Automatic cutting system of roll paper joint

A rolling paper, automatic technology, applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of low degree of automation, low work efficiency, manual cutting, etc., to achieve the effect of improving the level of automation and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention is further introduced below.

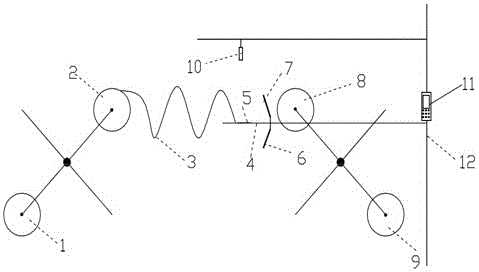

[0017] Examples such as figure 1 As shown, an automatic cutting system for reel joints, including a spare printing roll 1, a printing roll 2, a roll paper 3, a reel winding platform 4, a reel joint 5, a lower cutter 6, an upper cutter 7, a reel Volume 8, spare winding 9, infrared light sensor 10, controller 11, operation column 12. The roll paper splice cutting device is installed on the frame of the paper reel equipment, and the control system is connected with the infrared light sensor 10 and the cutter control motor respectively; The knife 7 and the lower cutter 6, the upper cutter 7 and the lower cutter 6 are rotated to a horizontal position, and the position of the knife edge is located at the front end of the winder near the winder; the control system includes a programmable controller 11, an infrared light sensor 10, and an upper control The forward and reverse control motors of the cutting knife 7 and the lower cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com