Full-automatic cutting device for building tile

A cutting device and fully automatic technology, applied in the construction field, can solve the problems of reducing production efficiency, reducing work efficiency, time-consuming and labor-intensive, etc., and achieve the effect of high degree of automation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

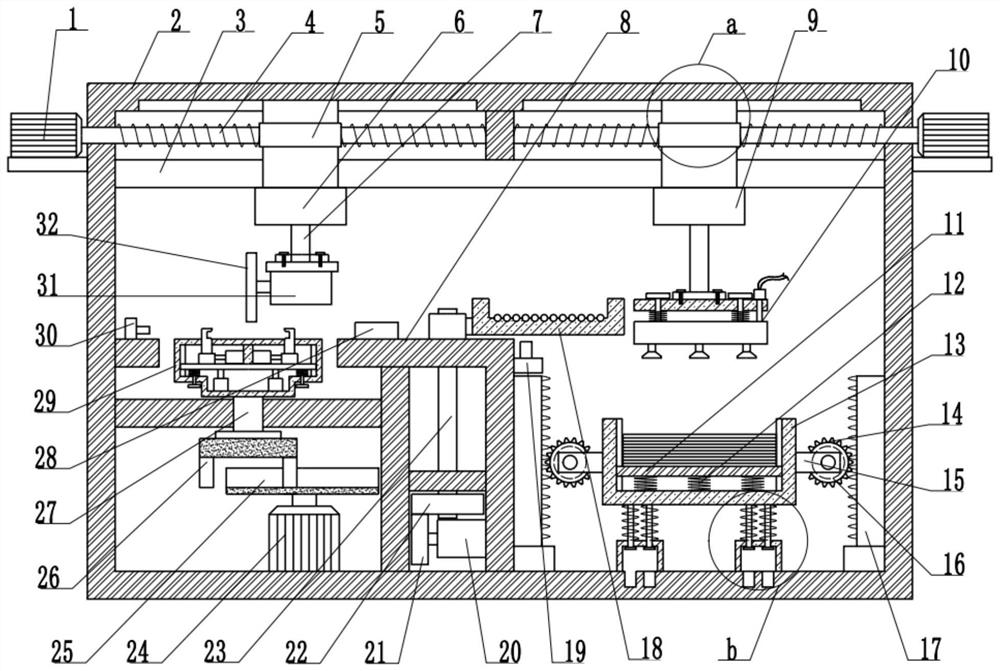

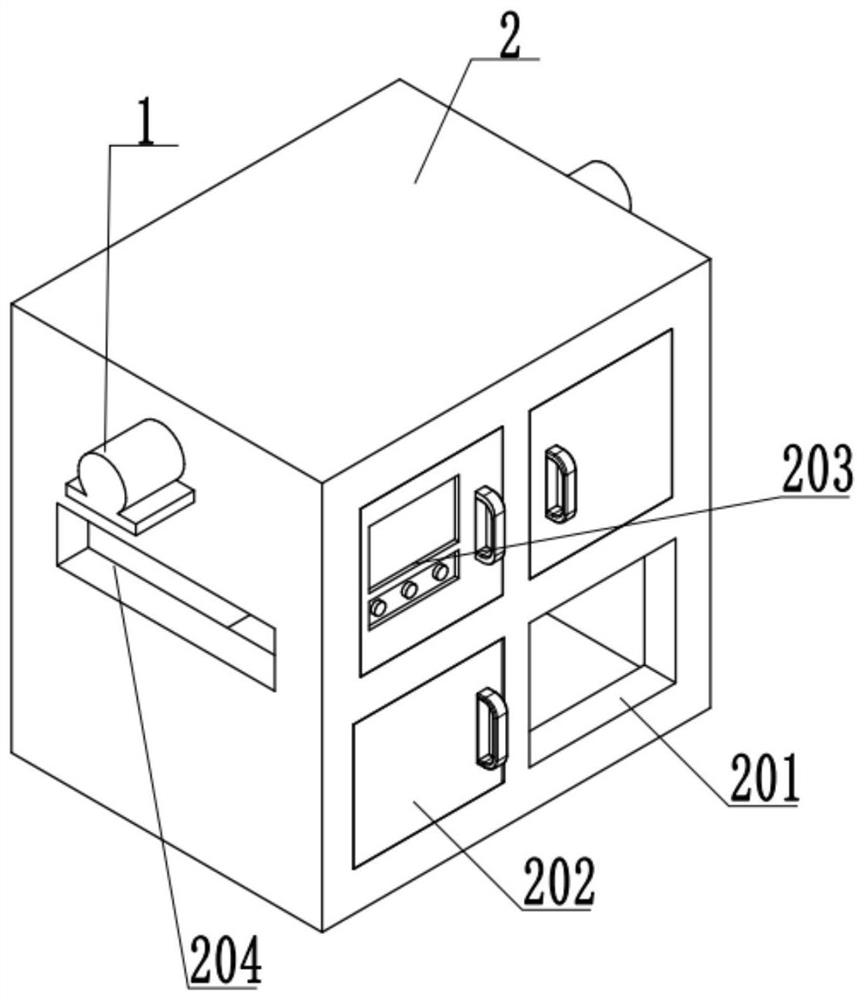

Embodiment 1

[0038] see Figure 1 to Figure 8, a fully automatic cutting device for architectural tiles, comprising a feeding box 13, a reclaiming device 10, a receiving tray 18, a fixing device 29, a cutting wheel 32 and a workbench 8, wherein ceramic tiles are placed inside the feeding box 13, And the second servo motor 16 embedded in the surface of the support 15 whose side wall is fixedly connected connects the drive gear 14 through the drive shaft, and the drive gear 14 connects the rack 17 inlaid with the frame 2 inner wall through the gear teeth, and utilizes gear meshing transmission In principle, the second servo motor 16 can drive the feeding box 13 to move up and down along the rack 17, realizing the function of automatic feeding, which has the characteristics of high degree of automation and improves work efficiency.

[0039] The retrieving device 10 is located above the feeding box 13, and is connected to the hydraulic cylinder 2 9 through the hydraulic strut 2 to automaticall...

Embodiment 2

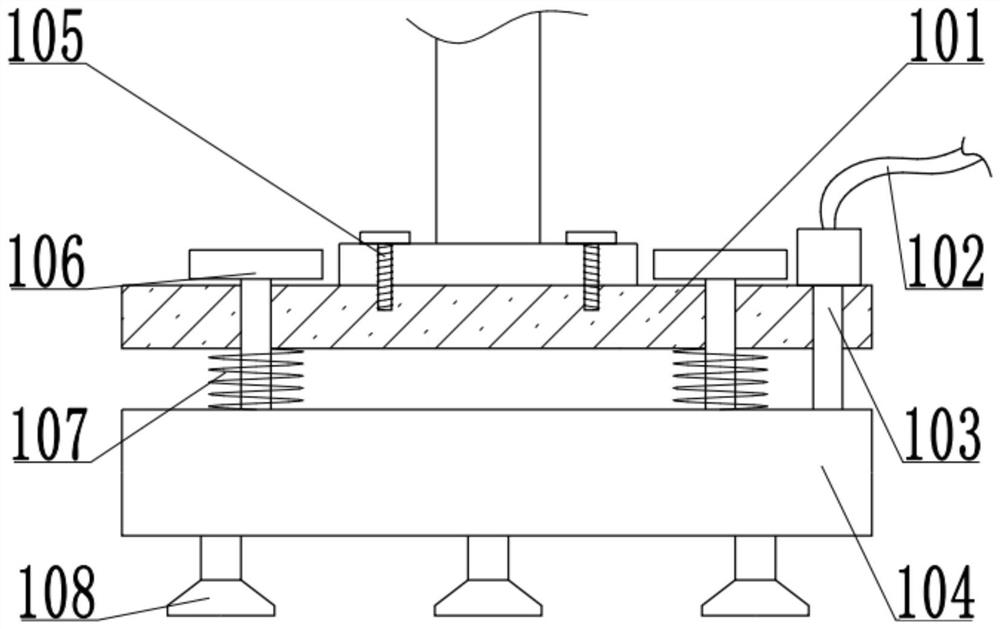

[0048] see figure 1 , image 3 , Figure 4 with Figure 9 , a fully automatic cutting device for building tiles, further comprising a reclaimer 10, the reclaimer 10 also includes a fixed bottom plate 101, bolts 105, a fixed pin 106 and a damping spring 107, the fixed pin 106 The side wall is embedded in the through hole provided on the surface of the fixed bottom plate 101, and the bottom is fixedly connected to the top of the vacuum nozzle mounting plate 104. The fixed bottom plate 101 is connected to the hydraulic strut 2 through bolts 105, which is easy to disassemble. The surface of the pin one 106 is sleeved with a damping spring one 107, and the damping spring one 107 can weaken the vacuum suction nozzle 108 from the longitudinal force from the ceramic tile, prevent it from being damaged, and prolong the service life.

[0049] The fixing device 29 also includes a shock-absorbing spring 298 and a fixing pin 299. The side wall of the fixing pin 299 is embedded in the th...

Embodiment 3

[0052] see figure 1 , a fully automatic cutting device for building tiles, also includes a feeding box 13, a top plate 12 is embedded in the loading box 13, and the top plate 12 is connected to the bottom of the feeding box 13 through a return spring 12, and the number is Several, and evenly distributed on the lower surface of the top plate 12, the top plate 12 plays the role of supporting tiles, as the number of tiles above the top plate 12 decreases, the return spring 12 can drive the top plate 12 to move upwards according to a certain distance, which is convenient for the retrieving device 10 Take out the tiles and have the characteristics of good flexibility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com