Patents

Literature

40results about How to "Realize the function of automatic cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

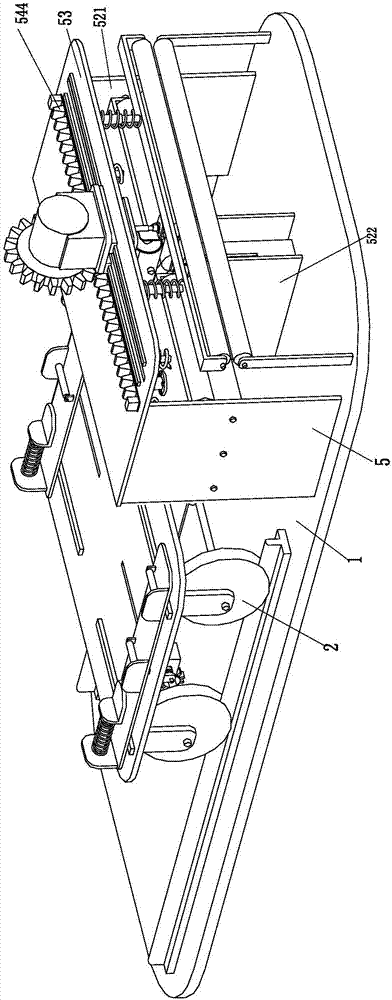

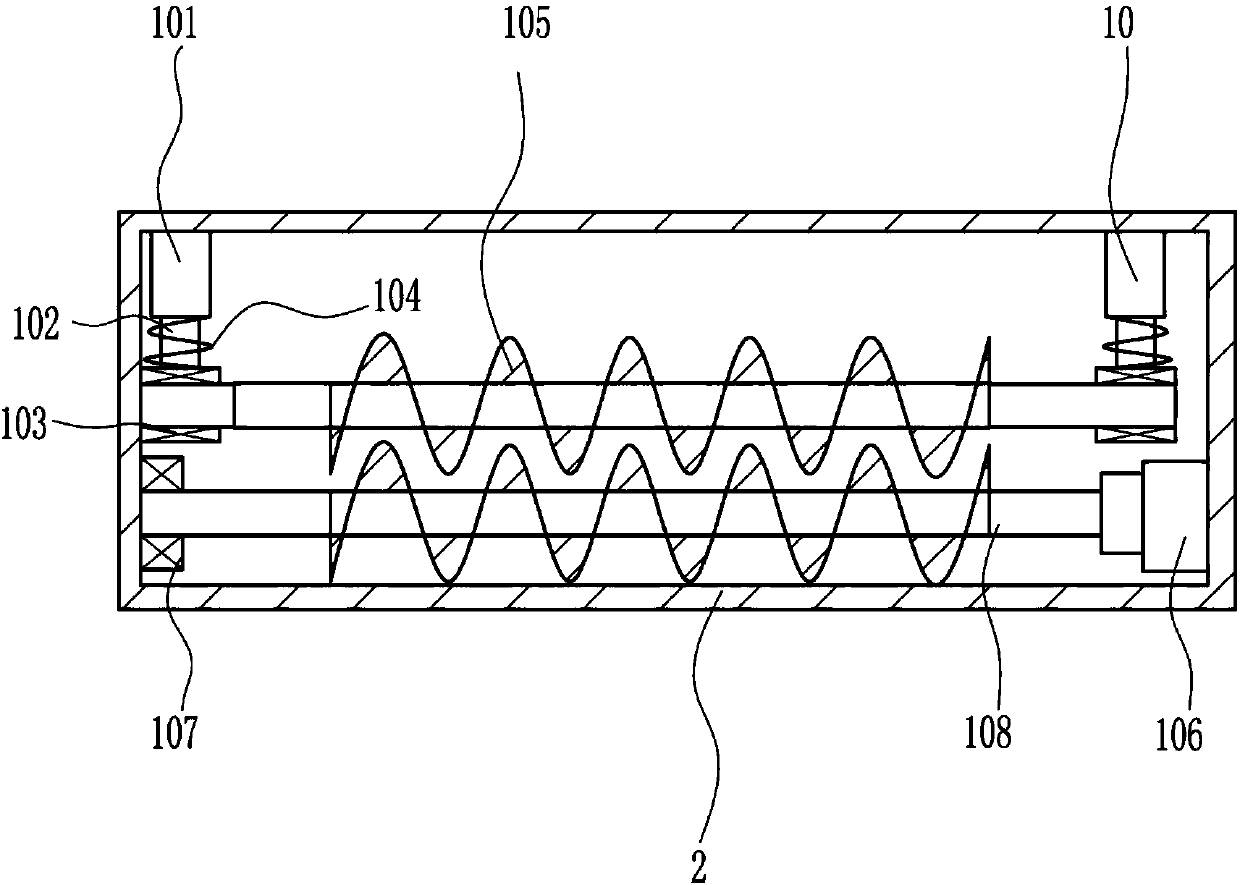

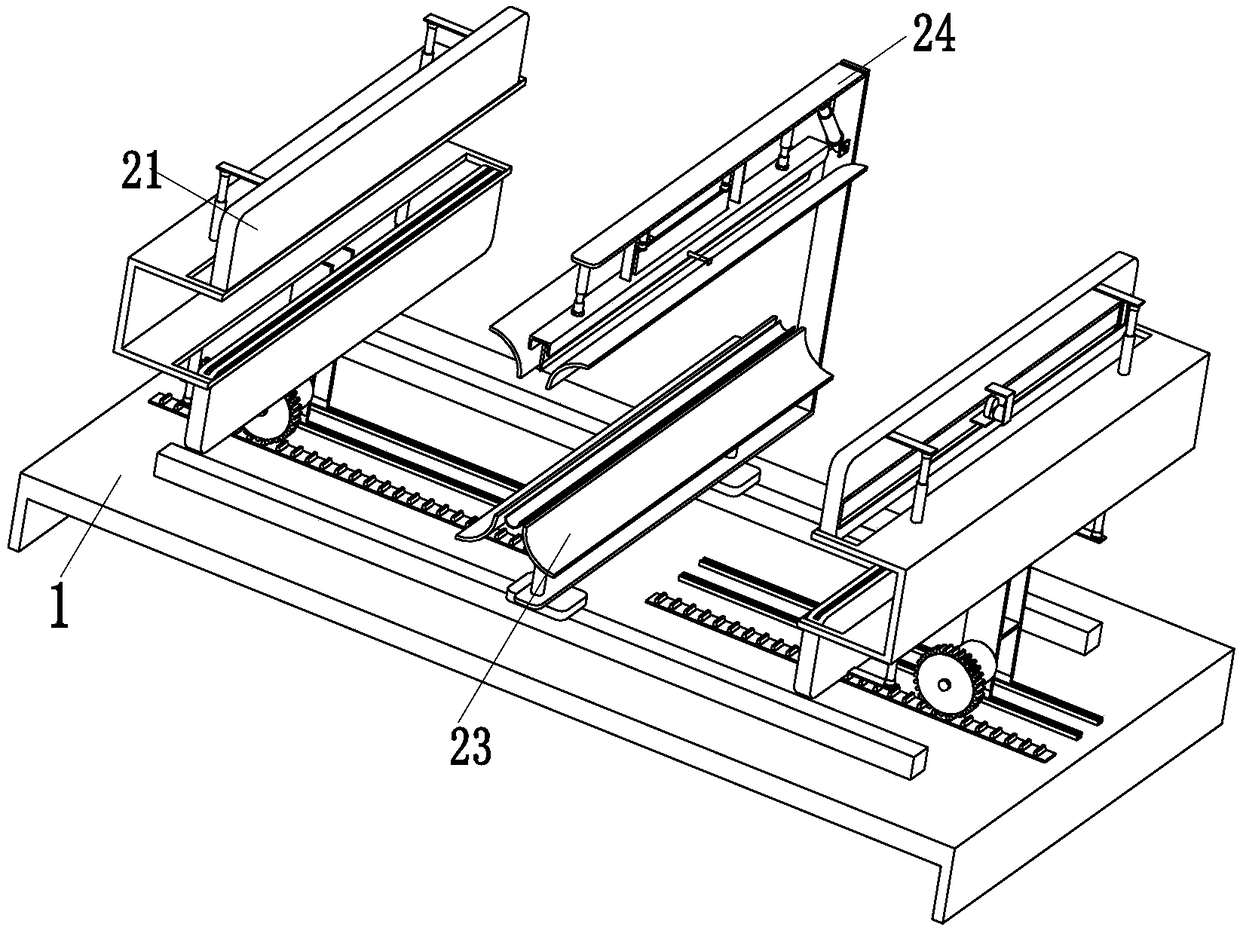

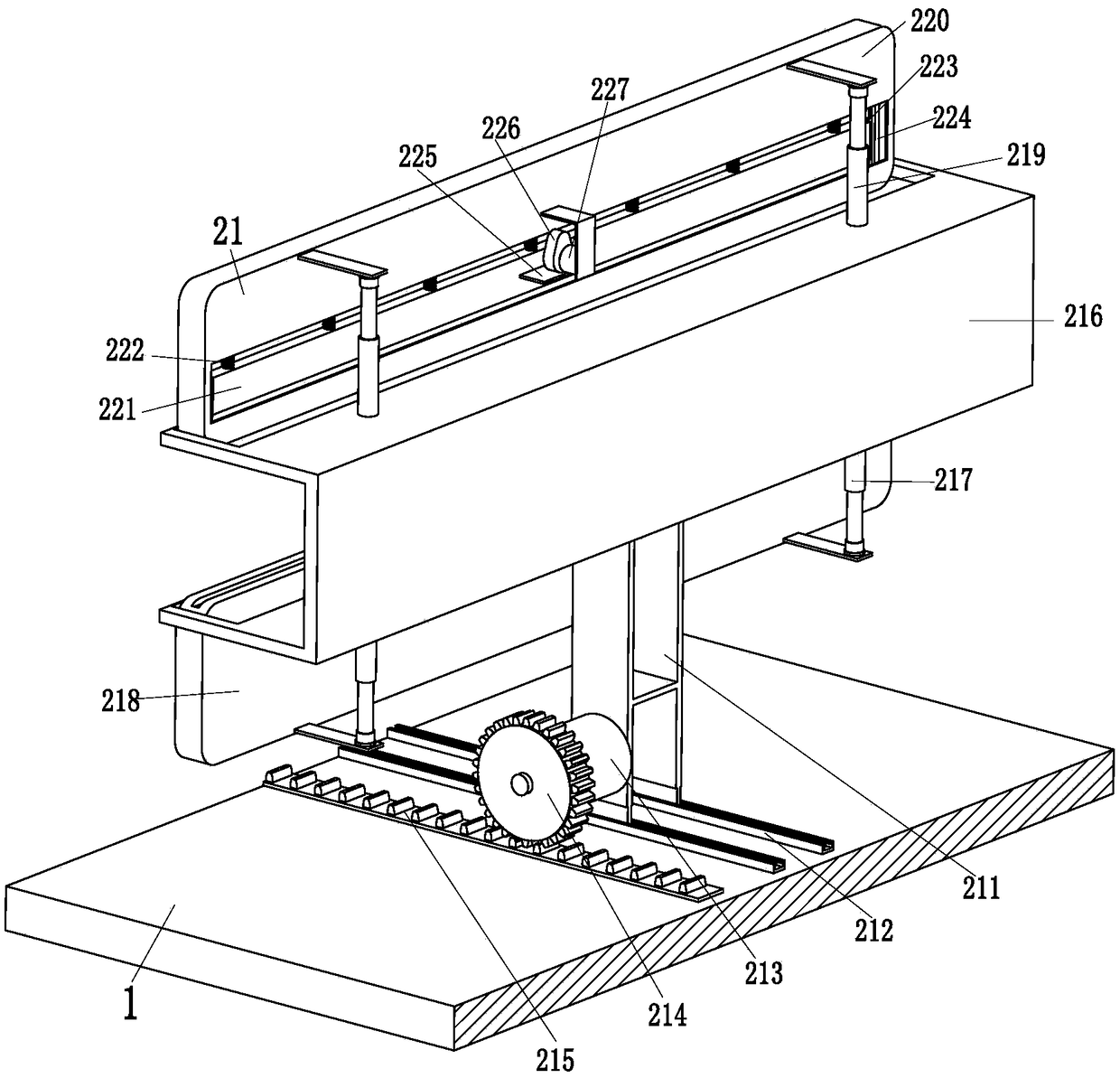

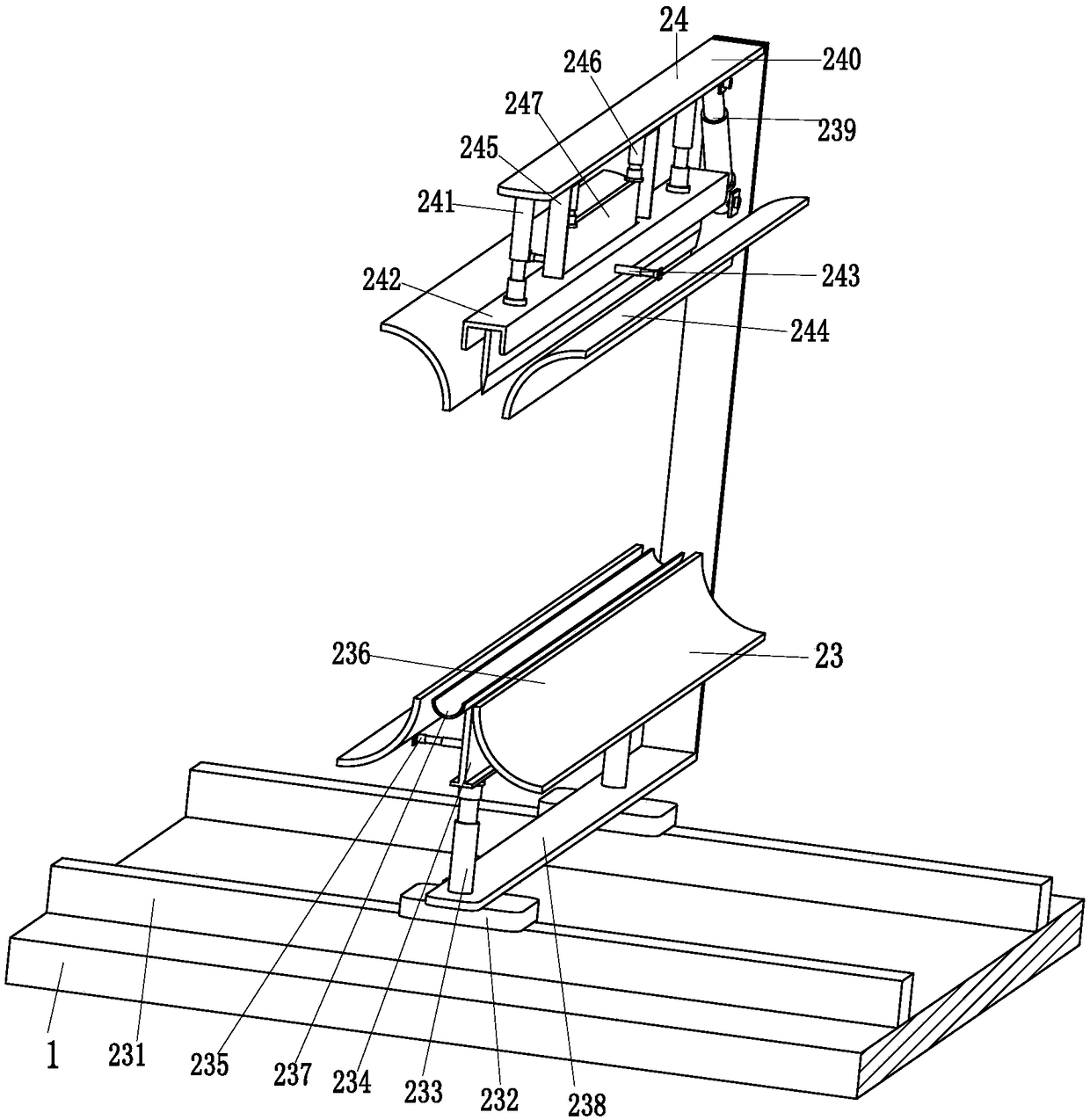

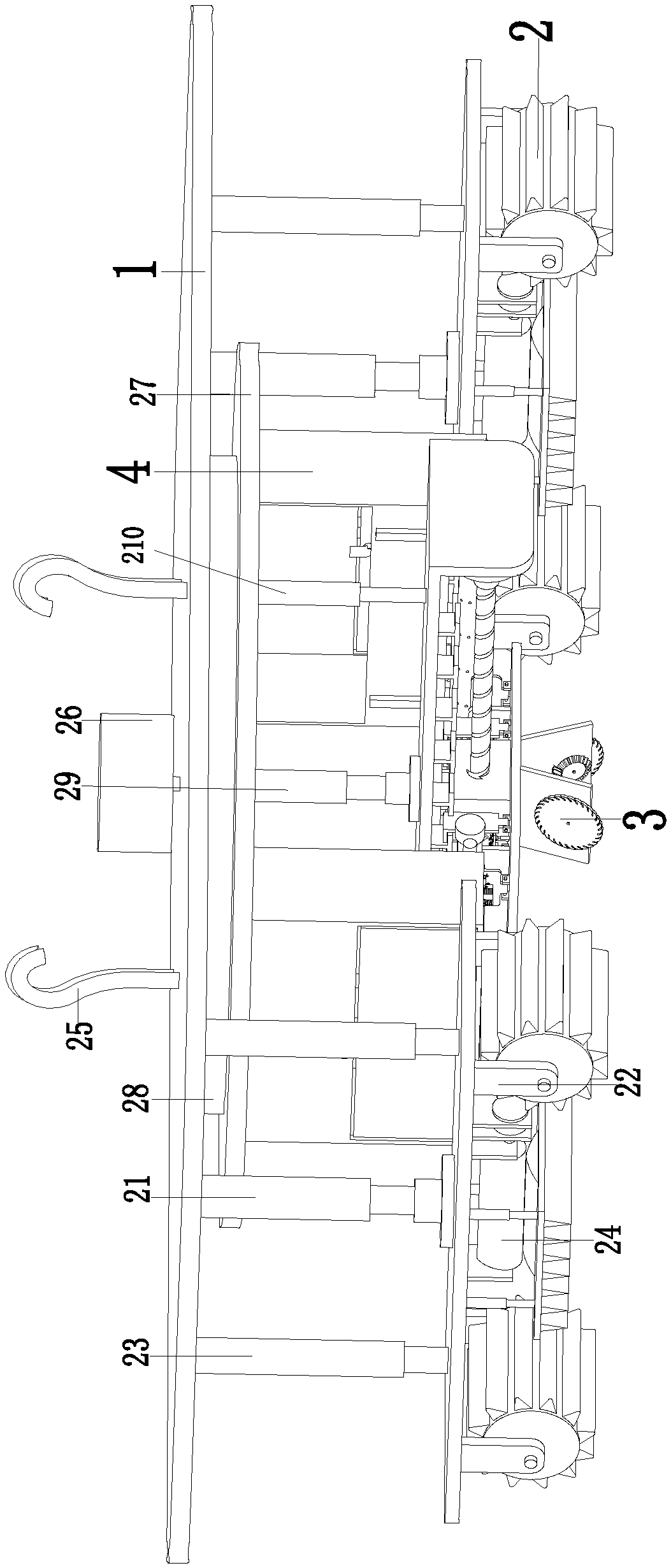

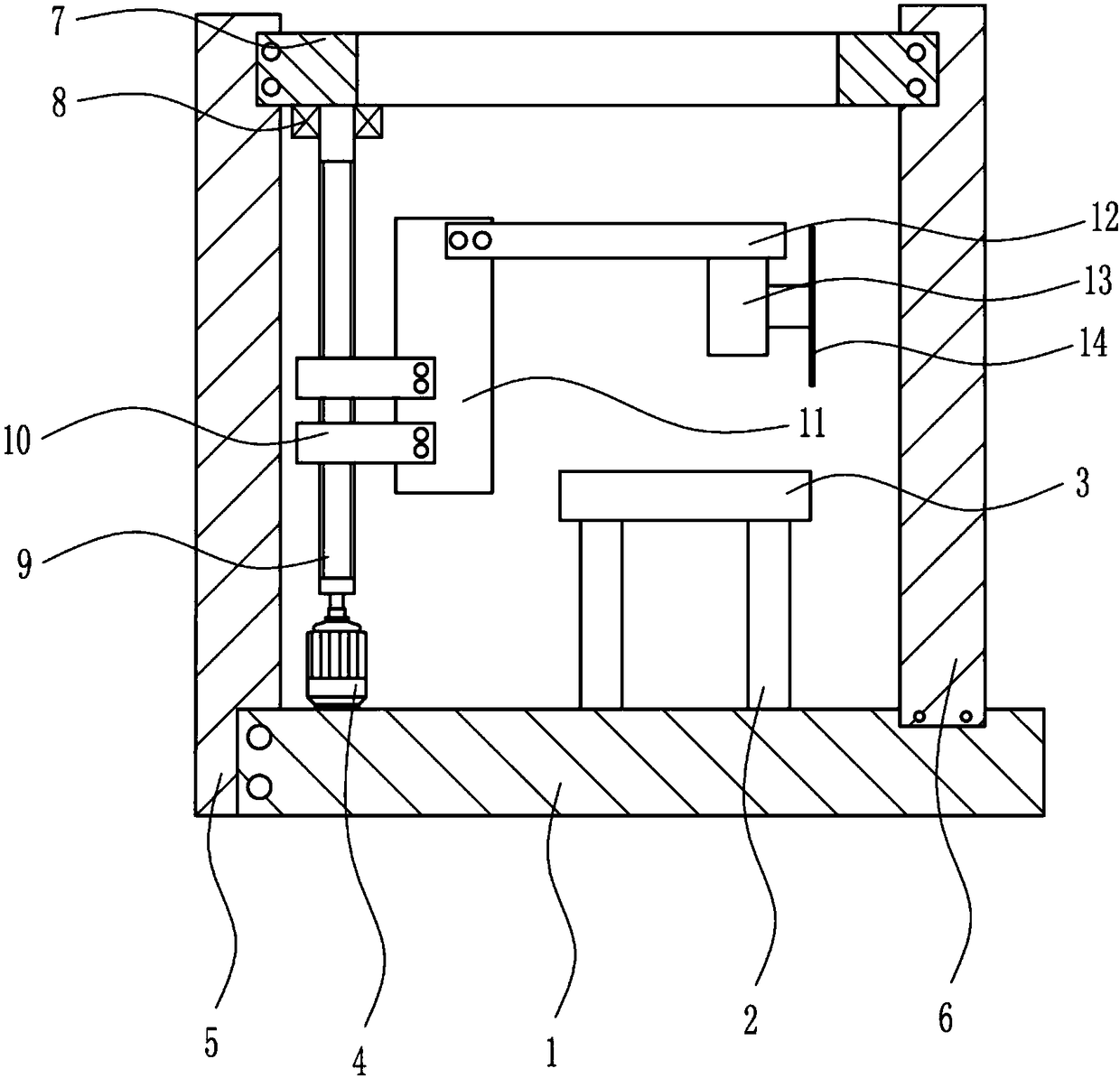

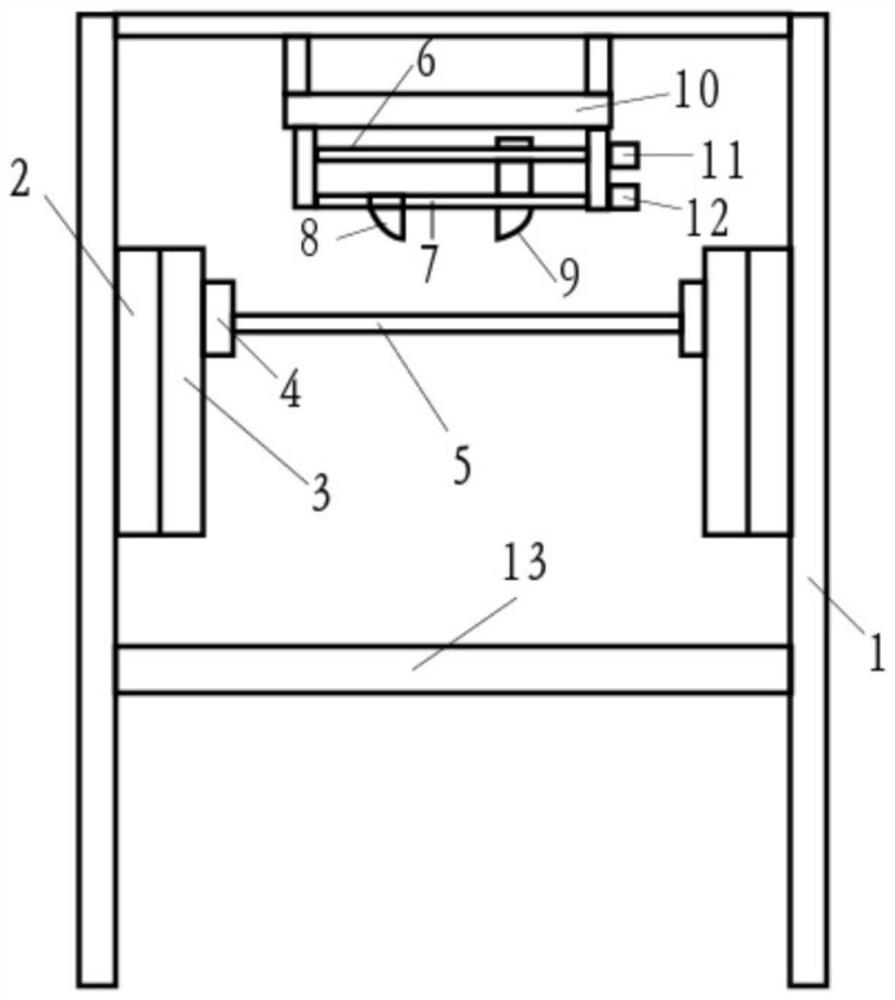

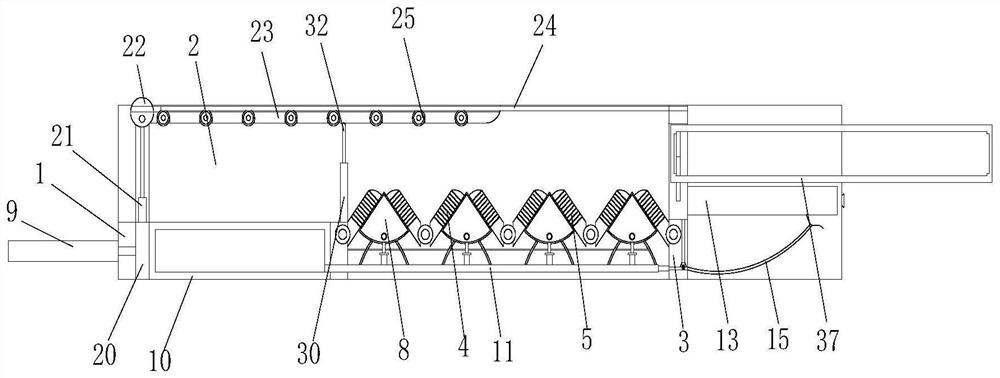

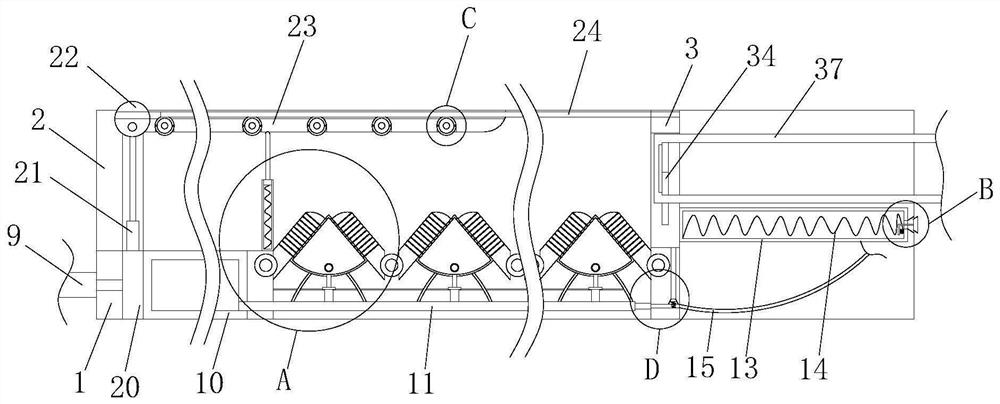

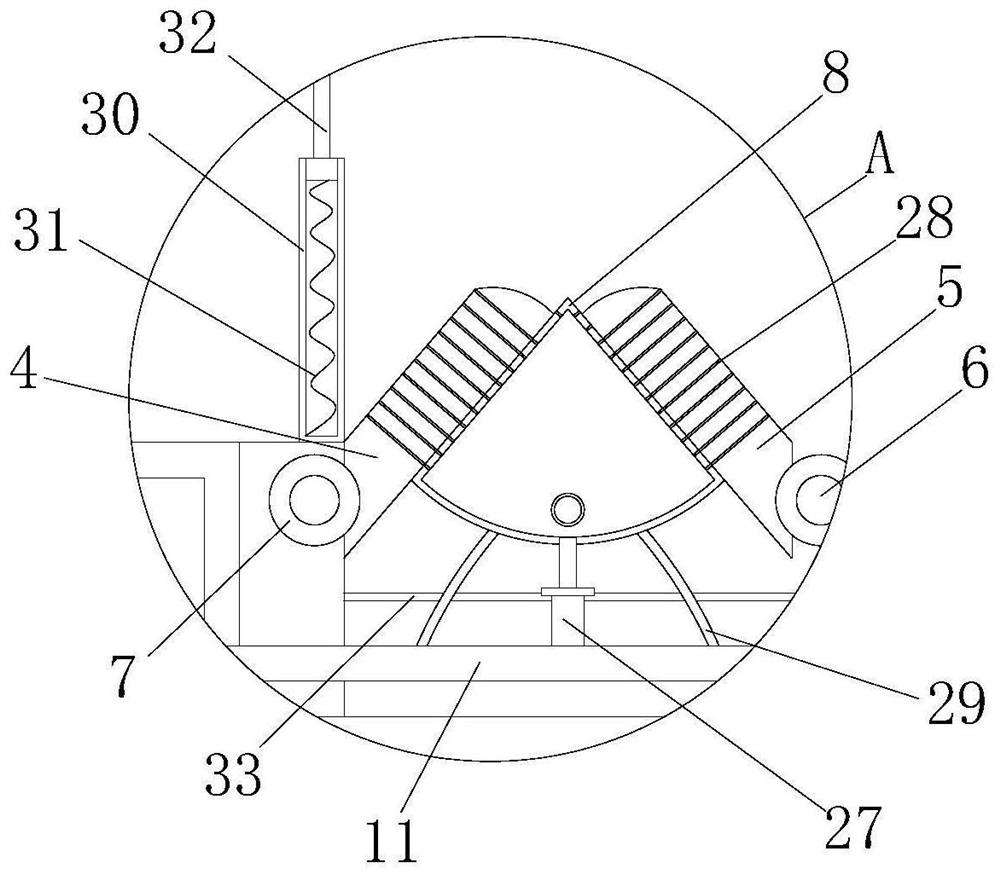

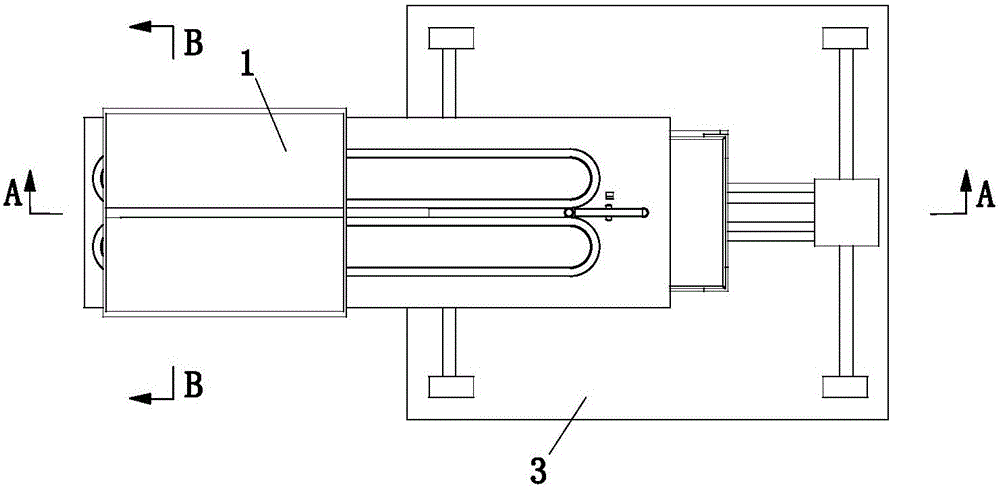

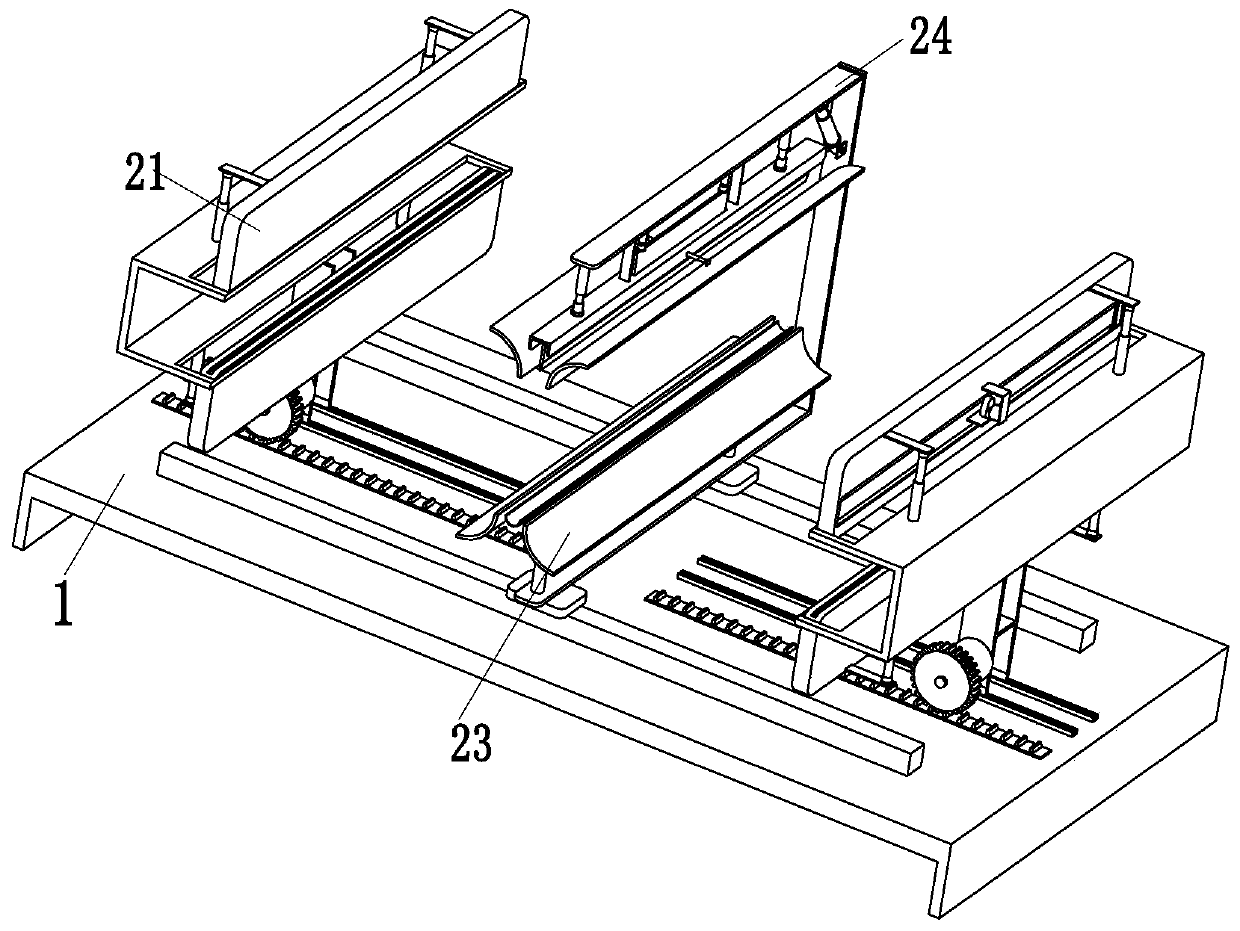

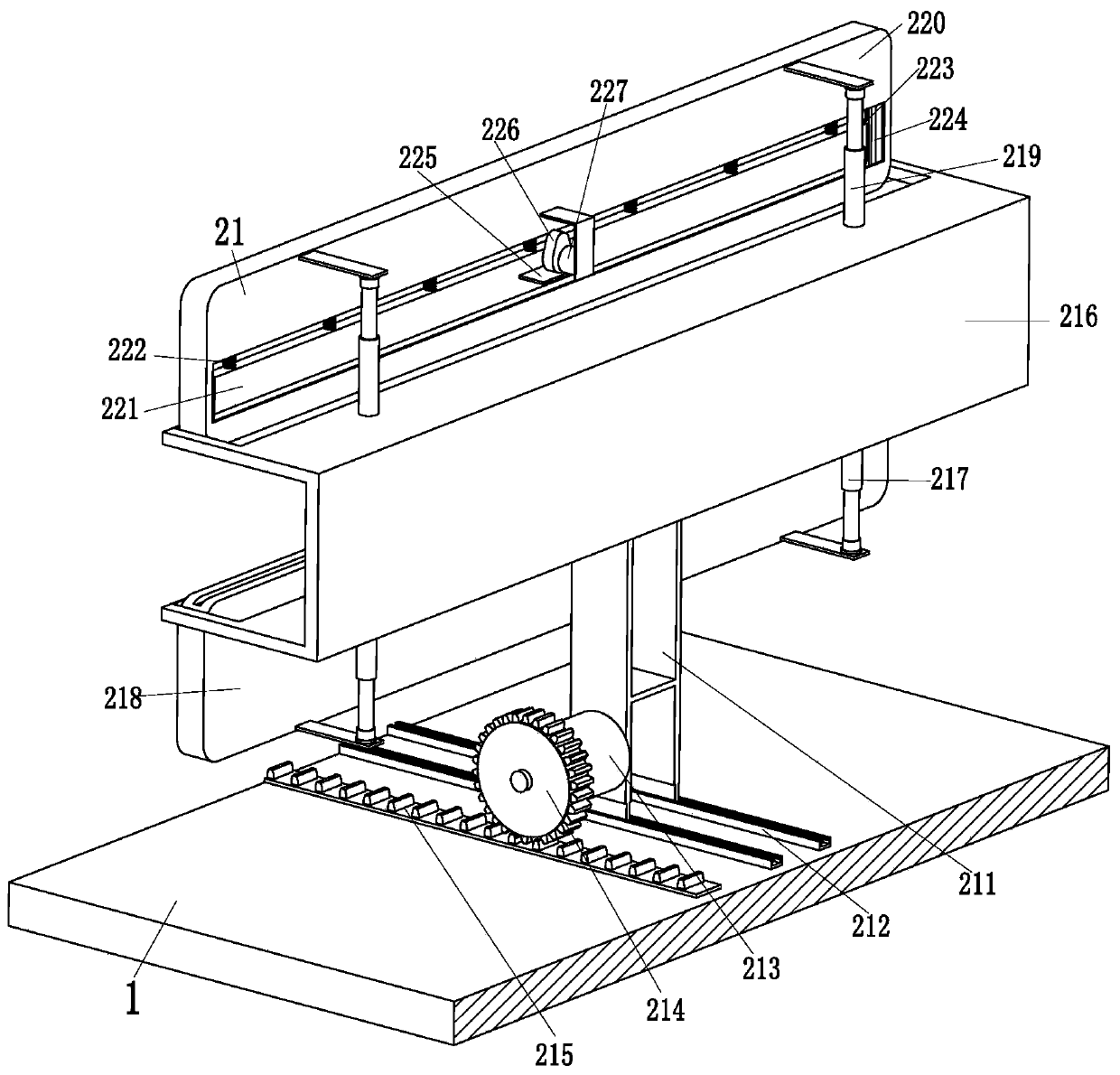

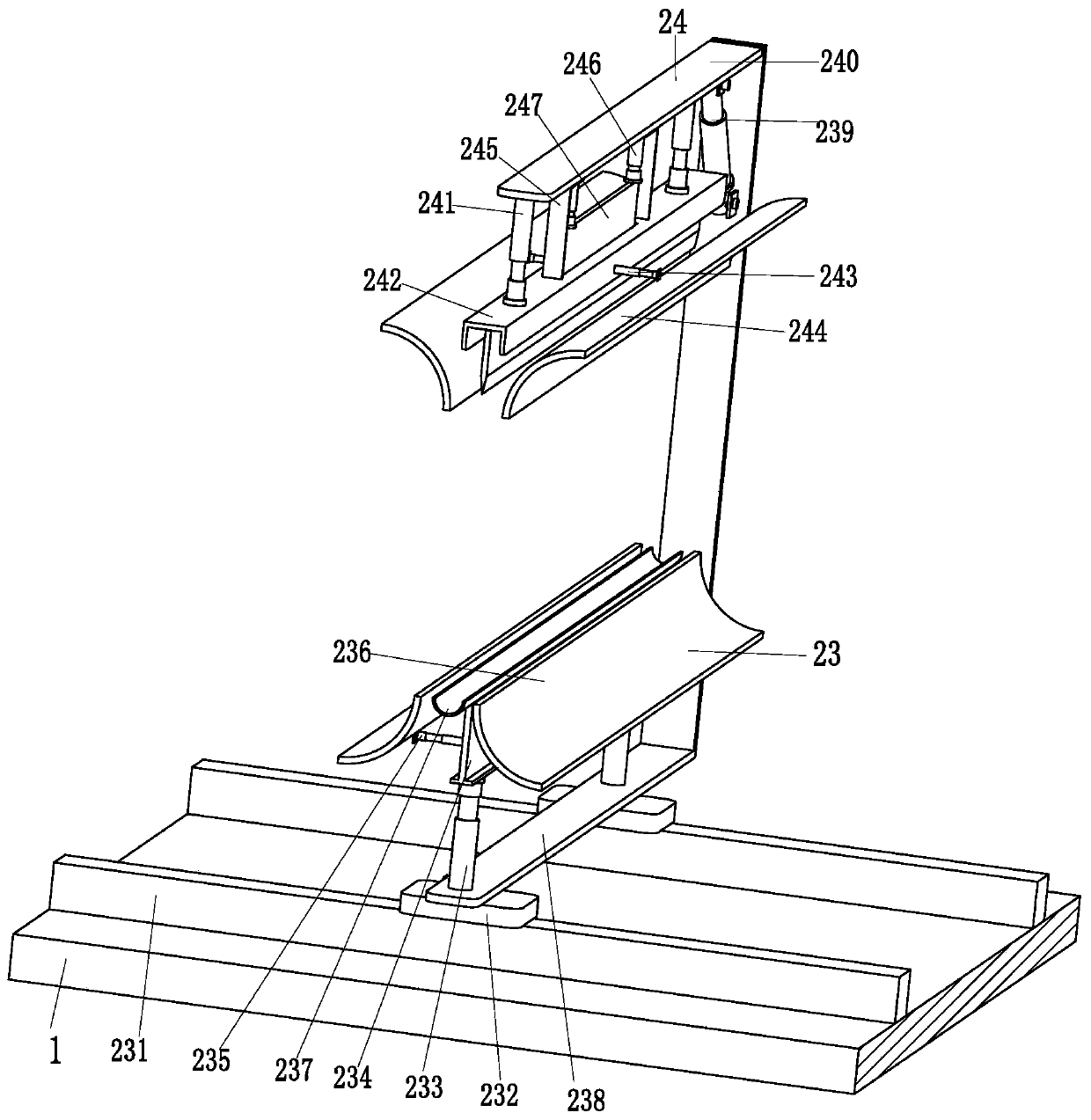

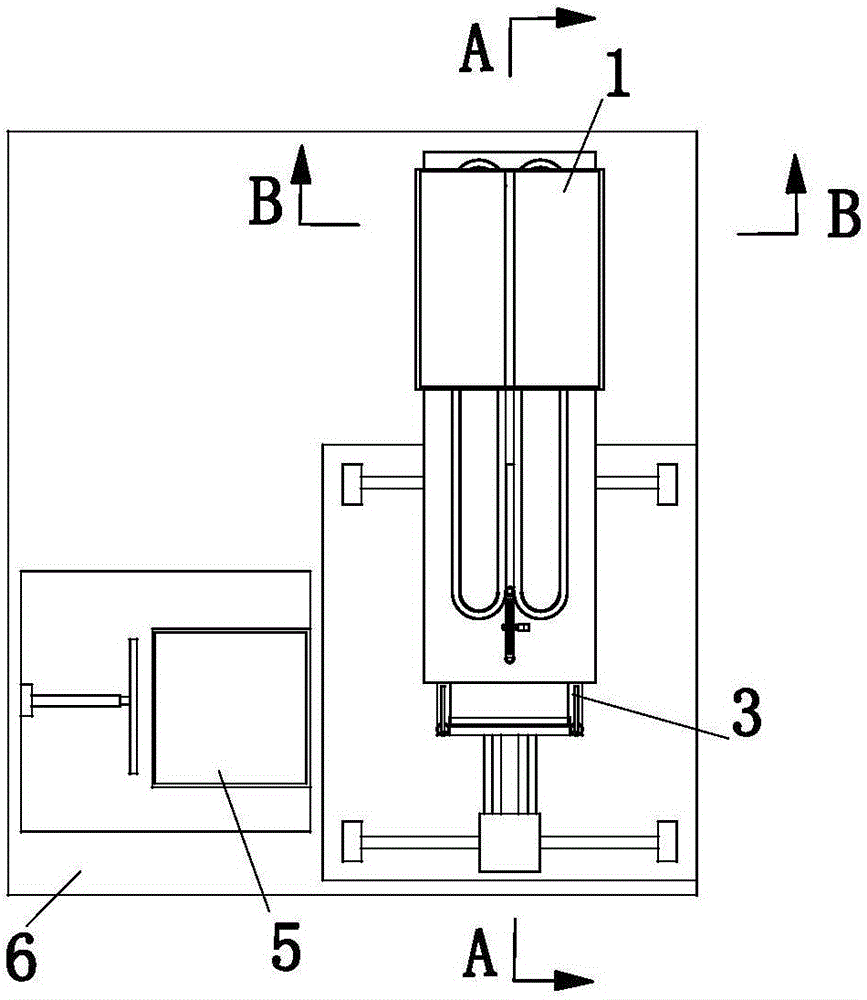

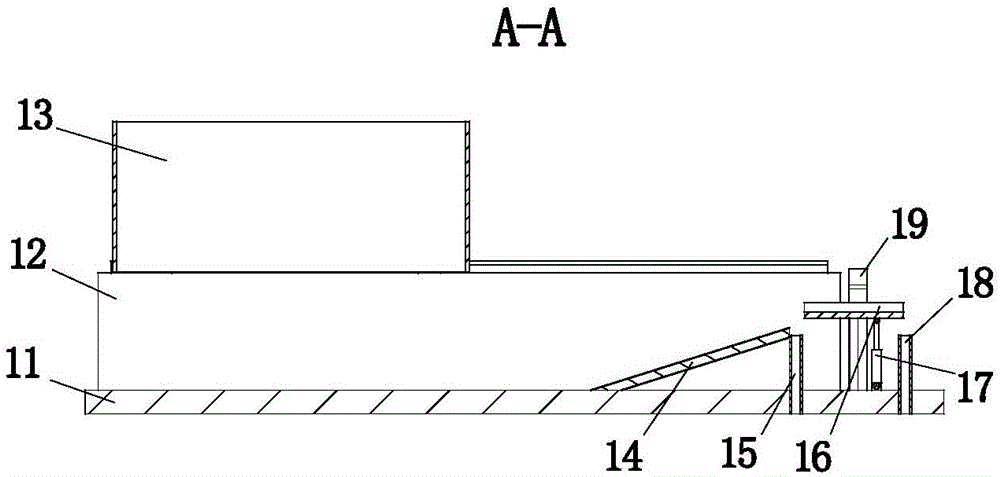

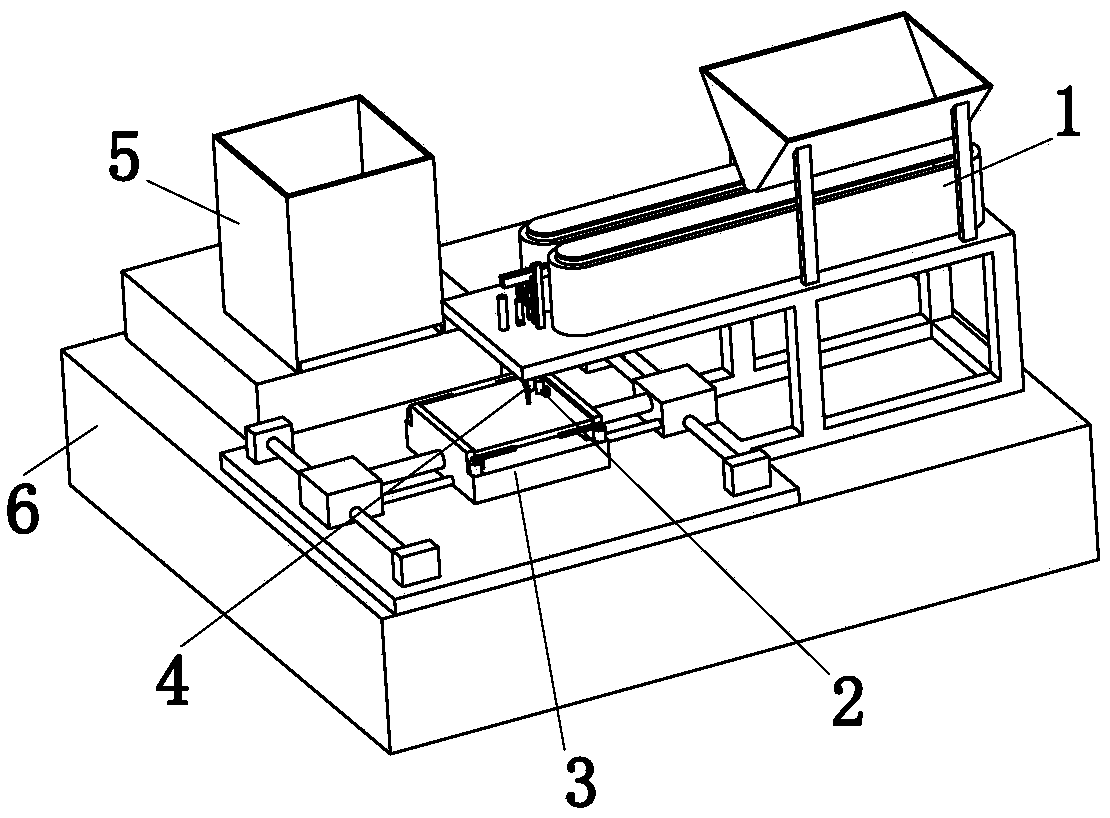

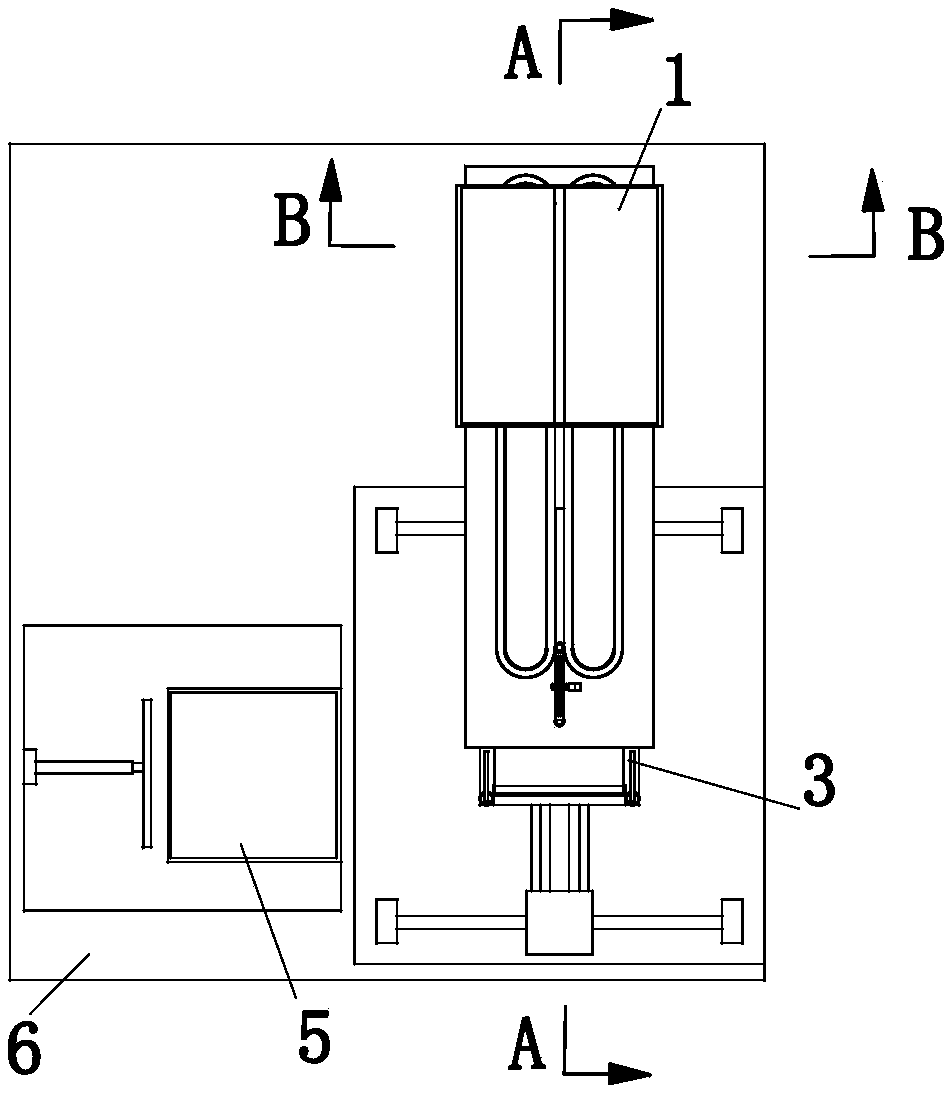

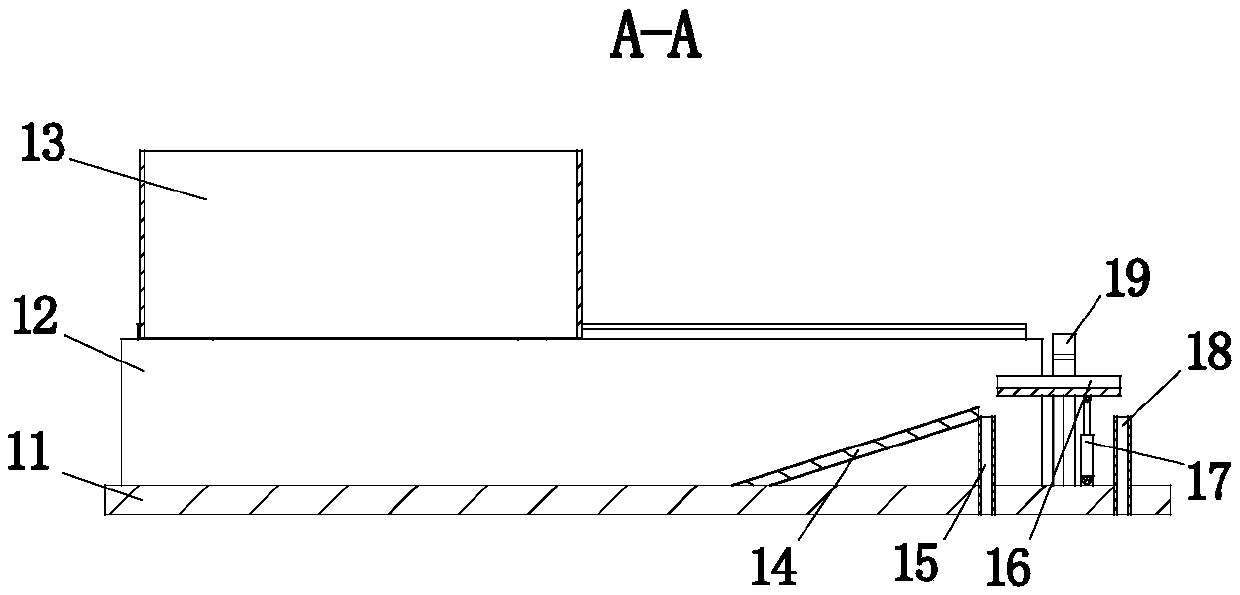

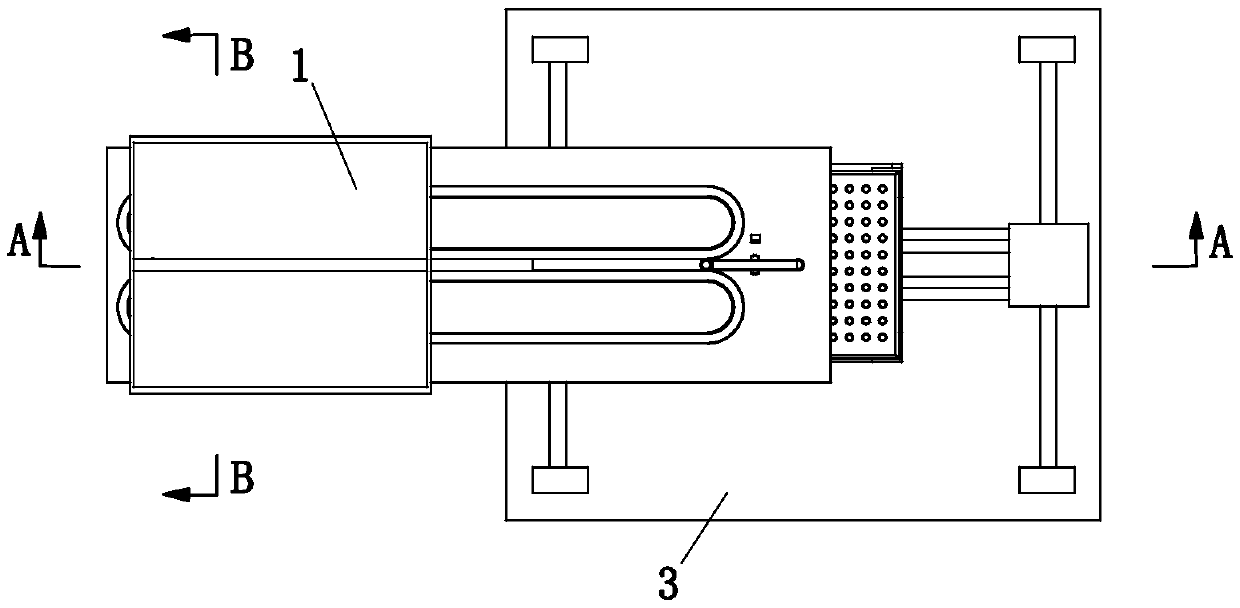

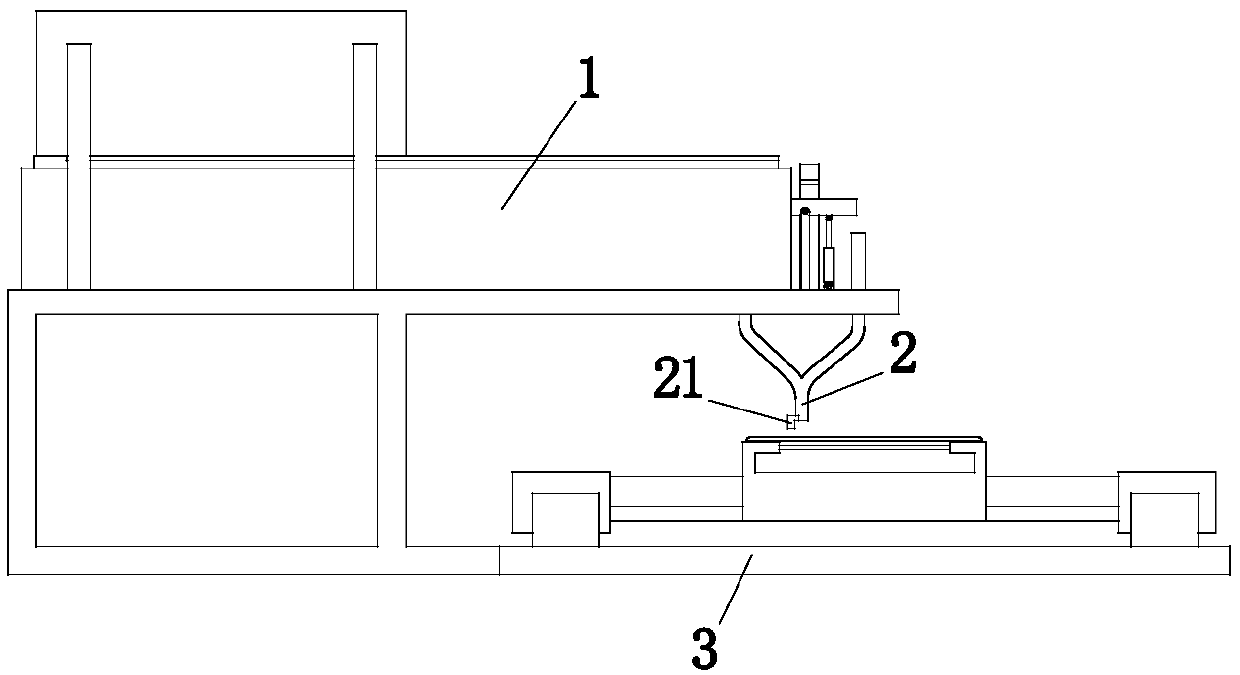

Automatic cutting machine for artificial wood fiber board

InactiveCN107127827ARealize the function of automatic cuttingReduce labor intensityGuide fencesGripping devicesFiberEngineering

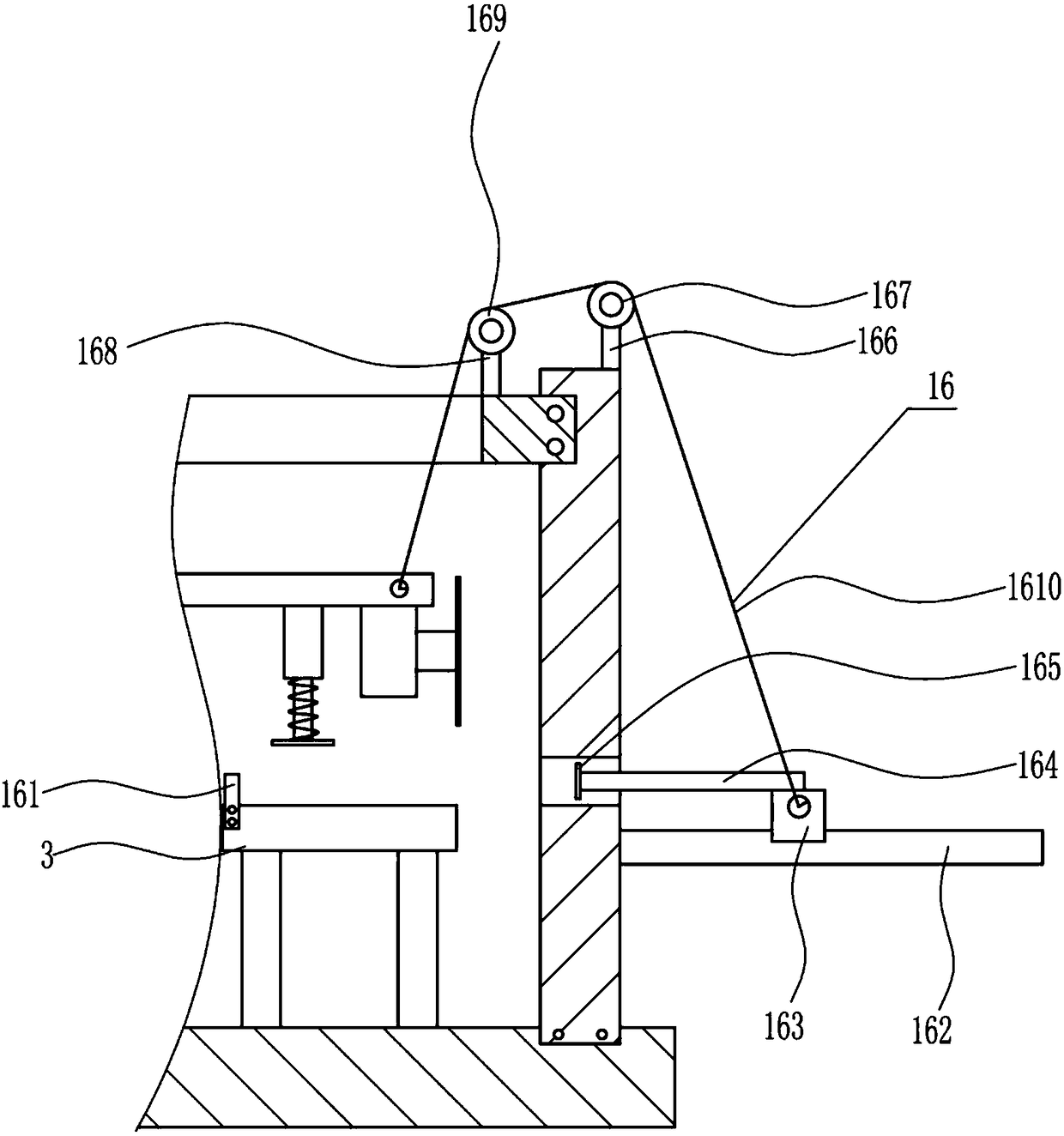

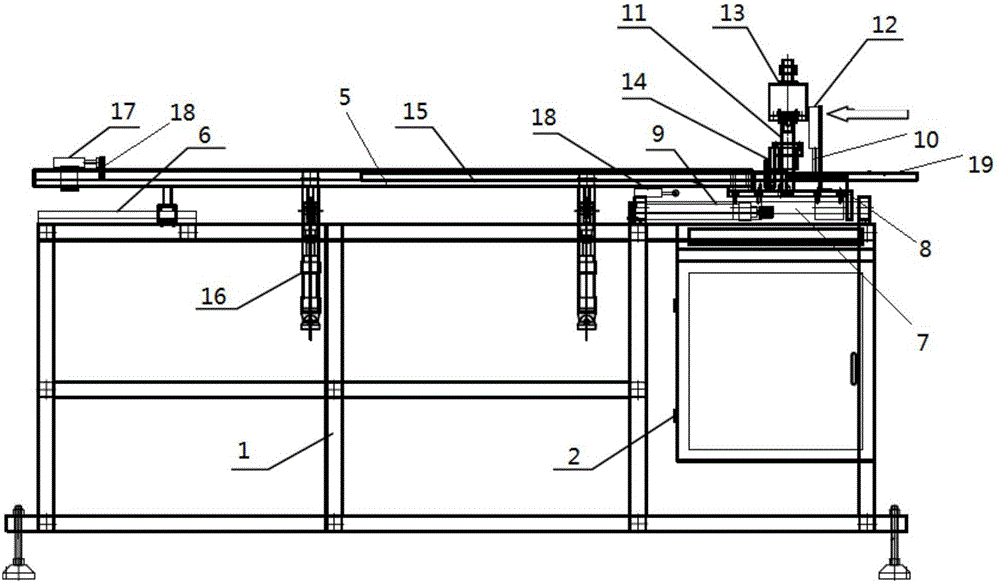

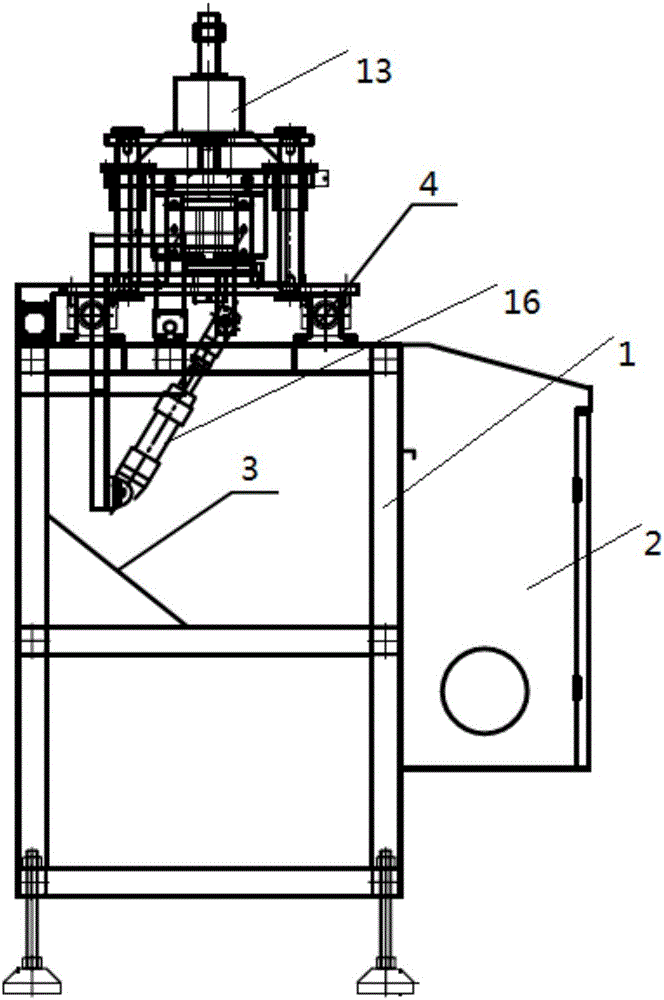

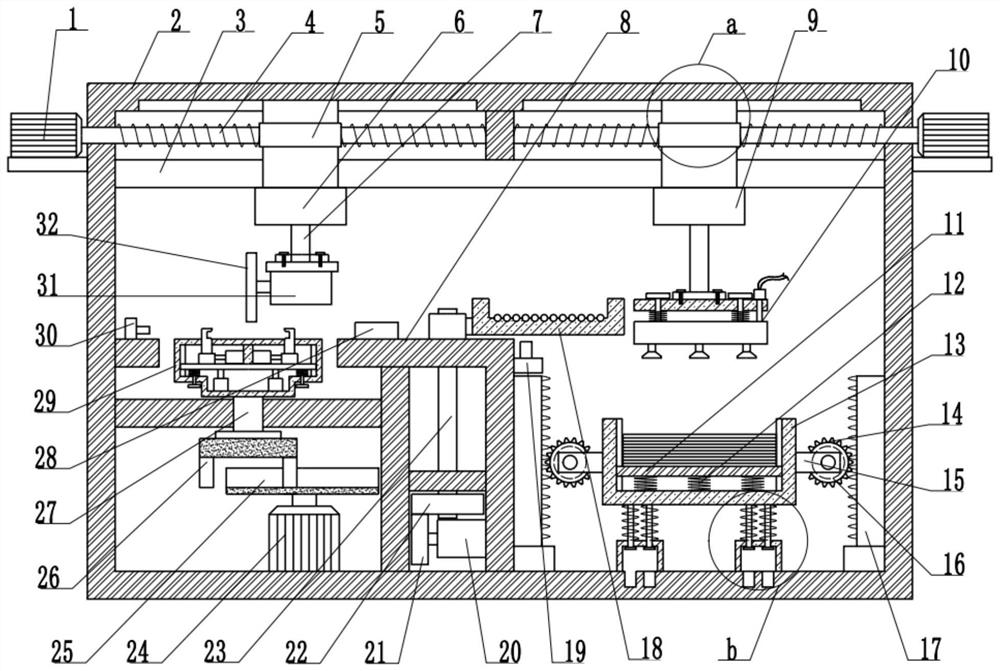

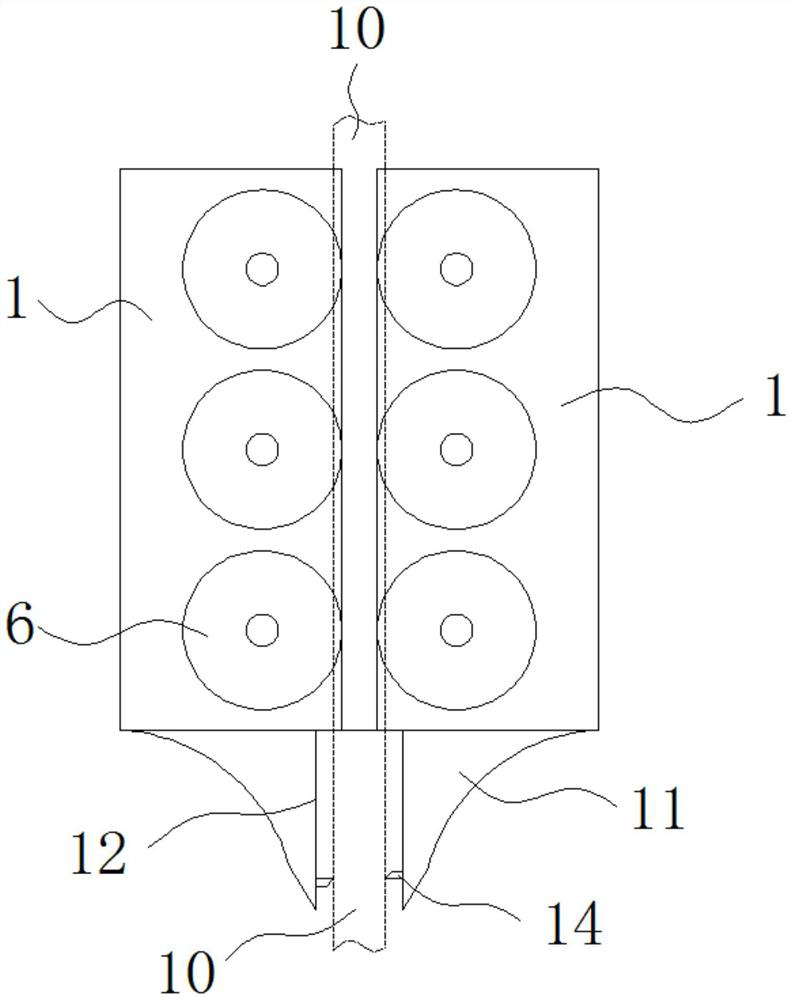

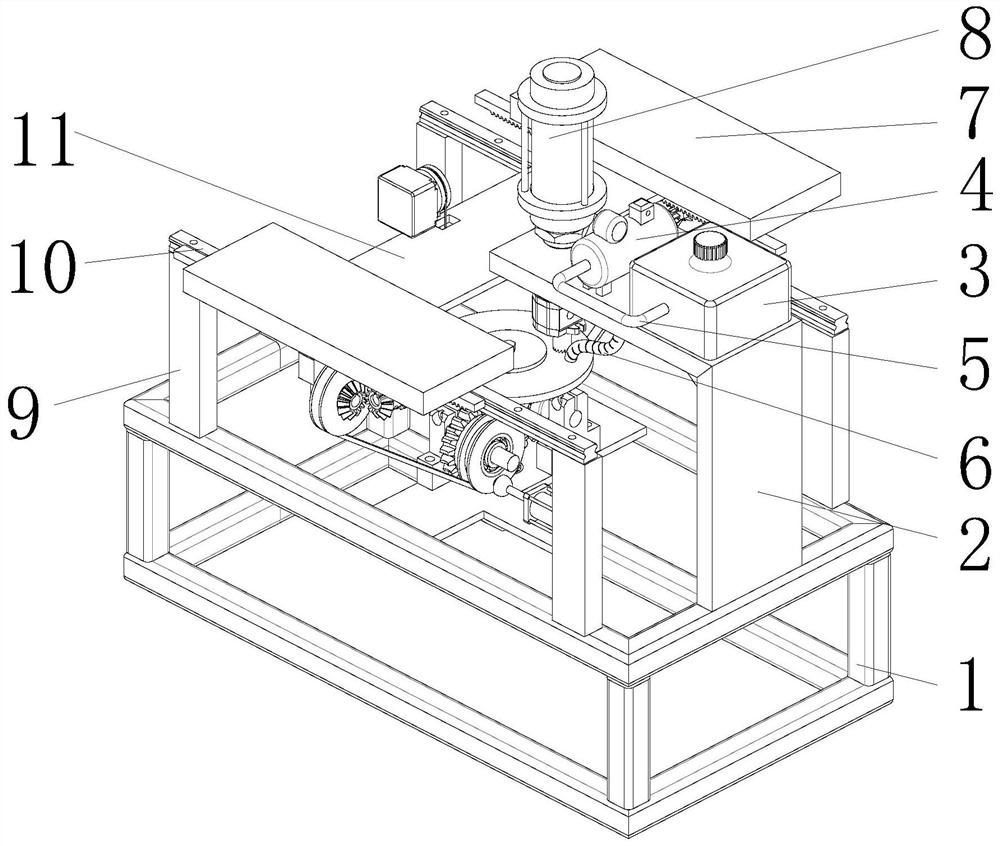

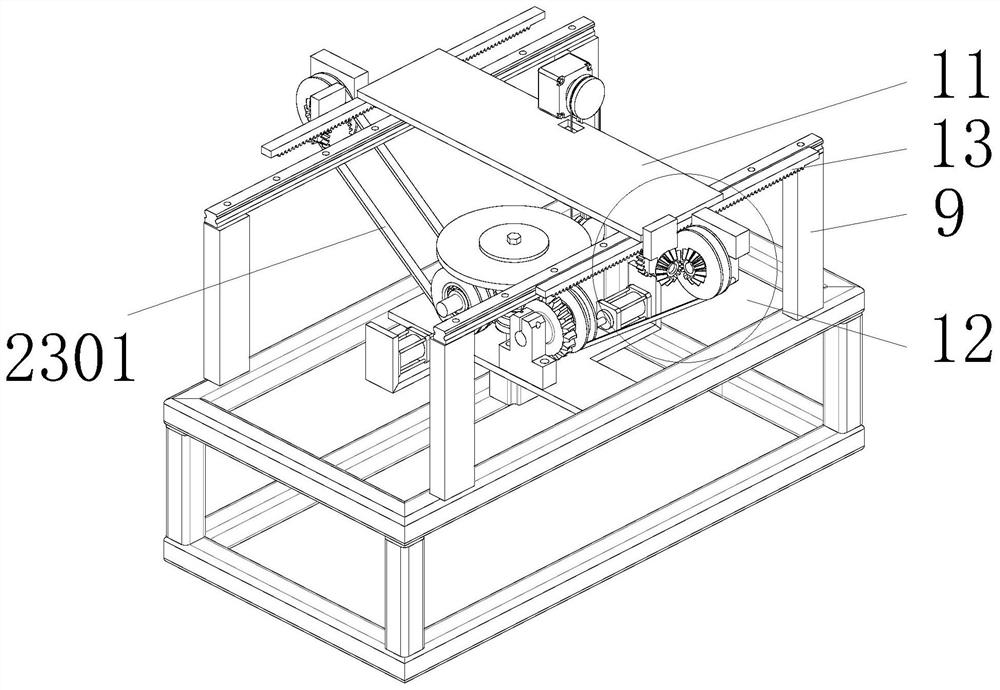

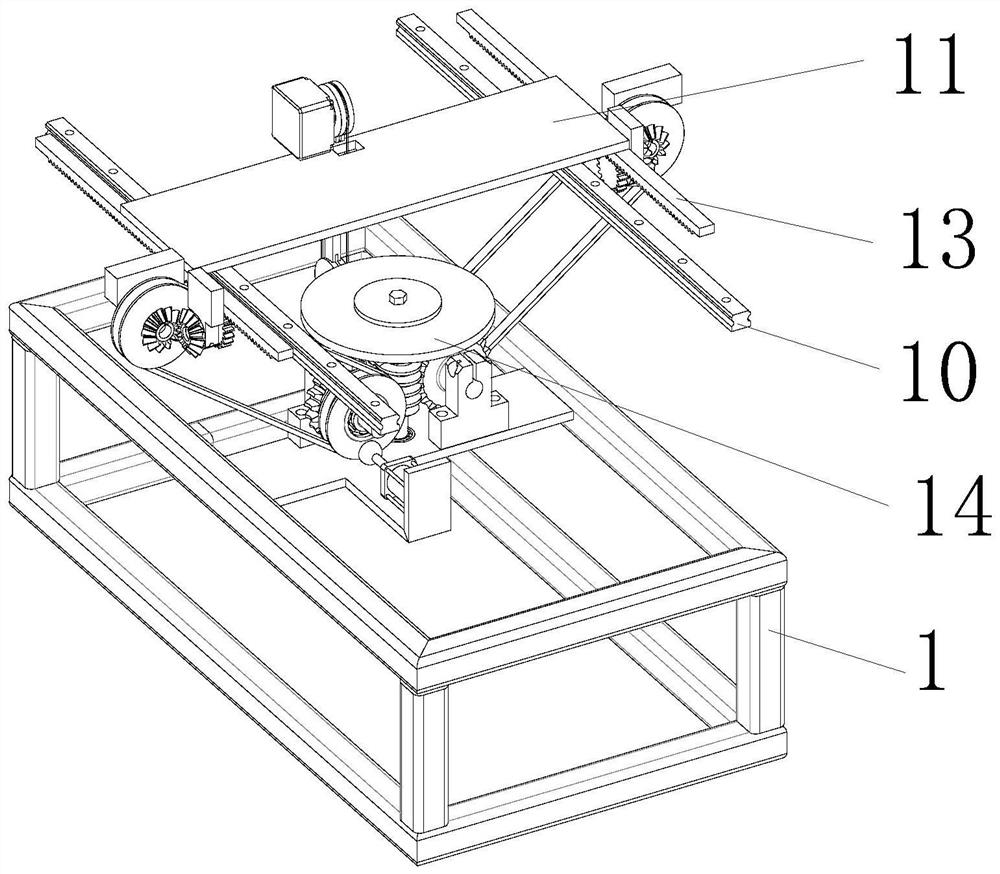

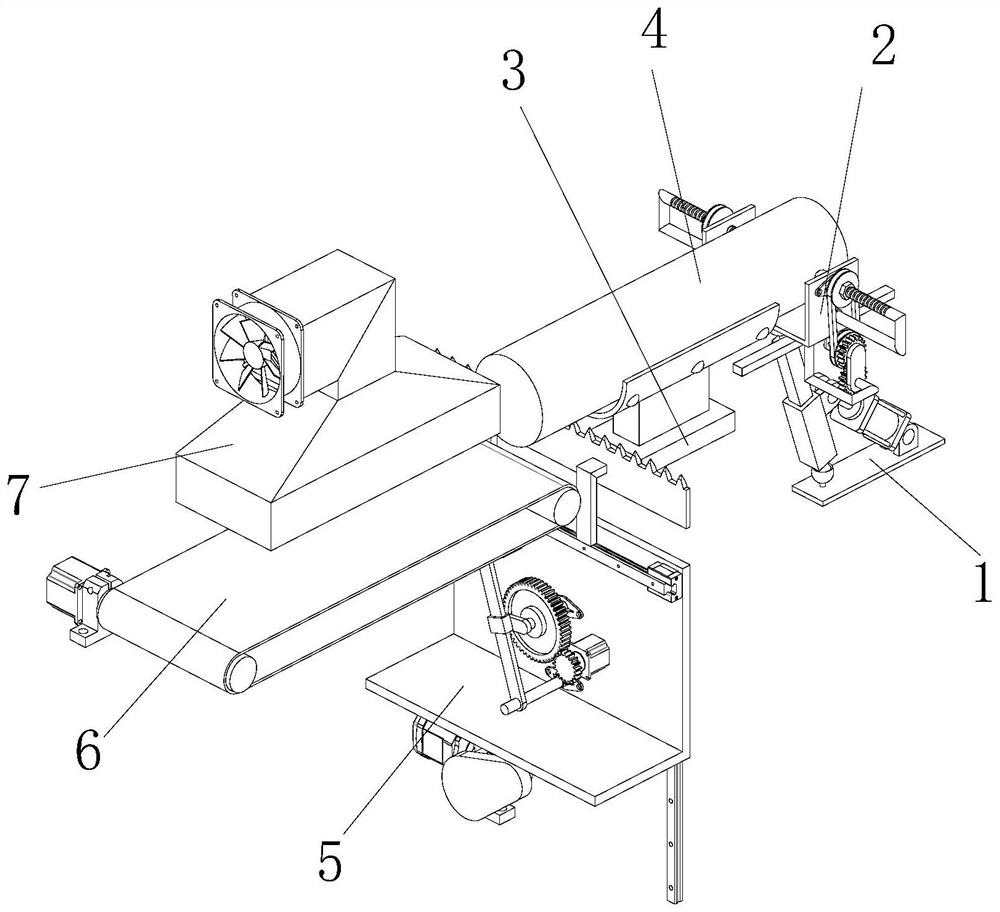

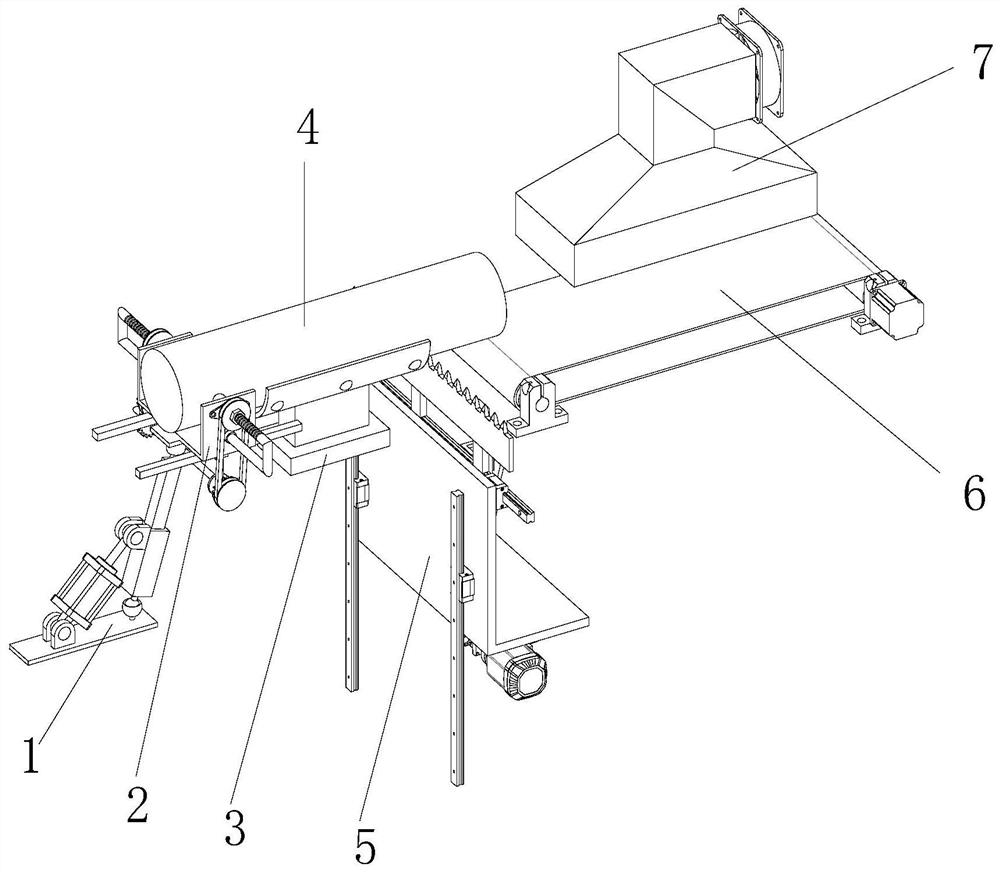

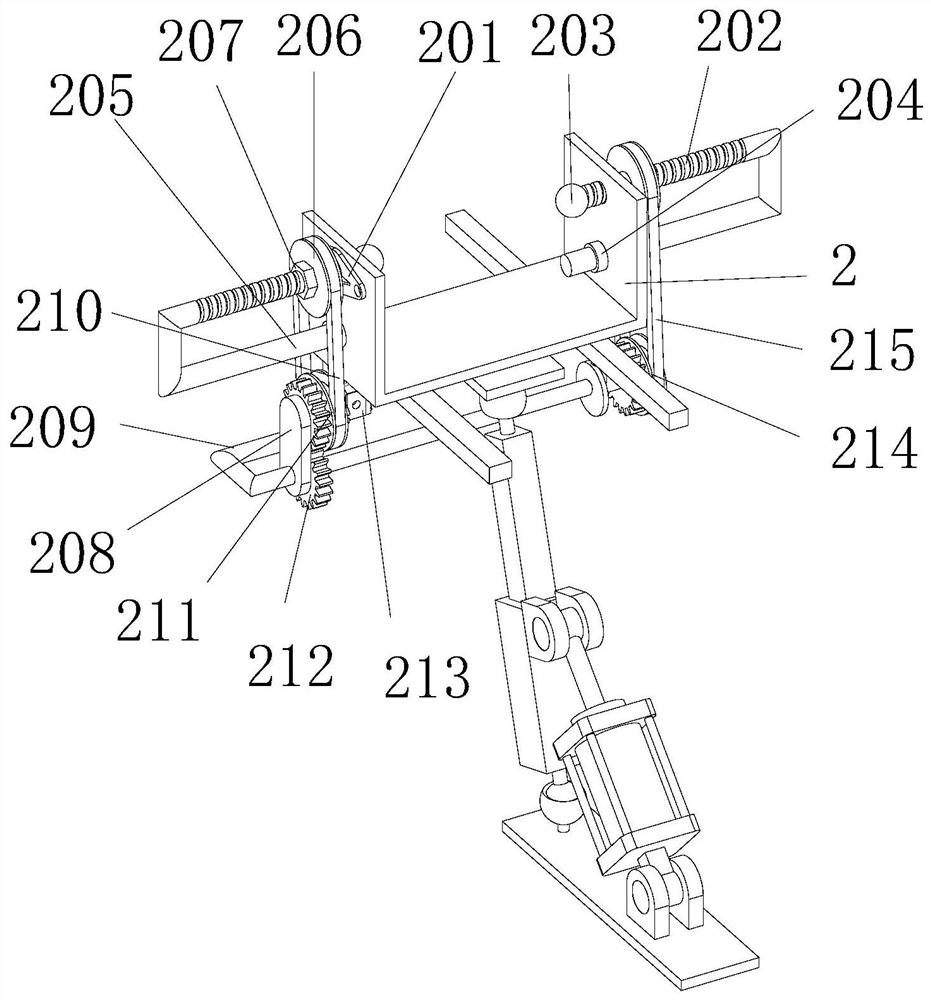

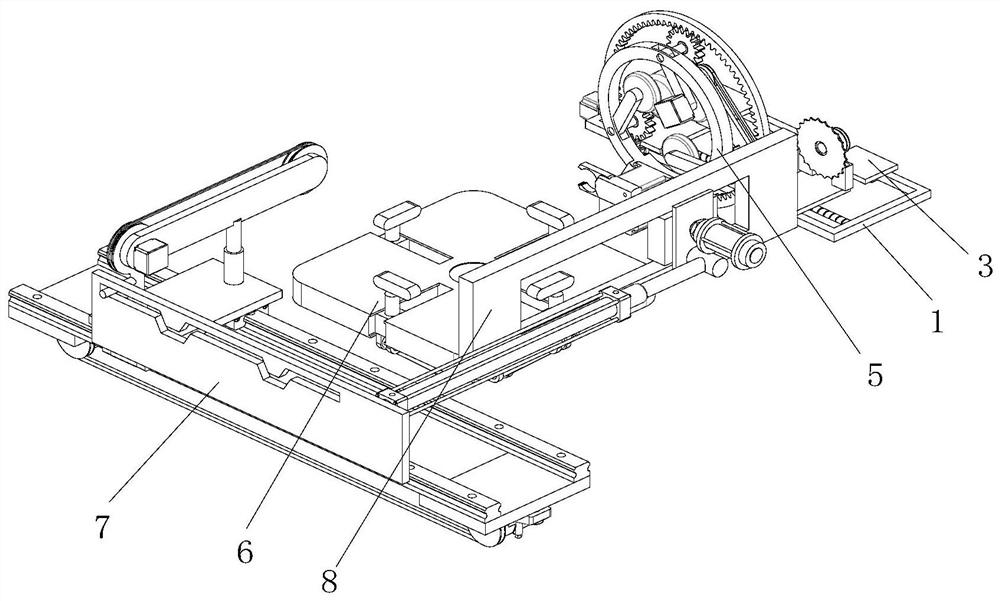

The invention relates to an automatic cutting machine for an artificial wood fiber board. The automatic cutting machine for the artificial wood fiber board comprises a base board, a movable pushing device is mounted at the rear end of the base board, two supporting boards are symmetrically mounted in the middle of the base board, a first supporting roller is mounted between the inner walls of the upper ends of the two supporting boards through a bearing, a cutting device is mounted at the front end of the base board, and the movable pushing device and the cutting device cooperate with each other to complete the automatic processing technology of boards. The automatic cutting machine can solve the problems that workers need to use clamps to push the boards and use a disk saw to cut the boards when using a traditional cutting method to conduct cutting processing in small-sized board processing factories, the cutting precision is low, clamps need to be replaced manually according to needs of different board widths, the labor intensity is high, the traditional board cutting method can only conduct cutting in one direction, the boards need to be processed for a second time, and the working efficiency is low; and the automatic cutting machine can achieve the function that the boards are cut automatically.

Owner:广西鹿寨通用人造板有限公司

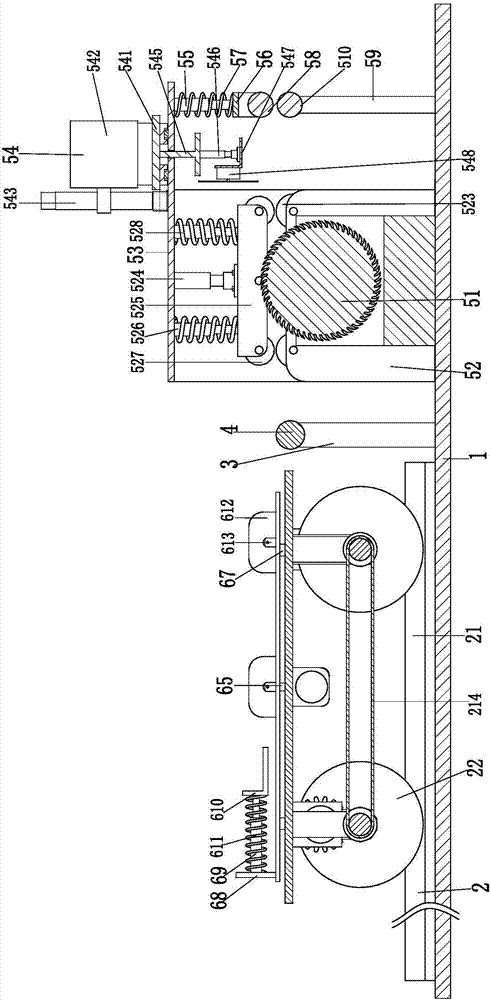

Rail steel plate processing device for rail transit

InactiveCN112091623AHigh precisionEasy for automatic sandingOther manufacturing equipments/toolsLarge fixed membersSteel platesGrinding

The invention discloses a rail steel plate processing device for rail transit, and belongs to the field of plate processing. The rail steel plate processing device comprises a fixed guide rail, wherein a movable sliding block and a fixed sliding block are mounted on the fixed guide rail, the movable sliding block is slidably connected with the fixed guide rail, the fixed sliding block is fixedly connected with the fixed guide rail, a polishing assembly is fixedly mounted above the fixed guide rail, A material cutting assembly is fixedly installed on one side of the grinding assembly, a dust removal assembly is fixedly installed on the side, away from the material cutting assembly, of one side of the grinding assembly, a feeding assembly is fixedly installed at the top end of the fixed sliding block, a material pulling assembly is fixedly installed at the top end of the movable sliding block, the feeding assembly comprises a fixed table and a stand column, a feeding channel is mounted at the top end of the stand column, steel balls are arranged on the two sides of the feeding channel respectively, and the steel balls penetrate through the inner side and the outer side of the feedingchannel. The steel balls are arranged on the two sides of the feeding channel respectively, so that the feeding friction force is reduced.

Owner:嵇明军

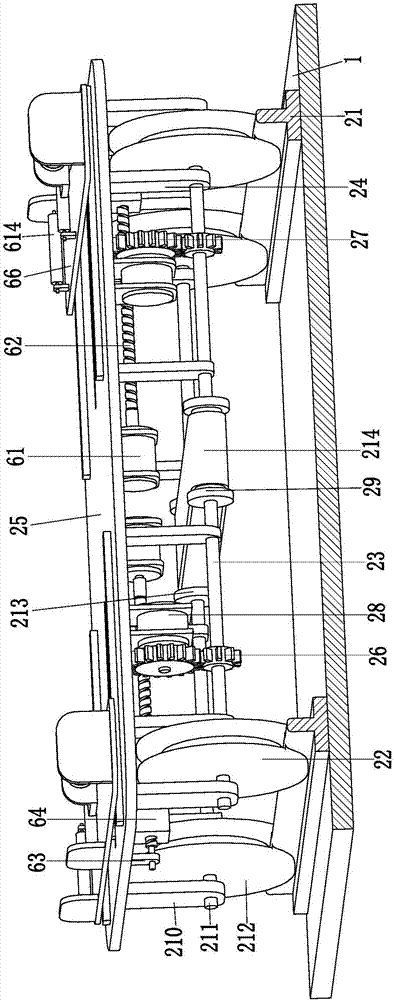

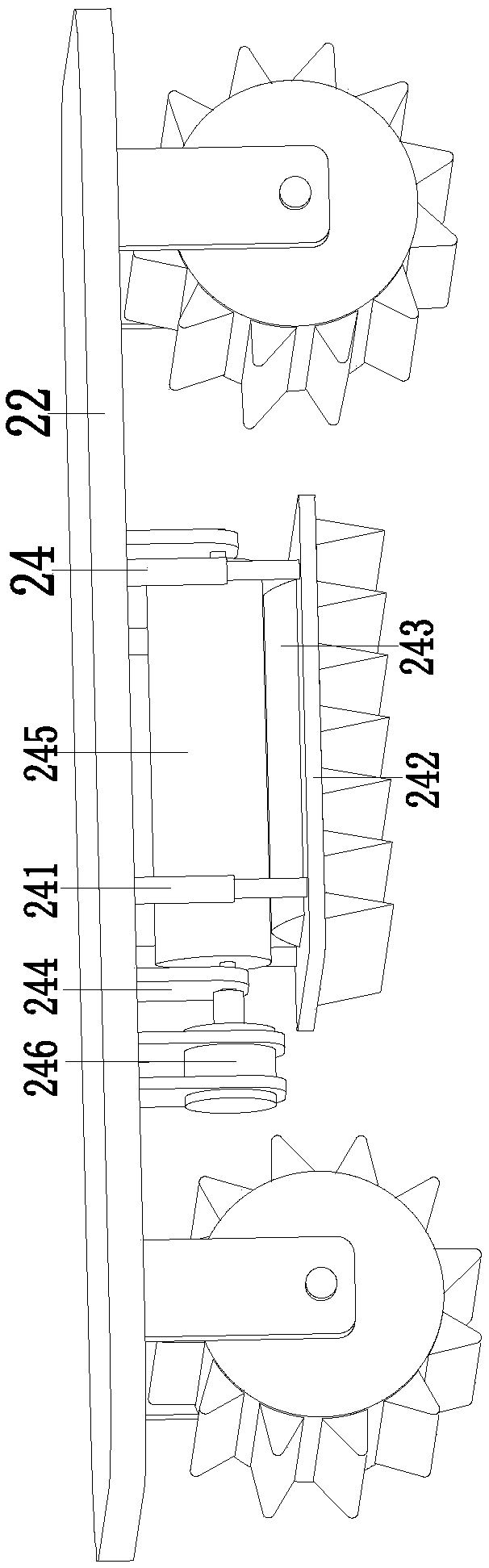

Mechanical automation processing device for chain

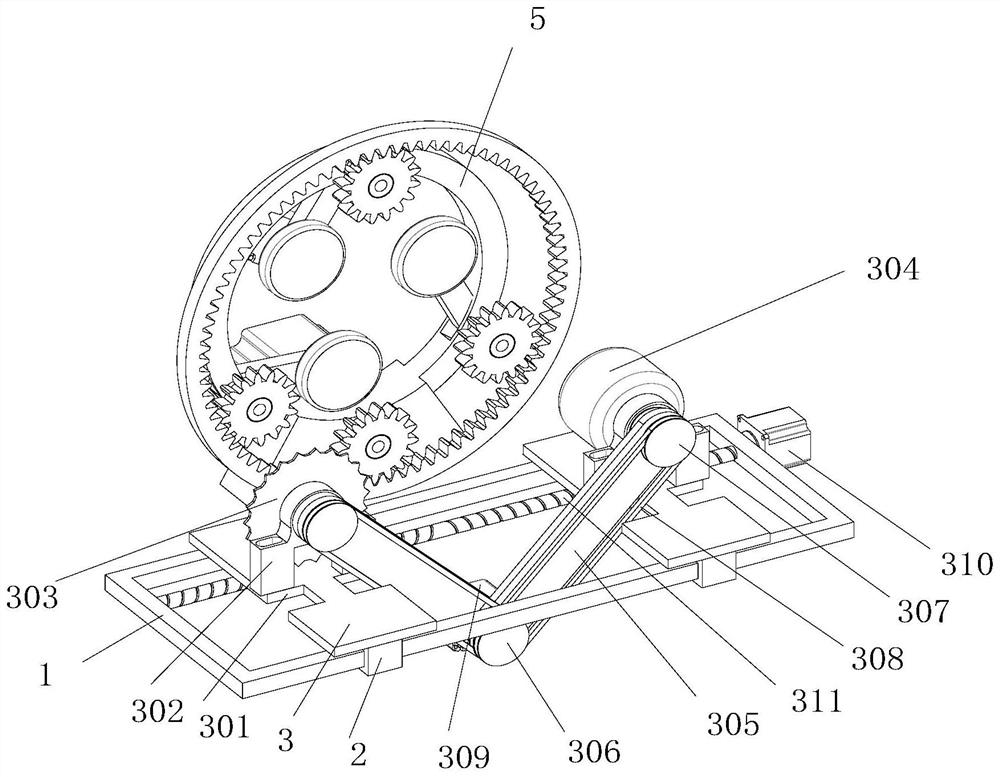

ActiveCN112247241ARealize the function of automatic cuttingAutomate processingShearing machinesFeeding apparatusElectric machineryMechanical Treatments

The invention discloses a mechanical automation processing device of a chain, and belongs to the field of chain processing. The mechanical automation processing device comprises a shearing table, twopushing guide rails are fixedly arranged at the top end of the shearing table, sliding blocks are arranged on the pushing guide rails, the sliding blocks are in sliding connection with the pushing guide rails, and the top ends of the two sliding blocks are jointly and fixedly provided with a sliding table; a vertical plate is fixedly mounted at the top end of the sliding table, two shaft seats arefixedly mounted at one side of the vertical plate, cutting discs are mounted at the top ends of the shaft seats and rotationally connected with the shaft seats, the two cutting discs are connected through a fretsaw, one cutting disc is mounted at the output end of a cutting motor, and the output end of the cutting motor penetrates through one of the shaft seats to be fixedly connected with the cutting discs; and an elastic piece is fixedly installed at one side of the vertical plate, a ball head is installed at the output end of a pushing air cylinder, and a ball shell matched with the ball head is arranged at one side of a pushing sliding block. According to the mechanical automation processing device, the waste chain can be subjected to automatic mechanical treatment.

Owner:江苏松田电子科技有限公司

Waste paper scrap collecting device

InactiveCN107930804AFunction of excisionRealize the function of automatic cuttingCleaning using toolsGrain treatmentsPaper dustPulp and paper industry

The invention relates to a collecting device, in particular to a waste paper scrap collecting device. The waste paper scrap collecting device comprises a frame and the like; a rack is fixedly connected to the upper portion of the frame, a sliding rail is fixed to the lower portion inside the rack, two sliding blocks are in sliding connection to the sliding rail, a loading box is fixedly connectedabove the two sliding blocks, a handle is fixedly connected to the left side of the loading box, the left side of the upper portion of the rack is movably connected with a cover plate through a pin, and a support is fixedly connected to the lower portion of the outer side of the right wall of the rack. The cutting function is achieved, a large amount of paper can be automatically cut, rapid cutting is achieved, concentrated collecting is achieved, and the beneficial effects of being high in cutting speed, convenient to operate, easy to manufacture, low in manufacturing cost, convenient to popularize and the like are achieved.

Owner:王静娴

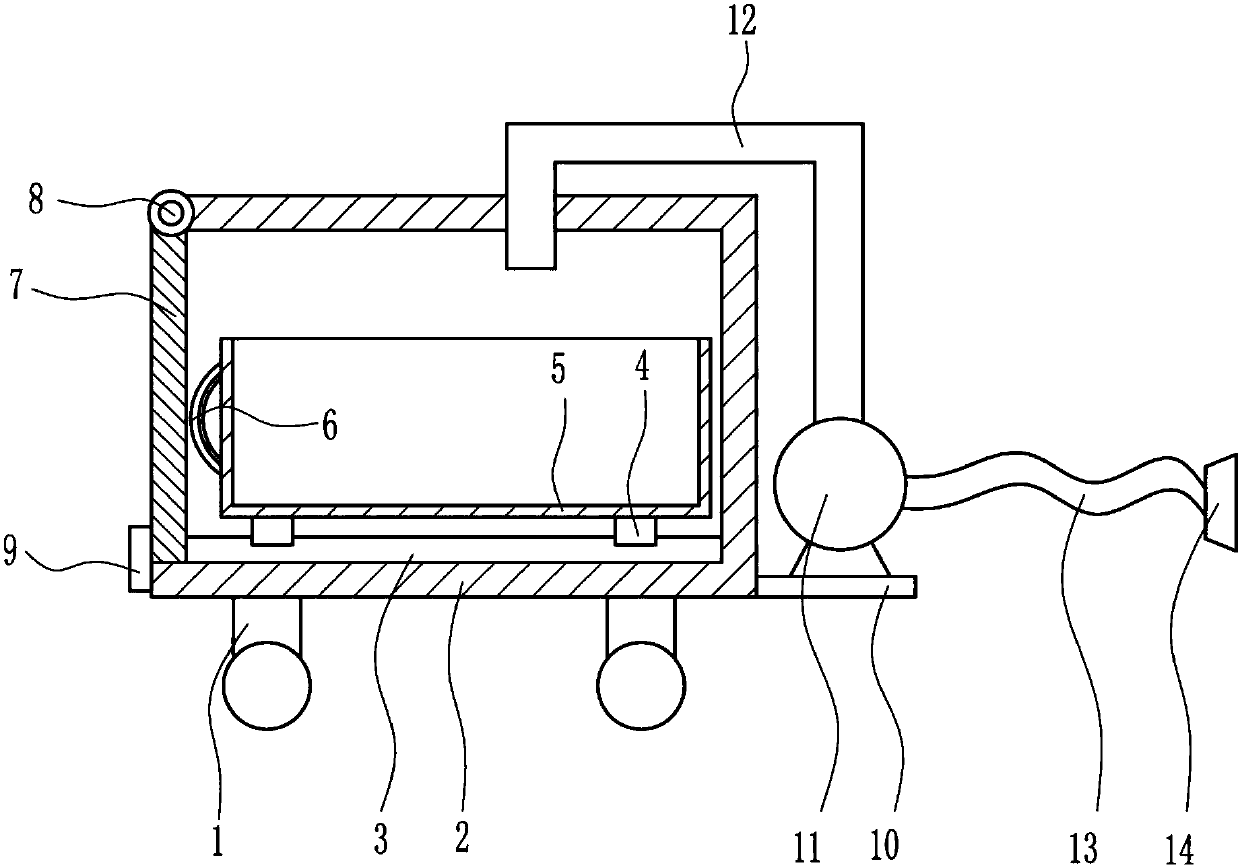

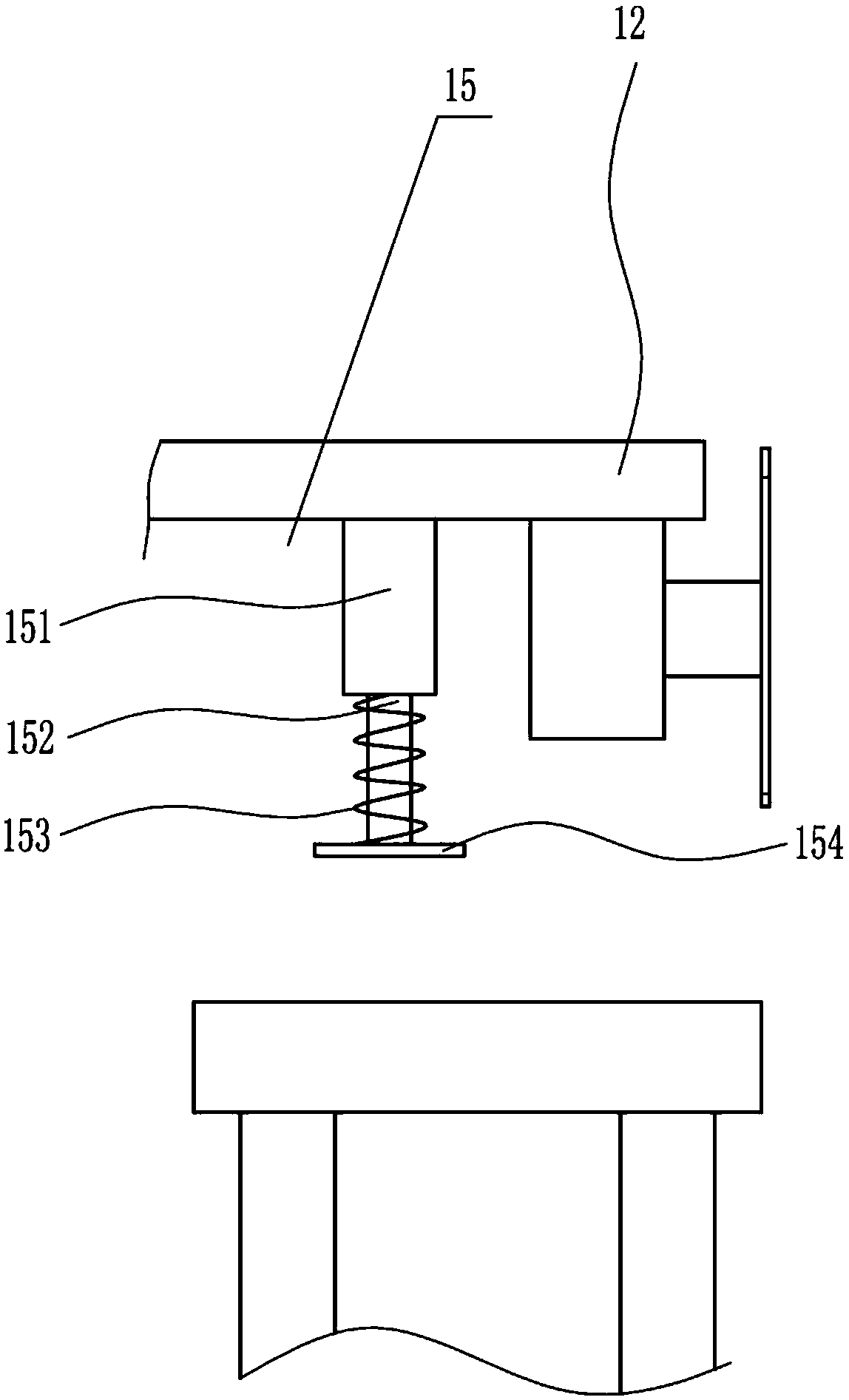

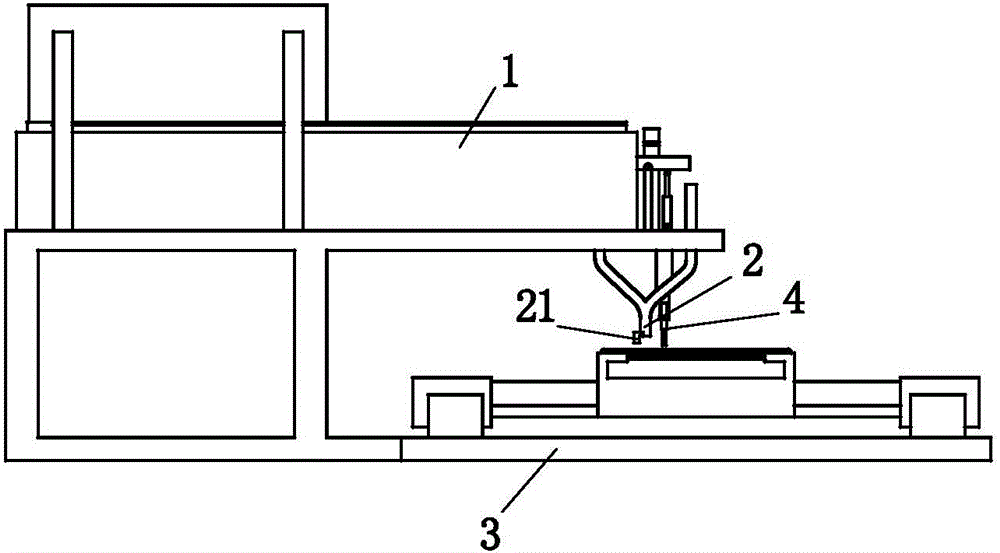

Automatic air column roll material cutting robot for express packaging

ActiveCN108860828ARealize the function of automatic cuttingEnsure safetyContainers to prevent mechanical damageEngineeringUltimate tensile strength

The invention relates to an automatic air column roll material cutting robot for express packaging. The robot comprises a U-shaped support, two limit cutting mechanisms, an auxiliary mechanism and a cutting mechanism. The two limit cutting mechanisms are installed at the left and right ends of the U-shaped support, the auxiliary mechanism is installed in the middle of the U-shaped support, and thecutting mechanism is installed at the upper end of the auxiliary mechanism. According to the automatic air column roll material cutting robot for express packaging, the problems can be solved that anexisting air column roll material needs to be manually cut, during cutting, a worker needs to take the air column roll material by one hand and cut the air column roll material by the other hand, dueto the fact that the air column roll material is not in a tensioned state, a cutter easily deviates from the position, and as a result the cutter cuts through the air column roll; when using the cutter, the worker can be possibly cut and hurt due to misoperation, the consumed time is long, the labor intensity is high, and the efficiency is low; the function can be achieved that the air column roll material is automatically cut off.

Owner:张杰

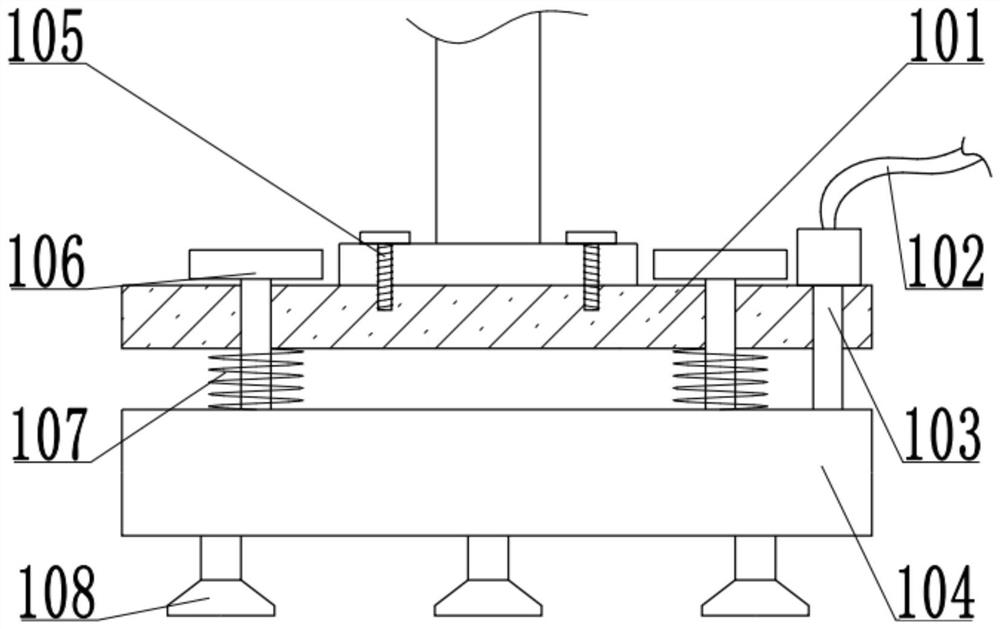

Rebar die automatic cutting equipment for building concrete herringbone steel structure

The invention relates to an automatic cutting equipment for steel bar molds for building concrete herringbone-shaped steel structures, which includes a lifting plate, a mobile adjustment device is installed on the lower end of the lifting plate, a cutting device is installed on the lower end of the mobile adjustment device, and symmetrically installed on the lower end of the mobile adjustment device. Two collection devices. The present invention can solve the problems existing in the cutting process of existing herringbone-shaped building structure steel bar molds, which require manual use of cutting tools to cut steel bars, cutting steel bars at different positions requires manual handling and cutting equipment, and manual cutting of steel bars requires the use of existing ladders, etc. When the tool is used for climbing operations, it is necessary to manually collect the steel bars scattered on the ground after cutting. Manually moving the cutting equipment is labor-intensive, and the cutting operation with the help of climbing equipment is unstable and has potential safety hazards. Manually collecting the cut steel bars is complex and labor-intensive. It can realize the function of automatic cutting of herringbone building structure steel bar molds to solve the problems of high strength and low work efficiency.

Owner:储德姣

Iron sheet cutting equipment for battery box machining

InactiveCN108372329AWith fixed functionImplement fixed functionMetal sawing devicesEngineeringMachining

The invention relates to cutting equipment, in particular to iron sheet cutting equipment for battery box machining. According to the iron sheet cutting equipment for battery box machining, manual work is replaced with machinery. The iron sheet cutting equipment for battery box machining comprises a base, first supporting rods, a supporting plate, a first motor, a first support, a second support,a third support, a bearing, a screw, nuts, a fixing plate, a fourth support and the like, wherein the two first supporting rods are fixedly connected to the base, the supporting plate is fixedly connected to the top ends of the two first supporting rods, the first motor is fixedly connected to the left side of the upper portion of the base, and the first support is fixedly connected to the left end of the base. The iron sheet cutting equipment for battery box machining has the advantages of being capable of achieving the automatic cutting function, capable of achieving the automatic iron sheetfixing function, convenient to use, safe in operation, simple to operate, low in manufacturing cost and the like.

Owner:史志成

Plastic product pneumatic automatic cutting machine

InactiveCN106003190ARealize the function of automatic cuttingImprove controllabilityMetal working apparatusEngineeringControllability

The invention discloses a plastic product pneumatic automatic cutting machine which comprises a machine frame and an electronic control box. A collection tank is arranged on the upper portion of the machine frame, a front and back moving device is installed at the upper end of the machine frame and comprises a moving support, a sliding rail and a linear guide rail, the sliding rail and the linear guide rail are installed at the two ends of the machine frame respectively, the rear end of the moving support is in sliding fit with the sliding rail through a guide base, the front end of the moving support is fixedly provided with a moving sliding base, back-pushing cylinders parallel to the linear guide rail are installed on the two sides of the moving sliding base respectively, and a pressing support and a cut-off support are installed on the moving sliding base. The function of plastic workpiece automatic cutting is achieved, and the whole machine has high controllability and stability.

Owner:SHUCHENG HONGYE HARDWARE & PLASTIC PROD

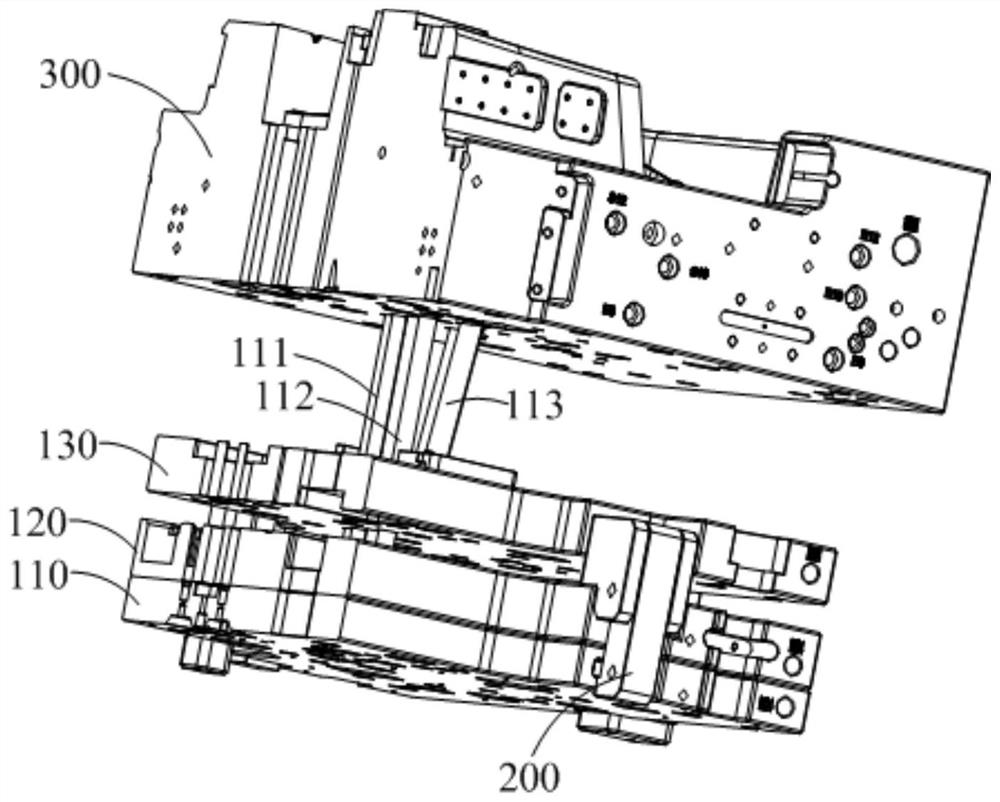

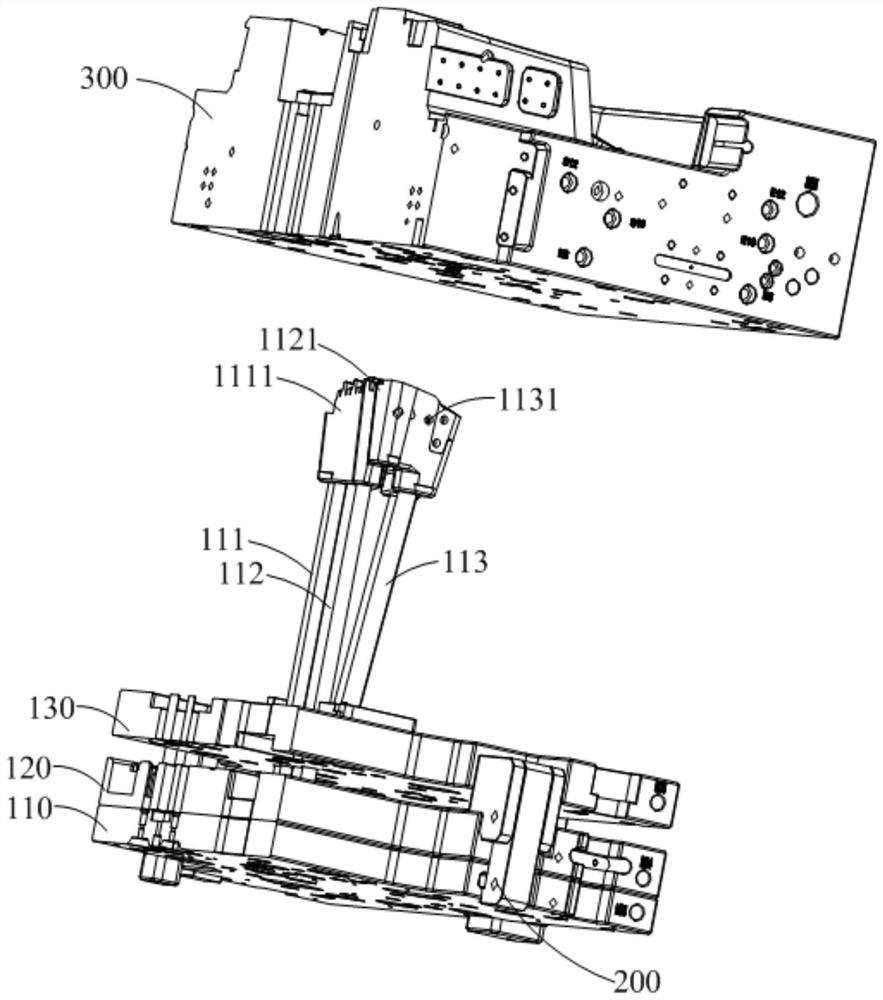

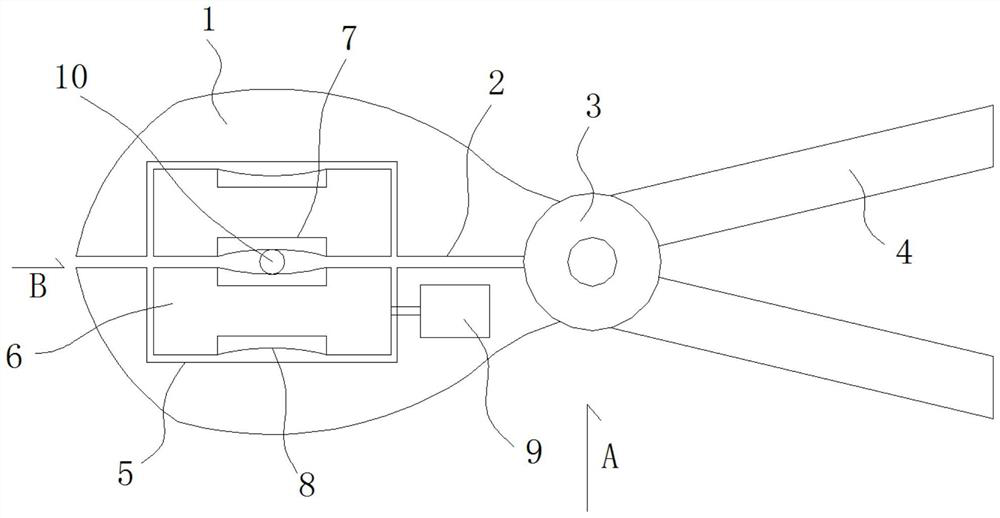

Ejection mechanism and injection mold

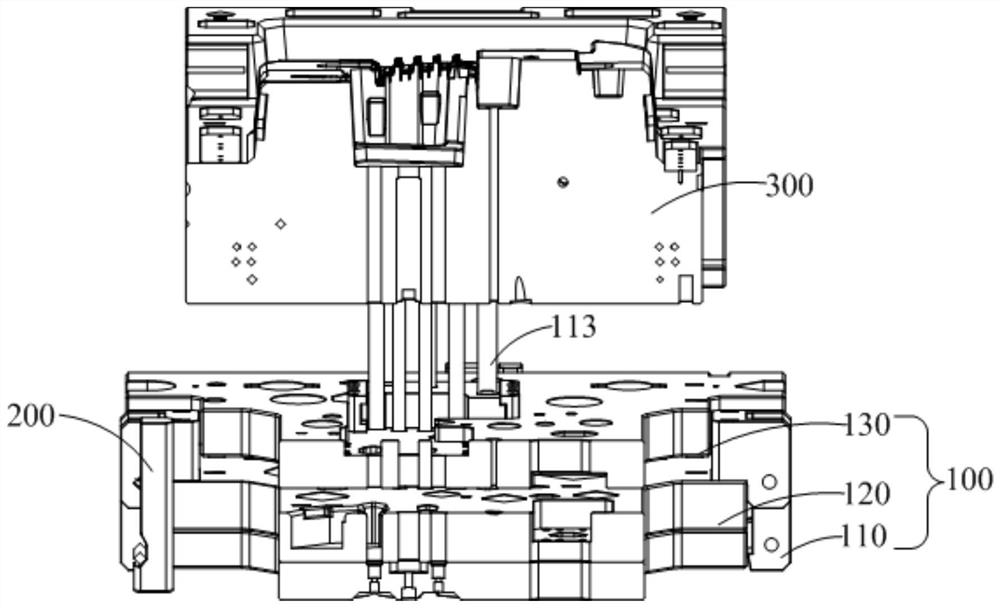

PendingCN112936773ARealize the function of automatic cuttingRealize the function of ejection automatic cuttingMechanical engineeringPhysics

The invention discloses an ejection mechanism and an injection mold. The ejection mechanism comprises a fixing plate, an ejector pin assembly and a buckling machine assembly; the ejector pin assembly is movably arranged on the fixing plate and is in driving connection with an oil cylinder; the buckling machine assembly is connected with the ejector pin assembly and is used for limiting the ejector pin assembly when the injection mold is opened or closed; when the injection mold is in a mold opening state, under driving of the oil cylinder, the ejector pin assembly is separated from the buckling machine assembly to cut off a water gap of a formed product when the ejector pin assembly is ejected out of the initial position to the first preset position. The ejection structure of the mold is improved, the functions of ejection and automatic cutting of the water gap are achieved, the production efficiency of products is improved, and the production and manufacturing cost is reduced.

Owner:南通银宝山新科技有限公司

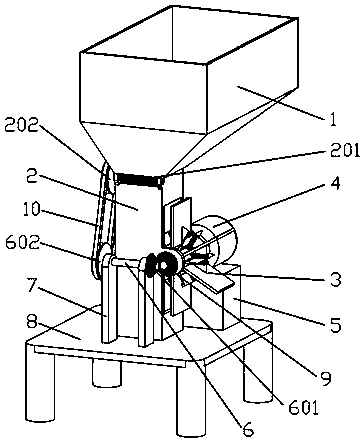

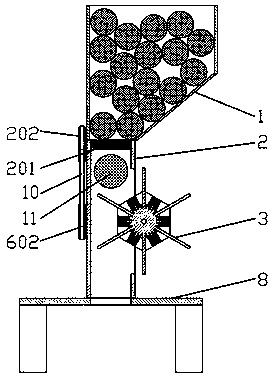

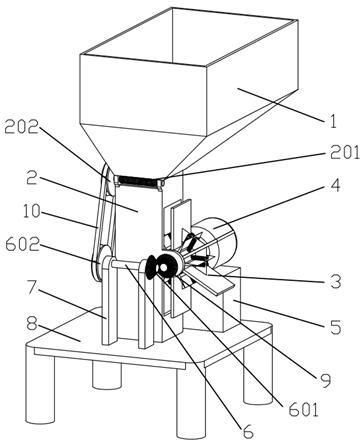

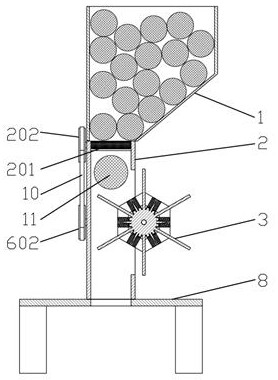

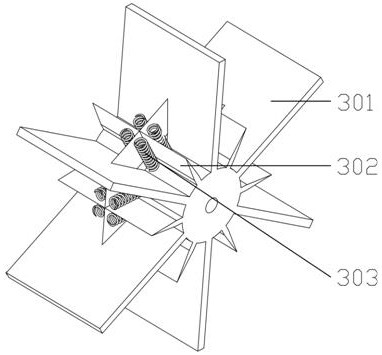

Automatic chestnut opening cutting apparatus

The invention relates to an automatic chestnut opening cutting apparatus, and belongs to the technical field of kitchen utensils. The apparatus includes a power transmission mechanism and an automaticblanking mechanism. The apparatus is characterized in that a motor, an impeller, a first reversing gear, a transmission shaft, a second reversing gear, a second belt pulley, a belt and a first belt pulley are arranged in the power transmission mechanism, a hopper, a chestnut conveying pipe and a base are arranged in the automatic blanking mechanism, the impeller is driven by the motor to realizethe function of automatic chestnut opening cutting, and a drum rotates through the action of the power transmission mechanism, thereby ensuring that chestnuts cannot be stuck at a chestnut conveying pipe opening. The automatic chestnut opening cutting apparatus solves the problem of low efficiency of manual cutting of the chestnuts, and also solves the problem of hidden danger caused by a cuttingknife when the chestnuts are manually cut.

Owner:南京幸庄科技创新产业园管理有限公司

Full-automatic cutting device for building tile

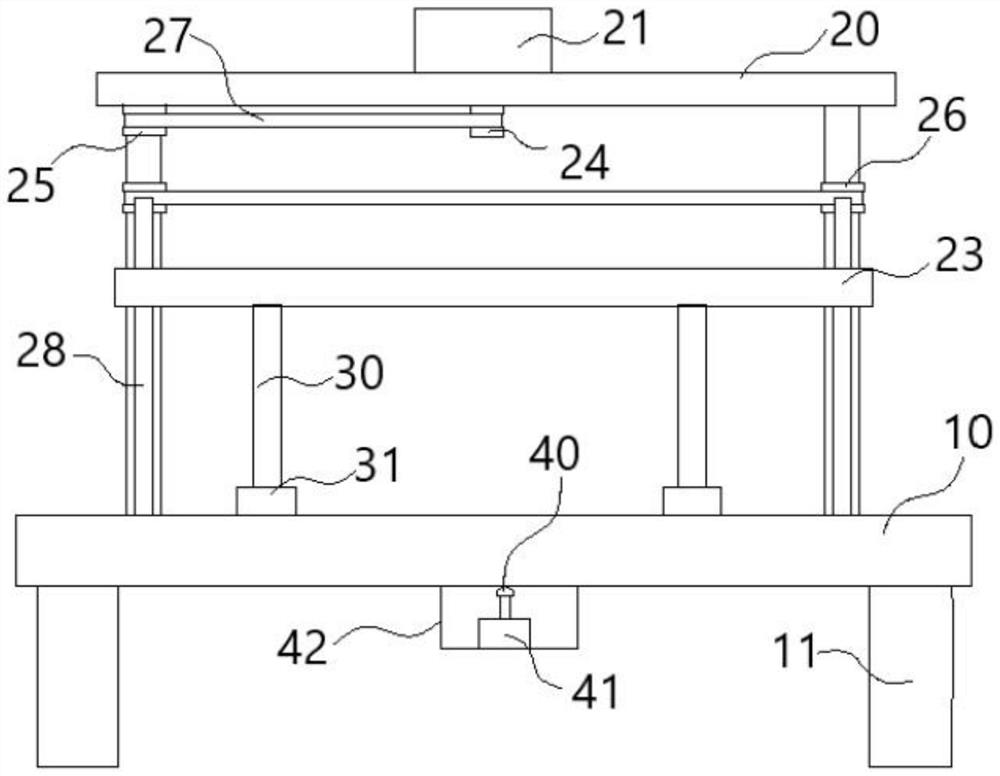

InactiveCN112497543ARealize the function of automatic feedingRealize the function of automatic fixingWorking accessoriesStone-like material working toolsRotational axisHydraulic cylinder

The invention discloses a full-automatic cutting device for a building tile, and belongs to the technical field of building. The full-automatic cutting device for the building tile solves the problemthat an existing full-automatic cutting device for the building tile is low in working efficiency. The full-automatic cutting device for the building tile comprises a feeding box, a material fetchingdevice, a material receiving disc, a fixing device, a cutting wheel and a workbench, wherein tiles are placed in the feeding box, the material fetching device is located above the feeding box and connected with a second hydraulic cylinder through a second hydraulic supporting rod, the material receiving disc is located above the workbench and connected with a first rotating shaft through a base embedded in the side wall of the material receiving disc, a driven gear embedded at the bottom of the first rotating shaft is connected with a second driving gear through gear teeth, and the second driving gear is connected with a third servo motor through a motor shaft. An intermittent transmission wheel connected to the bottom of the fixing device through a second rotating shaft is engaged with anintermittent driving wheel, the intermittent driving wheel is connected with a fourth servo motor through a motor shaft, and a cutting wheel is connected with a fifth servo motor through a driving shaft. The full-automatic cutting device for the building tile has the advantage of high work efficiency.

Owner:黄海清

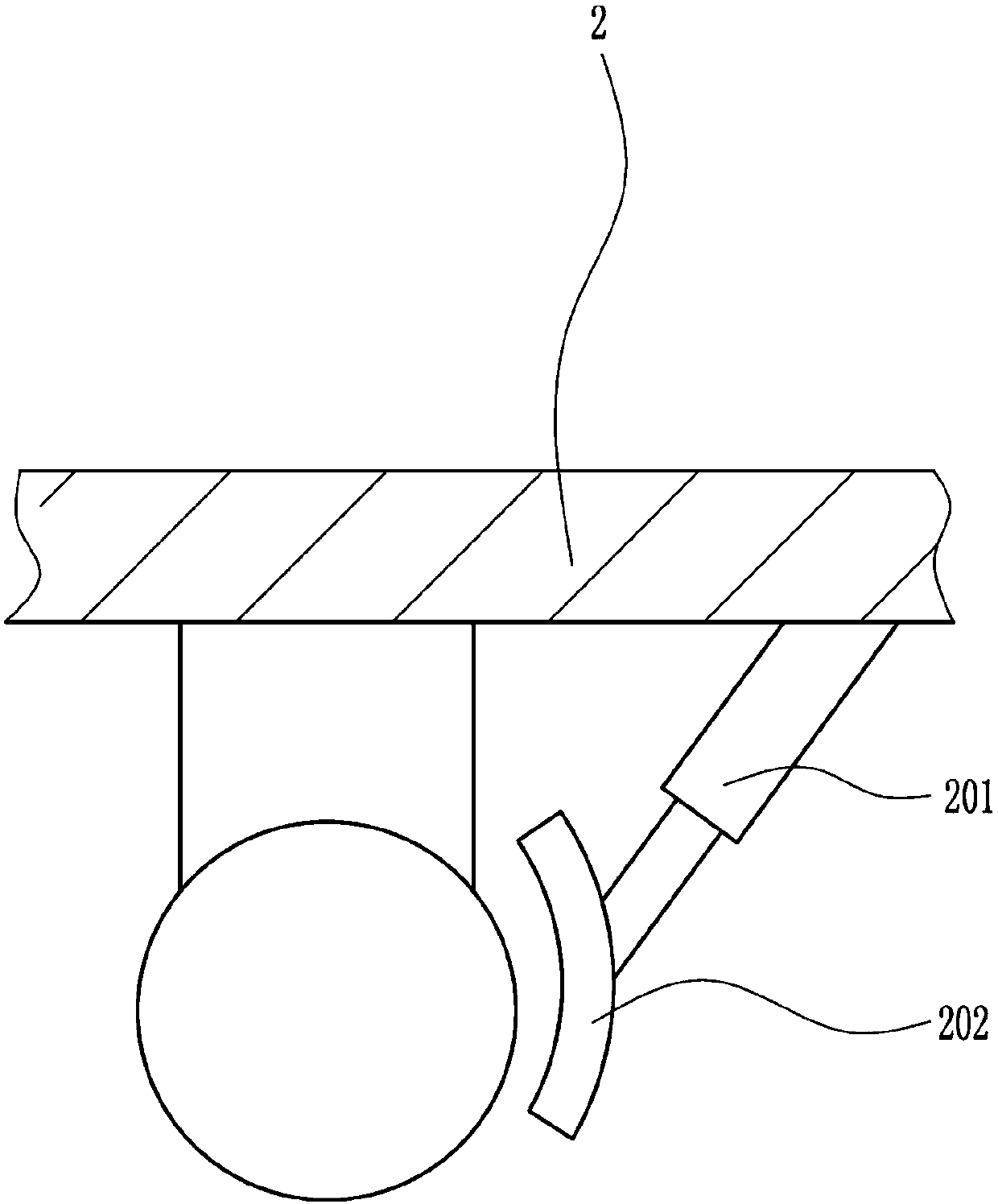

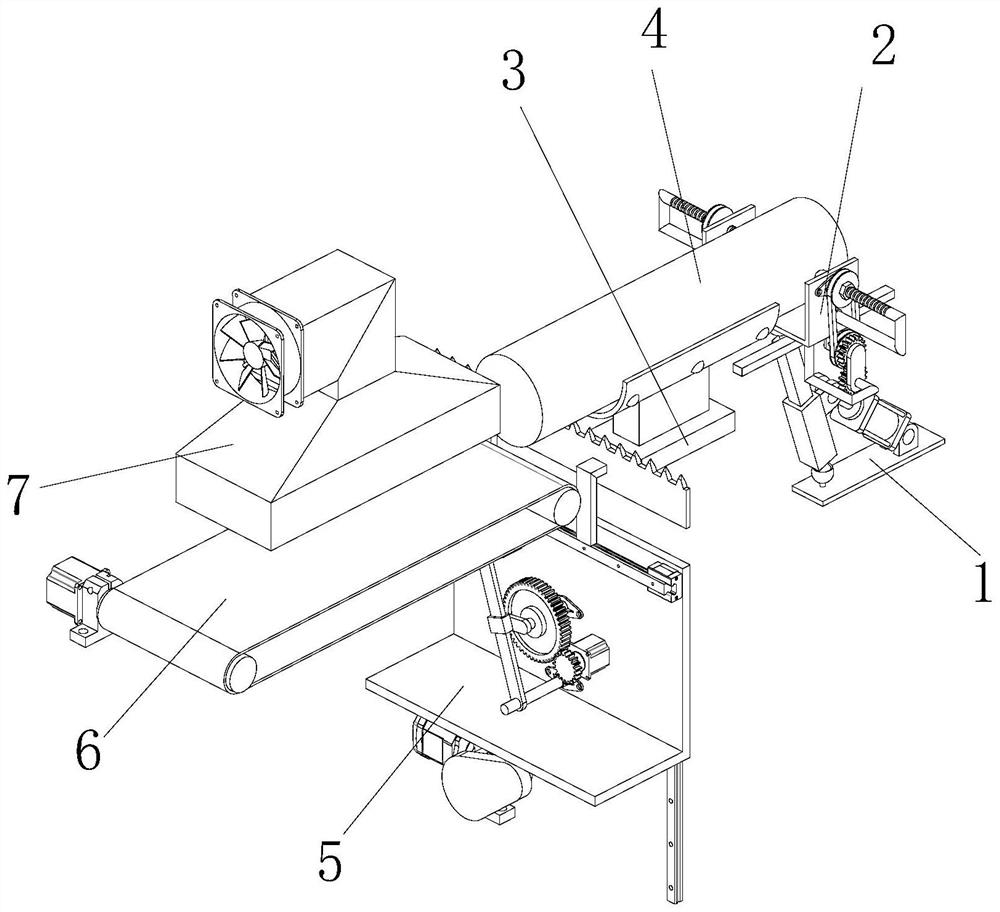

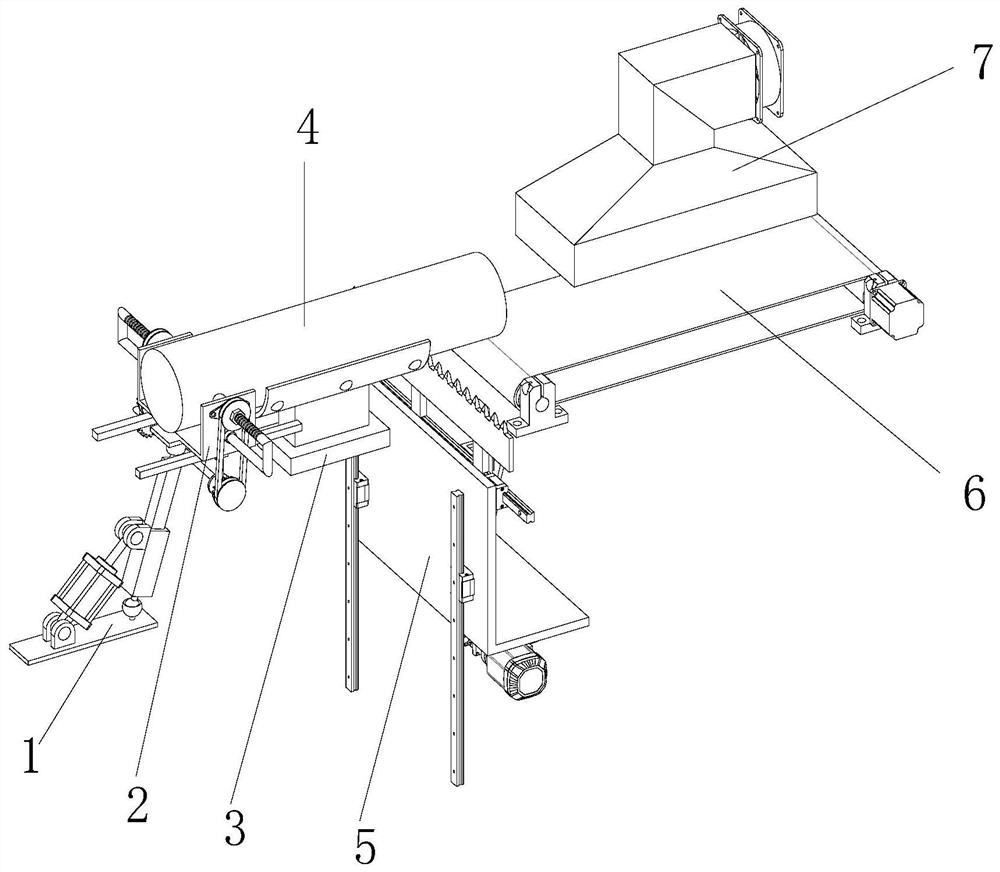

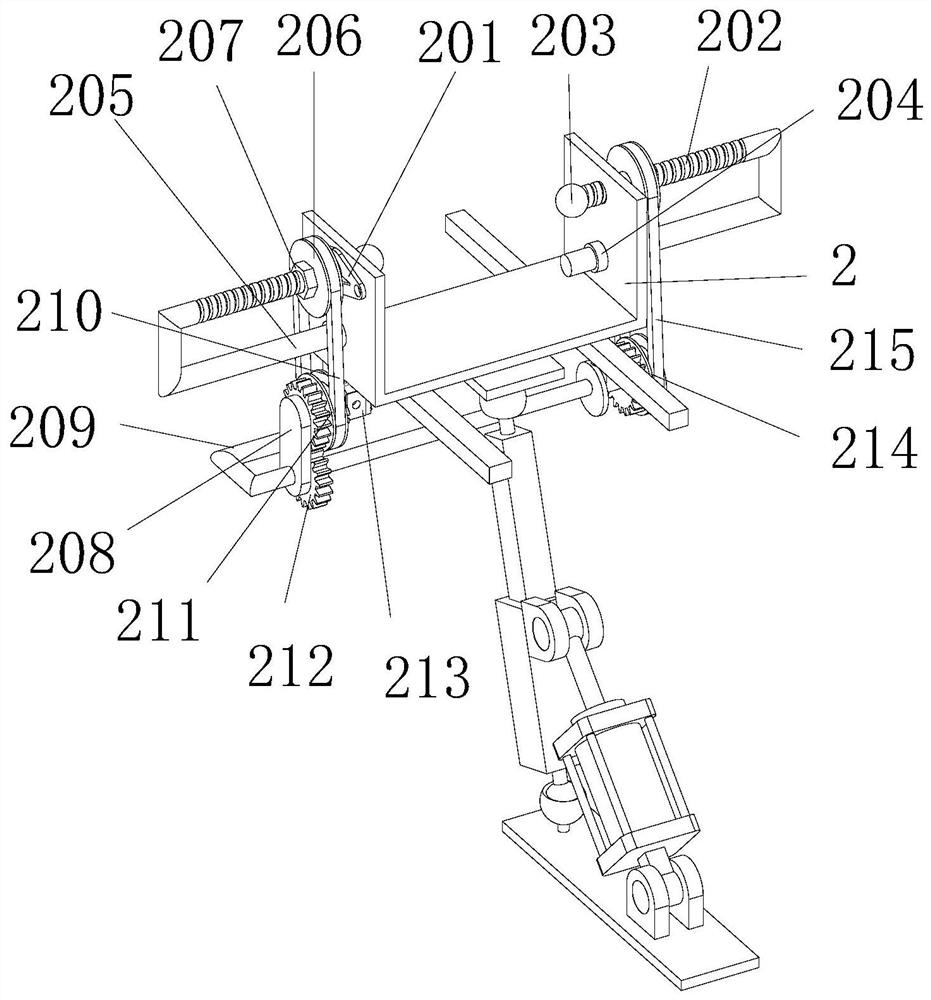

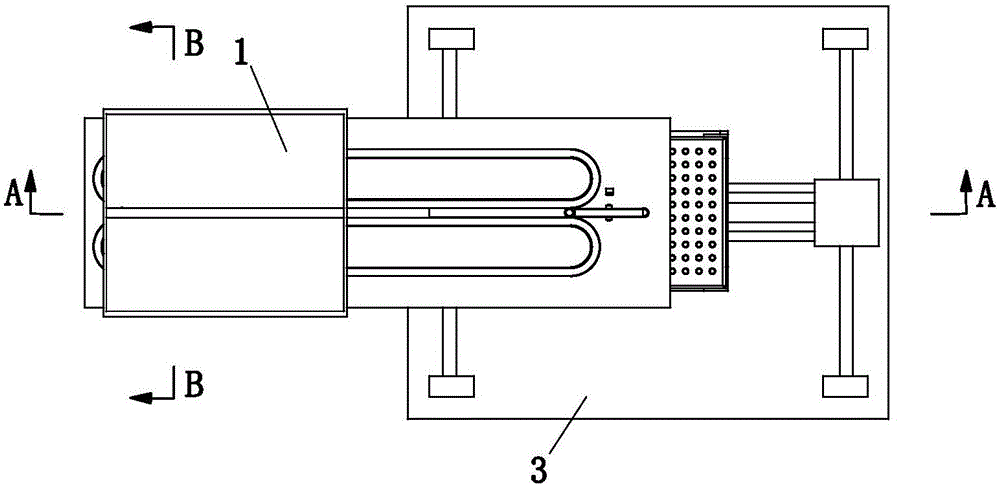

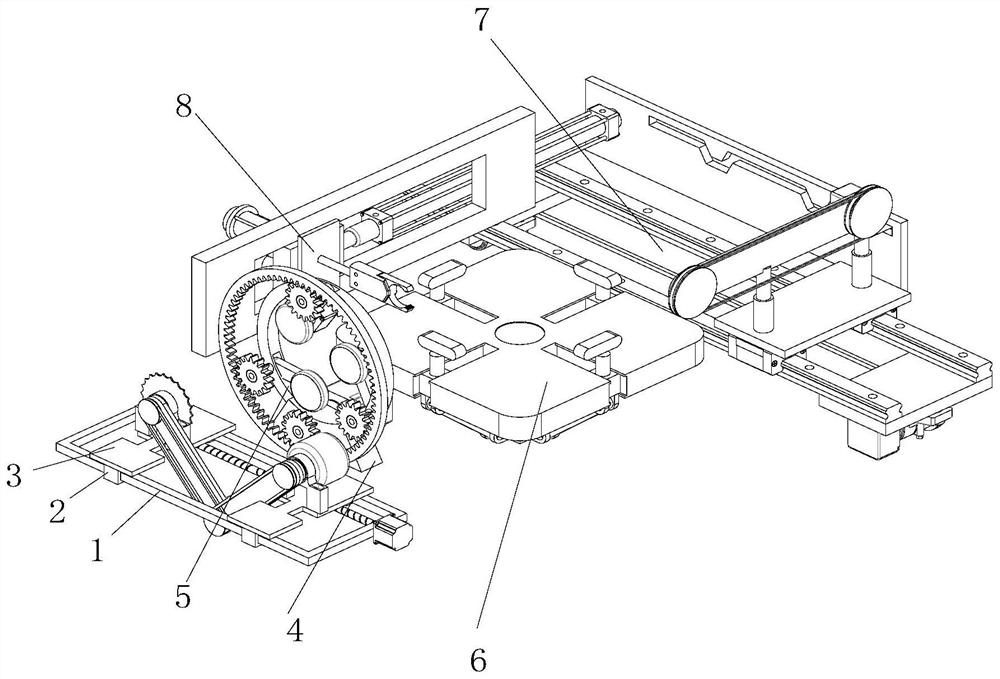

Cutting and drying machine for wood manufacturing

ActiveCN112454534AReduce frictionRealize automatic advancementFeeding devicesDrying gas arrangementsStructural engineeringThreaded rod

The invention discloses a cutting and drying machine for wood manufacturing, and belongs to the field of wood processing. The cutting and drying machine comprises a fixing plate, the fixing plate is fixedly installed relative to the ground, and a pushing frame is installed above the fixing plate. First shaft seats are fixedly installed on the two sides of the pushing frame, and pushing wheel discsare installed on one sides of the first shaft seats. The pushing wheel discs are rotationally connected with the first shaft seats, threaded rods are inserted into the inner sides of the pushing wheel discs in a penetrating mode, and propelling nuts matched with the threaded rods are arranged in the middles of the pushing wheel discs. The wood processing efficiency is high.

Owner:安吉美源家具有限公司

Plastic film cutting equipment

PendingCN112918816ARealize the function of automatic cuttingAvoid the constant cutting problemPackagingMetal working apparatusStructural engineeringPlastic film

The invention provides plastic film cutting equipment. The plastic film cutting equipment comprises a rack, a cutting device, a movable cutting panel and a material receiving plate are sequentially arranged on the rack from top to bottom, the cutting device is fixedly arranged at the top of the rack, the movable cutting panel is movably arranged on the rack, and the material receiving plate is arranged below the movable cutting panel. The plastic film cutting equipment has the beneficial effects that the plastic film cutting equipment is novel in structure, easy and convenient to operate and stable in performance, efficiency is improved, and the plastic film cutting equipment has wide market prospects in the popularization of a burr-proof cutting device for a plastic film.

Owner:TIANJIN HAIJING PLASTIC PROD

Traditional Chinese medicine decoction piece processing equipment and processing method thereof

InactiveCN112958520AEasy to cleanAvoid stickingPharmaceutical product form changeCleaning using toolsMedicinal herbsEngineering

The invention relates to the technical field of pharmaceuticals, and discloses traditional Chinese medicine decoction piece processing equipment and a processing method thereof. The traditional Chinese medicine decoction piece processing equipment comprises a fixing plate; front and rear side faces of the fixing plate are fixedly connected with front and rear side plates; grooves are formed in the right sides of the front and rear side plates and a sliding side plate is arranged in each groove in a sleeved manner; four sets of bottom plates A and bottom plates B are arranged on the front and rear side plates in a sleeved manner; the bottom plates A and the bottom plates B are arranged, and in the process of processing medicinal materials by the equipment, continuous switching between a corrugated state and a transverse state can be formed; in the corrugated state, a better cleaning effect on the medicinal materials can be achieved with the cooperation of sharp protrusions and pressing and pushing of a brush plate on the medicinal materials; sharp ends of connecting pads can conform to recesses in the medicinal materials through deformation after being in contact with the medicinal materials, so that wrinkles on the medicinal materials are cleaned, and the cleaning effect is improved; and the equipment can be in the transverse state after rubbing once, so that rubbed off impurities are accommodated in the connecting pads and are discharged alone, thus avoiding the problem that the impurities are adhered to or embedded into the medicinal materials in subsequent rubbing.

Owner:北京图腾猎技科技有限公司

Automatic water culture propagation equipment for China roses

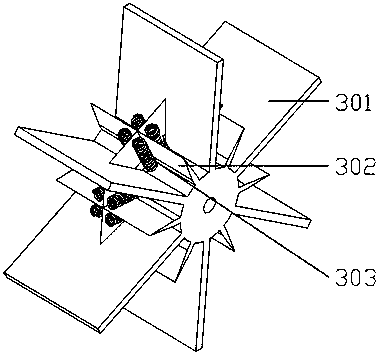

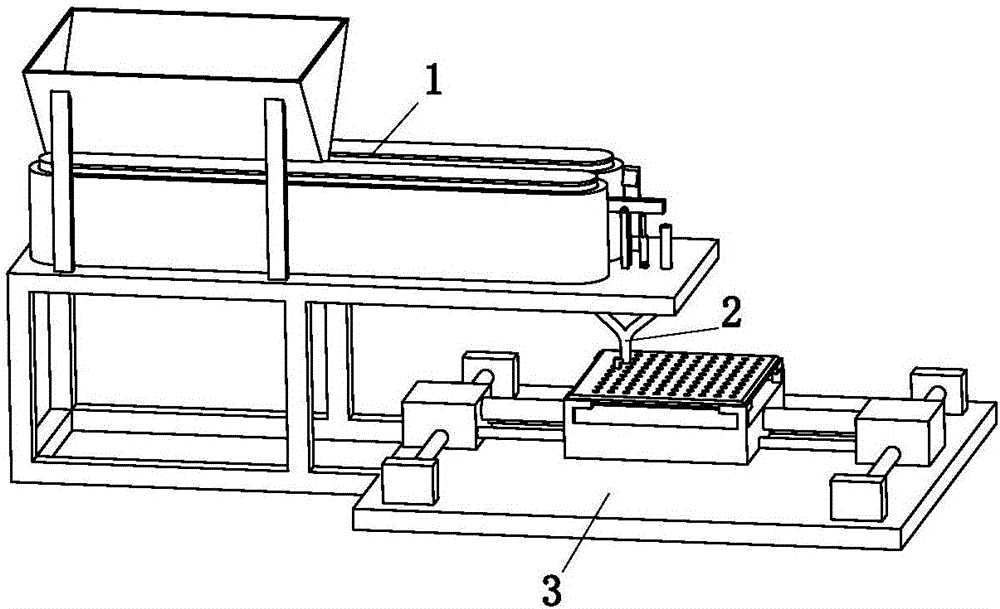

ActiveCN106256195AAchieve mechanical propertiesRealize automatic cuttingAgriculture gas emission reductionPlant cultivationWorkloadWaste management

The invention relates to the field of flowers and plants, in particular to automatic water culture propagation equipment for China roses. The automatic water culture propagation equipment for China roses comprises a righting device, a conveying pipeline, a moving device and a perforating device, wherein the righting device is located above the moving device, the conveying pipeline is located between the righting device and the moving device, and the perforating device is located below the righting device. According to the automatic water culture propagation equipment for China roses, a foam board is automatically perforated through the perforating device, and China rose cutting branches righted by the righting device are conveyed into holes in the foam board of the moving device through the conveying pipeline, so that automatic perforating and mechanical righting and automatic cutting of the China rose cutting branches are achieved, the workload of people is greatly reduced, and the working efficiency is improved.

Owner:江苏新境界农业发展有限公司

Automatic ivy cutting pliers

PendingCN114303666ARealize the function of automatic cuttingGuaranteed cut offVegetative propogationRattanEngineering

The invention discloses an automatic ivy cutting clamp which comprises two clamp bodies which are correspondingly arranged, a corresponding butt joint end face is arranged between the two clamp bodies, the two clamp bodies are correspondingly installed into a whole through a hinge assembly and a clamp handle, and the two clamp bodies can be correspondingly opened or closed. When the cutting device is used, the clamp bodies on the two sides are opened, cutting vines are placed between the cutting rollers on the two sides, particularly between the strip-shaped elastic pieces on the two sides, the strip-shaped elastic pieces have elasticity, the cutting vines are correspondingly clamped and fixed between the cutting rollers on the two sides, then the driving device is started, the cutting rollers are driven to rotate, and then the cutting vines are clamped and fixed between the cutting rollers on the two sides. The cutting roller can correspondingly move downwards to be cut in the matrix, then the cutting rattan is cut, and the automatic cutting function can be achieved.

Owner:江苏九谷生态农业有限公司

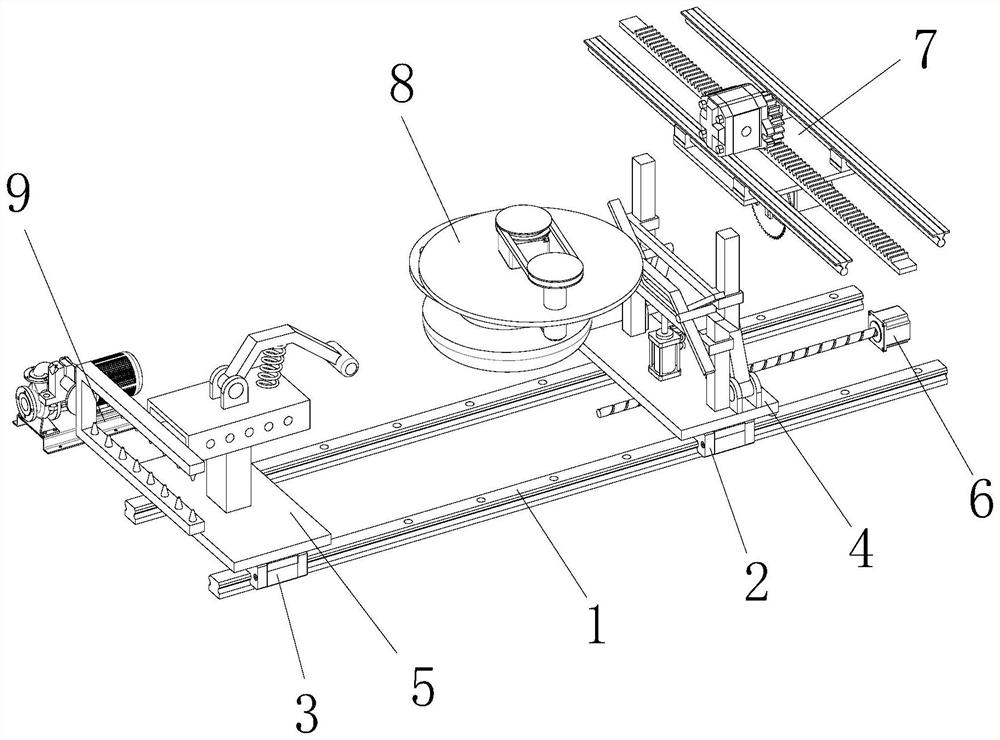

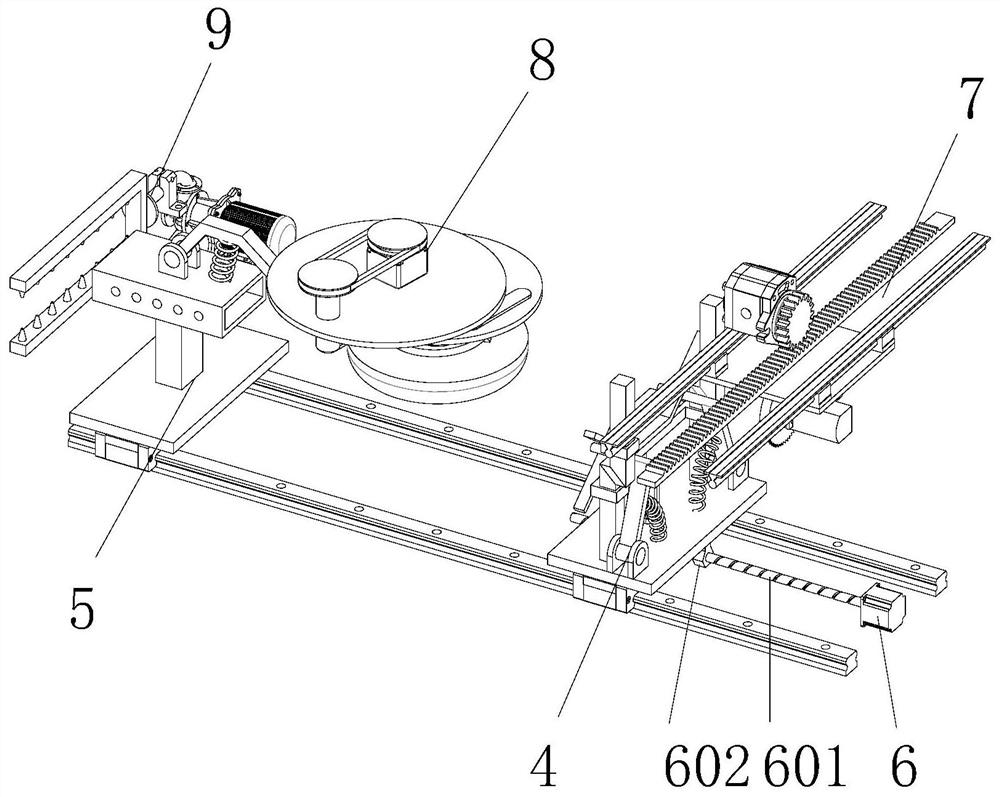

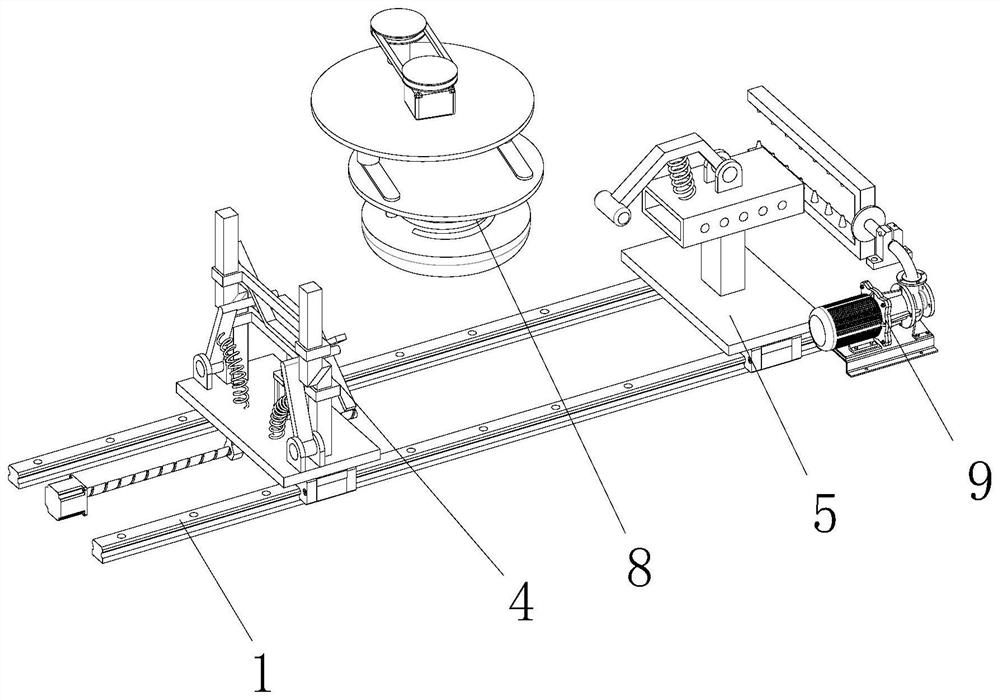

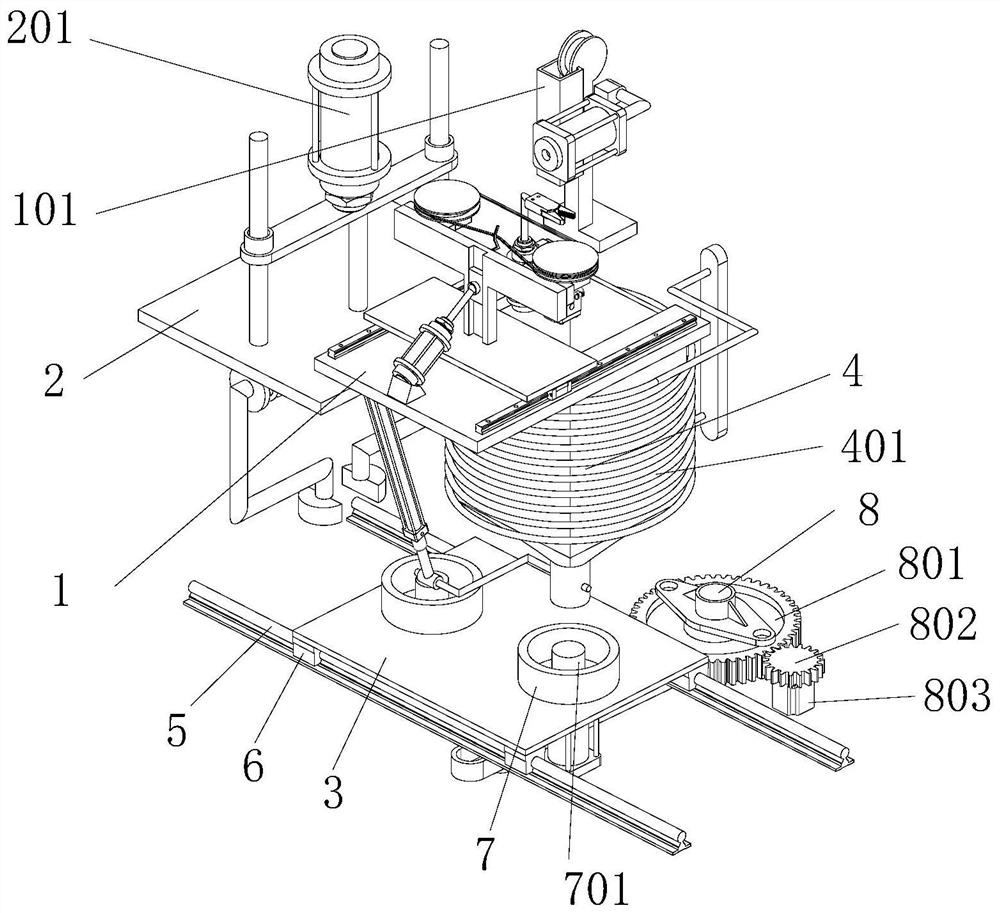

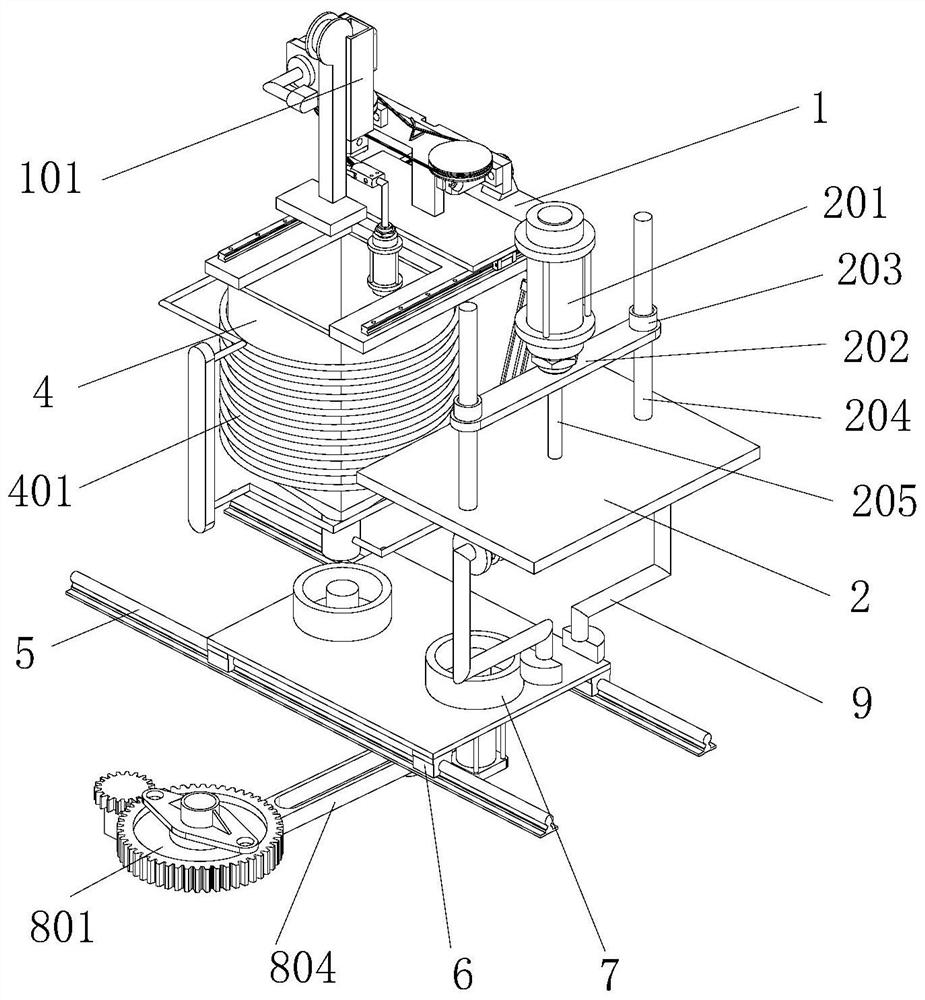

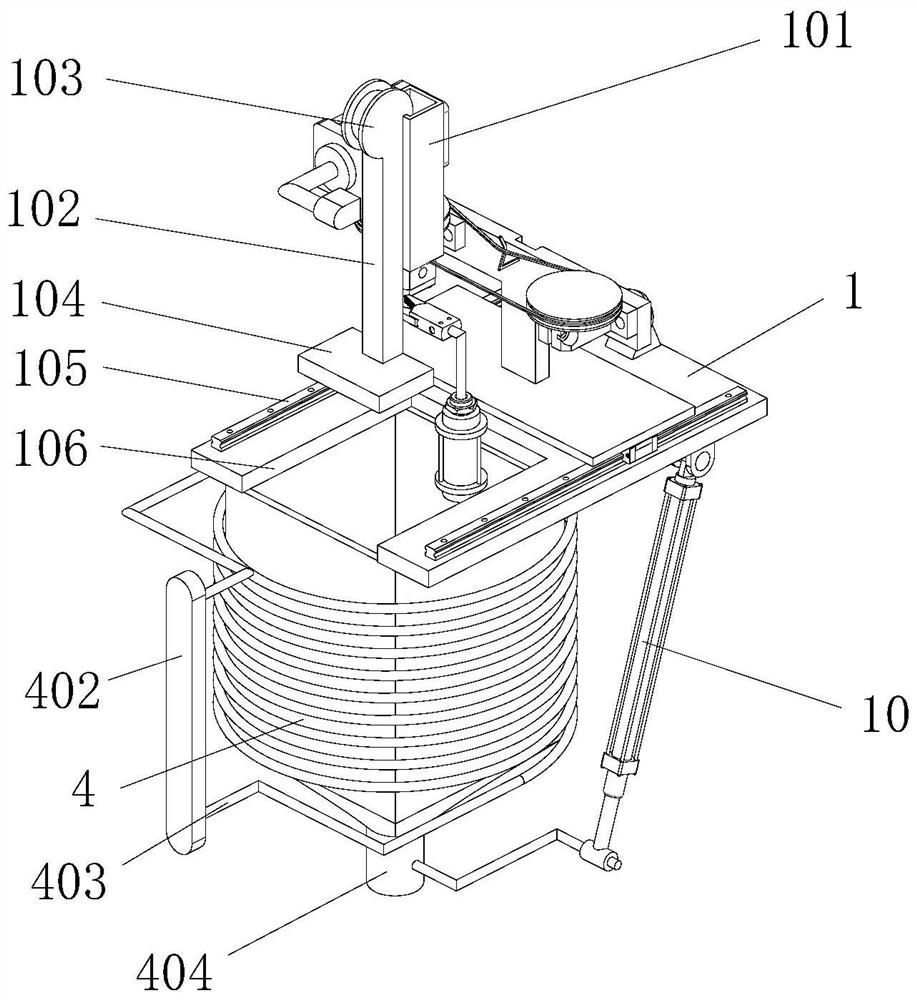

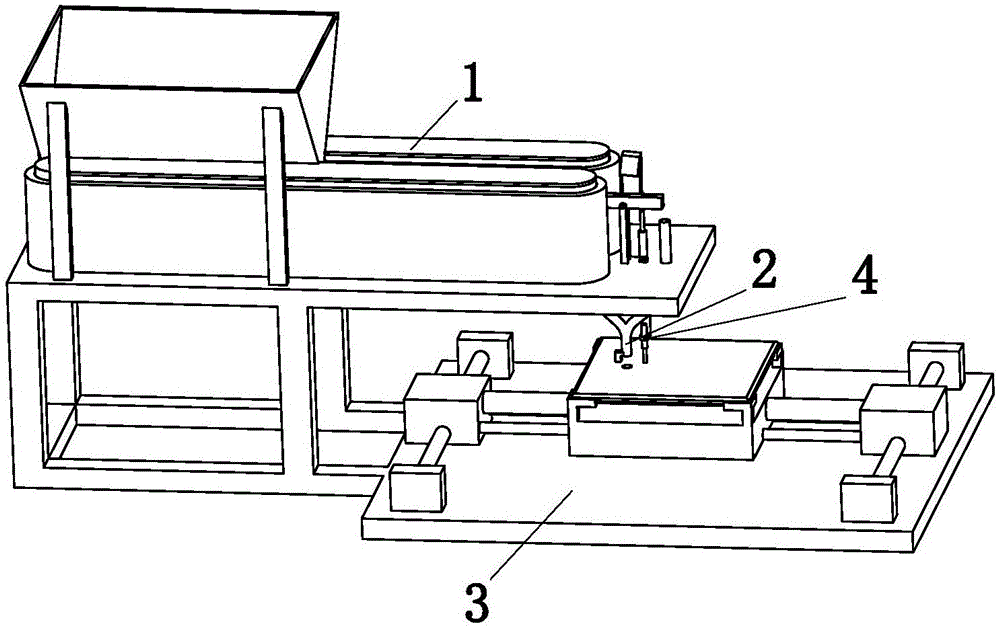

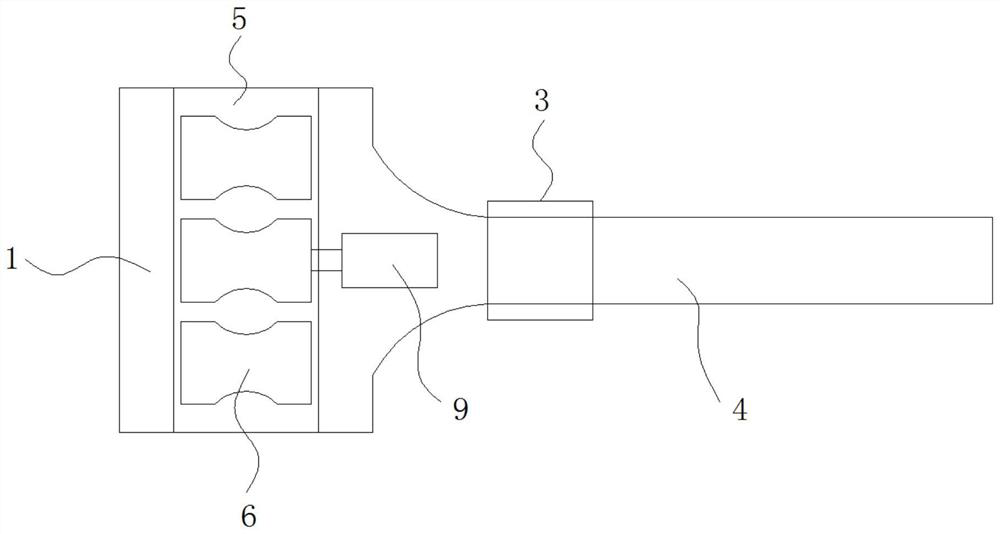

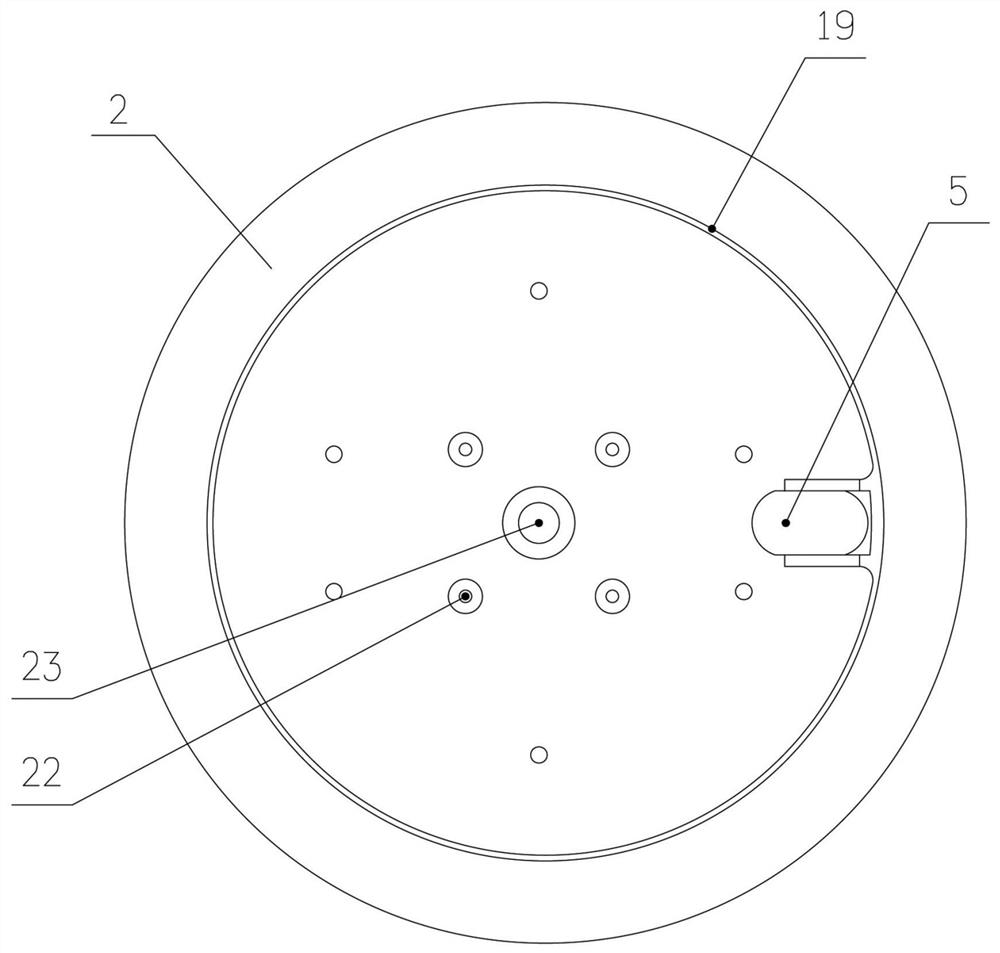

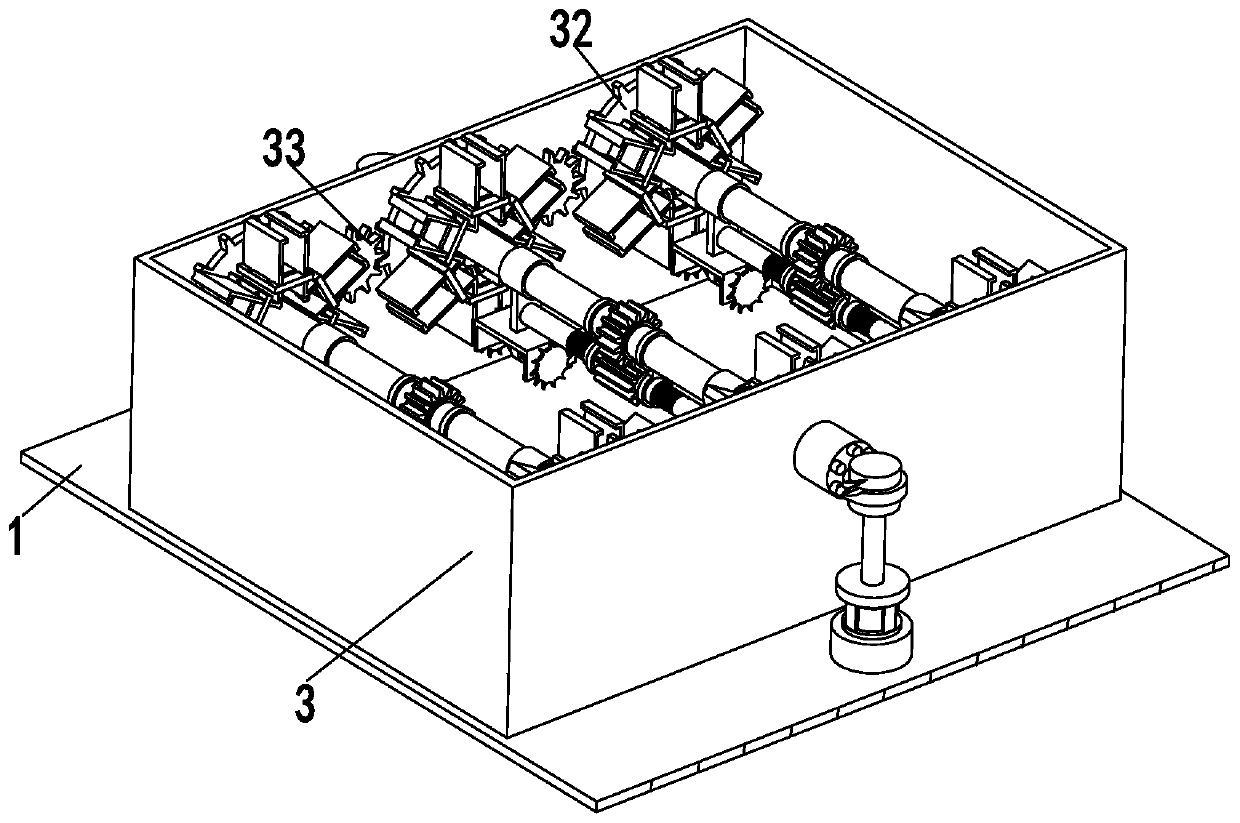

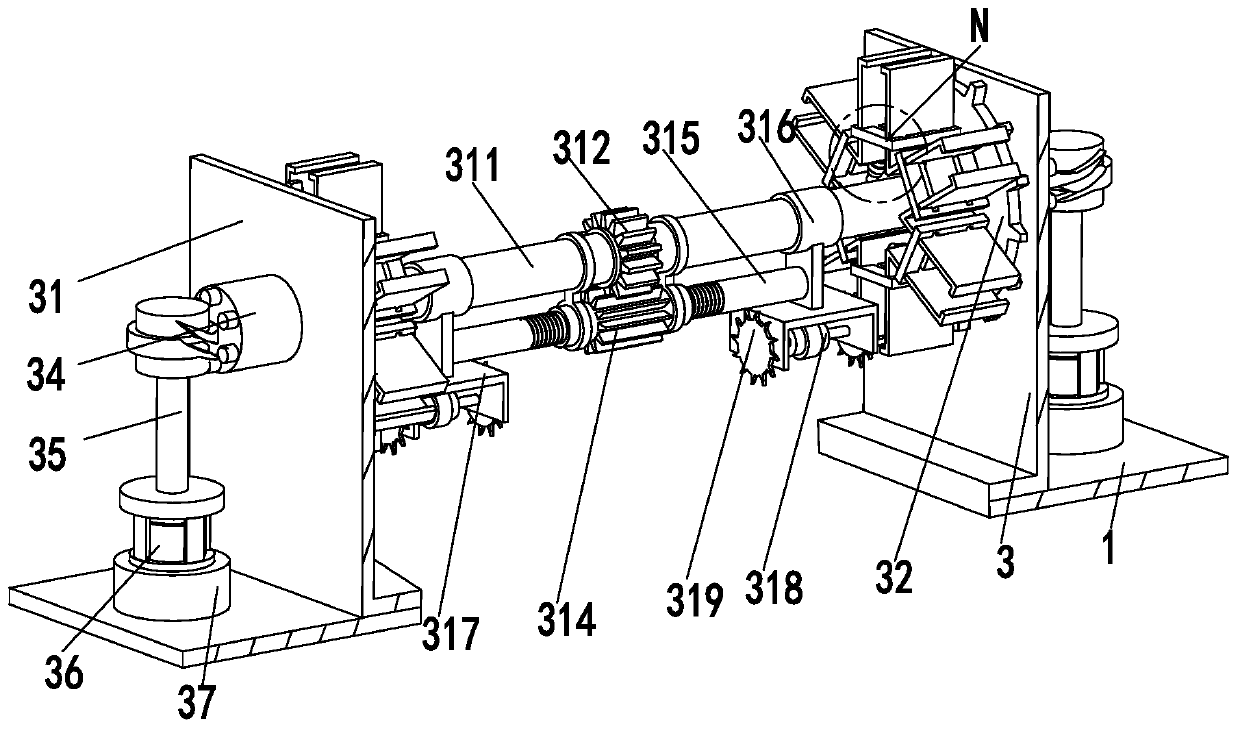

A kind of automatic processing device and working method of furniture circular plate

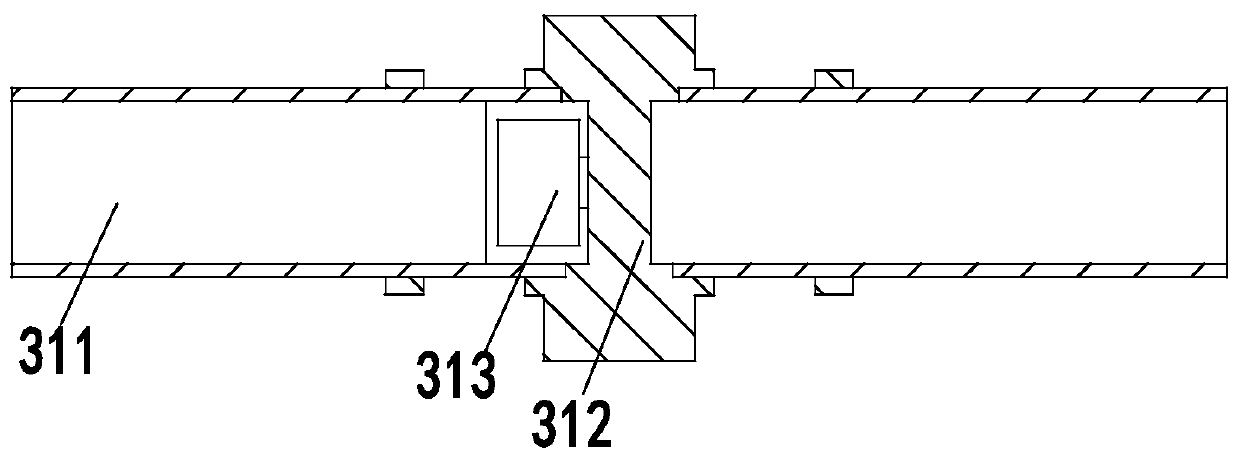

ActiveCN111687957BRealize the function of automatic cuttingReduce manual operationsFeeding devicesGripping devicesFixed bearingDrive wheel

The invention discloses an automatic processing device for furniture circular plates and a working method thereof. The automatic processing device for furniture circular plates comprises an operation table, a center plate is arranged in the middle of the operation table, and side plates are arranged on both sides of the center plate , the cross section of the side plate is L-shaped, a fixed bearing is fixedly installed in the middle of the center plate, the outer ring of the fixed bearing and the center plate are fixedly connected, the inner ring of the fixed bearing is fixedly installed with a worm, and the round rod is sleeved with a movable Bearing, and the round rod is slidably connected with the inner ring of the movable bearing, a driving wheel is installed on the outer side of the movable bearing, and the driving wheel is fixedly connected with the outer ring of the movable bearing, the worm is installed on the output end of the servo motor, the servo The motor is fixed on the bottom end of the center plate, a clutch cylinder is fixedly installed on one side of the side plate, and a ball sleeve is installed at the output end of the clutch cylinder, and a ball head is installed on the inner side of the ball sleeve, and the ball head fits actively side of the wheel.

Owner:山东凯迪威家具有限公司

An air column automatic cutting robot for express packaging

ActiveCN108860828BRealize the function of automatic cuttingEnsure safetyContainers to prevent mechanical damageEngineeringMechanical engineering

Owner:张杰

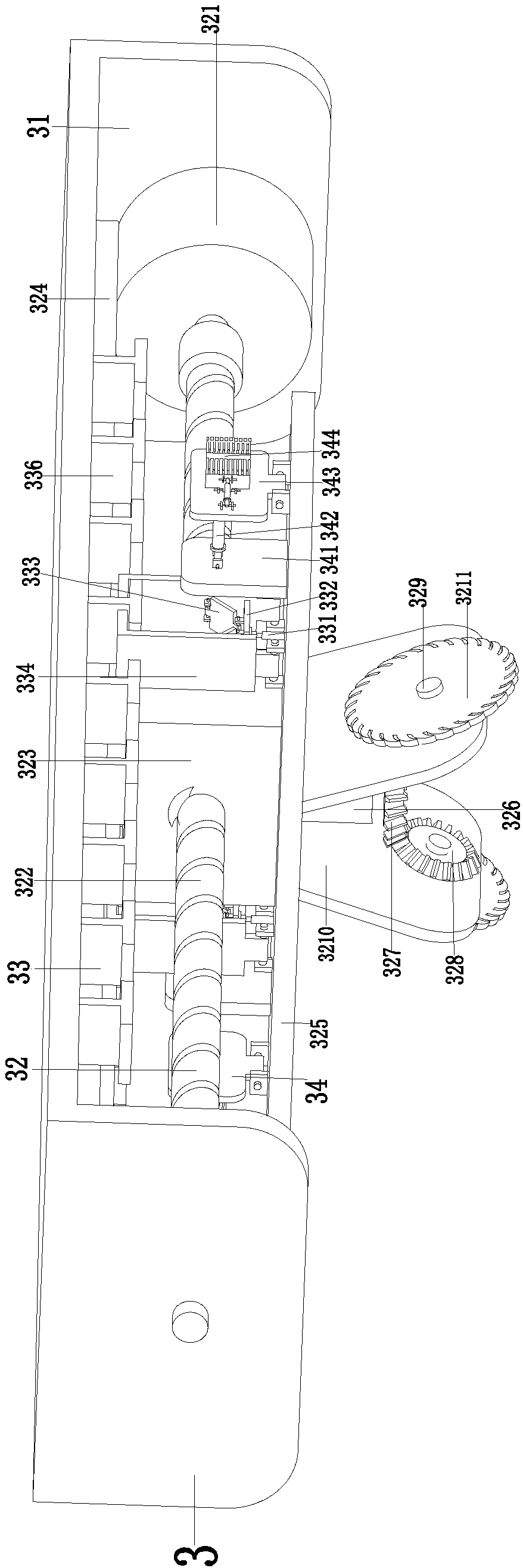

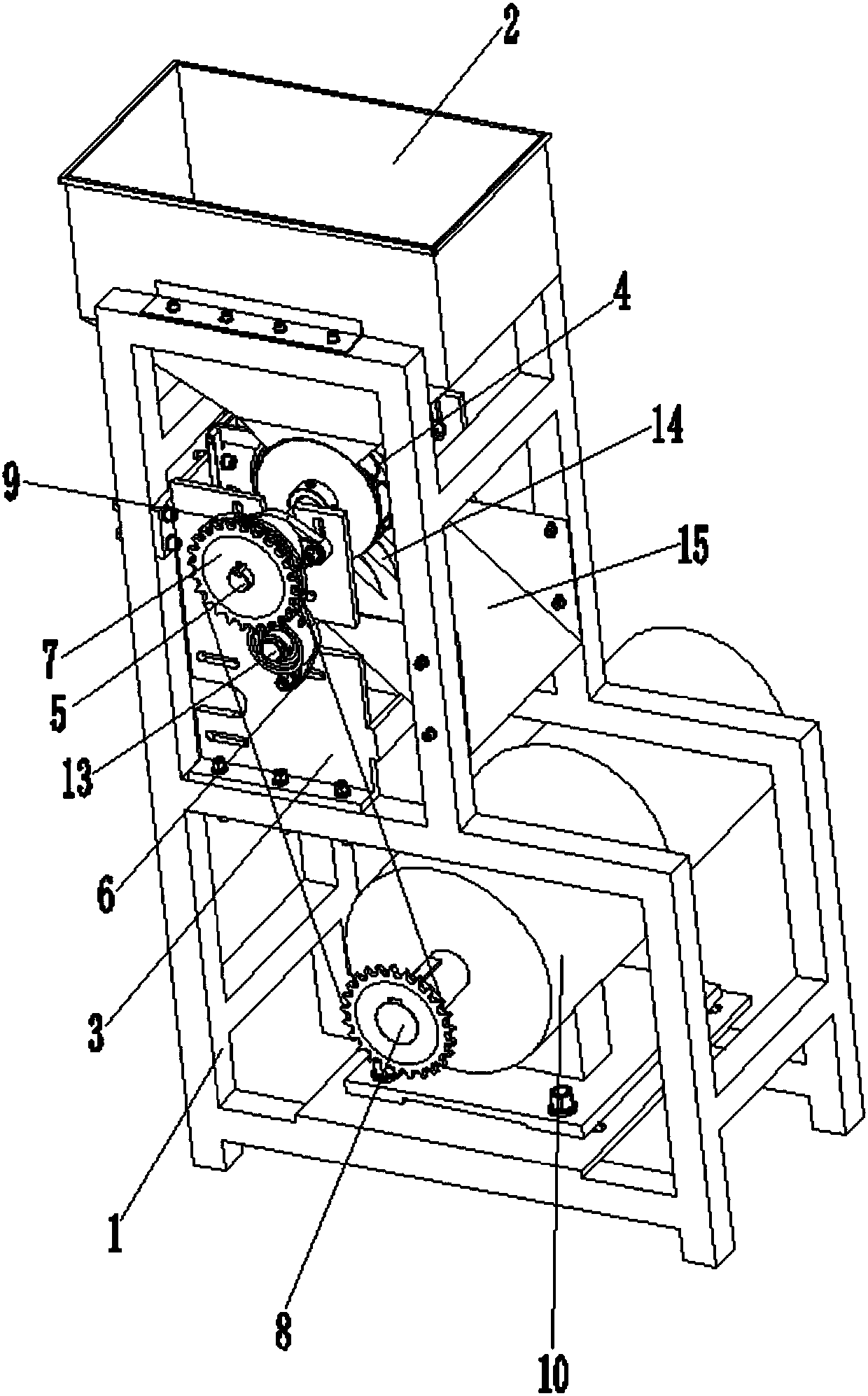

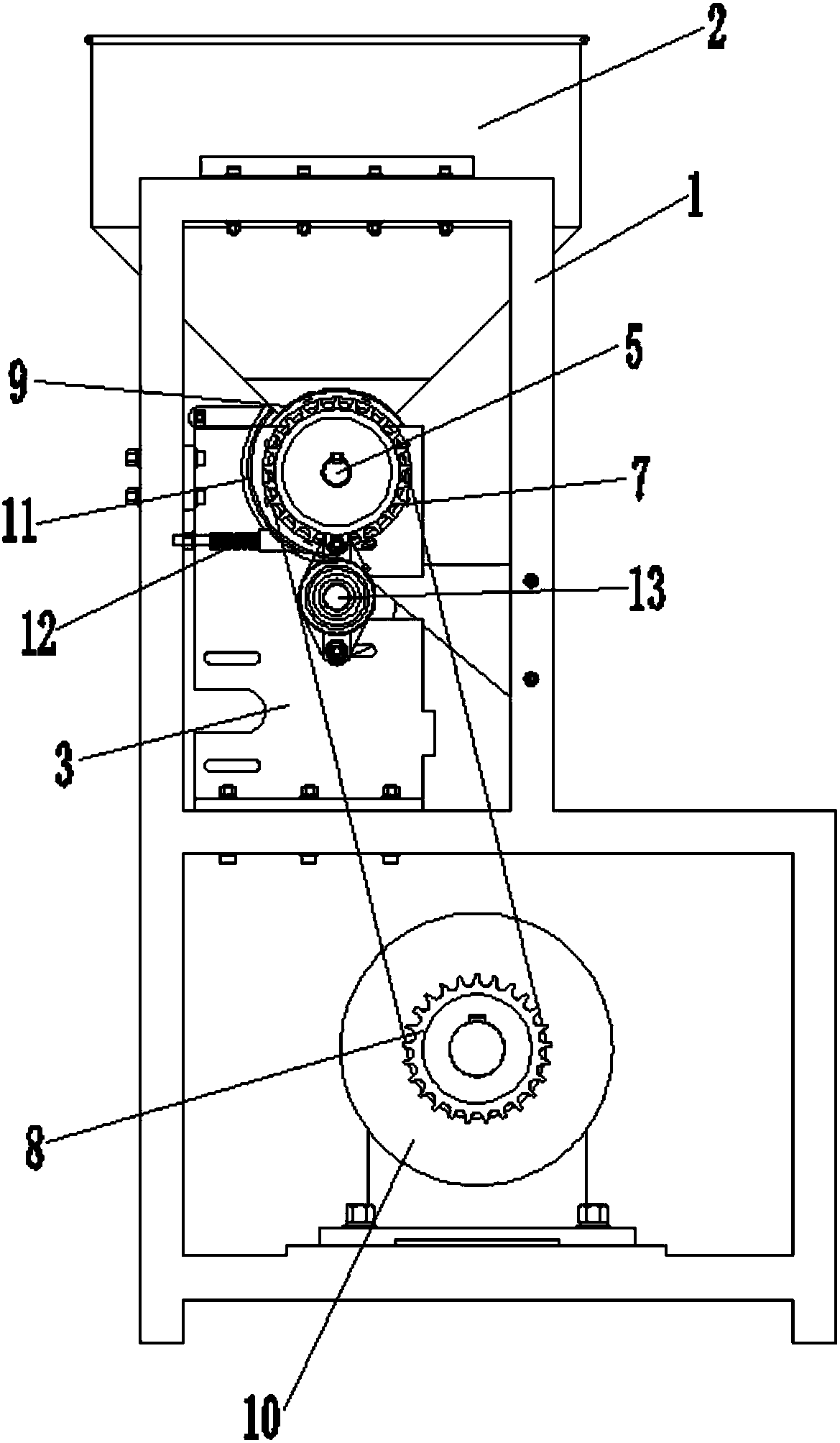

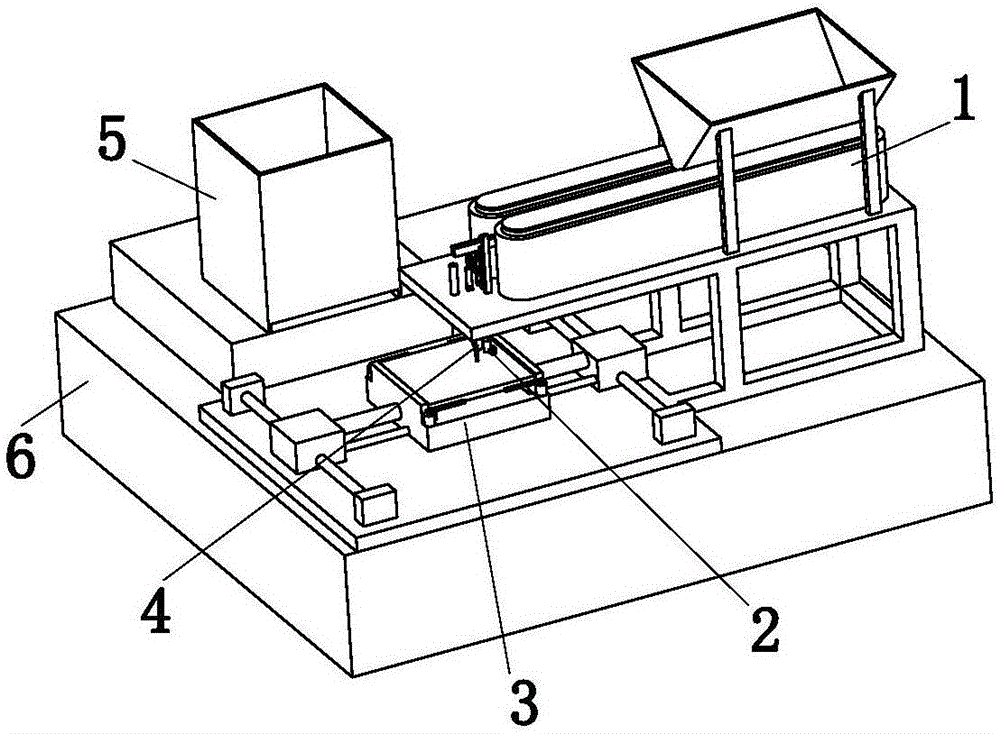

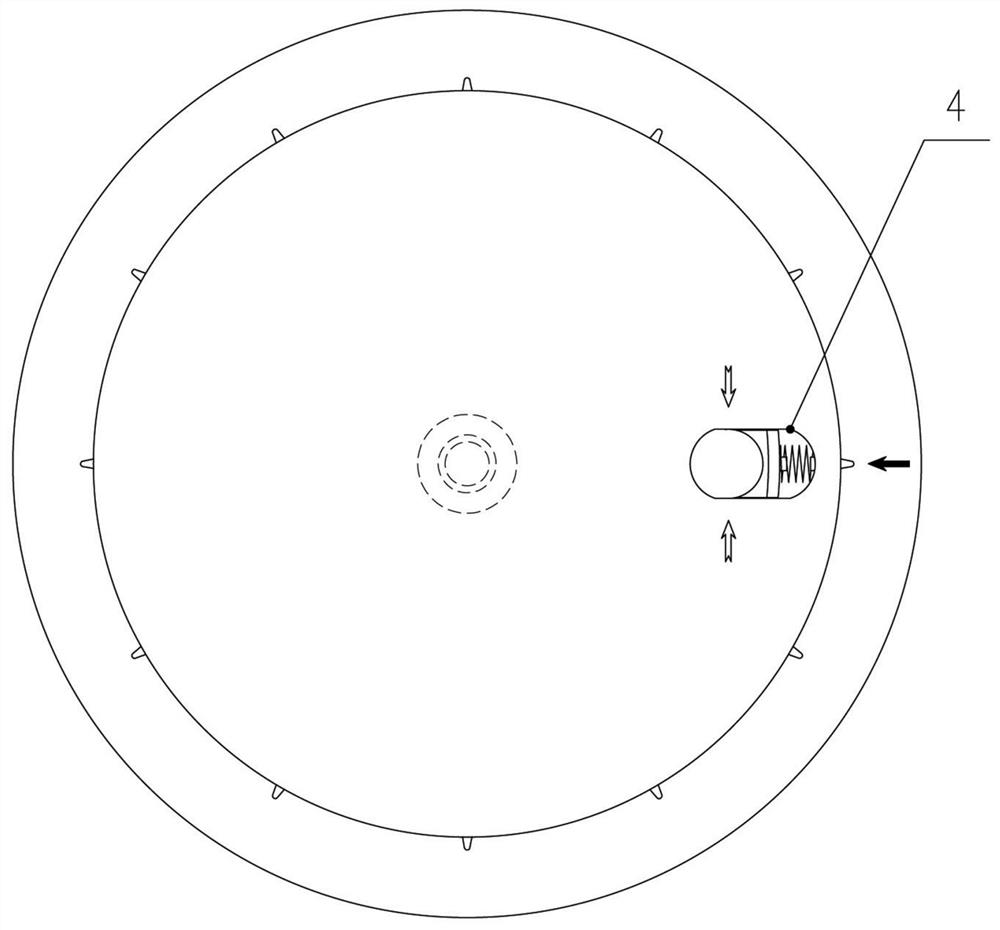

A fully automatic betel nut cutting device

The invention relates to a fully automatic betel nut device which comprises a rack, a feeding hopper, a fixed bracket, a feeding roller, a feeding rotary shaft, a plummer block, a driven sprocket, a driving sprocket, a driving chain, a motor, a guiding and compressing groove, a prepressing spring, a blade fixing shaft, a rotary cutting blade and a discharging guide groove, wherein the feeding hopper is fixed on a U-shaped frame at the upper end of the rack; the left and right ends of the feeding roller are respectively connected with the fixing plate of the fixed bracket through the feeding rotary shaft; the driven sprocket is arranged at one end of the feeding rotary shaft; the driving sprocket and the driven sprocket are connected through the driving chain; the driving sprocket is fixed on the output shaft of the motor; the rotary cutting blade is fixed on the blade fixing shaft; and the discharging guide groove is mounted below and in front of the rotary cutting blade. The fully automatic betel nut device can realize automatic cutting of betel nut, and is simple to operate and convenient to use; an operator only needs to feed materials in time; one person can operate a plurality of machines to realize a high-yield, high-efficiency and high-quality betel nut automatic cutting function.

Owner:YIYANG SHENGXI MACHINERY EQUIP MFG

Automatic water cutting reproducing machine for Chinese rose

ActiveCN106258379AAchieve mechanical propertiesRealize automatic cuttingCultivating equipmentsPlant cultivationEngineeringAirbag

The invention relates to the field of flowers and plants, in particular to an automatic water cutting reproducing machine for Chinese rose. The automatic water cutting reproducing machine comprises a straightening device, a conveying pipeline and a moving device, the straightening device is positioned above the moving device, and the conveying pipeline is positioned between the straightening device and the moving device. Chinese rose cutting branches after being straightened by the straightening device reach into through holes in an airbag of the moving device through the conveying pipeline, and mechanical straightening and automatic cutting of the Chinese rose branches are realized, so that labor amount of people is greatly reduced, and working efficiency is improved.

Owner:HAIMEN MAOFA ART DESIGN CO LTD

Cutting and drying machine for wood manufacturing

ActiveCN112454534BReduce frictionRealize automatic advancementFeeding devicesDrying gas arrangementsEngineeringThreaded rod

Owner:安吉美源家具有限公司

Processing mechanism of LED lamp

ActiveCN112917158ARealize the function of automatic cuttingEasy to processOther manufacturing equipments/toolsMetal working apparatusElectric machineryEngineering

The invention discloses a processing mechanism of an LED lamp, and belongs to the field of lamp processing. The processing mechanism comprises a fixed square frame, the fixed square frame is sleeved with folding square sleeves, the folding square sleeves are divided into two sets, the two sets of folding square sleeves are in sliding connection with the fixed square frame, the top end of the fixed square frame is provided with a folding table, and one side of a movable shaft seat is provided with a grinding roller. The grinding roller is rotationally connected with corresponding moving shaft seat, torsion arms are arranged on the other sides of the moving shaft seats, the ends of the torsion arms are rotationally connected with the two moving shaft seats correspondingly, the other ends of the torsion arms are meshed with each other, a wheel disc set is arranged at the bottom ends of the torsion arms, and the wheel disc set is rotationally connected with the ends of the torsion arms. A driven roller is arranged at the top end of one torsion arm, a processing belt is arranged between the driven roller and the corresponding torsion arm, a processing motor is fixedly installed at the bottom ends of the torsion arms, and the output end of the processing motor penetrates through the torsion arms and is fixedly connected with the side wall of the wheel disc set. The processing motor drives the two processing belts to operate. Automatic processing can be achieved.

Owner:中山市艾尔之光照明科技有限公司

Cutting device for production of plastics

PendingCN112809757ARealize the function of automatic cuttingIncrease productivityMetal working apparatusEngineeringMechanical engineering

The invention discloses a cutting device for production of plastics. The cutting device comprises a working platform, clamping pieces, a lifting mechanism and a cutting unit, wherein the working platform is horizontally arranged; a plurality of support legs are arranged at the lower end of the working platform; two groups of clamping pieces are arranged and are positioned at the upper end of the working platform at intervals on the left side and the right side; the lifting unit is arranged at the upper end of the working platform, is in transmission connection with the two groups of clamping pieces and is used for driving the two groups of clamping pieces to be moved up and down; and the cutting unit is arranged on the working platform, wherein the clamping pieces are used for clamping plastic products and the cutting unit is used for cutting the plastic products.

Owner:湖北科斯特塑料实业有限公司

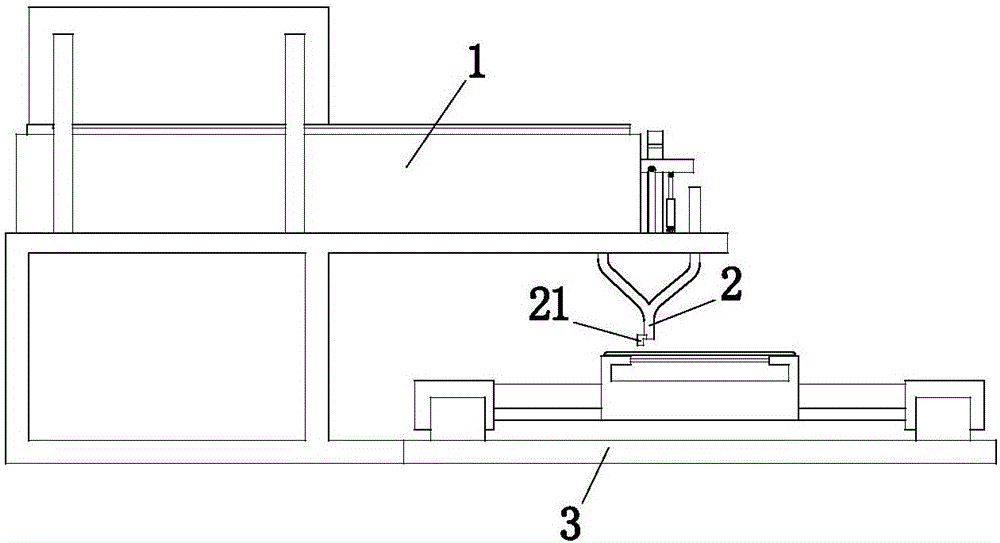

Integrated hydroponic breeding platform used for China roses

ActiveCN106106114AReduce laborImprove work efficiencyAgriculture gas emission reductionCultivating equipmentsEngineeringWorkload

The invention relates to the flower field, in particular to an integrated hydroponic breeding platform used for China roses. The platform comprises a straightening device, a conveying pipeline, a movable device, a punching device, a conveying device and an air bag. The movable device is arranged above the air bag. The straightening device is arranged above the movable device and installed on the air bag. The conveying pipeline is located between the straightening device and the movable device. The punching device is arranged below the straightening device. The conveying device is located on the right side of the movable device. The integrated hydroponic breeding platform used for China roses has following beneficial effects: the platform is capable of finishing mechanical straightening operation, automatic punching operation, automatic cuttage, and automatic throwing of foaming plates inserted with branches into a hydroponic pool so that integrated hydroponic breeding of China roses can be achieved; workload is greatly decreased and working efficiency is increased.

Owner:临沂高新文旅发展有限公司

A Chinese rose integrated hydroponic propagation platform

ActiveCN106106114BRealize mechanized rightingReduce laborAgriculture gas emission reductionCultivating equipmentsPunchingEngineering

The invention relates to the flower field, in particular to an integrated hydroponic breeding platform used for China roses. The platform comprises a straightening device, a conveying pipeline, a movable device, a punching device, a conveying device and an air bag. The movable device is arranged above the air bag. The straightening device is arranged above the movable device and installed on the air bag. The conveying pipeline is located between the straightening device and the movable device. The punching device is arranged below the straightening device. The conveying device is located on the right side of the movable device. The integrated hydroponic breeding platform used for China roses has following beneficial effects: the platform is capable of finishing mechanical straightening operation, automatic punching operation, automatic cuttage, and automatic throwing of foaming plates inserted with branches into a hydroponic pool so that integrated hydroponic breeding of China roses can be achieved; workload is greatly decreased and working efficiency is increased.

Owner:临沂高新文旅发展有限公司

A chestnut automatic cutting device

The invention relates to an automatic chestnut cutting device, which belongs to the technical field of kitchen utensils. Including a power transmission mechanism and an automatic blanking mechanism, it is characterized in that the power transmission mechanism is equipped with a motor, an impeller, a first reversing gear, a transmission shaft, a second reversing gear, a second pulley, a belt, and a first pulley ; The automatic blanking mechanism is provided with a hopper, a chestnut conveying pipe, and a base; the motor drives the impeller to realize the function of the automatic incision of the chestnut, and the drum is rotated through the action of the power transmission mechanism to ensure that the chestnut will not be stuck in the chestnut. at the delivery nozzle. The invention solves the problem of low efficiency of manual cutting of chestnuts, and also solves the problem of potential safety hazard caused by cutting knife when manual cutting of chestnuts is performed.

Owner:南京幸庄科技创新产业园管理有限公司

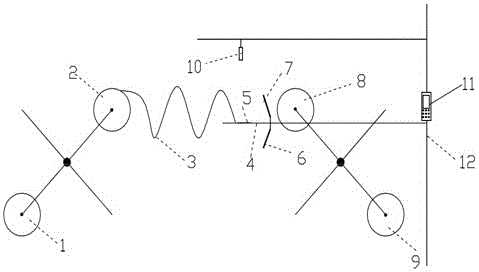

Automatic cutting system of roll paper joint

InactiveCN106241476AEliminate manual cutting processSave human effortArticle deliveryWinding machineRolling paper

The invention discloses an automatic cutting system of a roll paper joint. The automatic cutting system comprises a roll paper joint cutting device and a control system. The automatic cutting system is characterized in that the roll paper joint cutting device is installed on a rack of paper winding machine equipment, and the control system is respectively connected with an infrared light sensor 10 and a cutter control motor. The problems of low degree of automation and low working efficiency of the equipment because the roll paper joint is directly cut by a cutter after arrival of the roll paper joint observed by human eyes and at least one person on duty is needed respectively on the unwinding end and the winding end of a paper winding machine because the roll paper joint needs to be manually cut in the paper winding process of a traditional paper winding machine are solved.

Owner:GUIZHOU JIN RUI NEW STYLE PACKAGING MATERIALS

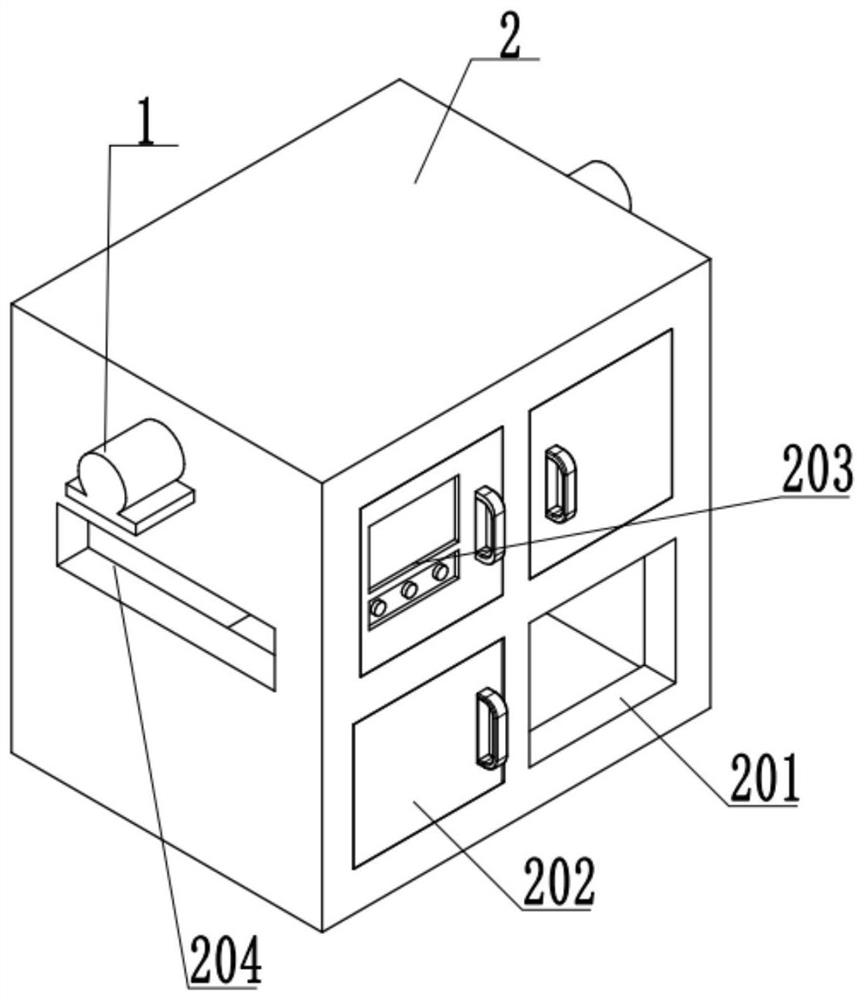

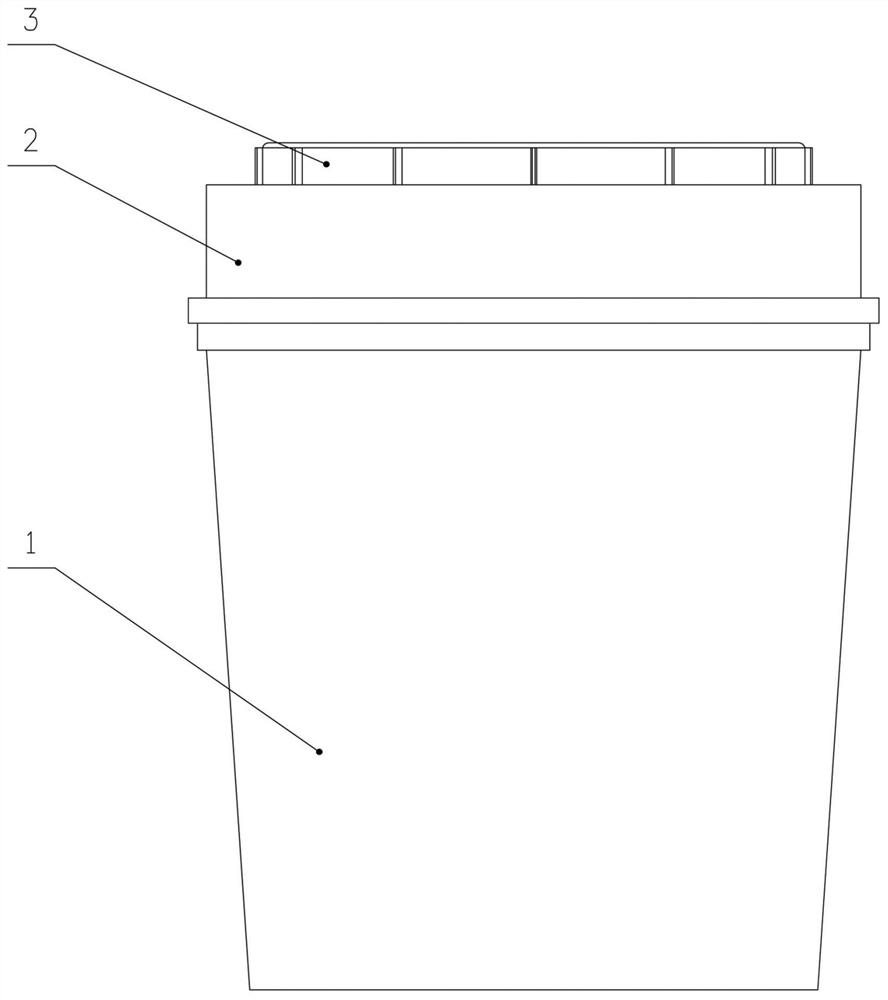

Sharps storage box with automatic cutting function

ActiveCN112569003BAvoid problemsEfficient cuttingSurgical furnitureInfusion needlesStructural engineeringMechanical engineering

The invention discloses a sharps storage box with automatic cutting function, which comprises a cup body, a cup cover and an auxiliary cover. The cup cover is installed on the top of the cup body, and the auxiliary cover is installed on the top of the cup cover through a rotating shaft, and the rotating shaft is located at the center of the cup cover and the auxiliary cover. position, the auxiliary cover rotates on the cup cover with the rotating shaft as the center, and there are corresponding openings on one side of the cup cover and the auxiliary cover, and the openings of the two are exposed and closed by the relative rotation of the cup cover and the auxiliary cover. The cutting device of the present invention is built in the box cover to avoid the problem of falling off after long-term use, and the box cover can be replaced with the box body of the same size at will. When it is full, it can be used again only by replacing the box body, saving and environmental protection. In particular, the present invention adopts an electric cutting method without manual cutting, which can effectively avoid the problem of difficult cutting due to insufficient strength, and save time and effort for quick storage.

Owner:翟晨岚

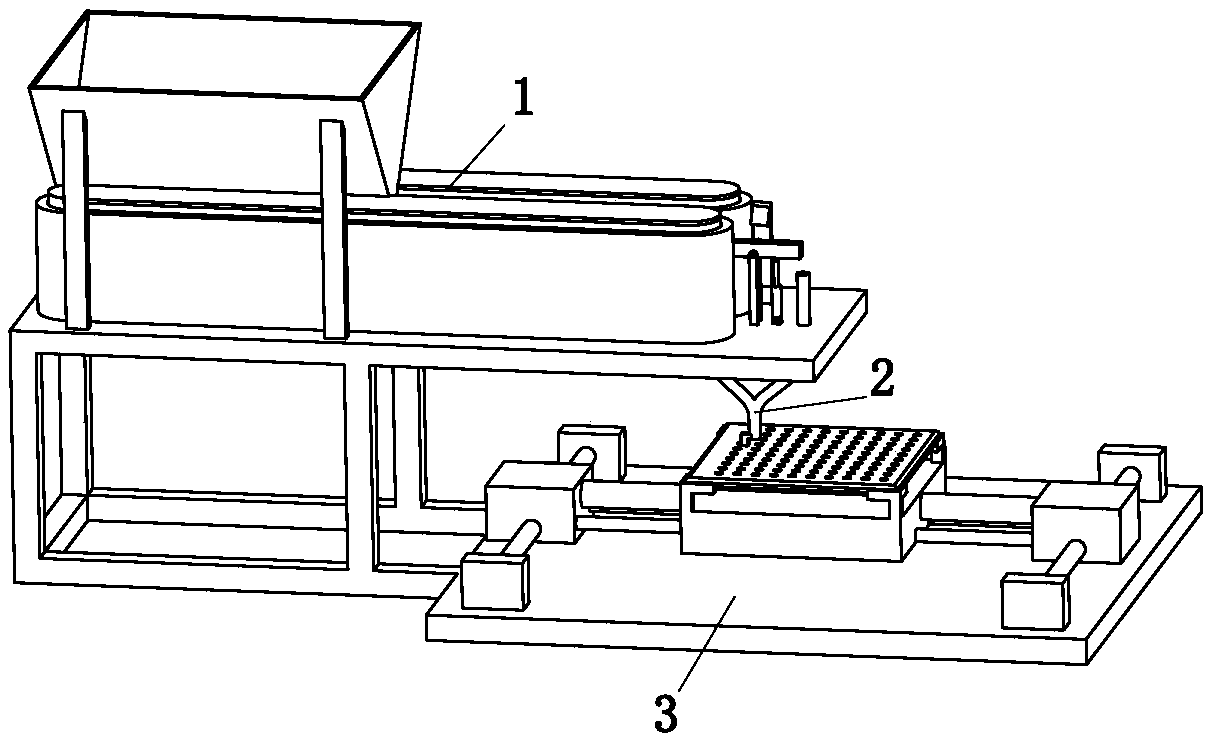

A kind of plastic film automatic processing equipment and plastic film automatic processing technology

ActiveCN109176973BRealize the function of automatic cuttingNot easy to tanglePlastic recyclingElectric machineGas cylinder

The invention relates to plastic film automatic treatment equipment and a plastic film automatic treatment process. The plastic film automatic treatment equipment comprises a base plate and a shearingdevice, wherein a square port is arranged in the middle portion of the base plate, and the shearing device is installed at the upper end of the square port, and comprises a working box, a rotating gear, a transition gear, a rotating column, a drive frame, a drive motor, an installing seat, a support plate, a pressing plate, a pressing gas cylinder, a connecting shaft, a connecting gear, a rotating motor, a driven gear, a screw rod, a sliding frame, a working frame, a bidirectional output motor and a shearing cutter blade. According to the present invention, with the process and the equipment,the problems that the plastic film is easily entangled with the crushing device, the safety hazard exists, the adjustability is poor, and the like during the existing plastic film crushing can be solved, the automated shearing before the crushing of the plastic film can be achieved, and the advantages of less entangling, no hidden danger, good adjustability and the like can be achieved.

Owner:赣州森航塑胶有限公司

An automatic water insertion propagation machine for rose flowers

ActiveCN106258379BRealize mechanized rightingReduce laborPlant cultivationCultivating equipmentsEngineeringAirbag

The invention relates to the field of flowers and plants, in particular to an automatic water cutting reproducing machine for Chinese rose. The automatic water cutting reproducing machine comprises a straightening device, a conveying pipeline and a moving device, the straightening device is positioned above the moving device, and the conveying pipeline is positioned between the straightening device and the moving device. Chinese rose cutting branches after being straightened by the straightening device reach into through holes in an airbag of the moving device through the conveying pipeline, and mechanical straightening and automatic cutting of the Chinese rose branches are realized, so that labor amount of people is greatly reduced, and working efficiency is improved.

Owner:HAIMEN MAOFA ART DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com