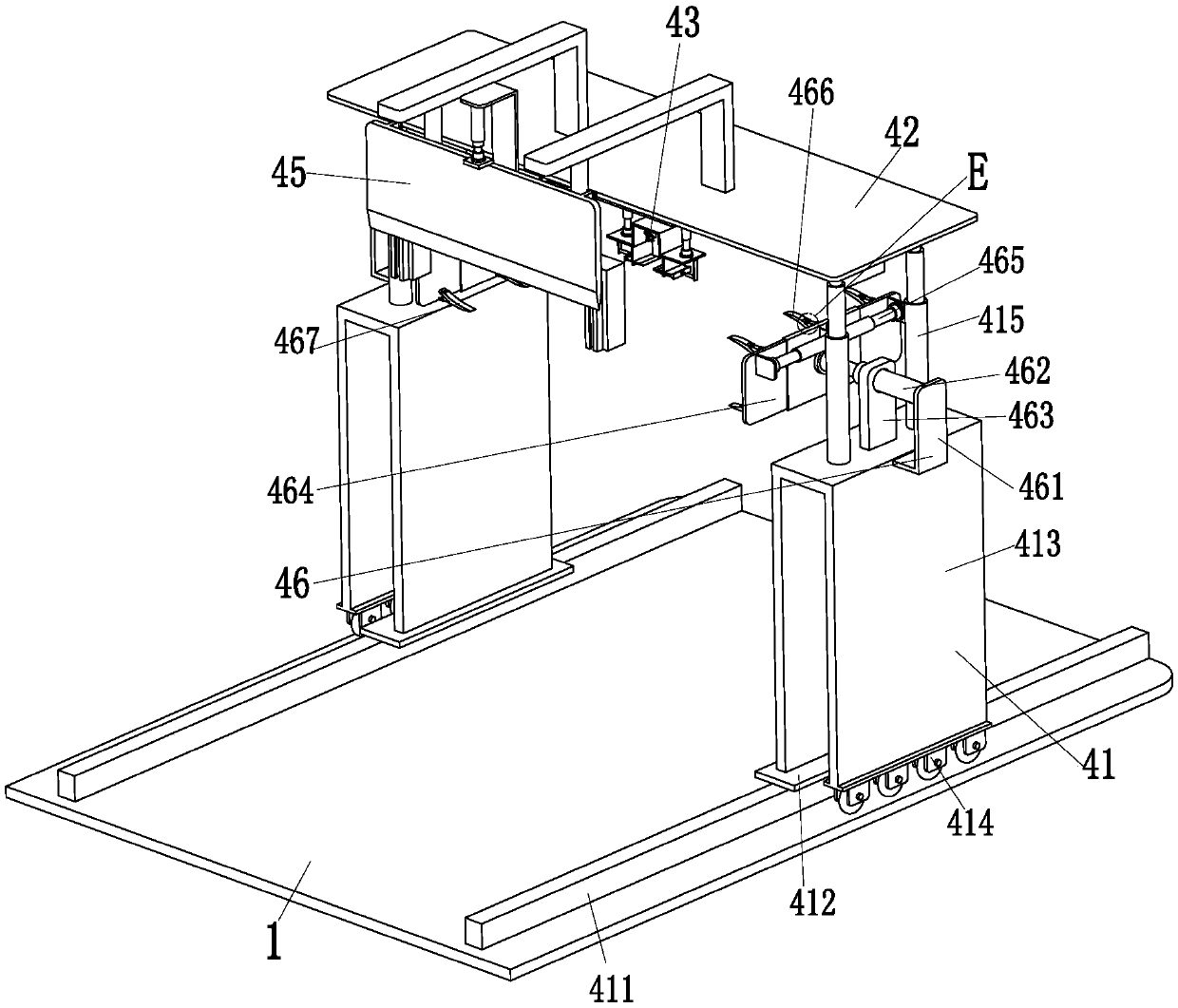

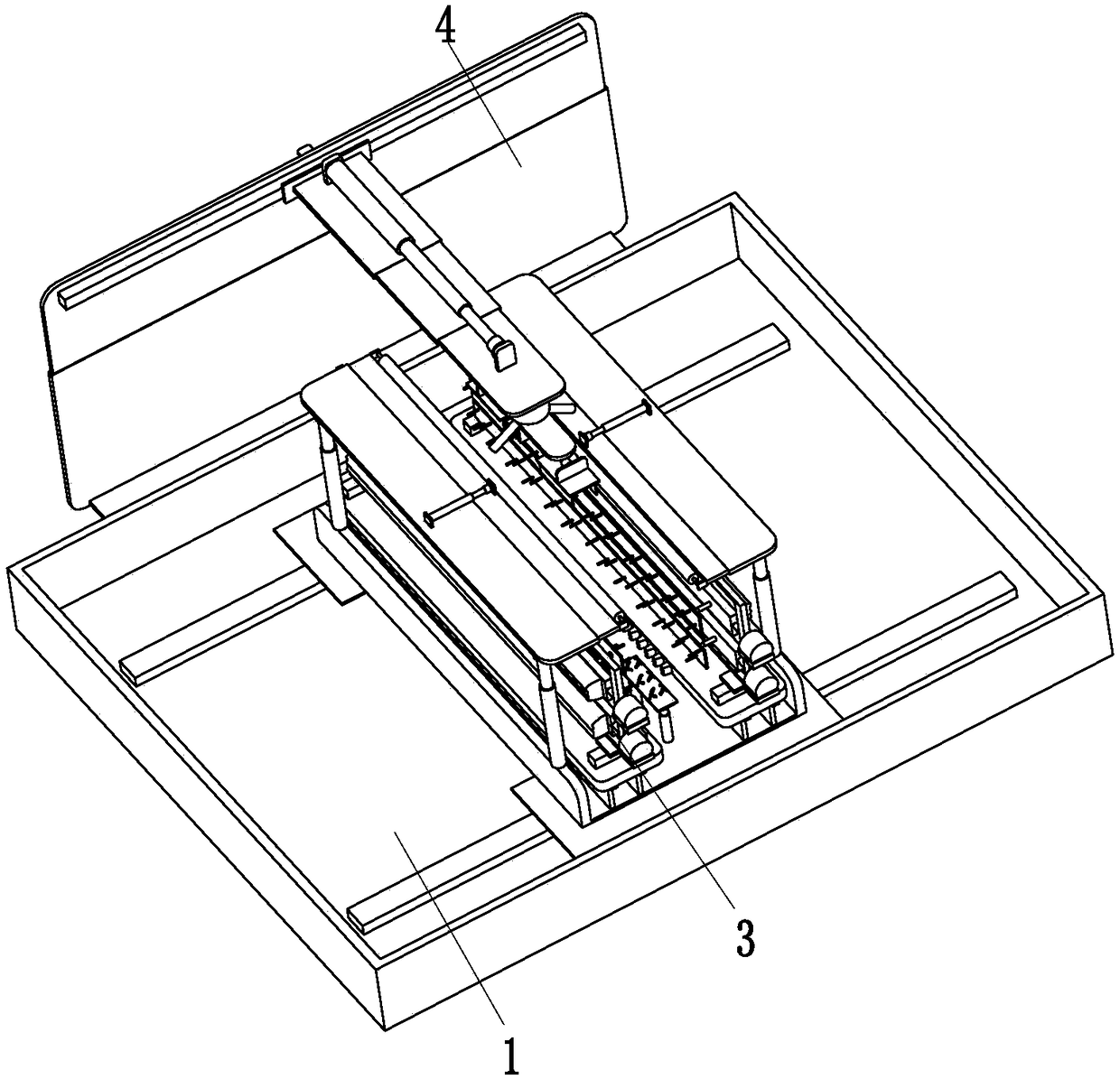

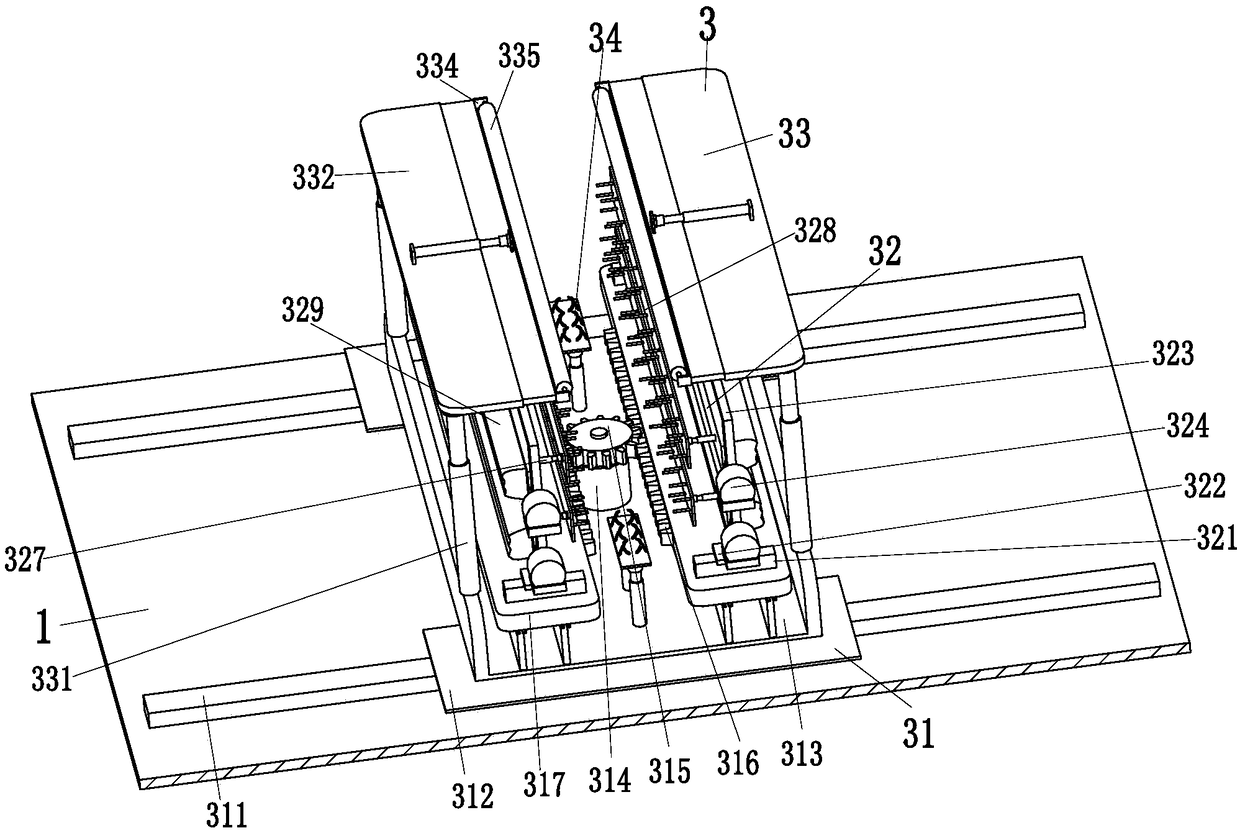

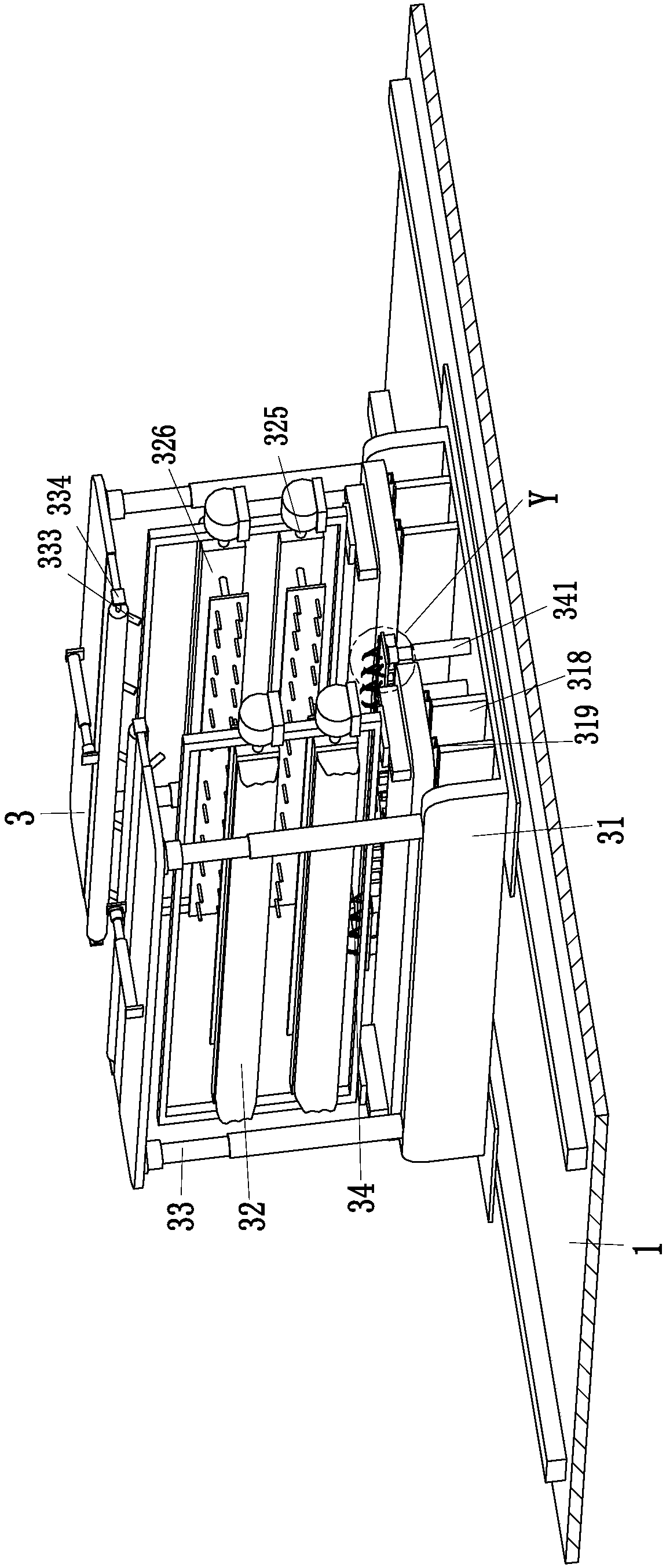

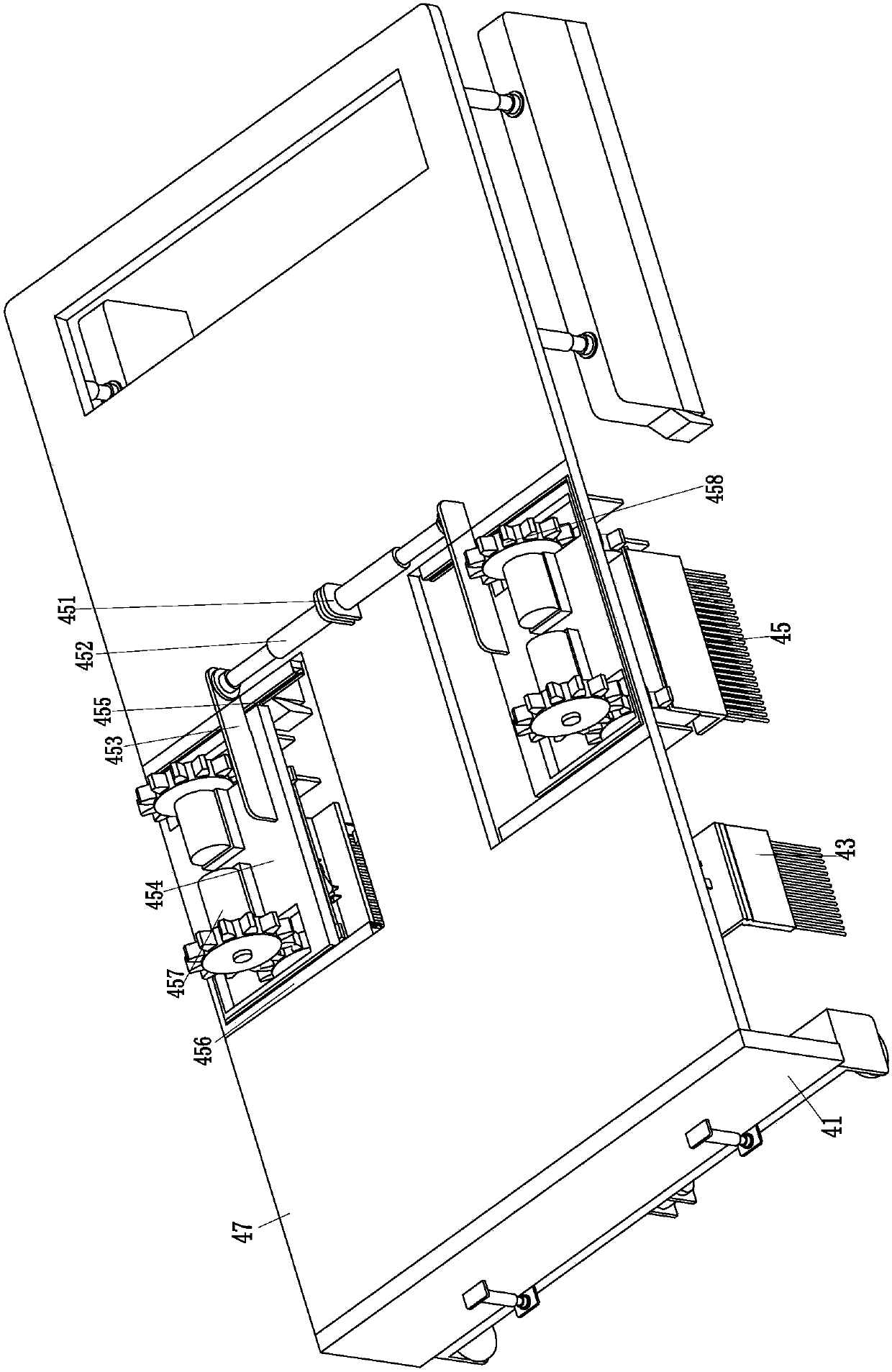

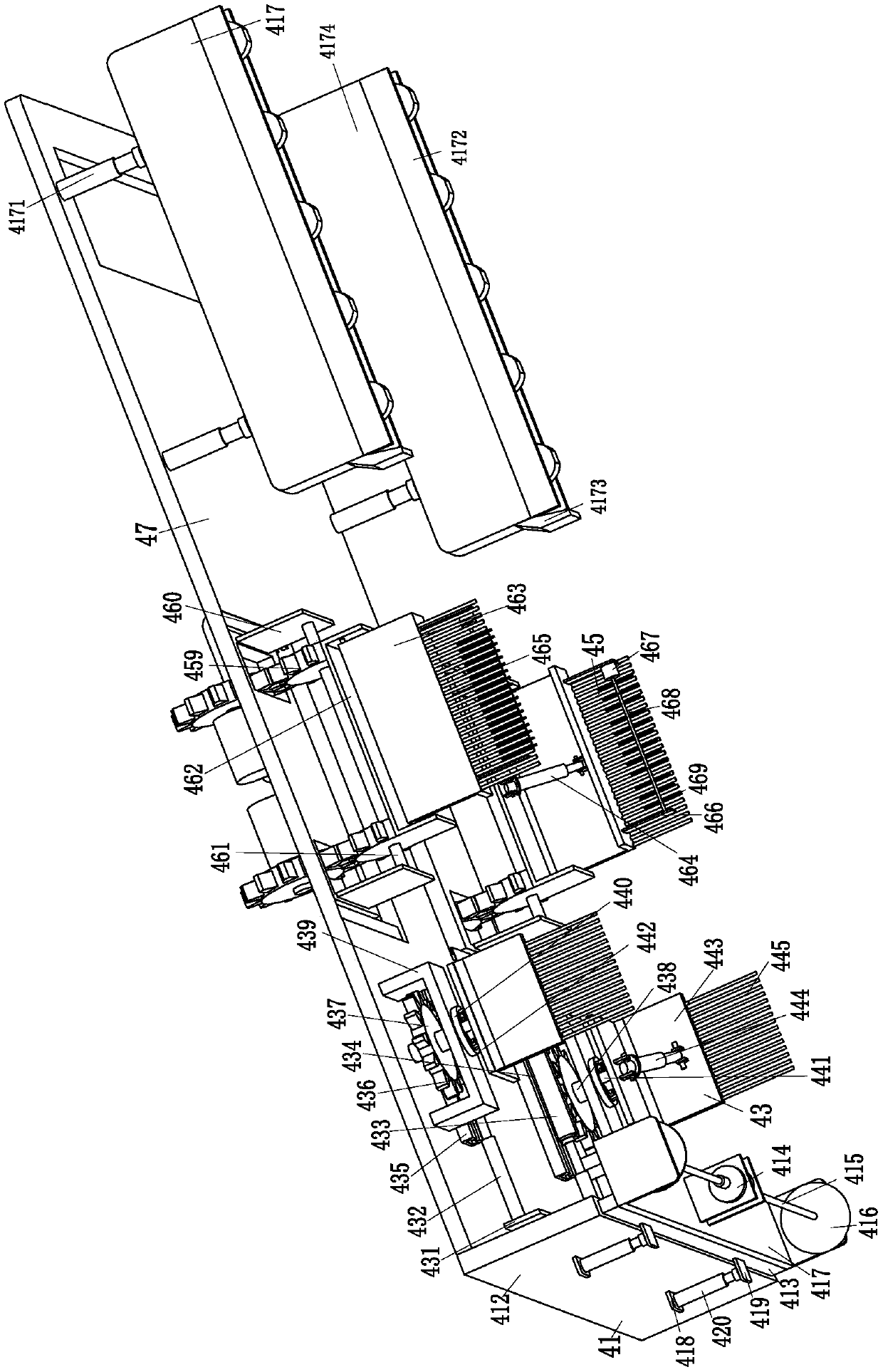

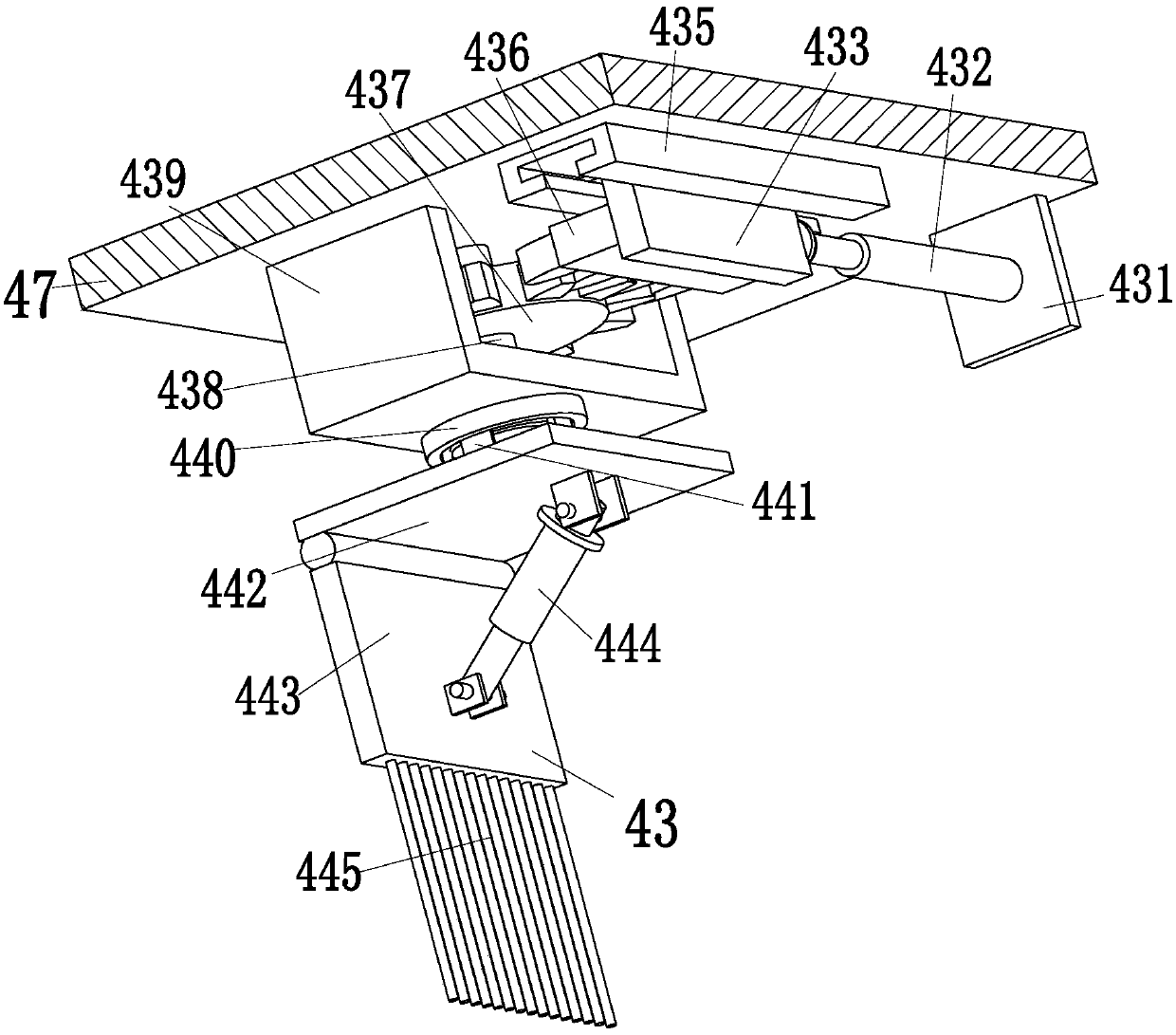

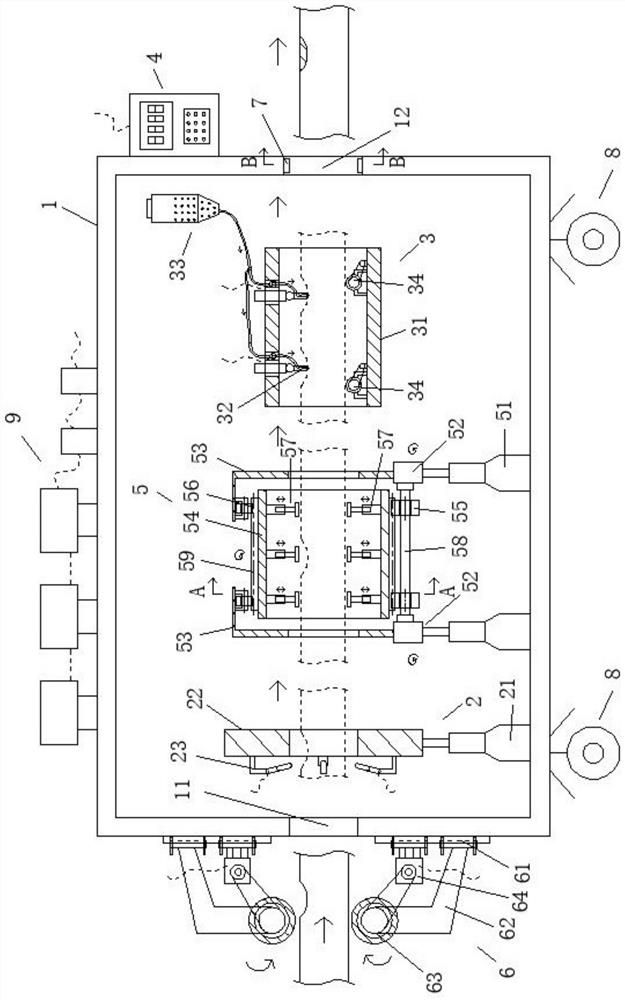

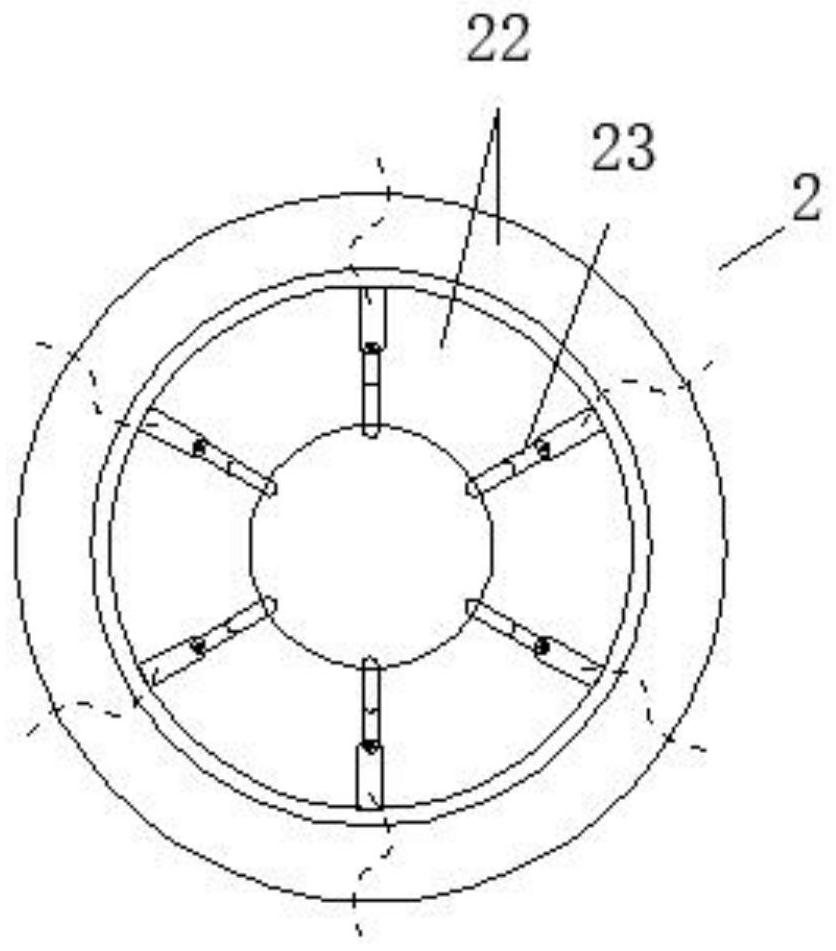

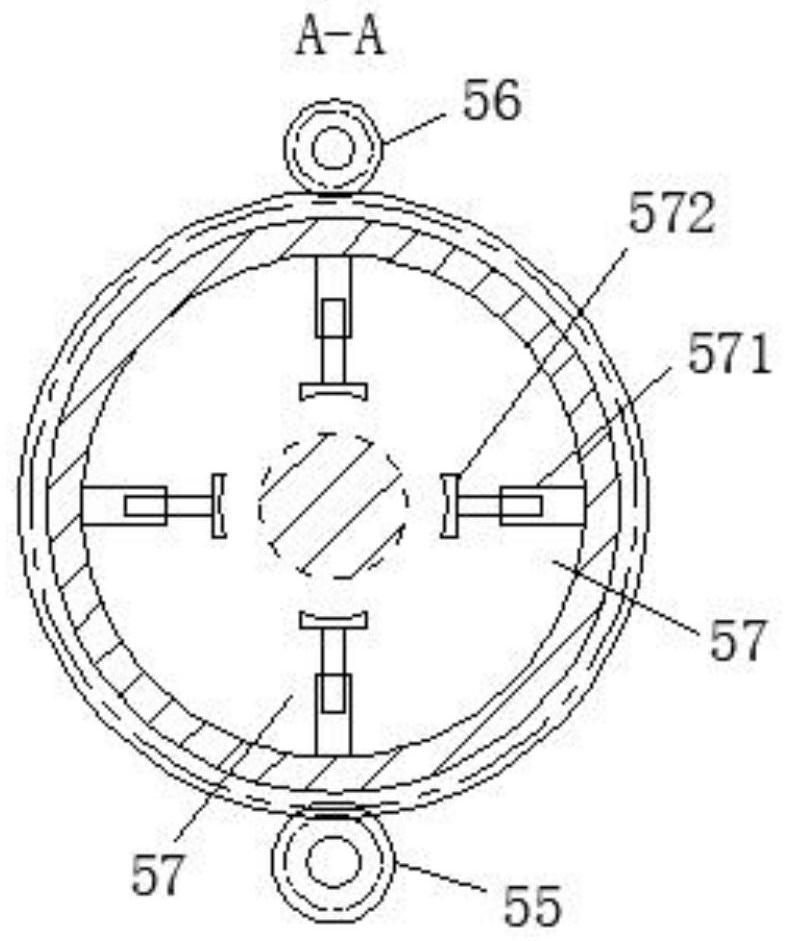

Vehicle fitting flywheel shell automatic treatment equipment and flywheel shell automatic treatment process

ActiveCN109128930AShort timeReduce labor intensityWork clamping meansMetal working apparatusEngineeringFlywheel

The invention relates to vehicle fitting flywheel shell automatic treatment equipment and a flywheel shell automatic treatment process. The equipment comprises a chassis, a positioning device and a cleaning device; the positioning device is mounted at the upper end of the chassis; and the cleaning device is mounted at the right end of the chassis. The equipment can solve the difficulties of difficult achievement of the positioning precision in traditional clamping of flywheel shells, difficult clamping of the flywheel shells by traditional clamping equipment due to higher weight of the flywheel shells, surface damage of the flywheel shells caused by easy looseness during machining, capability of machining different positions of the flywheel shells through renewed clamping of the flywheel shells by persons, halfway cleaning of iron chips attached in the flywheel shells through a manual mode, long consumed time, high labor intensity and low working efficiency, and can achieve automatic positioning and cleaning functions of the flywheel shells.

Owner:江苏固诺新材料科技有限公司

Livestock drinking device

InactiveCN107135973AStir wellEasy to observeAnimal watering devicesHollow article cleaningEngineeringMobile device

The invention relates to a drinking device, in particular to a livestock drinking device. According to the technical problem to be solved, the livestock drinking device is provided. The device comprises a base board, supports, mobile devices, a flume, a water tank, a water pump and the like; the supports are symmetrically arranged on the left side and the right side of the top of the base board, the mobile devices are symmetrically arranged below the right side of the left support and below the left side of the right support, and the flume is arranged between the left and right mobile devices; the water tank is arranged above the space between the left support and the right support and is located over the flume, a covering device is arranged on the top of the water tank, the water pump is arranged on the left side of the bottom in the water tank, a hard pipe is arranged on the left side of the water pump, and the lower end of the hard pipe penetrates the water tank. The livestock drinking device achieves the effects of advanced equipment, easy cleaning, low labor intensity of workers, high working efficiency and high hygienic standard, and the mobile devices can make the flume move up and down.

Owner:曾祥胜

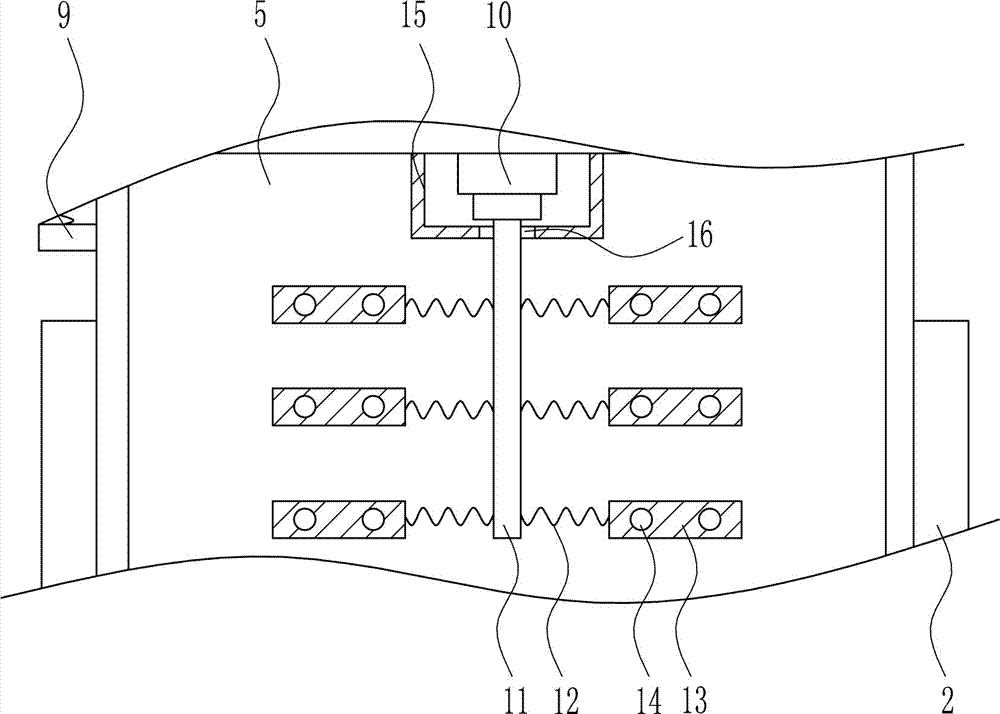

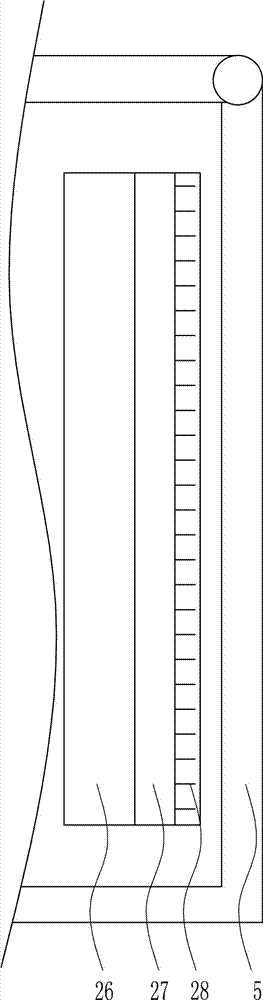

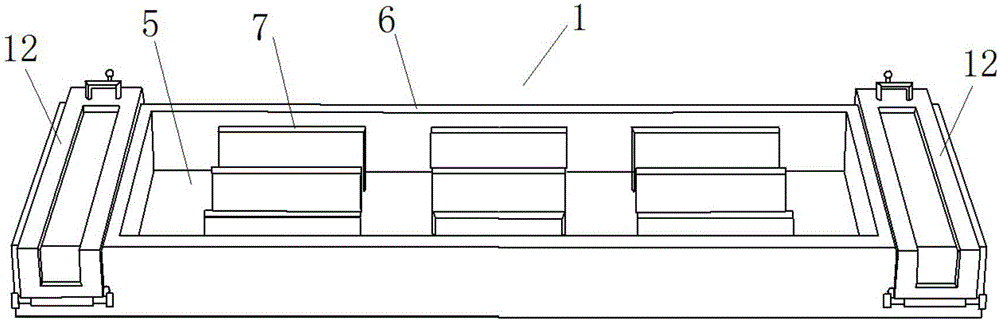

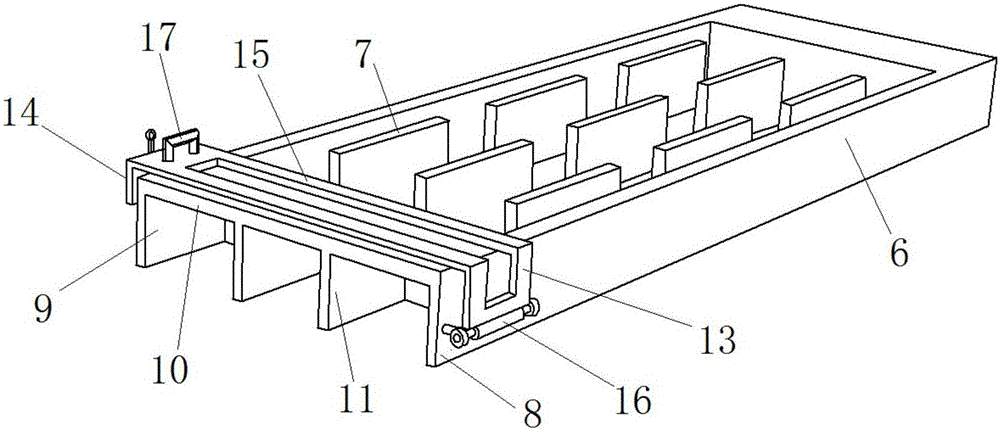

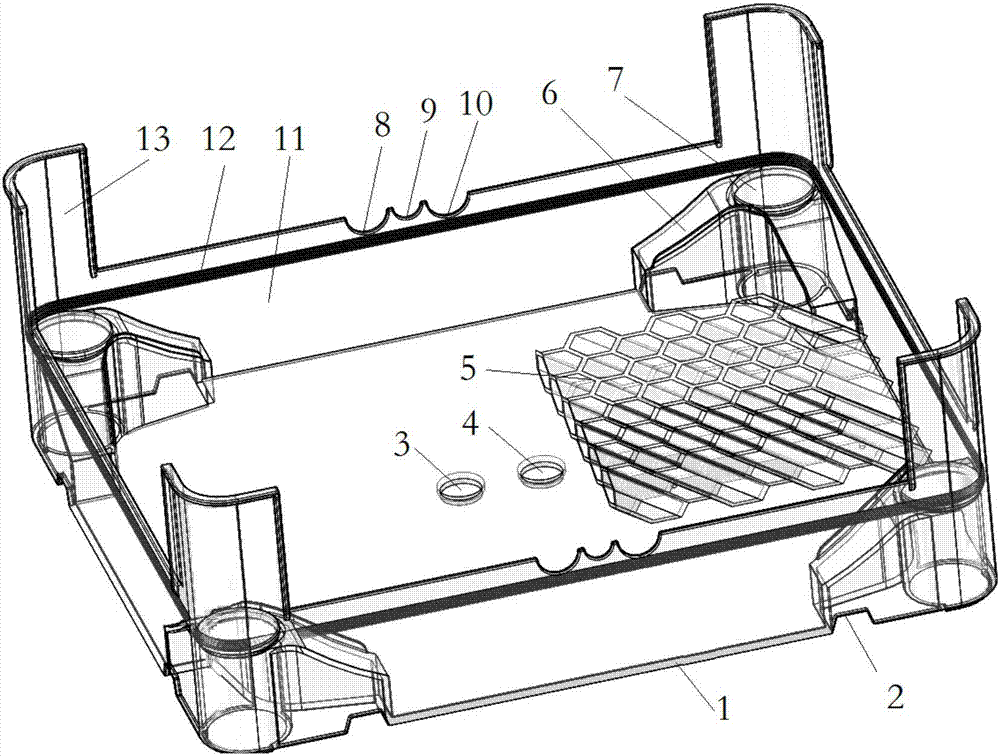

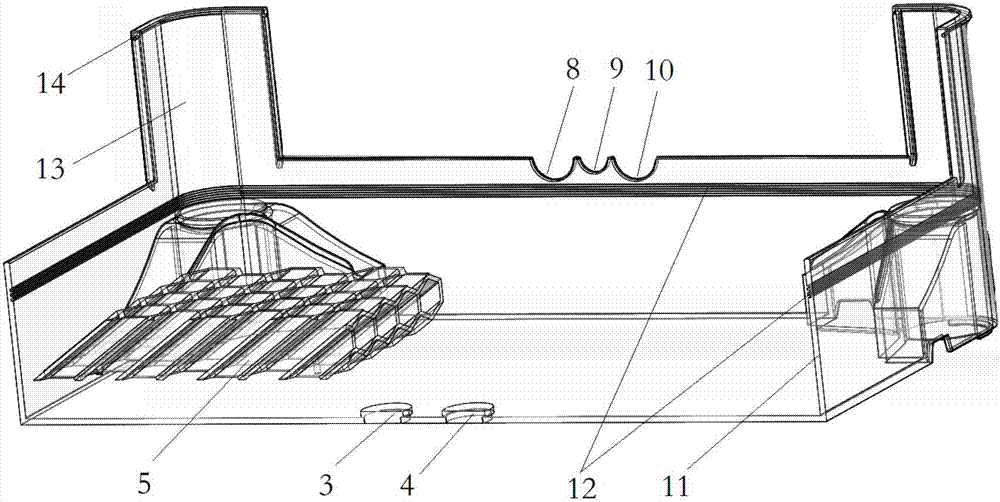

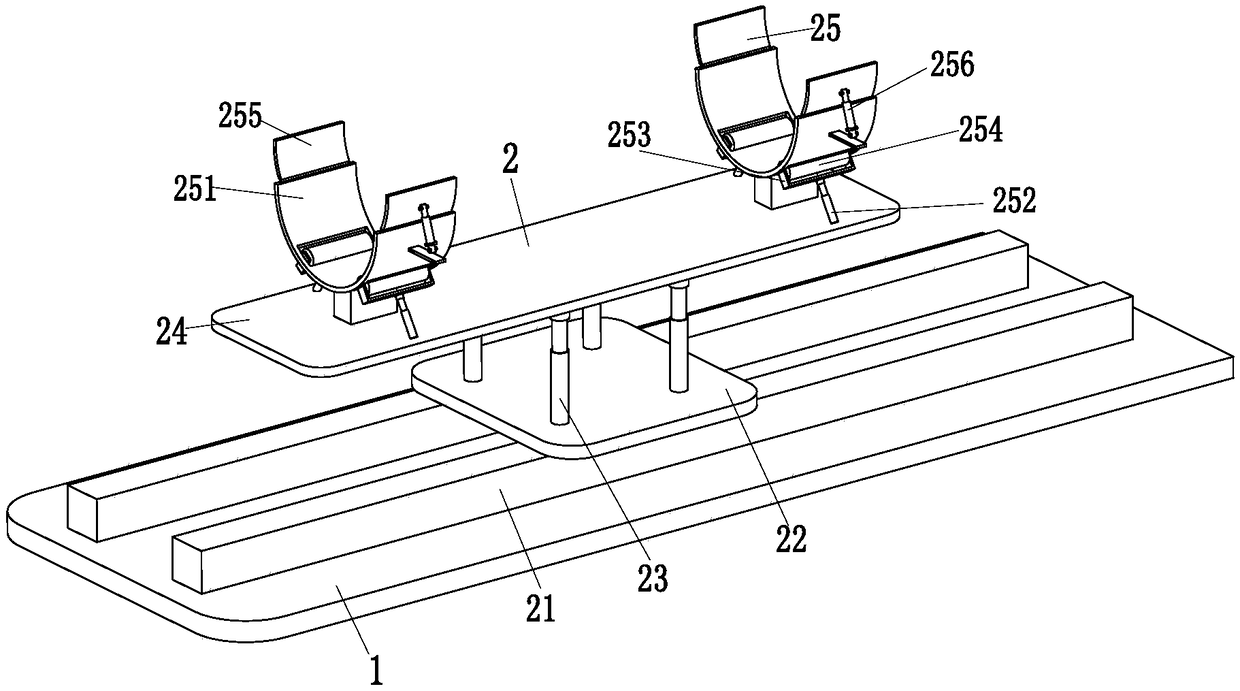

Mold assembly for manufacturing concrete narrow-gap slatted floor and application of mold assembly

ActiveCN106182362AStable structureNot easy to fall offMould auxillary partsFlooringIsolation layerThin layer

The invention belongs to the technical field of building materials and particularly relates to a mold assembly for manufacturing a concrete narrow-gap slatted floor and application of the mold assembly. The mold assembly comprises a mold and an isolating layer, wherein the mold comprises a base plate and a frame; the frame is formed by assembling four square side plates which are vertically arranged at the periphery of the base plate; a plurality of molding plates are vertically arranged on the base plate; and the isolating layer is attached to the base plate and the side plates. According to the mold assembly disclosed by the invention, the concrete narrow-gap slatted floor is produced by adopting the following method: firstly, uniformly spreading one thin layer of fine sands on the isolating layer, pouring a layer of concrete into the mold assembly and then starting a vibrating table for vibrating; secondly, putting the reinforcing mesh into the mold assembly, and continuously pouring concrete into the mold; when the concrete spills over the reinforcing mesh and is stacked to the top of the mold, plattening the top of the concrete and putting two reinforcing bars into the mold assembly; thirdly, uniformly spreading one layer of carborundum on the surface of the plattened concrete, and immediately turning over and demolding after plattening and forming, thus obtaining a finished product. According to the concrete narrow-gap slatted floor manufactured by adoption of the mold assembly, the pitted surface of the narrow-gap slatted floor surface can be effectively reduced, and surface quality of the floor is improved.

Owner:CHINA AGRI UNIV

Automatic air column roll material cutting robot for express packaging

ActiveCN108860828ARealize the function of automatic cuttingEnsure safetyContainers to prevent mechanical damageEngineeringUltimate tensile strength

The invention relates to an automatic air column roll material cutting robot for express packaging. The robot comprises a U-shaped support, two limit cutting mechanisms, an auxiliary mechanism and a cutting mechanism. The two limit cutting mechanisms are installed at the left and right ends of the U-shaped support, the auxiliary mechanism is installed in the middle of the U-shaped support, and thecutting mechanism is installed at the upper end of the auxiliary mechanism. According to the automatic air column roll material cutting robot for express packaging, the problems can be solved that anexisting air column roll material needs to be manually cut, during cutting, a worker needs to take the air column roll material by one hand and cut the air column roll material by the other hand, dueto the fact that the air column roll material is not in a tensioned state, a cutter easily deviates from the position, and as a result the cutter cuts through the air column roll; when using the cutter, the worker can be possibly cut and hurt due to misoperation, the consumed time is long, the labor intensity is high, and the efficiency is low; the function can be achieved that the air column roll material is automatically cut off.

Owner:张杰

Construction steel structure bridge reinforcement construction machine

ActiveCN108517792ARealize the function of all-round mechanical coatingAll-round mechanical coating function withoutBridge erection/assemblyBridge strengtheningFixed frameEngineering

The invention relates to a construction steel structure bridge reinforcement construction machine. The machine comprises an angle rotation device, an angle working plate is mounted on the upper end ofthe angle rotation device, a glue application device is mounted on the upper end of the angle working plate, the angle rotation device comprises an angle fixing frame mounted on a mobile device, an angle rotating motor is mounted on the left end inner wall of the angle fixing frame through a motor base, an output shaft of the angle rotating motor is connected to the left end of an angle rotatingroller through a coupler, and the right end of the angle rotating roller is mounted on the angle fixing frame through bearings. The machine can solve the problems that a prepared glue solution needs to be manually applied to a work surface in the existing building reinforcement glue solution coating process, operation on working faces at high places needs to be manually conducted with the help ofclimbing tools, irritating odor in the glue solution hurts the human health, manual coating of the glue solution is not uniform, and the manual operation on the working faces at high places by means of the climbing tools is not safe.

Owner:HEBEI HANGXIAO STEEL STRUCTURE

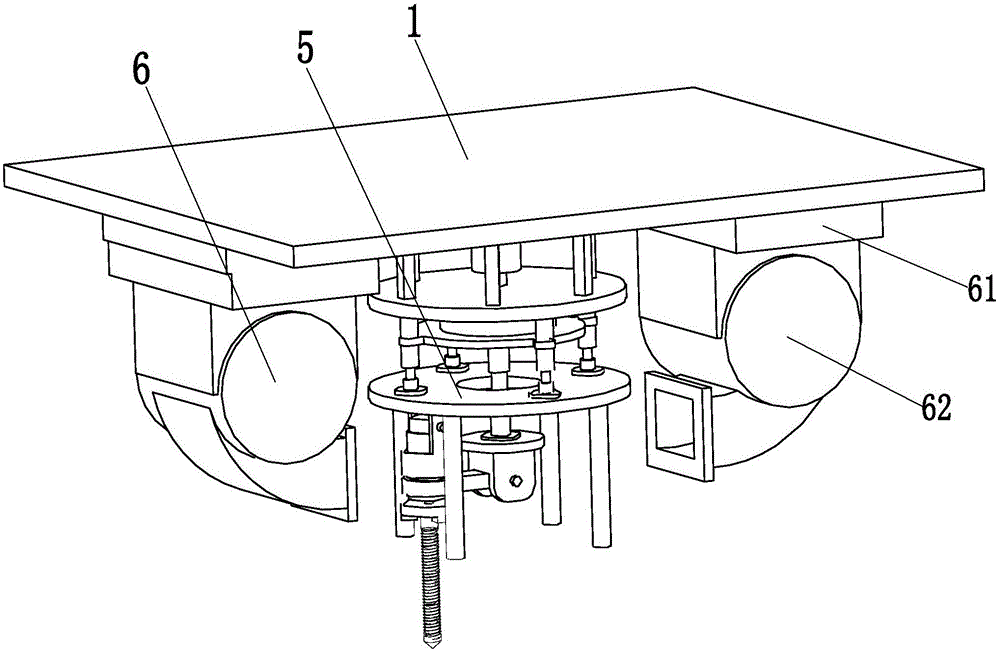

Automatic demounting and mounting device special for electric automobile charging pile and demounting and mounting method of automatic demounting and mounting device

ActiveCN106378614ASimple and fast operationImprove work efficiencyMetal working apparatusElectrical and Electronics engineering

The invention relates to an automatic demounting and mounting device special for an electric automobile charging pile and a demounting and mounting method of the automatic demounting and mounting device. The automatic demounting and mounting device comprises a bottom plate. A demounting and mounting mechanism is installed at the middle portion of the lower end face of the bottom plate. Movable mounting and automatic demounting functions can be achieved on an existing charging pile through the demounting and mounting mechanism, and manual installation is not needed. Two dust suction mechanisms are symmetrically installed on the left side and the right side of the end face of the bottom plate. The two dust suction mechanisms are oppositely located on the two sides of the demounting and mounting mechanism. Due to the fact that the demounting and mounting mechanism can generate a large amount of dust in the process of installing the existing charging pile, the two oppositely-arranged dust suction mechanisms can rapidly suck dust generated in the installation process, and the phenomenon that an operator sucks the dust, and consequently the body health is affected is prevented. According to the automatic demounting and mounting device special for the electric automobile charging pile and the demounting and mounting method of the automatic demounting and mounting device, the movable mounting and automatic demounting functions on the charging pile can be achieved, manual demounting and mounting are not needed, operation is easy and convenient, the work efficiency is high, and the beneficial effects that only one person needs to conduct operation, the labor cost is low, the labor intensity is low, the demounting and mounting process is fast, and the demounting and mounting efficiency is high are achieved.

Owner:ZHEJIANG ZHONGXIN ELECTRIC POWER DEV GRP CO LTD +2

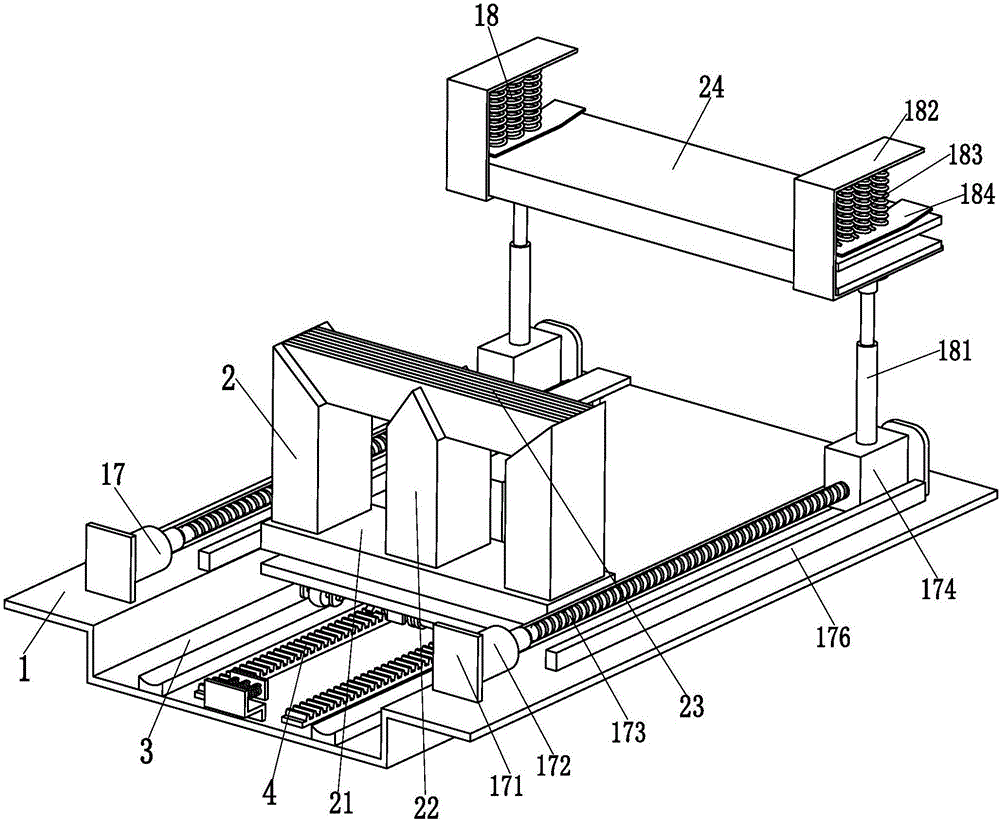

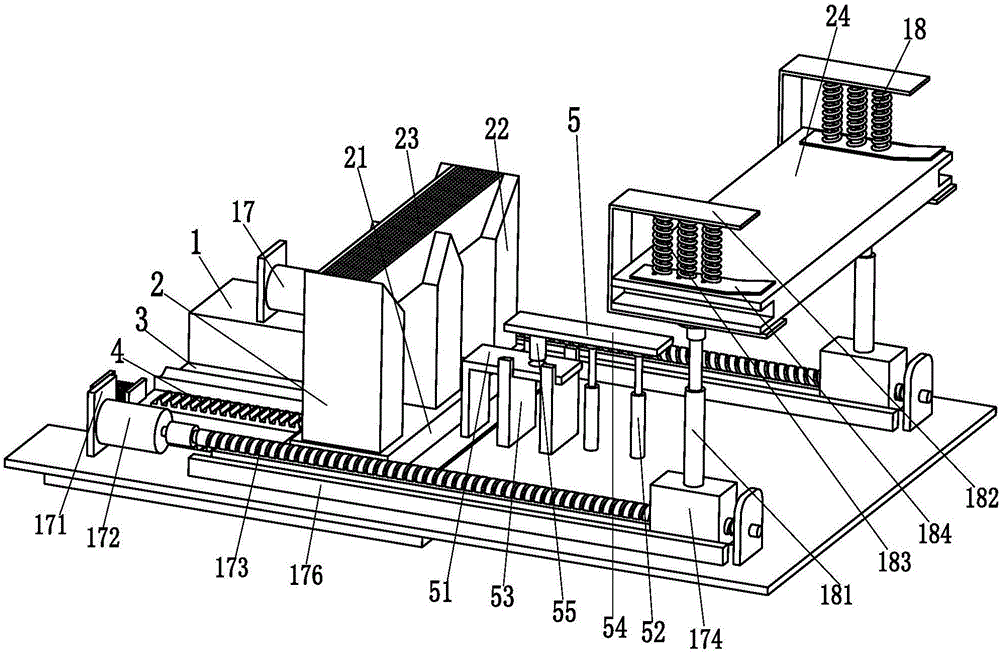

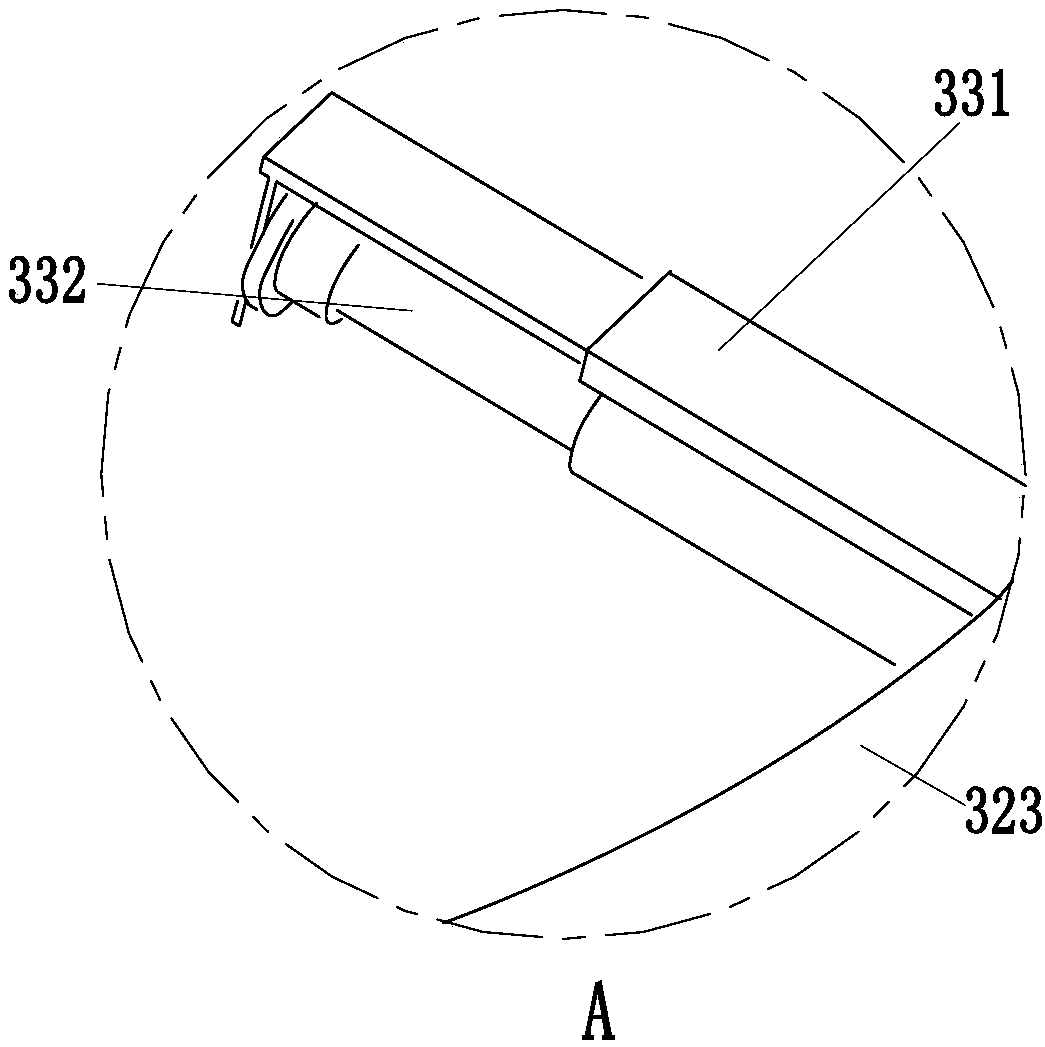

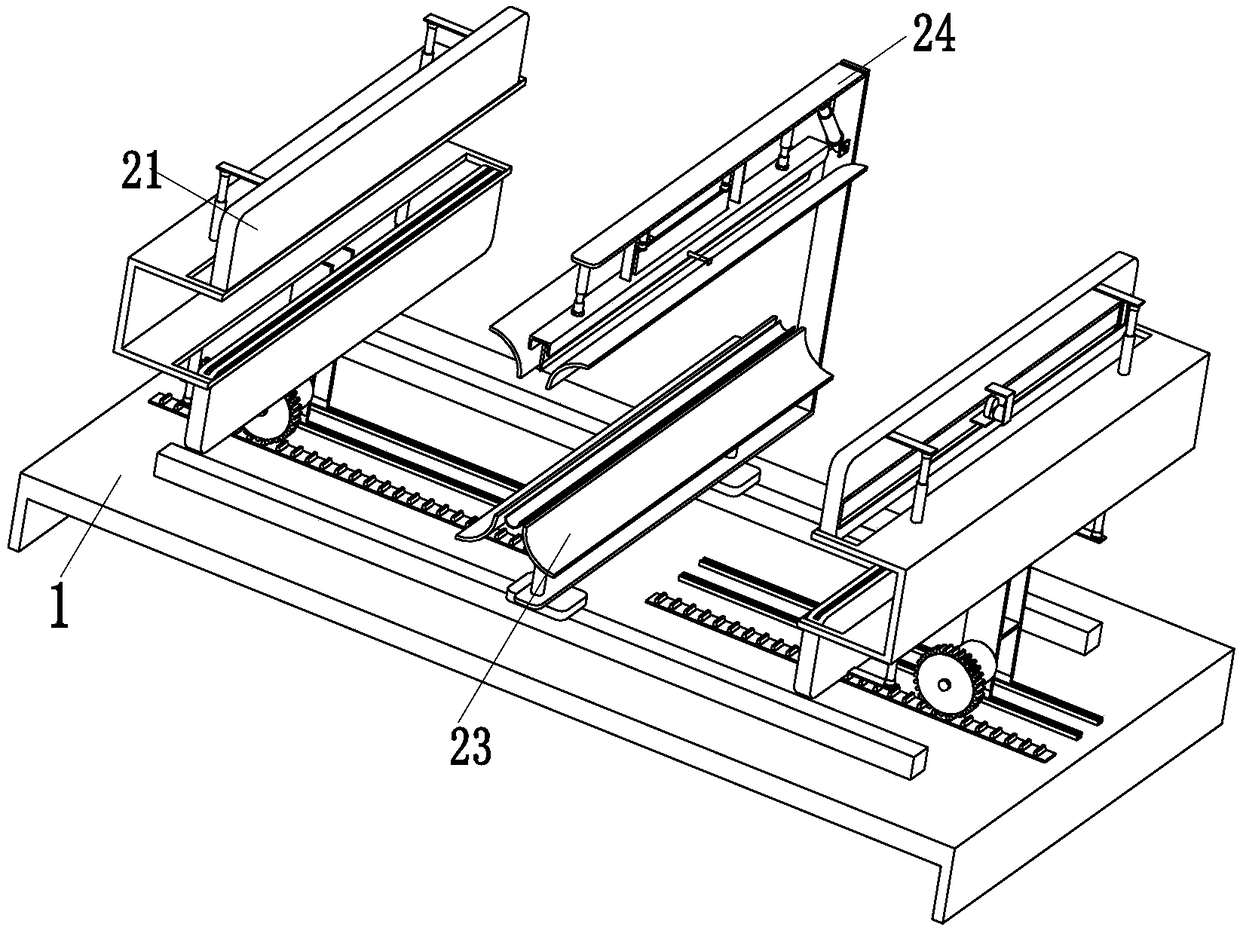

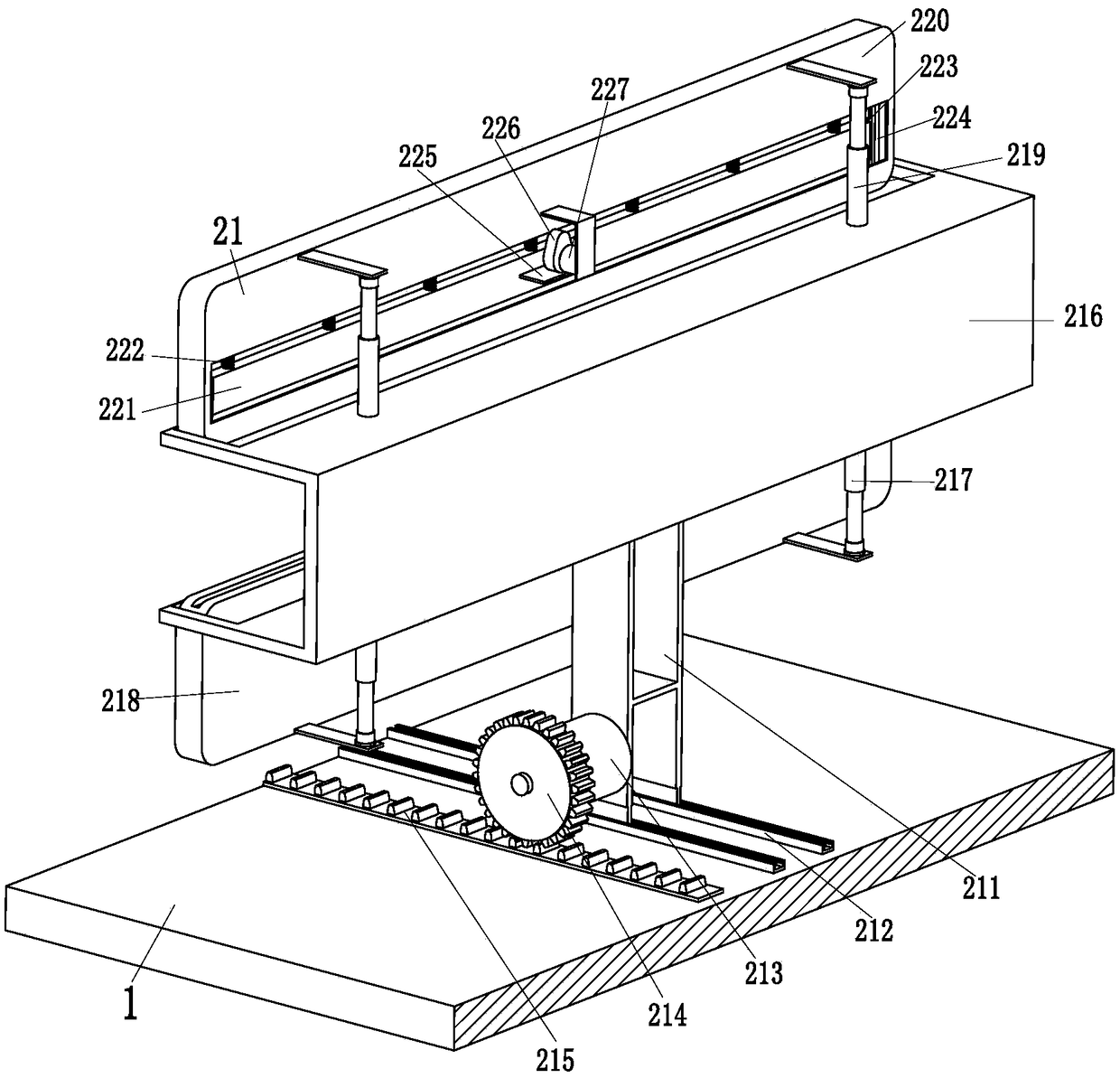

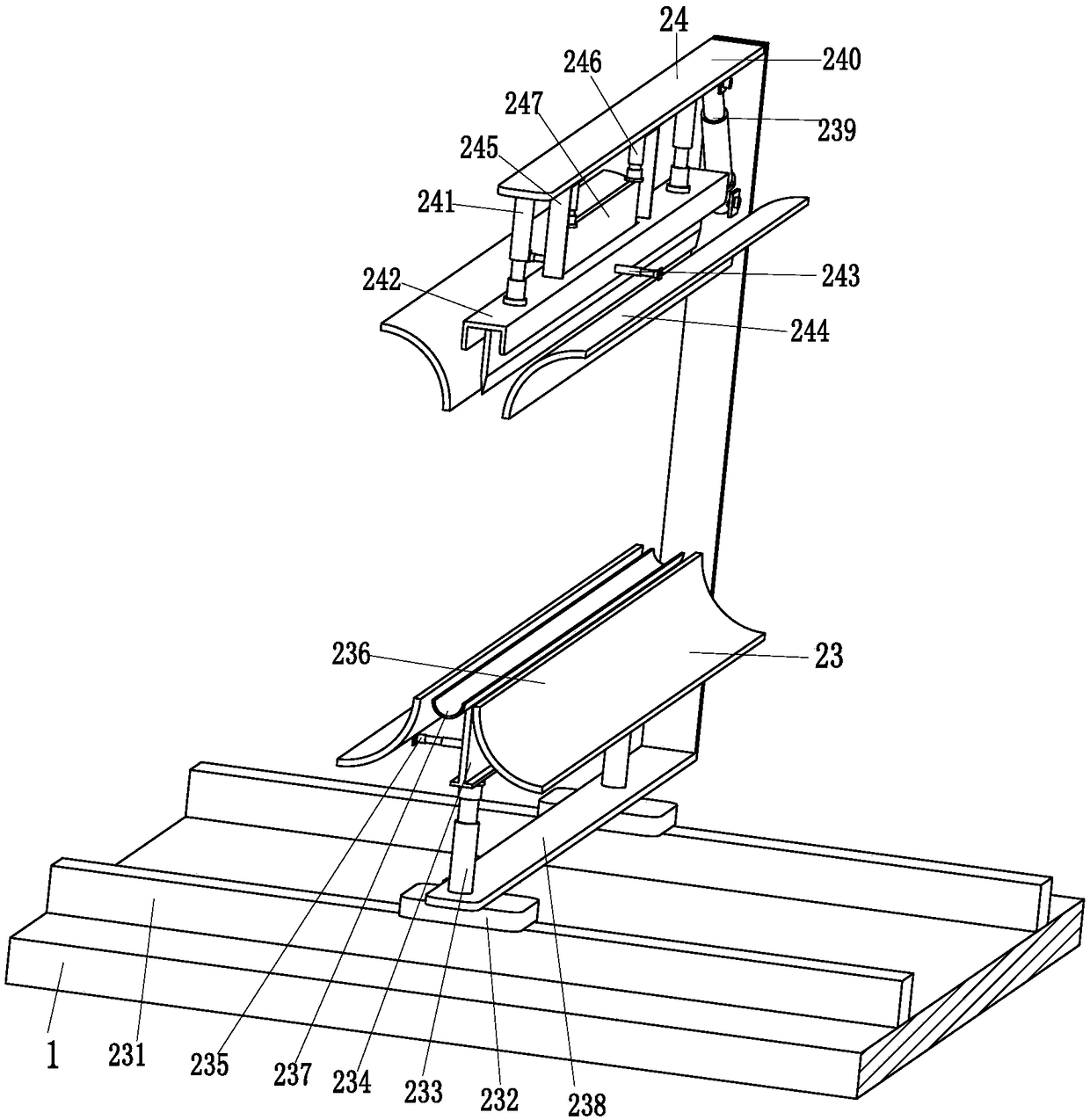

Grooving machine for bending machining of aluminum-plastic plate, and grooving machining method for aluminum-plastic plate

ActiveCN109093200AEasy to operateShort costFeeding apparatusMaintainance and safety accessoriesReciprocating motionEngineering

The invention relates to a grooving machine for bending machining of an aluminum-plastic plate, and a grooving machining method for the aluminum-plastic plate. The grooving machine comprises a main plate, a reciprocating motion mechanism, a chipping sweeping mechanism, a grooving mechanism and two buffer groove-cutting mechanisms; and the reciprocating motion mechanism is mounted at the right endof the main plate, the grooving mechanism is mounted at the lower end of the reciprocating motion mechanism, the two buffer groove-cutting mechanisms are mounted at the left and right ends of the grooving mechanism, and the chip sweeping mechanism is mounted at the right end of the reciprocating motion mechanism. According to the grooving machine, the problems that in the existing grooving processof an aluminum-plastic plate, manual grooving is needed, when grooving is started , if a grooving cutter directly conducts grooving on the aluminum-plastic plate, the life of the cutter is prone to be influenced, during manual grooving, part of a groove is not formed completely, chipping materials are accumulated on the two sides of the groove during grooving, consequently, the working progress is affected, as for manual grooving, the original position is prone to being deviated, the consumed time is long, the labor intensity is large, and the efficiency is low can be solved, and the functionof mechanical grooving of the aluminum-plastic plate can be achieved.

Owner:SUZHOU BEECORE HONEYCOMB MATERIALS

Electric power safety net maintenance equipment

ActiveCN108543728ANo manual operationEasy to operateCleaning using toolsCleaning using liquidsSafety netMultiple case

The invention relates to electric power safety net maintenance equipment. The electric power safety net maintenance equipment comprises a bottom frame, a primary cleaning device and a secondary cleaning device, wherein the middle of the bottom frame is provided with the primary cleaning device, and the left end of the bottom frame is provided with a secondary cleaning device. According to the electric power safety net maintenance equipment, the problems that a safety net needs to be cleaned when an existing electric power safety net is cleaned, the process is tedious and complex, the personnelcannot comprehensively clean the electric power safety net during scrubbing, primary cleaning is carried out in multiple cases, cleaning cannot be achieved at the dead corners of the net, and cleaning is not complete, the process is long in consumed time, large in labor intensity, low in efficiency and the like are solved, the function of carrying out automatic cleaning on the electric power safety net can be achieved, the electric power safety net can be automatically and comprehensively cleaned, repeated brushing can be carried out repeatedly, the dead corners of the net can be cleaned, andmanual operation is not needed; and the electric power safety net maintenance equipment has the advantages of being simple in operation, low in labor intensity, high in working efficiency and the like.

Owner:泰安泰山高压开关有限公司

Automatic sweeping environmental protection equipment for cleaning asphalt concrete pavements

InactiveCN107700398AReduce labor intensityImprove work efficiencyRoad cleaningRoad surfaceEngineering

The invention relates to an automatic cleaning and environmental protection equipment for asphalt concrete road surface cleaning, which includes a bottom plate, a moving mechanism, two cleaning mechanisms and two sweeping mechanisms. The lower end of the bottom plate is equipped with a moving mechanism, and two Auxiliary trough, a discharge chute is arranged on the bottom plate, two cleaning mechanisms are installed on the bottom plate, and two scraping mechanisms are installed on the bottom plate, and the scraping mechanisms are all located in the auxiliary trough. The invention can solve the problem that in the cleaning process of the road surface, it is necessary for personnel to clean the garbage together and then recycle the garbage. The process is cumbersome. The personnel bend over to clean with the help of tools. Long-term bending will easily cause safety hazards, and the personnel only clean the garbage in a certain area Then clean the lower part, and then recycle the garbage in each area. When recycling, the originally concentrated garbage is scattered due to external reasons, and the personnel need to clean it again. The personnel place the tools randomly, which shortens the tool life. The labor intensity is high and the efficiency is high. low-level problems.

Owner:汪成立

Ecological environment-friendly biological treatment system

InactiveCN106973861AFully converted treatmentFully effective transformationFood processingClimate change adaptationEcological environmentWorking environment

The invention provides an ecological environment-friendly biological treatment system. The ecological environment-friendly biological treatment system comprises a system bottom face and a system side edge around the system bottom face; a bottom spillway hole cover opening and a bottom limber hole cover opening are formed in the system bottom face, and a bioseparation hole penetrating through the system bottom face and a connecting device for an organism to crawl to the upper end of the bioseparation hole are arranged on the system bottom face; an overflow pipe opening for arranging an overflow pipe, a water inlet pipe opening for arranging a water inlet pipe and a contamination discharging pipe opening for arranging a contamination discharging pipe are formed in the system side edge. Abandoned ograngic matter pollution caused in human life can be reduced, high-cost machine input is reduced, secondary pollution to the environment is prevented, and working environment of breeding workers is improved. Combined stereoscopic cycling breeding with diversified breeding products is adopted in the system, ecological environment protection, ecological cultivation and function intensification are achieved, and the ecological environment-friendly biological treatment system further has the advantages of being small in occupied area, high in yield, easy to manage and low in labor intensity.

Owner:张立奎

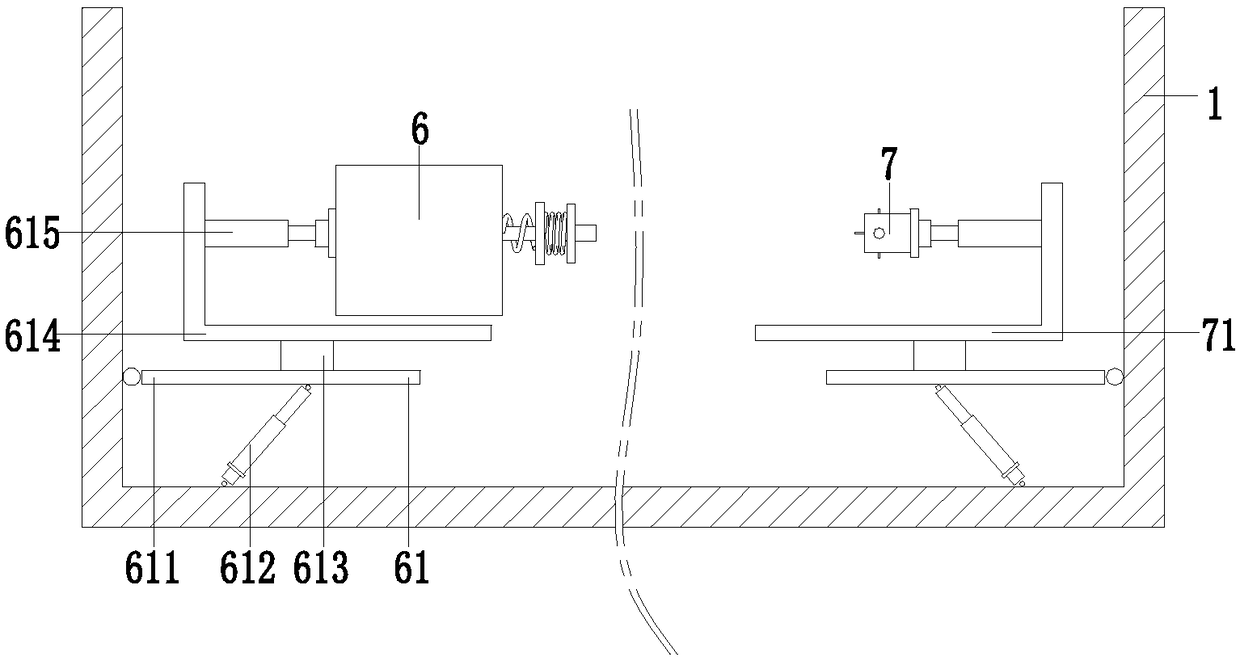

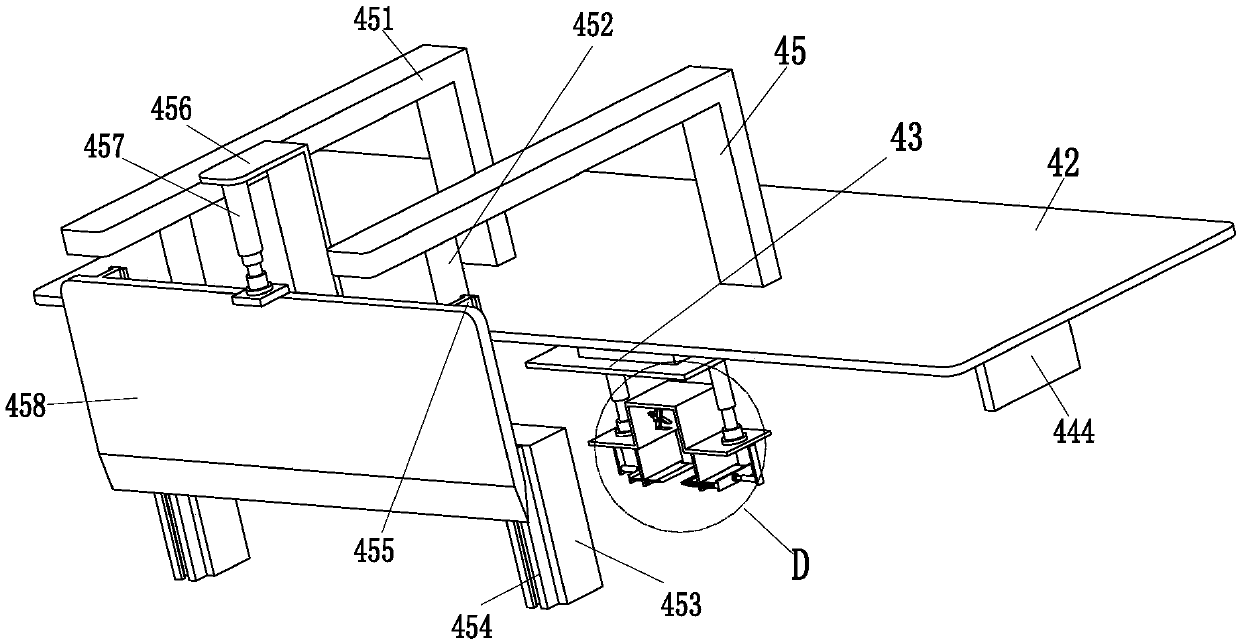

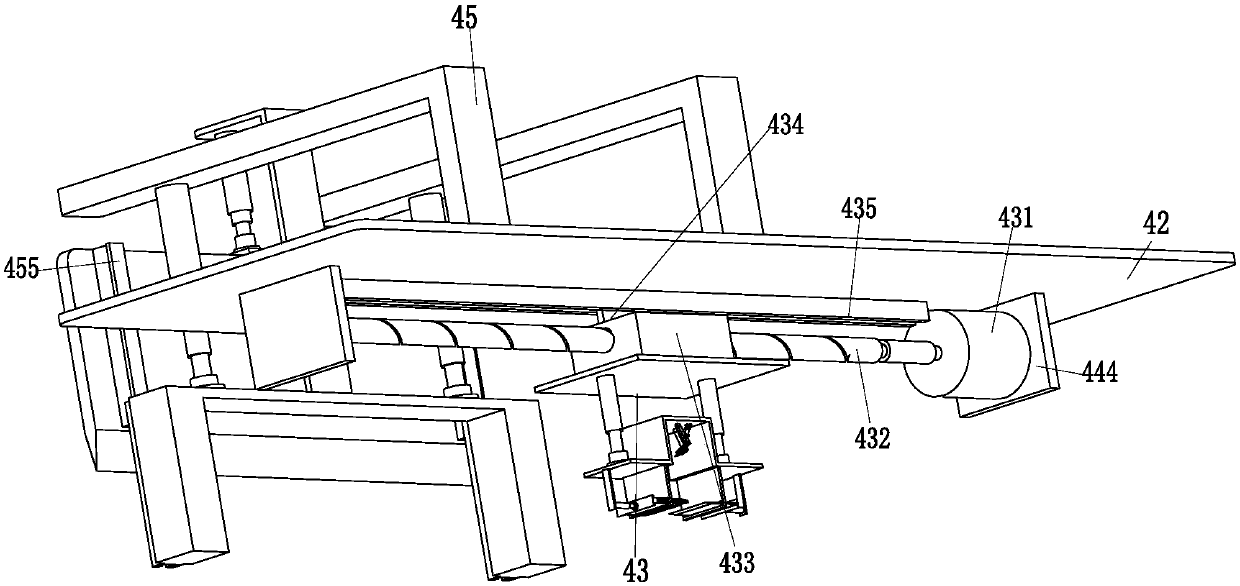

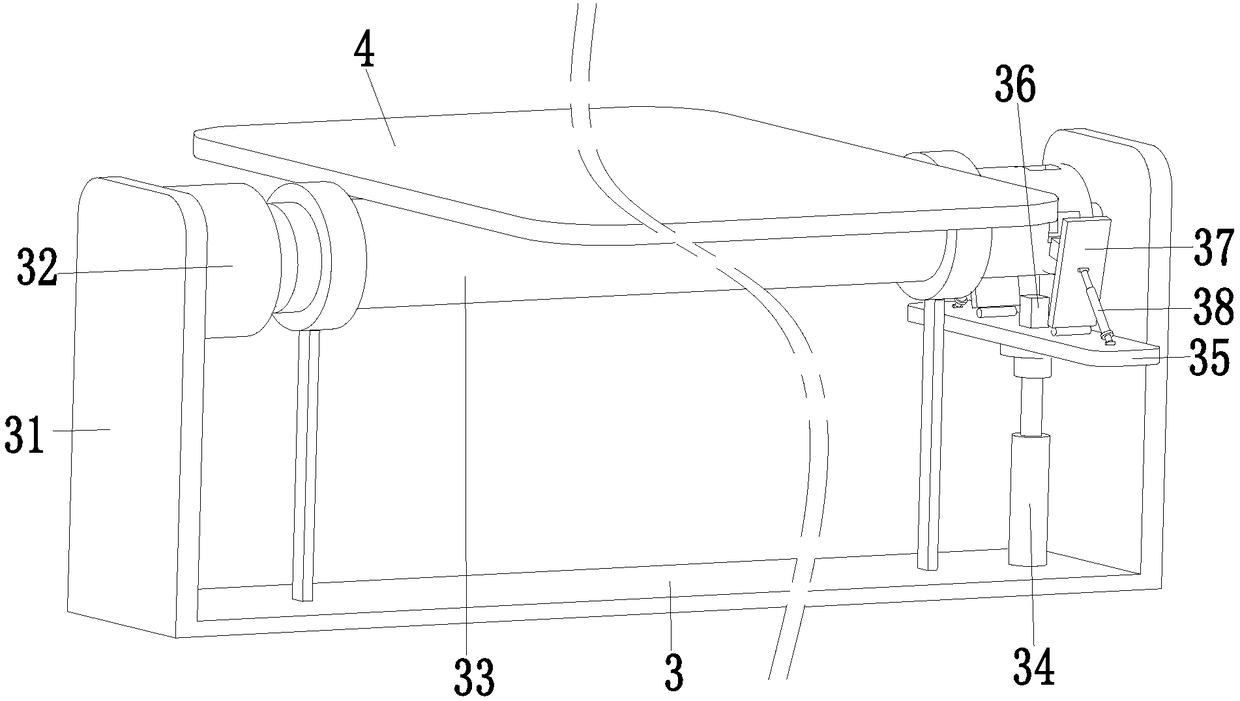

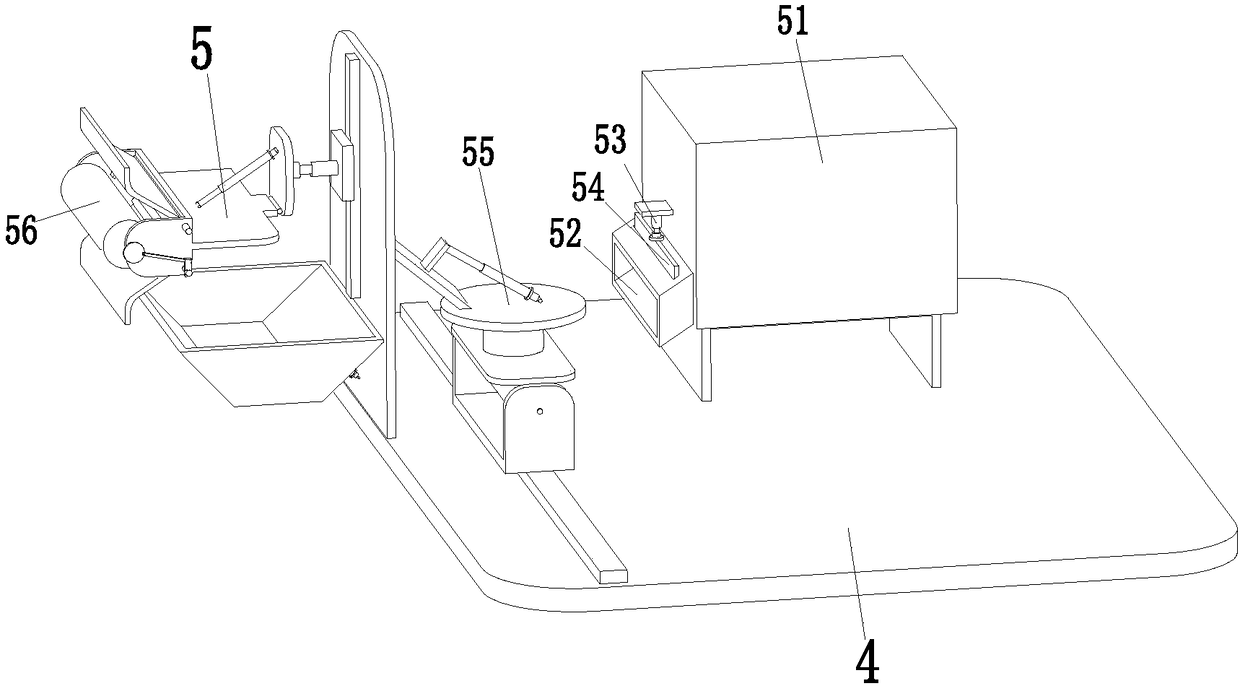

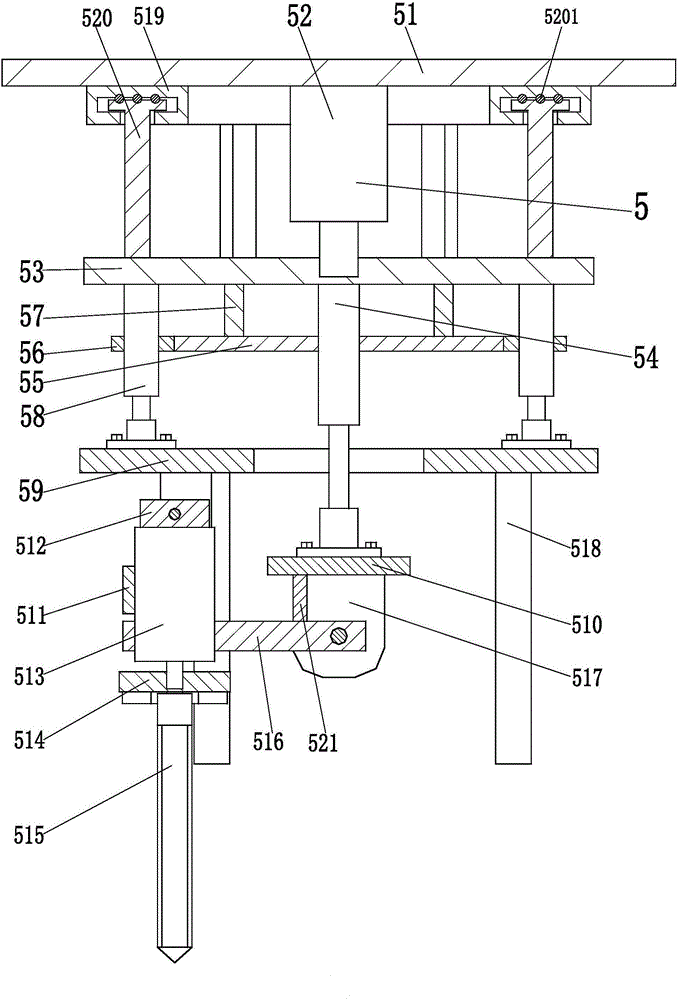

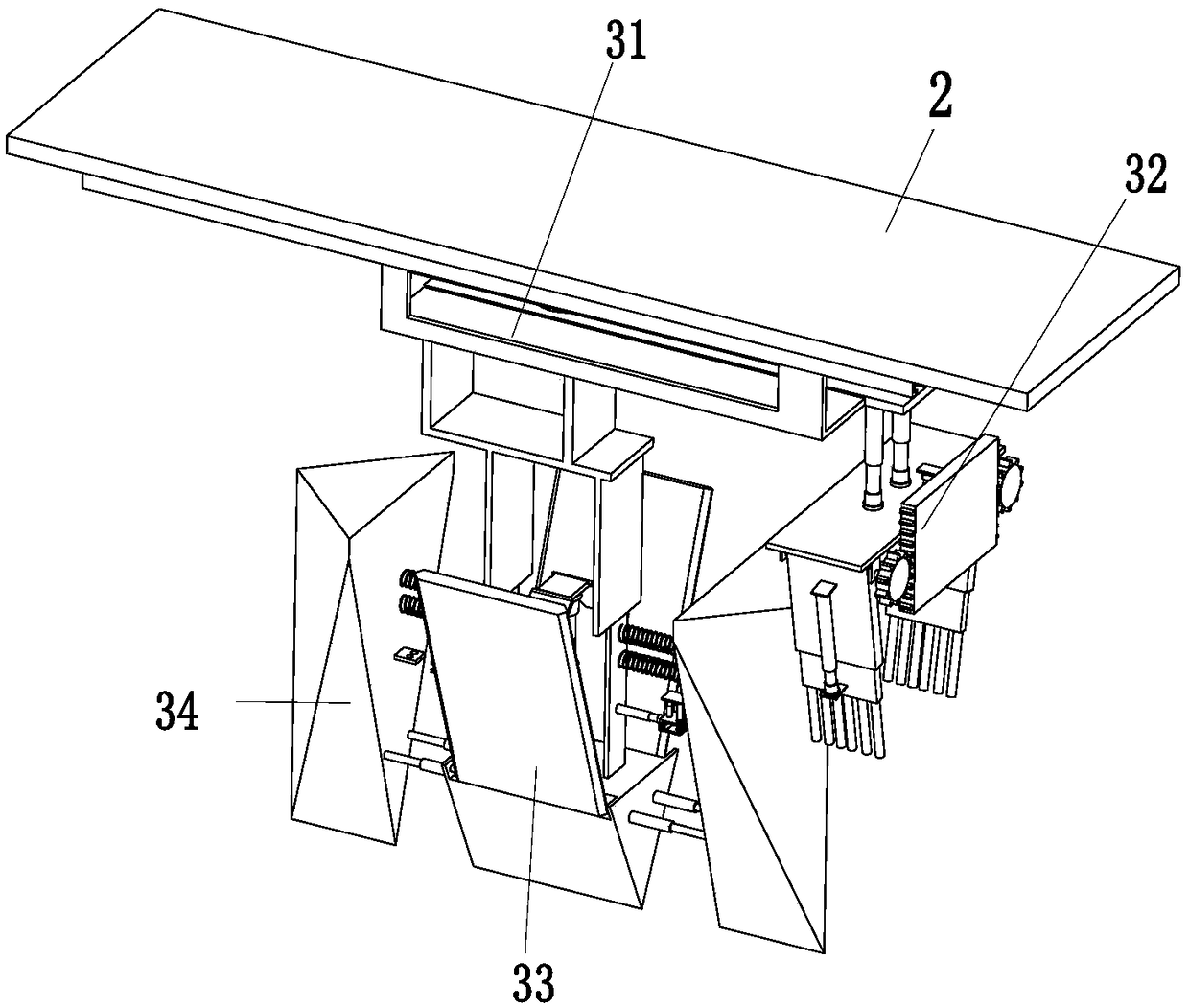

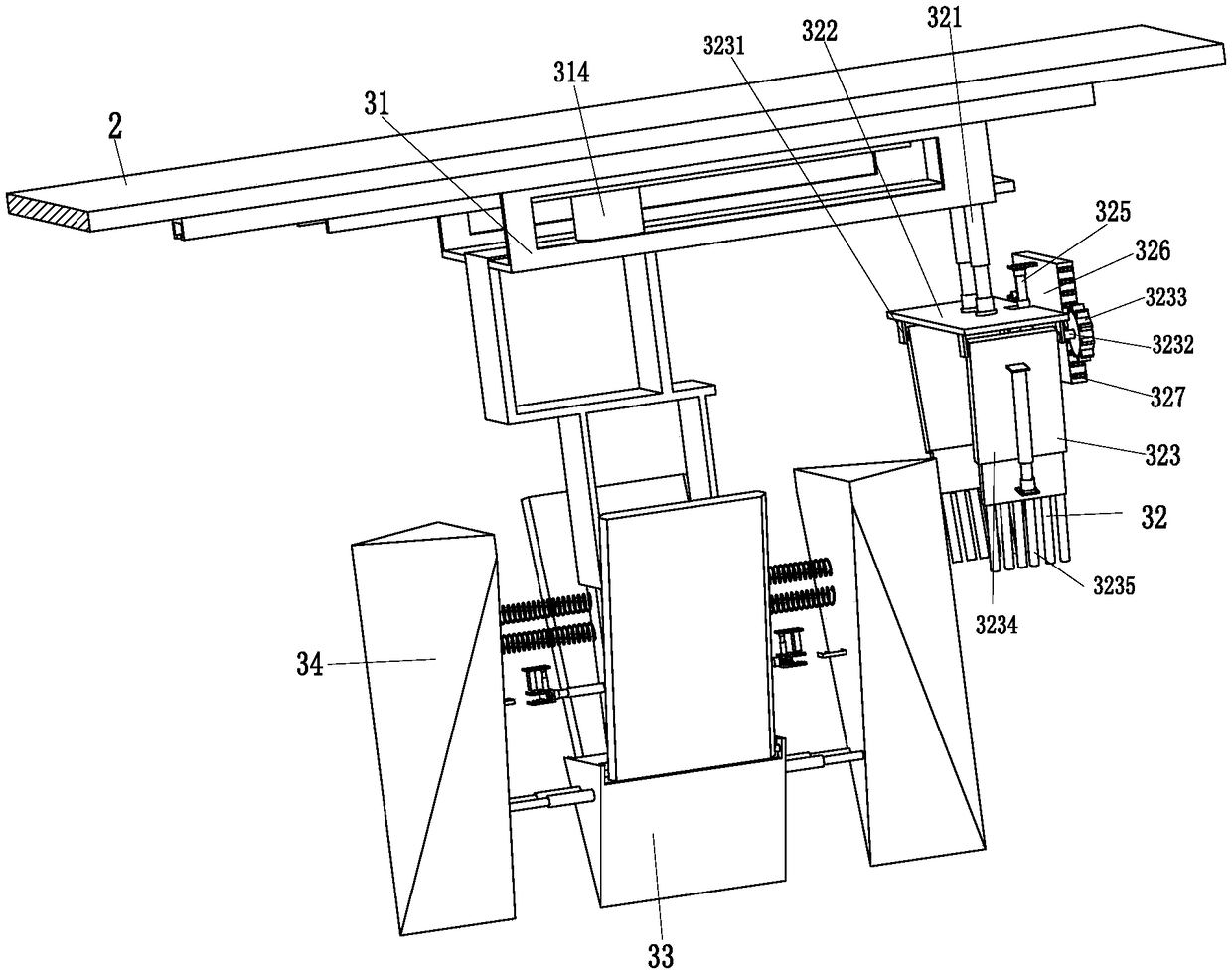

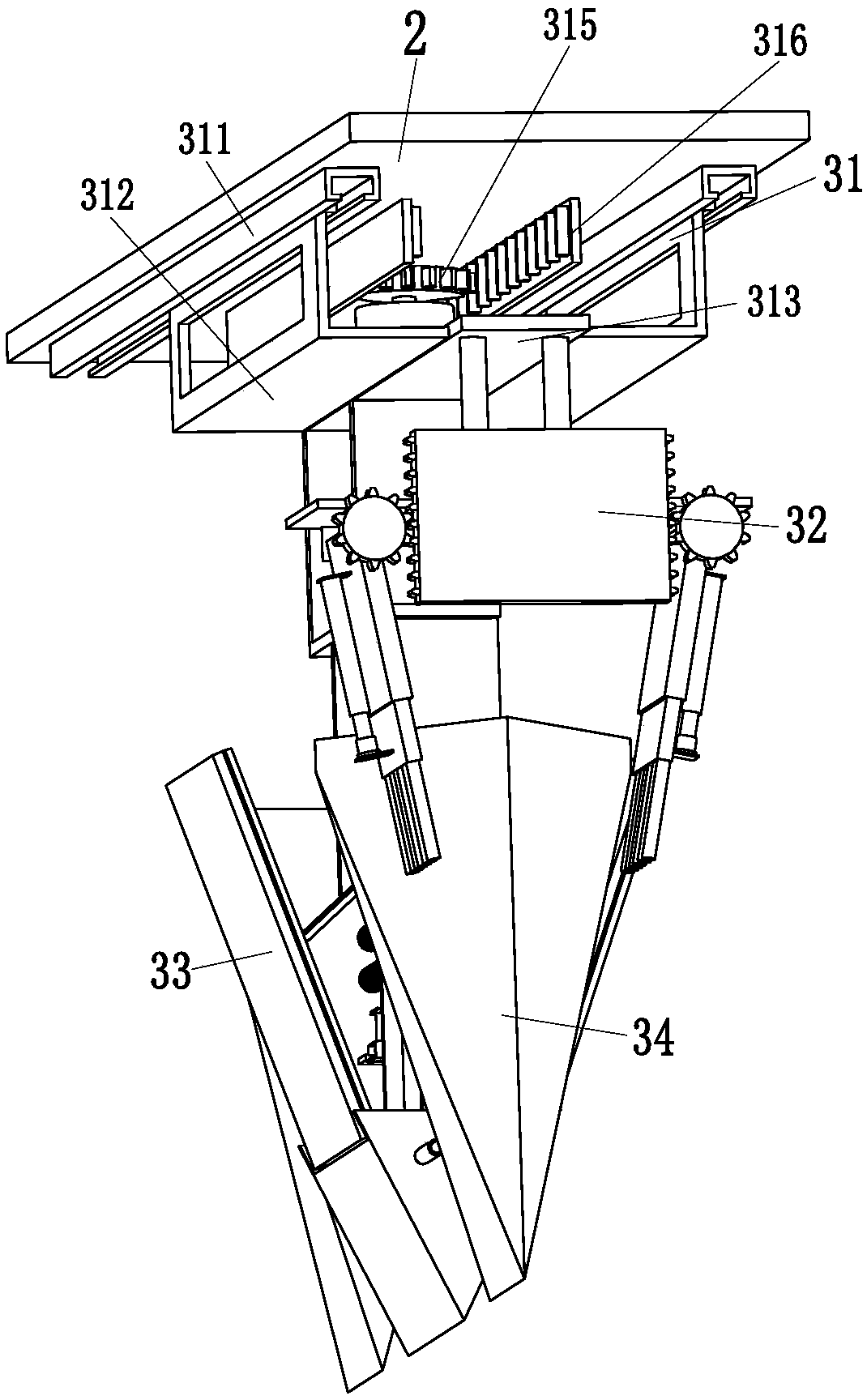

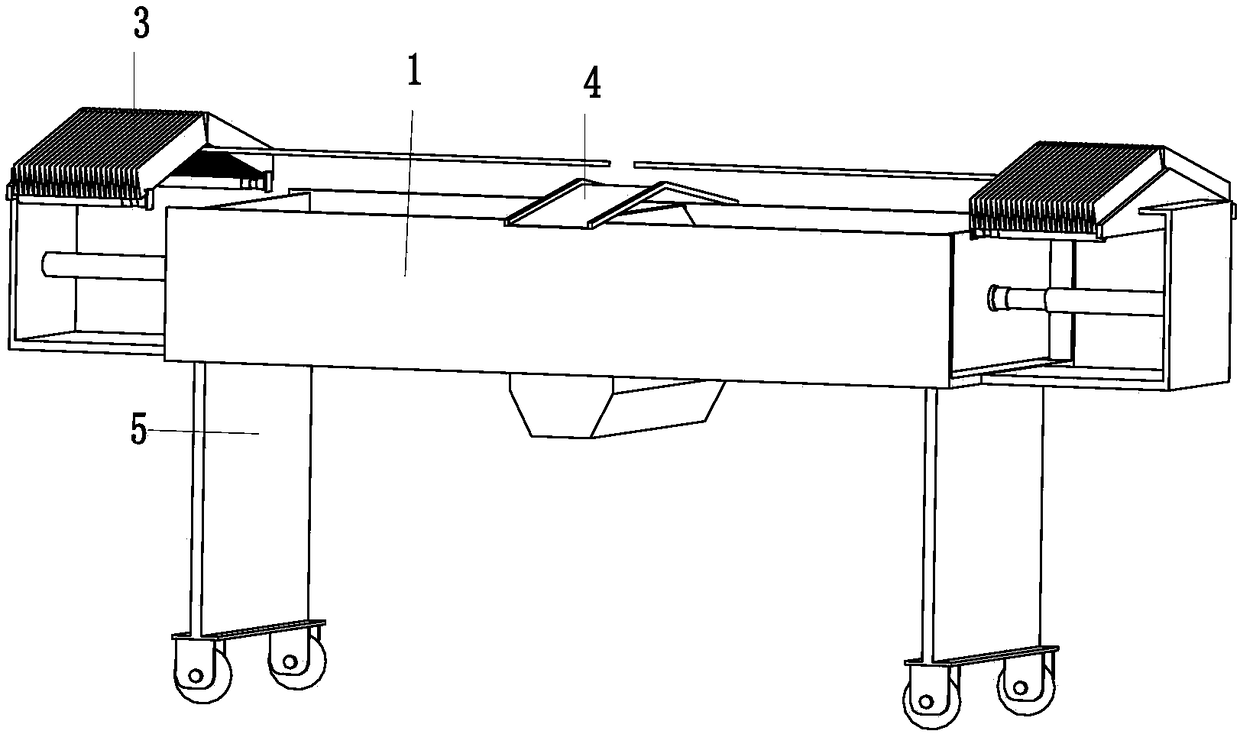

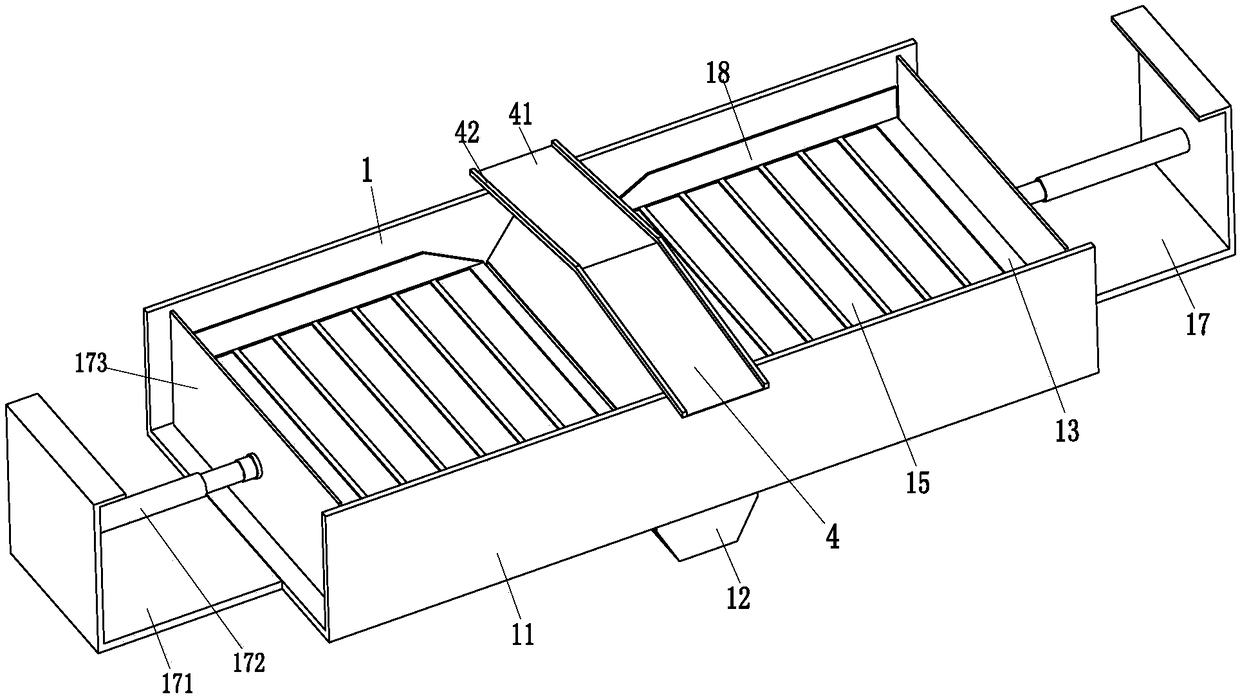

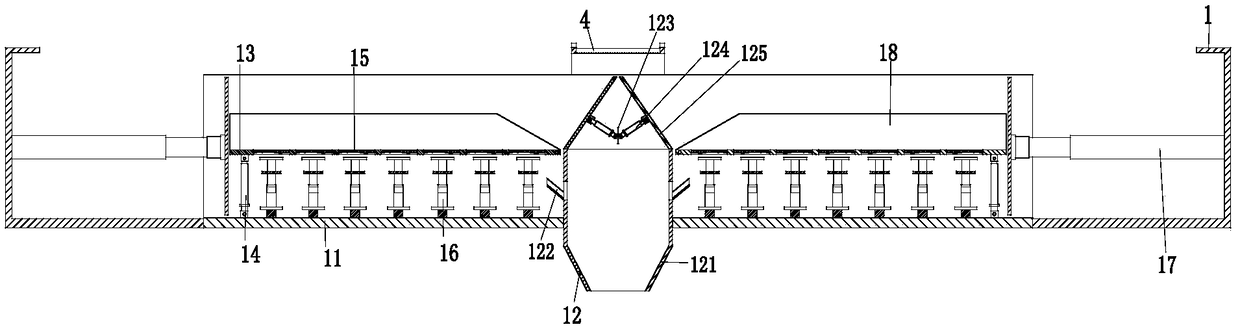

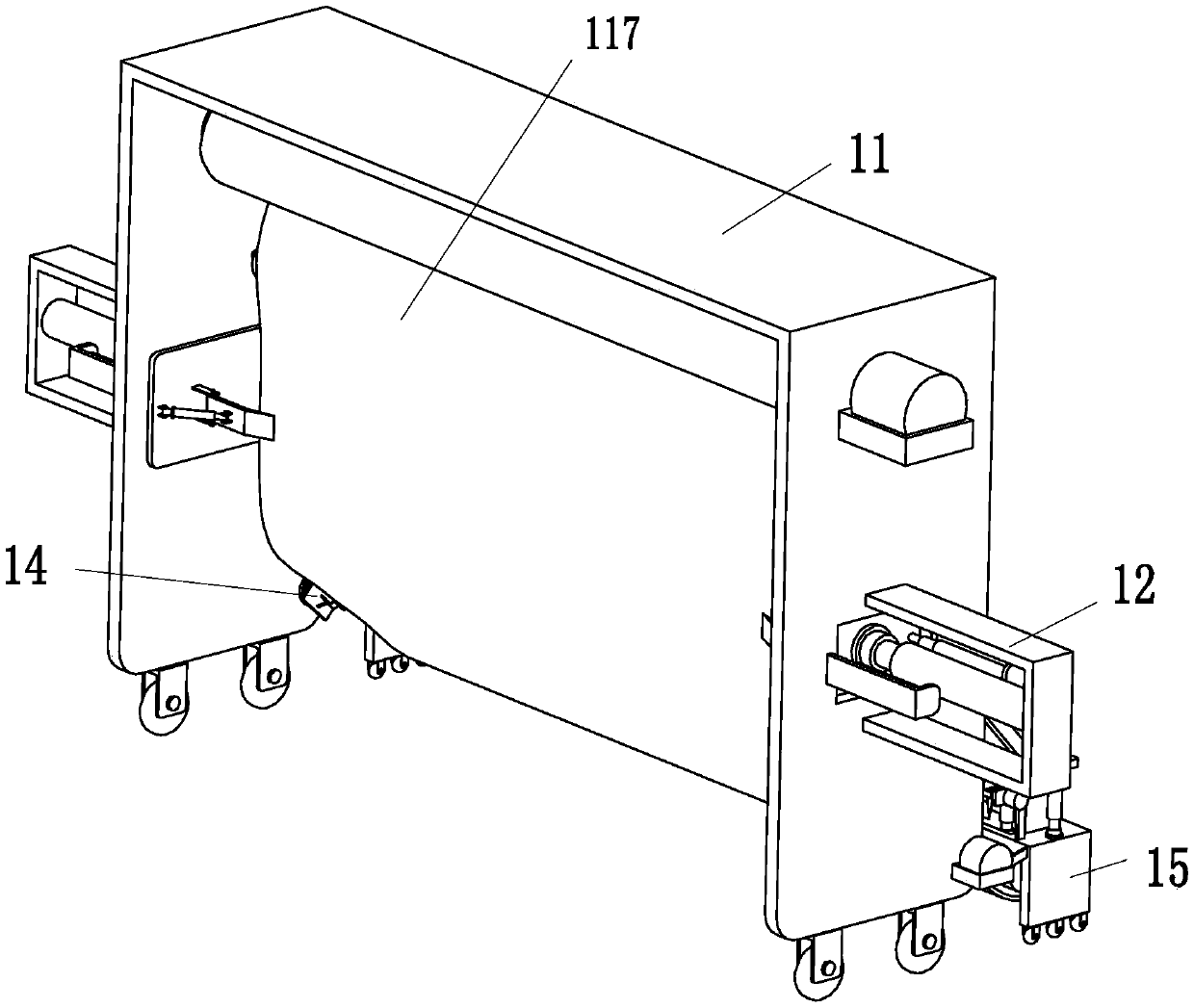

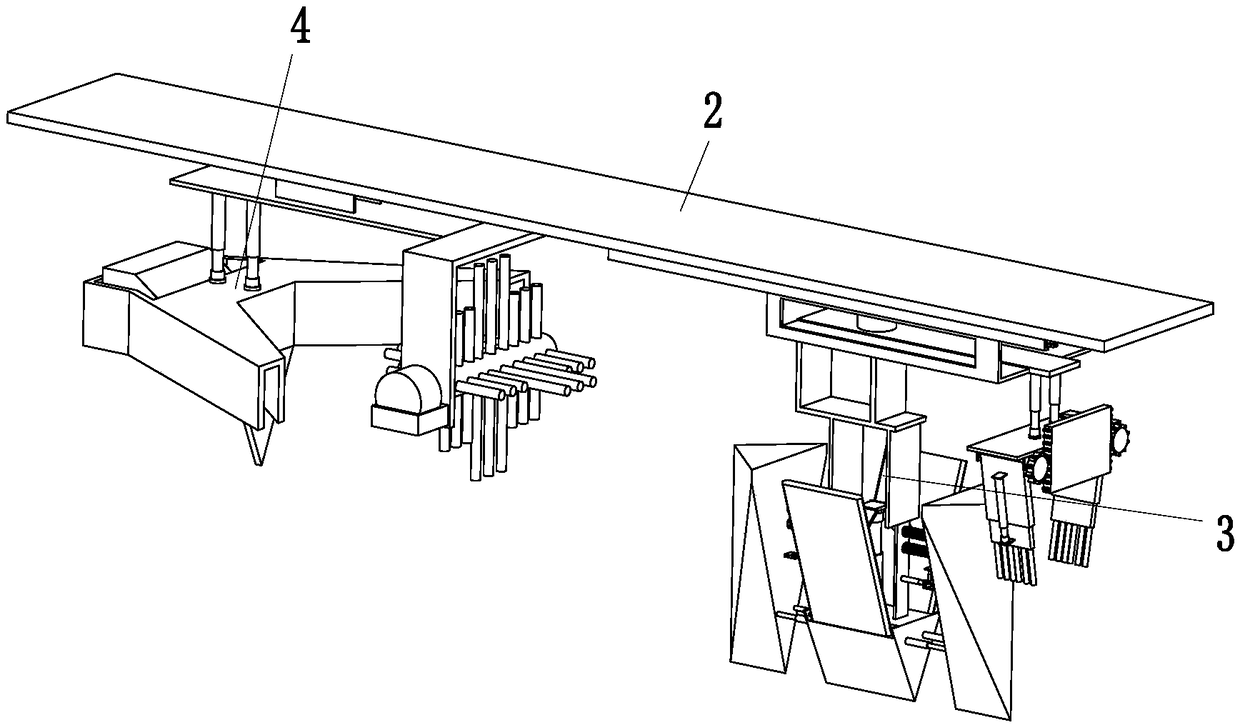

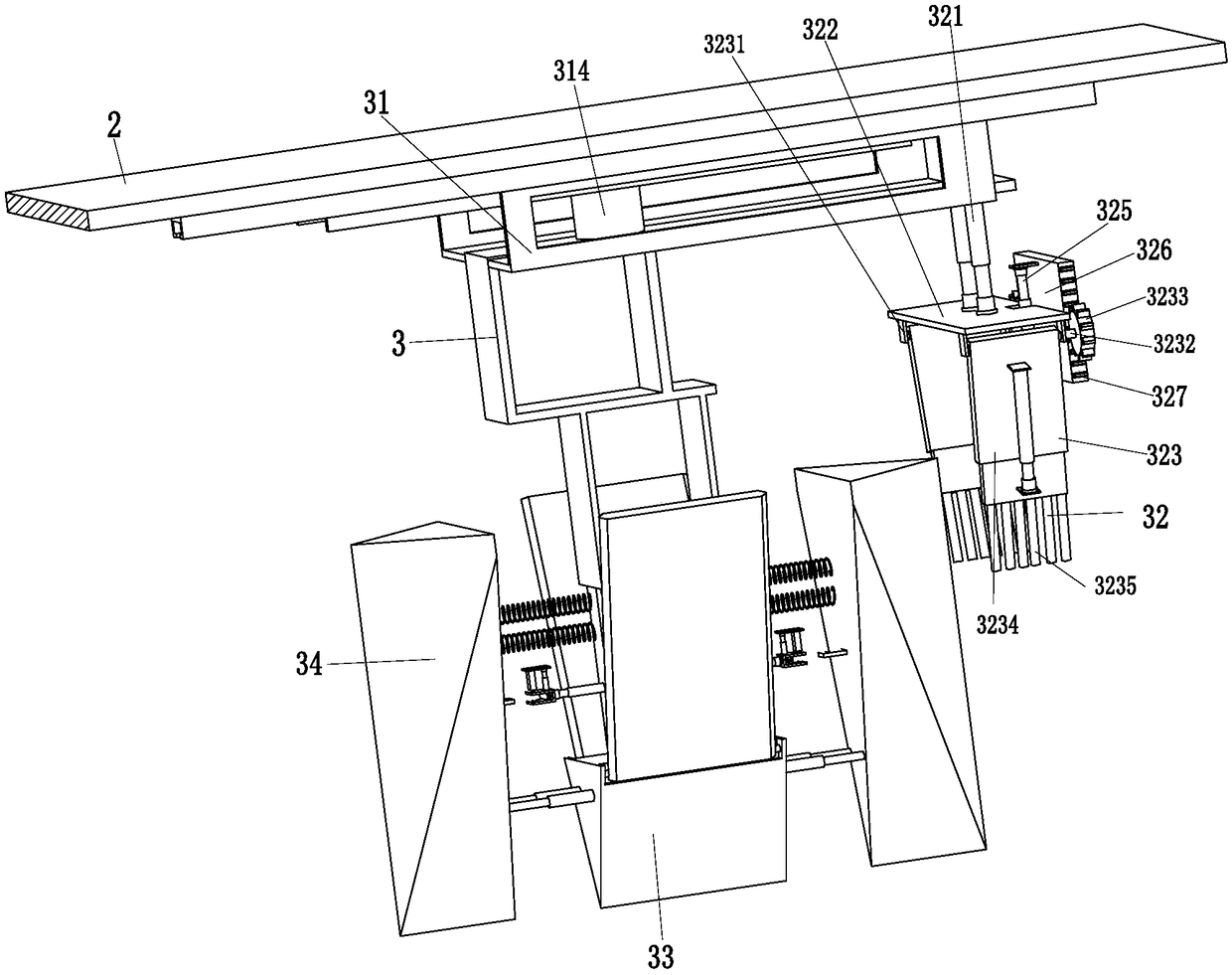

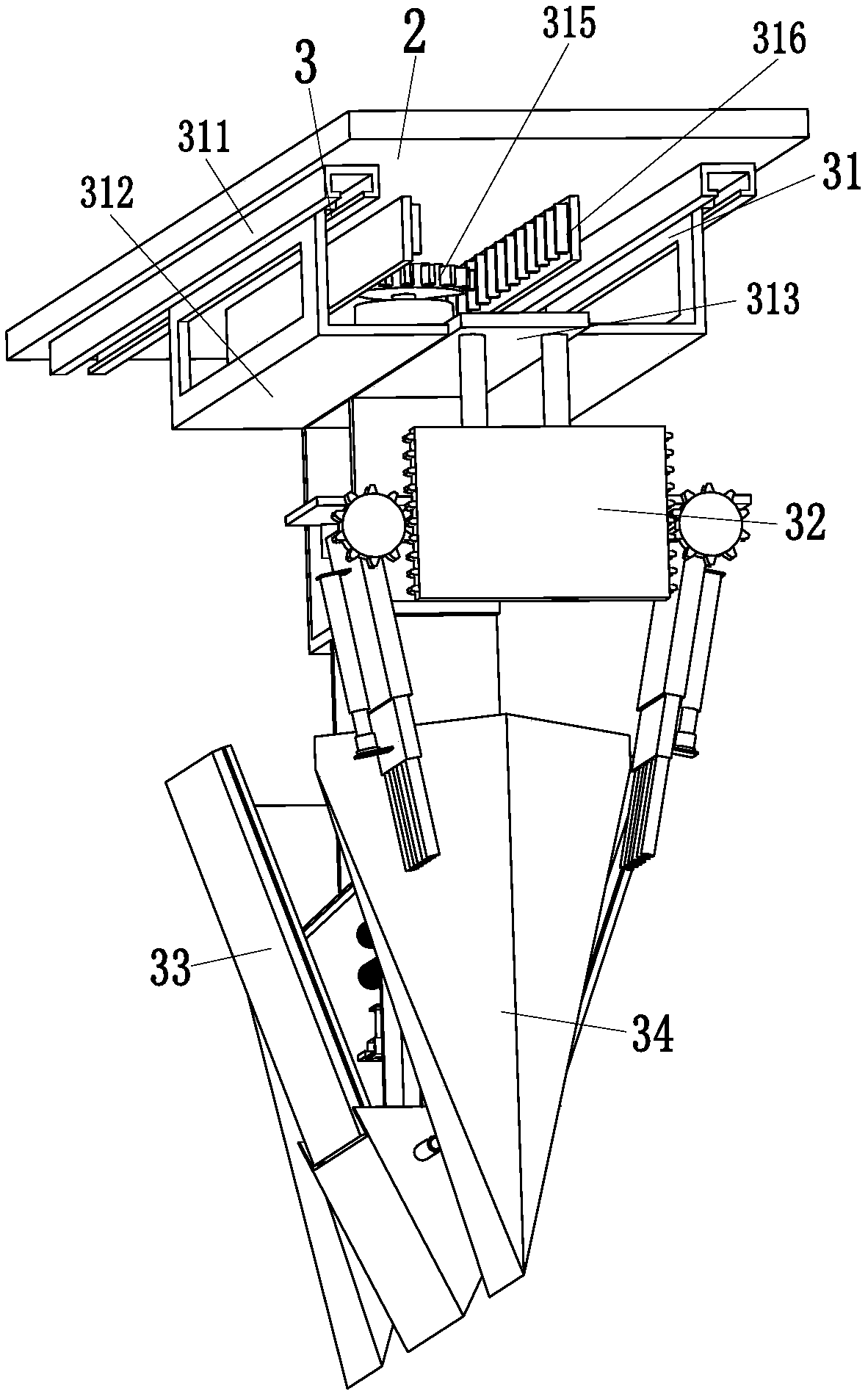

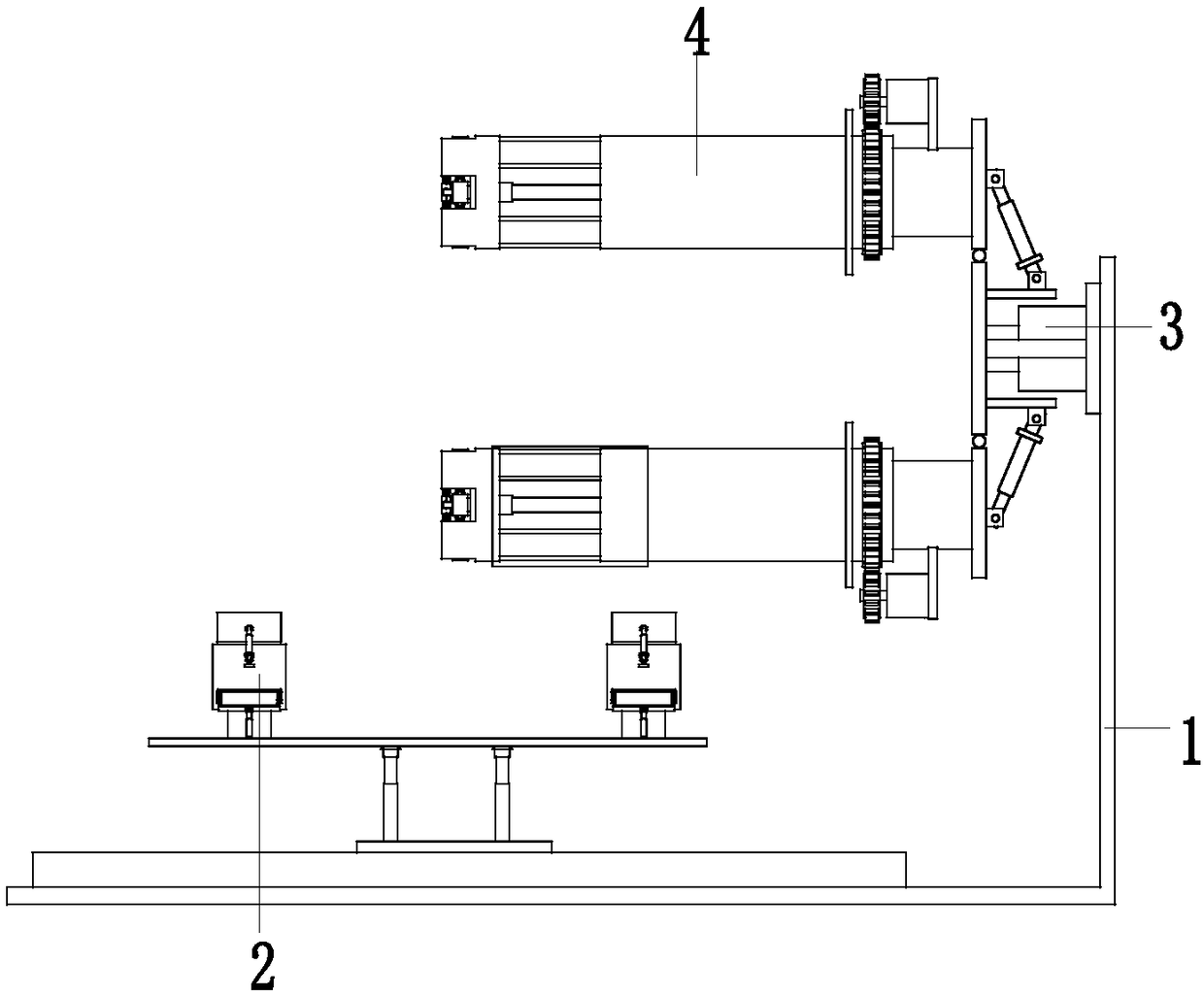

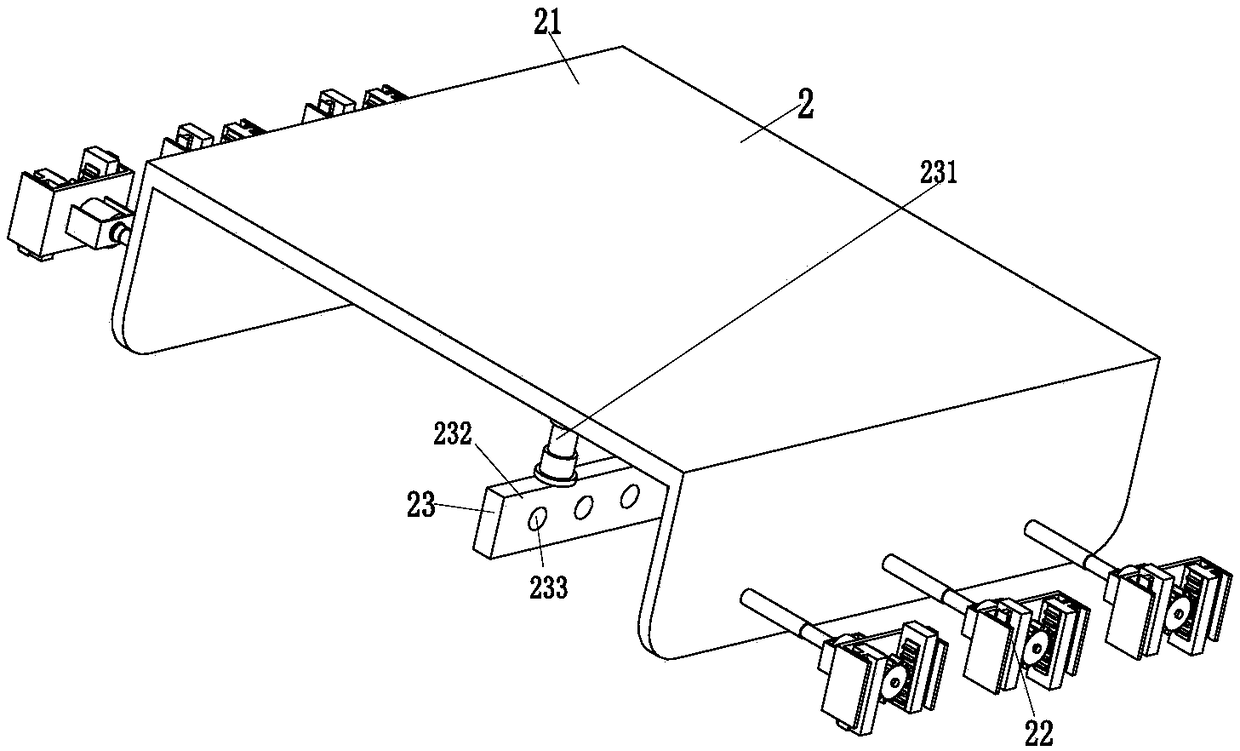

Tea sunshine-withering processing system and tea processing method of system

InactiveCN108782822APlay a limiting roleQuality is not affectedPre-extraction tea treatmentAgricultural engineeringTea leaf

The present invention relates to a tea sunshine-withering processing system and a tea processing method of the system. The system comprises a sunshine-withering device, two shielding devices, an auxiliary device and two moving brackets; the two moving brackets are arranged at the lower end of the sunshine-withering device; the two shielding devices are arranged at the left end and the right end ofthe sunshine-withering device; and the middle part of the upper end of the sunshine-withering device is provided with the auxiliary device. The system can solve the following problems: people need tolay sunshine-withering cloth on the ground during sunshine-withering in the prior art and then place fresh leaves on the cloth; the sunshine withering is not uniform; the fresh leaves need to be turned over by a plurality of people without timing; people cannot take back all the tea leaves when raining during the sunshine withering; meanwhile, rainwater is not easy to discharge, thereby causing tea leaf damping; the time consumed by the process is long; and the labor intensity is high, and the efficiency is low. The method can realize the functions of automatic over-turning sunshine witheringon tea leaves, rain blocking, drainage and centralized recovery.

Owner:陈妹儿

Building interior decoration-specialized intelligent masking tape applying device

The invention relates to a building interior decoration-specialized intelligent masking tape applying device. The building interior decoration-specialized intelligent masking tape applying device comprises a main body mechanism, two pull-back mechanisms, two clamping mechanisms and a compacting and cutting mechanism. The middle of the main body mechanism is provided with the two pull-back mechanisms which are symmetrically arranged; the lower end of the main body mechanism is provided with the two clamping mechanisms which are symmetrically arranged; the rear end of the main body mechanism isprovided with the compacting and cutting mechanism. The building interior decoration-specialized intelligent masking tape applying device can solve the problems that traditional seam beautifying operation is in a manual masking tape applying mode with complex processes, during masking tape application, workers who manually apply masking tapes fail to orderly apply the masking tapes along edges, and need to bend down for operation to result in body discomfort and potential risk; the workers need to cut the masking tapes with knives which possibly cut the hands; during operation, the masking tapes can possibly be wrinkled and the workers need to straighten the wrinkled masking tapes before continuing operation to result in long time consumption, high labor intensity, low efficiency and the like.

Owner:刘秀娟

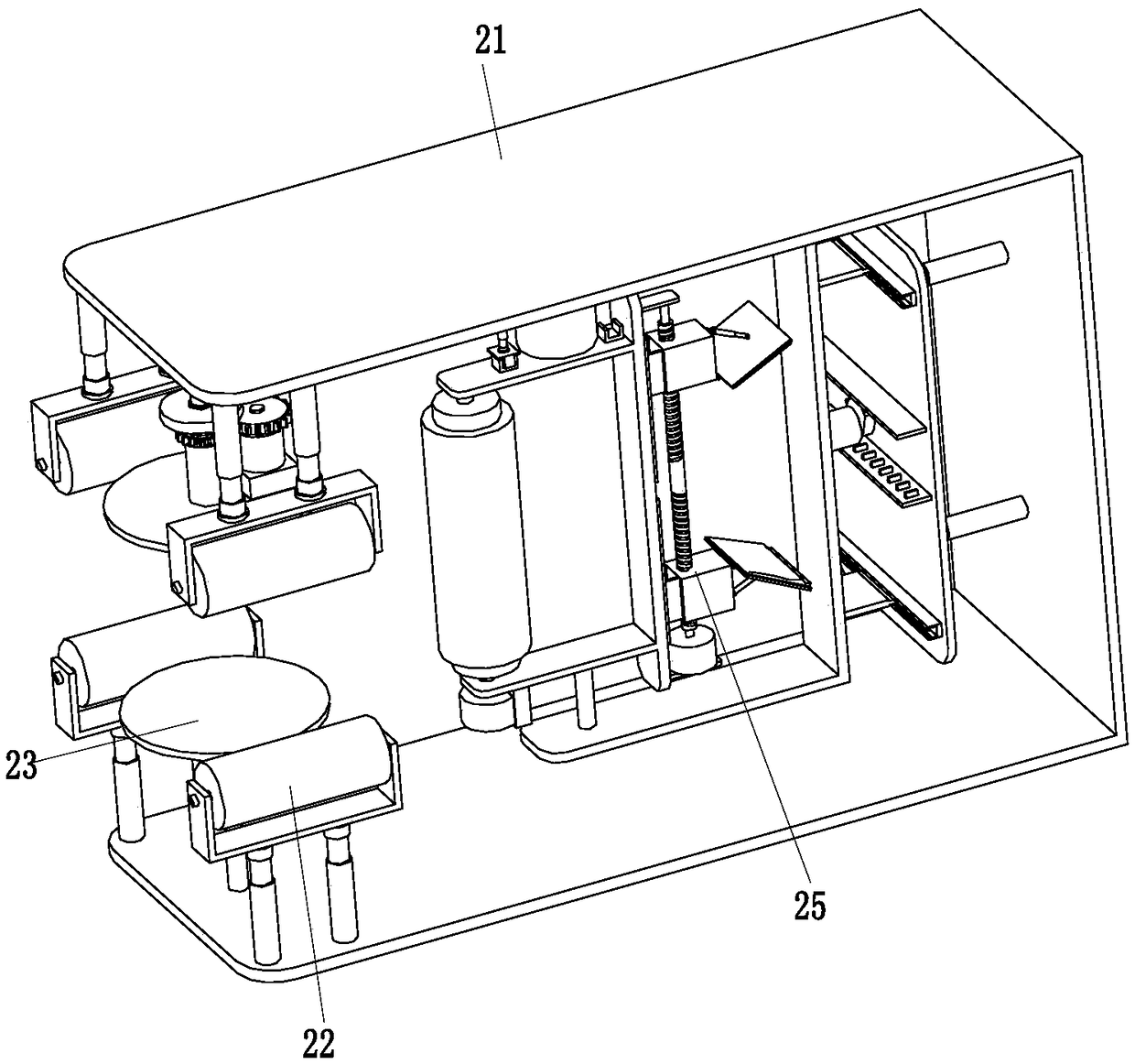

Power distribution cabinet assembling machine

ActiveCN108581448ANo drop phenomenonNo manual operationMetal working apparatusDual purposeEngineering

The invention relates to a power distribution cabinet assembling machine which comprises an adjusting device and a dual-purpose limiting device, wherein the dual-purpose limiting device is mounted atthe lower end of the adjusting device. The power distribution cabinet assembling machine provided by the invention can solve the problems that when screws are mounted on the power distribution cabinetat present, the screws need to be screwed up with corresponding screw drivers, the screws are commonly placed in work holes if being mounted, personnel screws up and mount the screws by means of tools then, as the screws are small, the screws may fall if being mounted manually, and when hex screws of different specifications are mounted, personnel works by means of corresponding tools, the consumed time in the process is long, the labor intensity is great and the efficiency is low and the like. The power distribution cabinet assembling machine can achieve a function of limiting the hex screwsof different specifications in a targeted manner without mounting the screws manually, so that the condition that the screws fall is avoided, the consumed time is short, and the power distribution cabinet assembling machine has the advantages of being simple to operate, small in labor intensity, high in work efficiency and the like.

Owner:东营胜华科贸有限公司

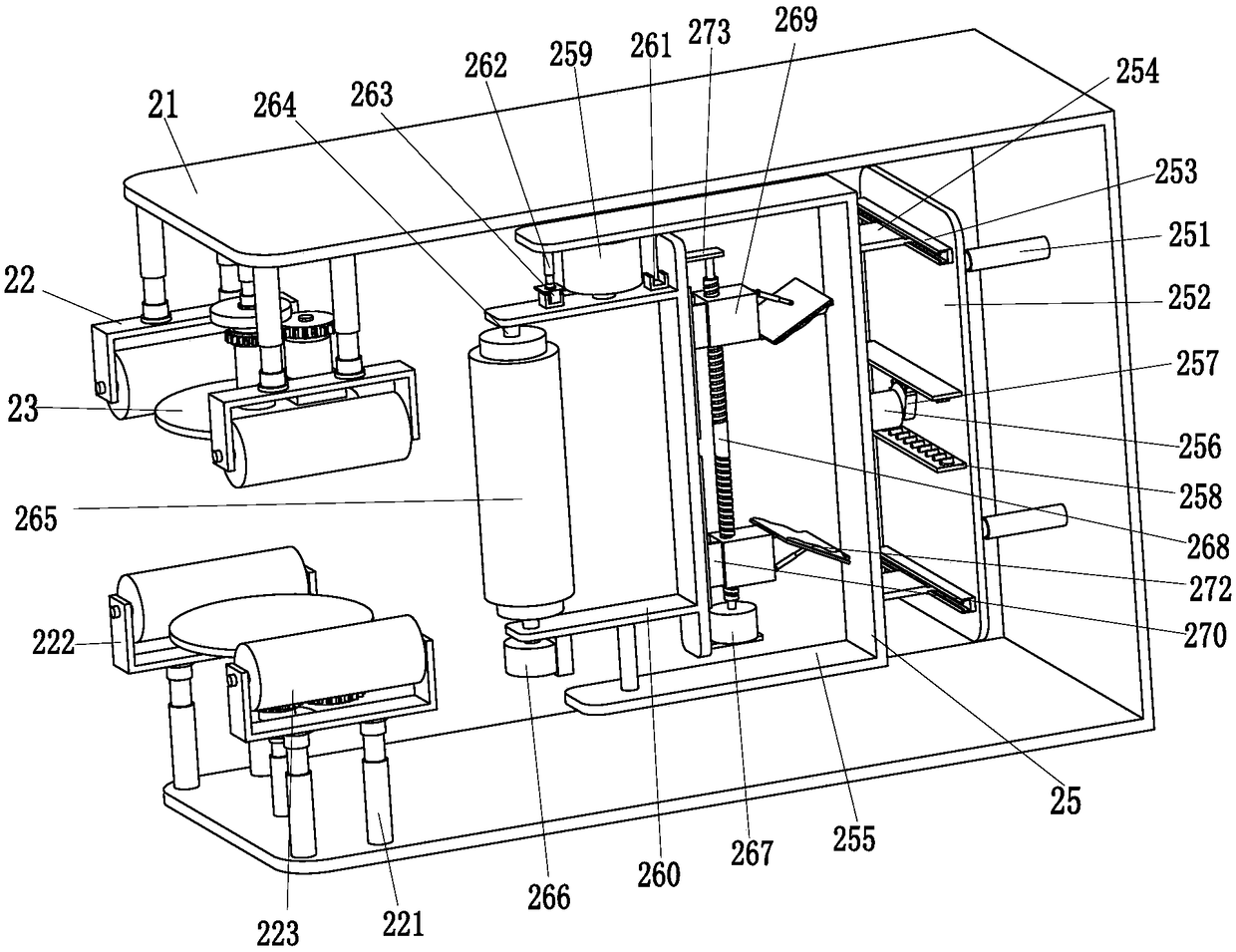

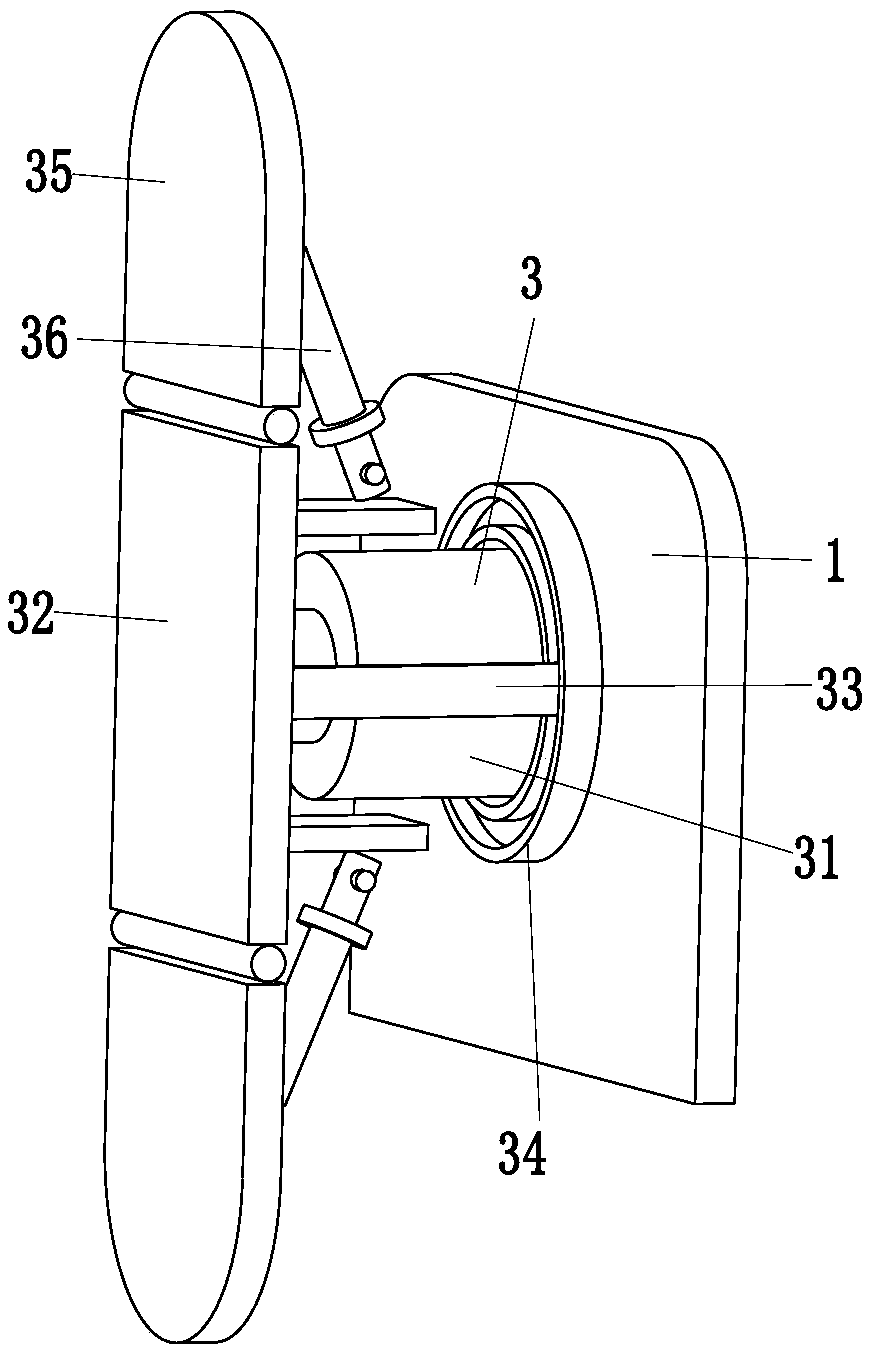

Power supply overhead cable surface detection damage repair device

ActiveCN113533367ALess detectableLow labor intensityMaterial analysis by optical meansDamage repairMechanical engineering

The invention discloses a power supply overhead cable surface detection damage repair device, and belongs to the technical field of overhead cable maintenance. The power supply overhead cable surface detection damage repair device comprises a box body, a detection mechanism and a repair mechanism, the box body is hollow, and two opposite ends of the box body in the length direction are respectively provided with a penetration hole and a penetration hole; the cable is inserted into the box body from the penetrating-in hole and penetrates out of the box body from the penetrating-out hole, the detection mechanism is arranged in the box body, is close to the penetrating-in hole and is used for carrying out visual detection on the damaged part of the circumferential surface of the penetrating-in cable, and the detection mechanism is connected with a visual detection system arranged on the outer wall of the box body. The detection mechanism sends out an alarm signal after detecting the damaged part of the cable, the repairing mechanism is arranged in the box body, is close to the penetrating-out hole and is used for receiving the cable output by the detection mechanism and repairing the damaged part of the cable, and the repaired cable penetrates out of the penetrating-out hole. The repair device has the beneficial effects that the labor intensity of cable damage detection and repair is low, automatic detection and repair can be realized, and time and labor are saved.

Owner:国网河北省电力有限公司涉县供电分公司 +2

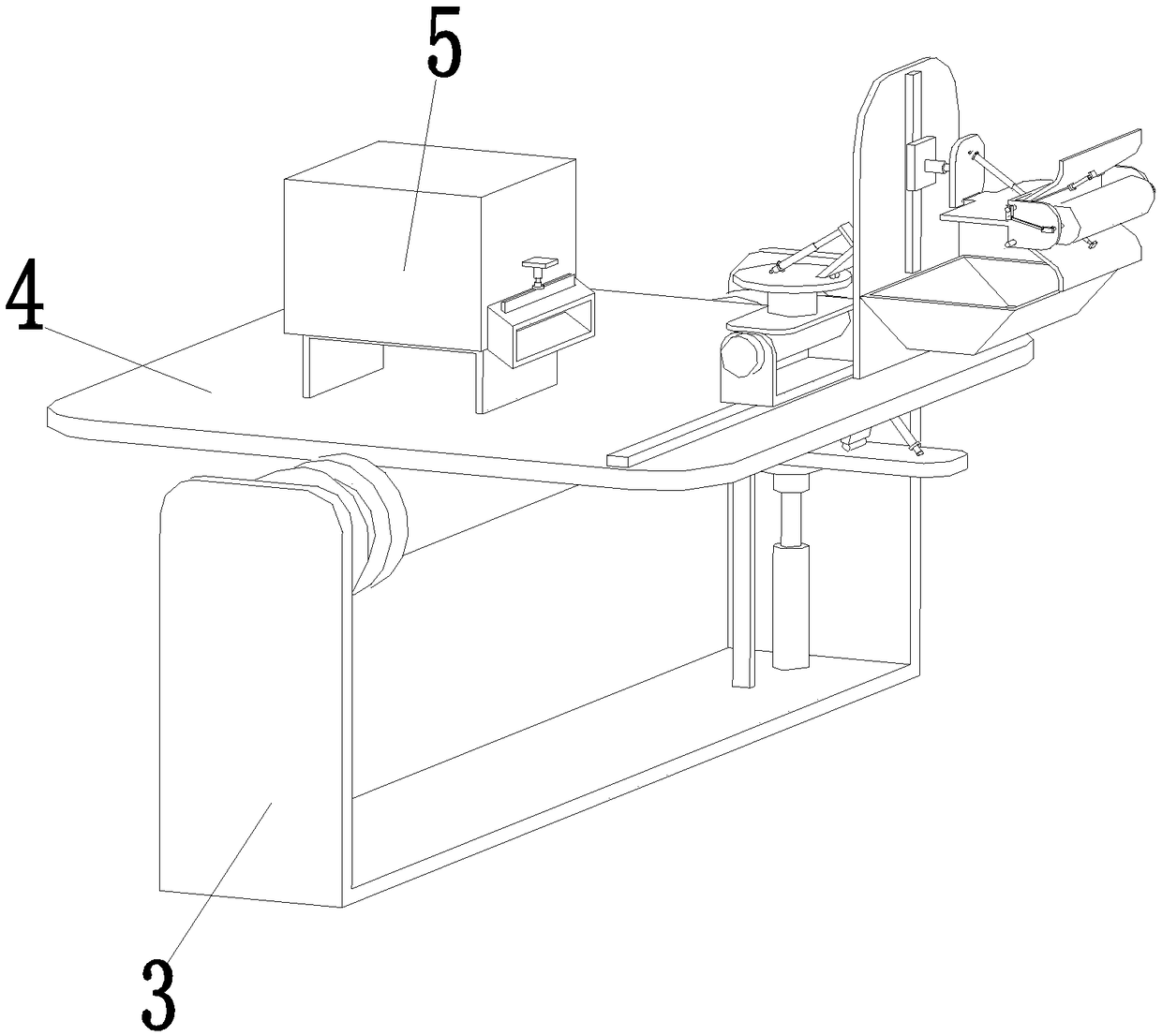

Aluminum plastic plate automatic machining robot

ActiveCN109047928AExtend your lifePlay a buffering effectFeeding apparatusMaintainance and safety accessoriesMachiningMotherboard

The invention relates to an aluminum plastic plate automatic machining robot which comprises a main plate, a grooving device and a chip removal device. The grooving device is mounted at the right endof the main plate, and the chip removal device is mounted at the left end of the main plate. The aluminum plastic plate automatic machining robot can solve the problems that manual grooving is neededin the grooving process of an existing aluminum plastic plate, when grooving is started, a grooving knife directly grooves the aluminum plastic plate, consequently the life of the knife is prone to being affected, parts of grooves are not completely formed during manual grooving, chips are stacked on the two sides of the grooves to affect the working progress during grooving, an original positionis prone to being deviated during manual grooving, the chips generated after grooving are not cleared in time, consequently the consumed time is long, the labor intensity is large, and the efficiencyis low; and the functions of automatic grooving and chip collecting for the aluminum plastic plate can be achieved.

Owner:任丘市华泰铝业有限公司

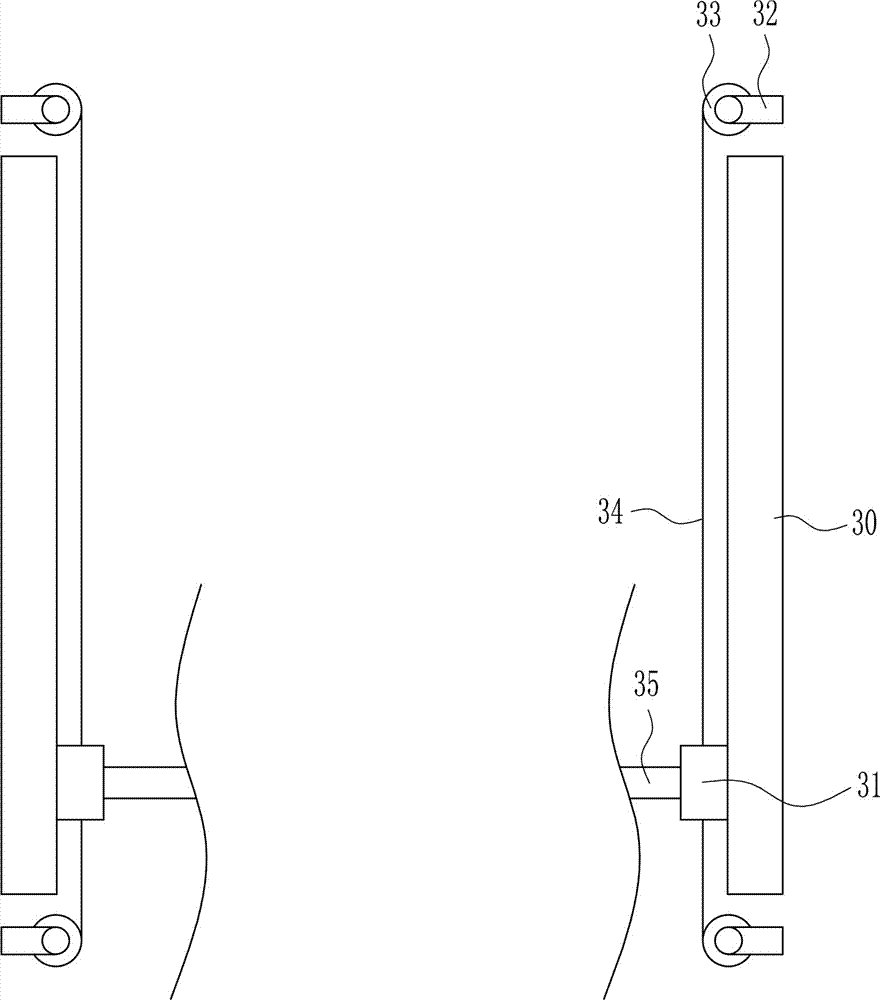

Full-automatic yarn feeding device of hank-mercerizing machine

The invention relates to a full-automatic yarn feeding device of a hank-mercerizing machine. The full-automatic yarn feeding device comprises a fixing rack, a conveying mechanism, an adjusting mechanism and two yarn feeding mechanisms, wherein the lower end of the fixing rack is provided with the conveying mechanism, the upper end of the fixing rack is provided with the adjusting mechanism, and the upper end and the lower end of the adjusting mechanism are provided with the two yarn feeding mechanisms. The problem can be solved that an existing hank-mercerizing machine needs manual yarn feeding performed by workers during yarn feeding, the workers need to stay beside the device for a long time for work and are possibly contaminated by harmful substances such as mercerizing liquid during long-time short-distance work, the bodies of the workers are harmed, the consumed time is long, the labor intensity is high and the working efficiency is low, yarn feeding and discharging functions of the hank-mercerizing machine can be achieved, automatic yarn feeding and discharging do not need long-time short-distance work performed by the workers, the safety of the workers is ensured, the consumed time is short, the labor intensity is low and the working efficiency is improved.

Owner:ZHEJIANG JINMA AUTOMATION TECH CO LTD

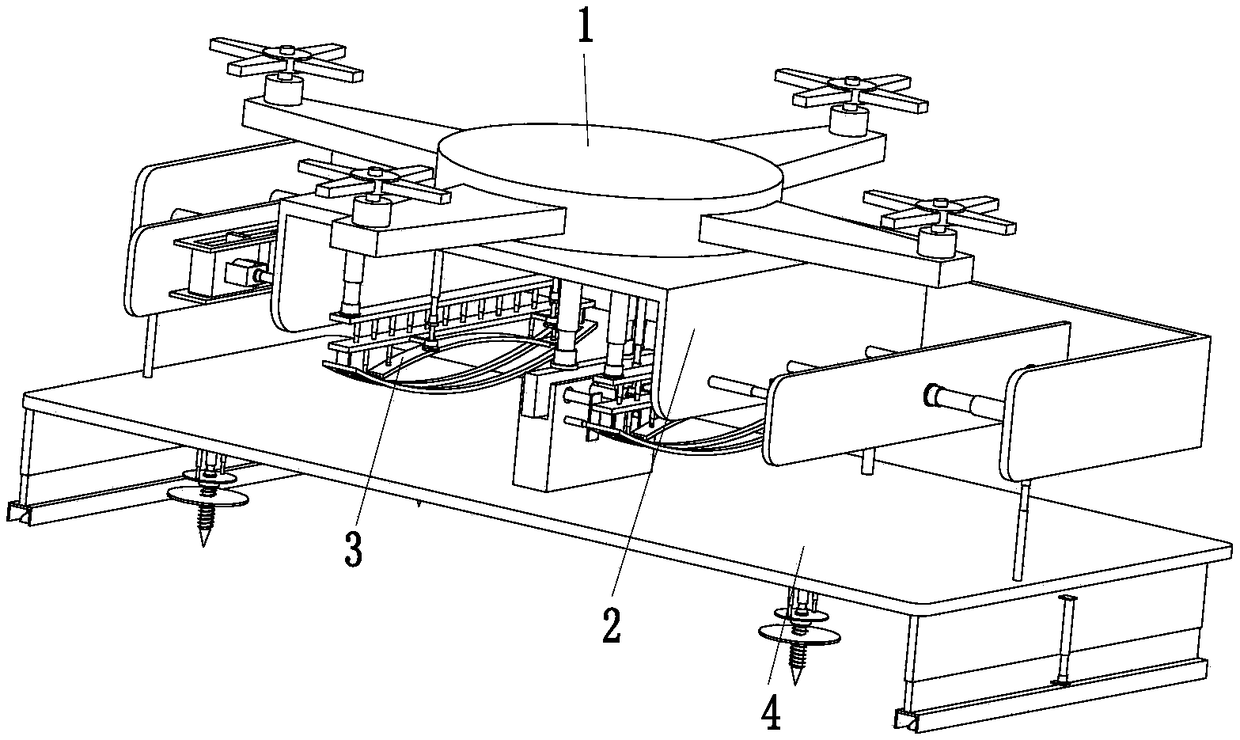

An intelligent takeoff and landing platform of an unmanned aerial vehicle

The invention relates to an intelligent take-off and landing platform of an unmanned aerial vehicle, which comprises an airframe, a parking device, two temporary landing devices and a landing platformdevice, wherein the parking device is arranged above the landing platform device, the two temporary landing devices are installed at the lower end of the parking device, the two temporary landing devices are located above the landing platform device, and the airframe is installed at the upper end of the parking device. The problems that as the exist unmanned aerial vehicle landing, uncorrected operation prevents the UAV from landing exactly where it was intended, existing landing platforms are usually placed directly on the ground, the placement is instable, when the UAV falls to the ground due to the fault in the flight process, the UAV itself will be damaged by impact due to the different terrain, the process takes a long time, the labor intensity is large and the efficiency is low canbe solved, and the functions of taking off and landing the UAV steadily and reducing the impact damage in the emergency landing are realized.

Owner:北京腾益电力科技有限公司

Tea tree trimming device

InactiveCN106358782AAddress operational complexitySolve the labor intensity of operationCuttersCutting implementsHydraulic cylinderEngineering

The invention relates to a tea tree trimming device which comprises a base plate. An adjusting plate is installed on the upper end face of the base plate through a hinge, first lug bases are installed at the left end of the adjusting plate, a first hydraulic cylinder is installed between the first lug bases, a second lug base is installed at the bottom end of the first hydraulic cylinder through a pin shaft and installed on the base plate and drives the adjusting plate to rotate on the base plate through the first hydraulic cylinder, a triangular inclined plate is welded to the right end of the adjusting plate, a second hydraulic cylinder is installed on the triangular inclined plate, the middle of the second hydraulic cylinder is fixed to a positioning frame, the lower end of the positioning frame is installed on the triangular inclined plate, a flange is installed at the top end of the second hydraulic cylinder through a thread, a motor supporting plate is installed on the flange through a screw, and the flange has an effect of connecting the motor supporting plate and the second hydraulic cylinder. The tea tree trimming device can achieve a function of quickly trimming tea leaves and is simple and convenient to operate, small in labor intensity, short in trimming time and high in working efficiency.

Owner:岳西县思民生态农业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com