Composite paperboard and making method of composite board

A manufacturing method and cardboard technology, applied in chemical instruments and methods, packaging paper, synthetic resin layered products, etc., can solve problems such as inability to prevent immersion, and achieve the elimination of manual cutting processes, strong impact resistance, and convenient unified handling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

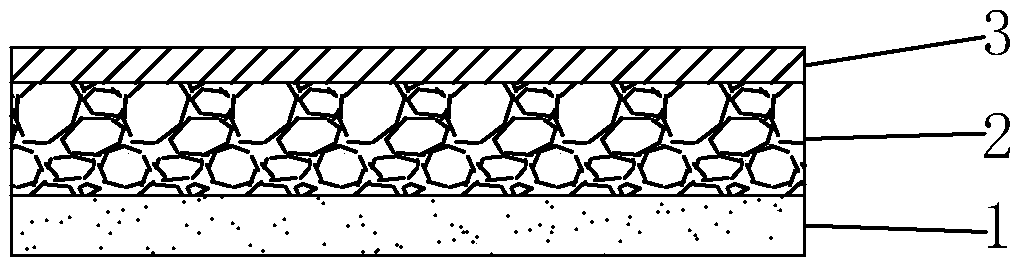

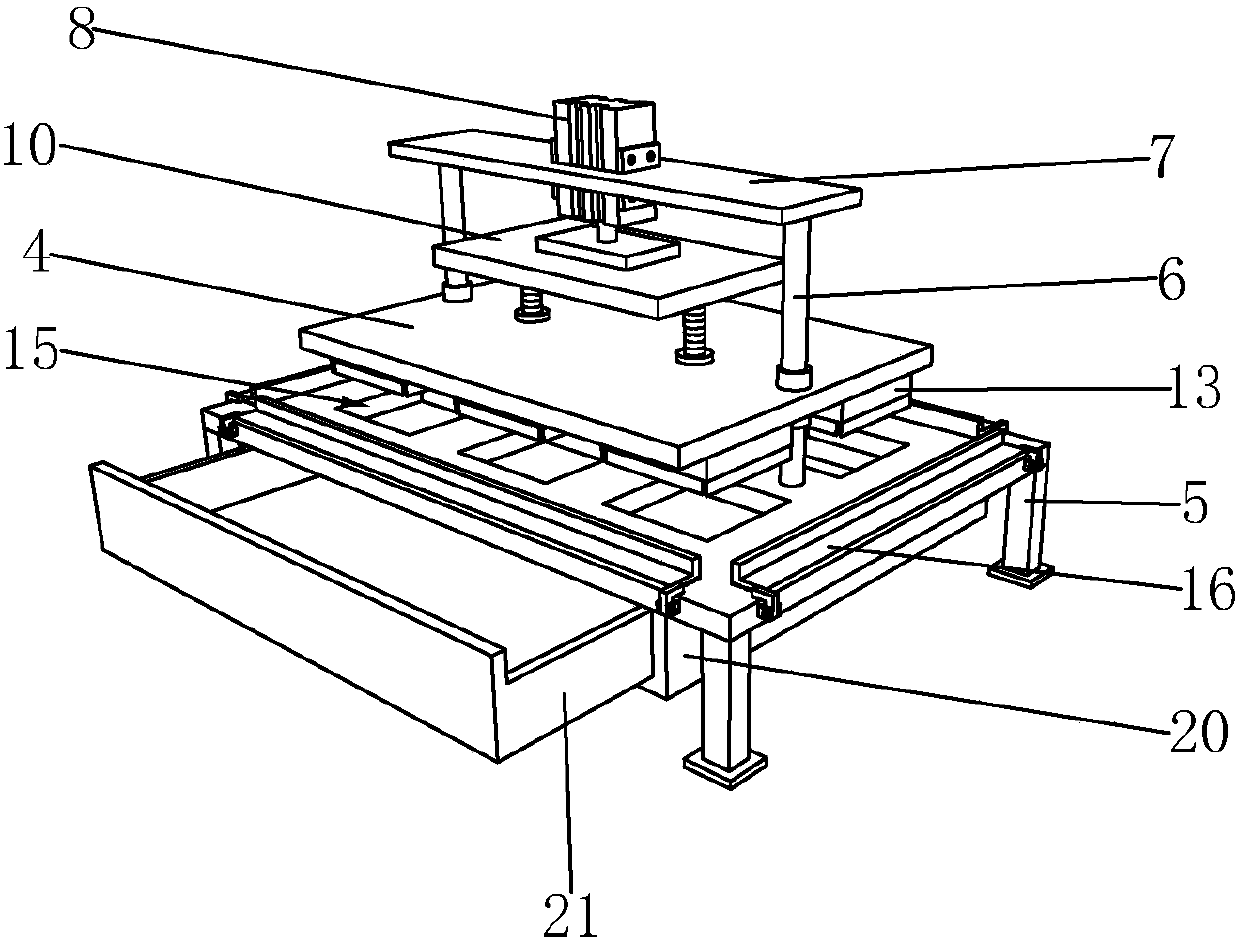

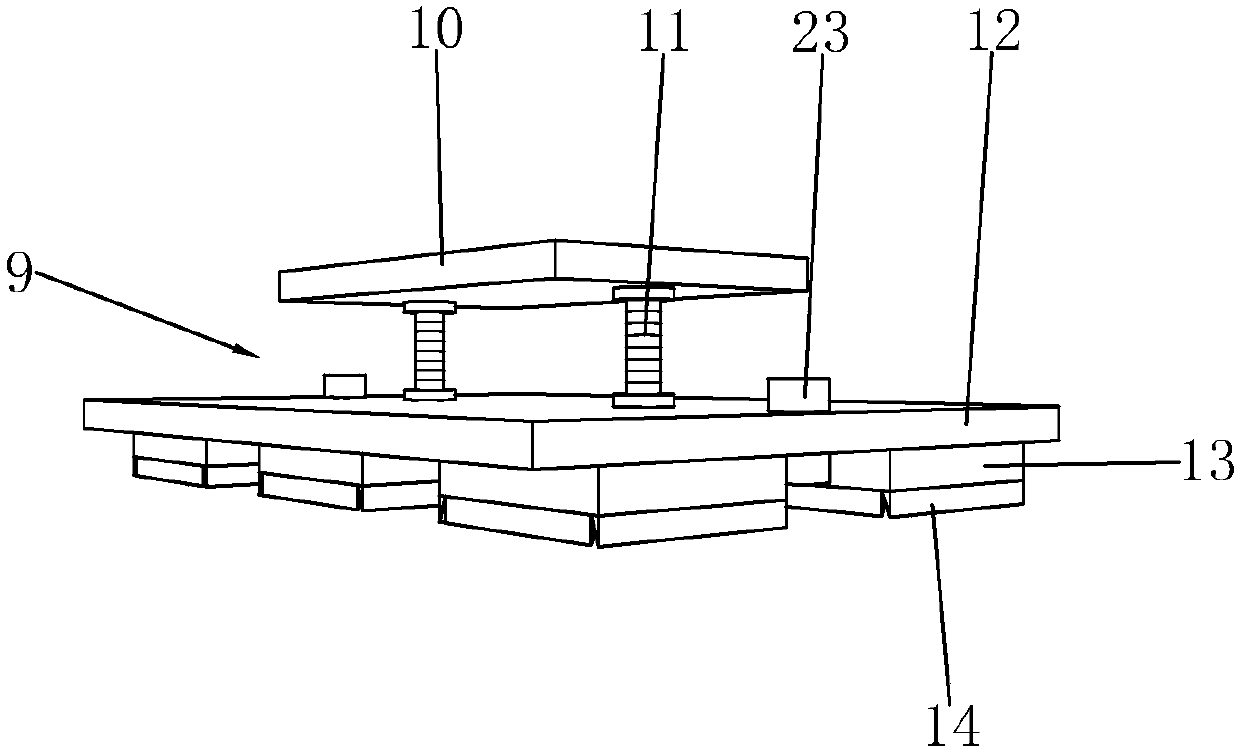

[0032] Such as Figure 1 to Figure 6 Shown, be a kind of composite cardboard of the present invention, comprise cardboard layer 1, pearl cotton layer 2 and aluminum foil layer 3, aluminum foil layer 3 is bonded and fixed on the front of pearl cotton layer 2 by adhesive, and this adhesive is mass ratio It is the composition of (3~8):(2~5):1:(0.1~0.3) polyester resin, silicone resin, epoxy resin and curing agent. Aluminum foil layer 3 has the advantages of tasteless, odorless, non-toxic, high temperature resistance, low temperature resistance, good plasticity, strong air barrier performance, anti-oxidation, waterproof, moisture-proof, etc. The surface of aluminum foil is extremely clean and hygienic, and no bacteria or microorganisms can be on its surface growth, play an antibacterial role. The cardboard layer 1 is bonded and fixed on the back of the pearl cotton layer 2. The thickness of the pearl cotton layer 2 is 3-7mm. The thermal conductivity of the pearl cotton is very lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com