Waste paper scrap collecting device

A technology for collecting equipment and paper scraps, applied in the field of waste paper scraps collection equipment, can solve the problems of difficult centralized collection, time-consuming and labor-intensive, environmental pollution, etc., and achieve the effects of convenient operation, simple manufacture, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

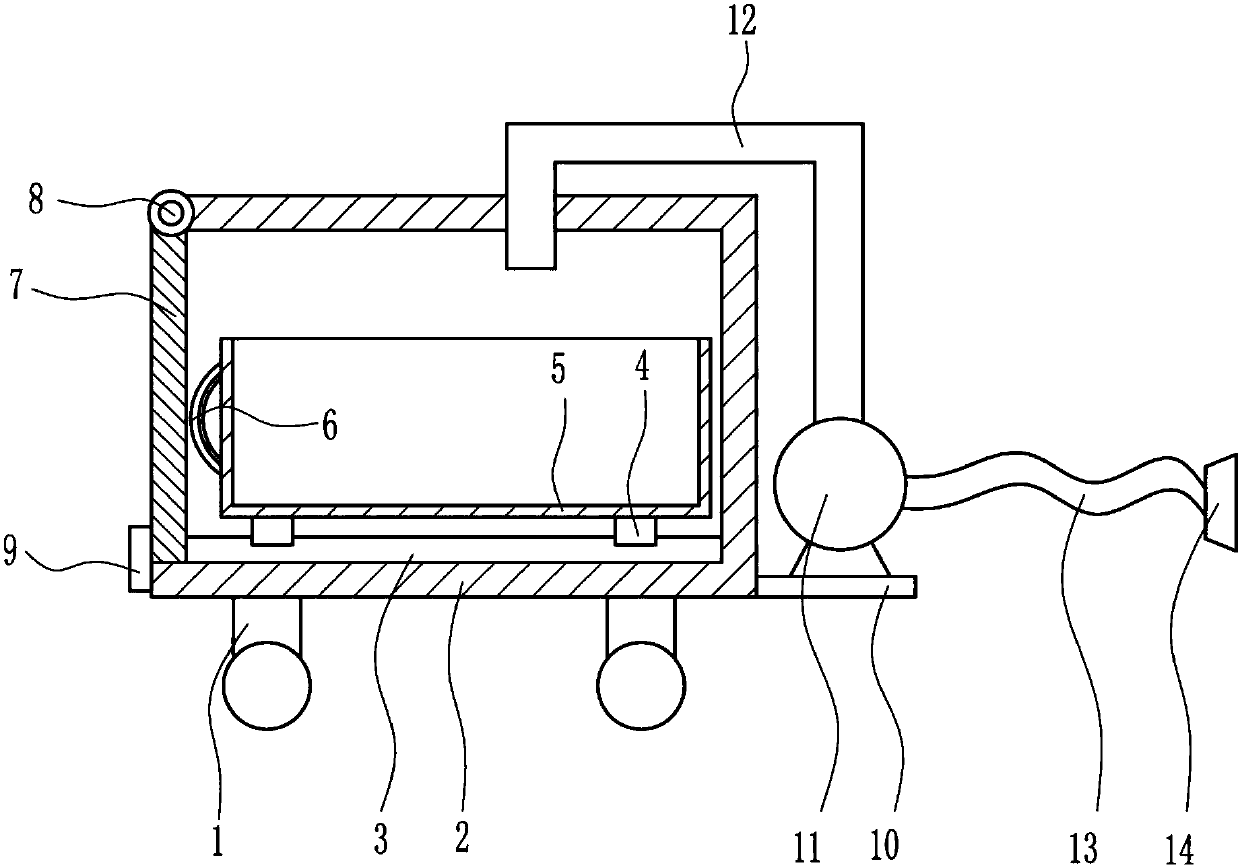

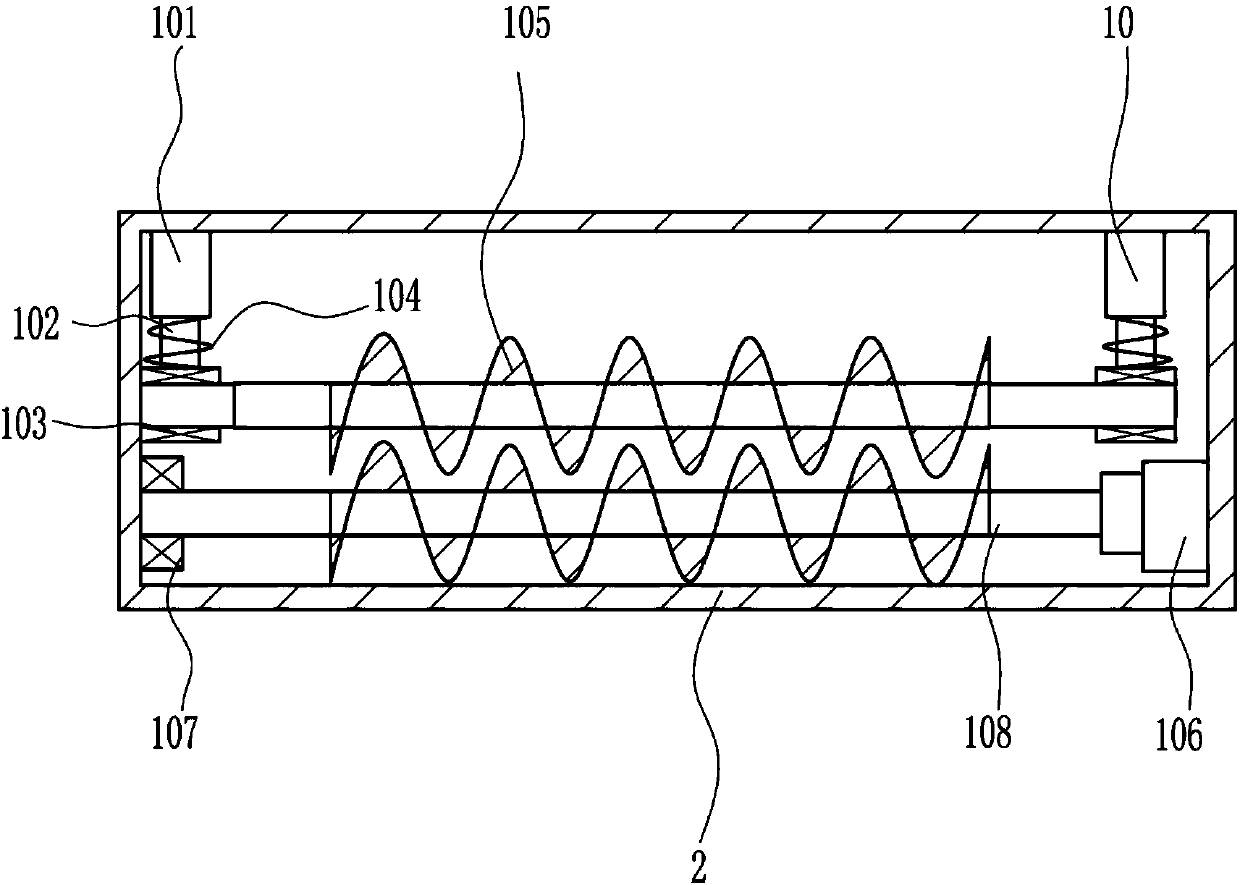

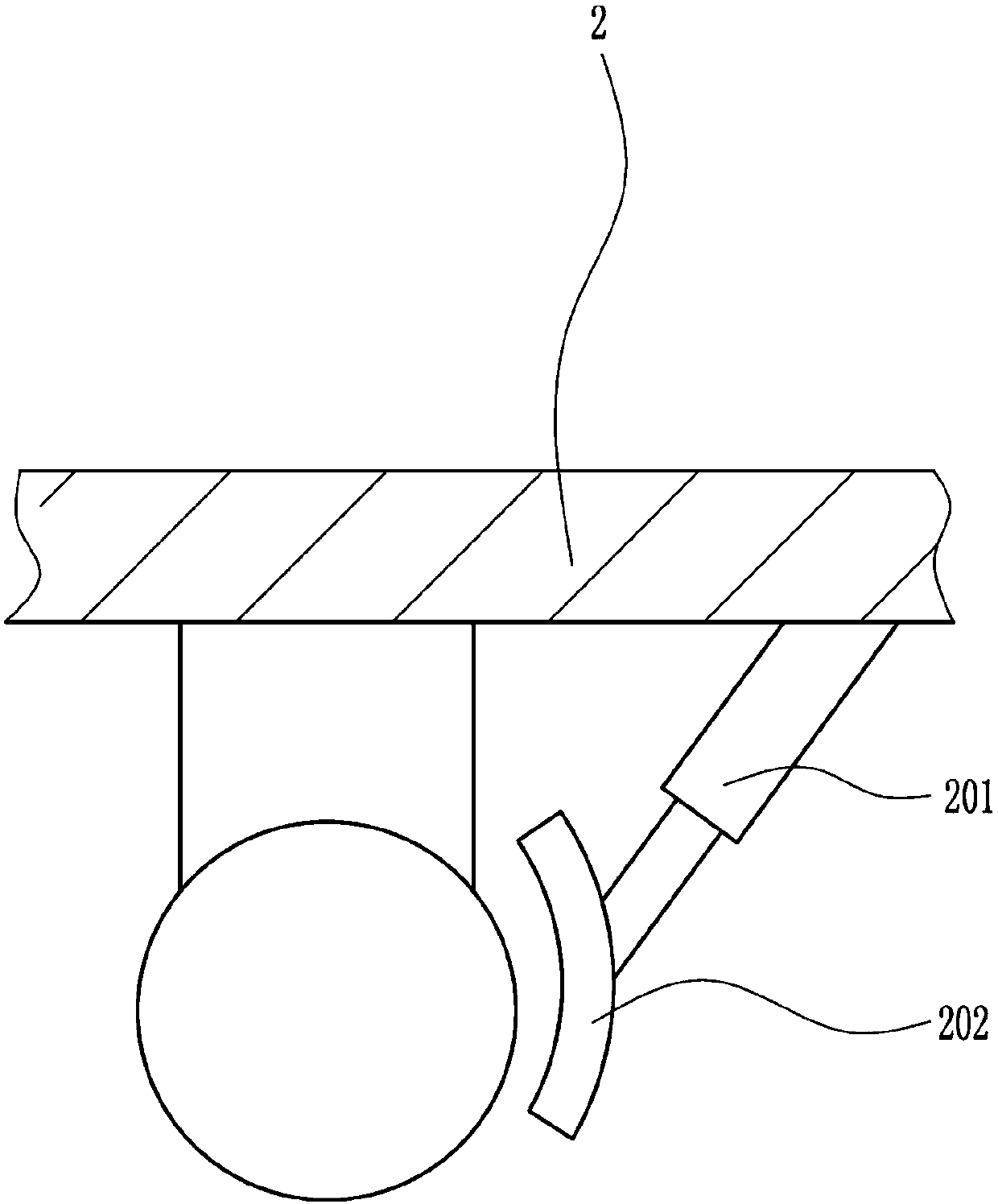

[0021] A kind of waste paper waste collection equipment, such as Figure 1-3 As shown, it includes frame 1, frame 2, slide rail 3, slider 4, charging box 5, handle 6, cover plate 7, pin 8, magnet 9, bracket 10, air pump 11, discharge pipe 12 , the universal suction pipe 13 and the suction head 14 are fixedly connected with the frame 2 on the top of the frame 1, and the slide rail 3 is fixed on the inside of the frame 2, and there are two sliding connections on the slide rail 3. The slider 4 is fixedly connected with a charging box 5 above the two sliders 4, and is fixedly connected with a handle 6 on the left side of the charging box 5, and the left side above the frame 2 moves through a pin 8 and a cover plate 7 Type connection, a bracket 10 is fixedly connected below the outer side of the right wall of the frame 2, an air pump 11 is arranged above the bracket 10, and a discharge pipe 12 is connected above the air pump 11, and the discharge pipe 12 is fixed on the frame 2 A ...

Embodiment 2

[0023] A kind of waste paper waste collection equipment, such as Figure 1-3 As shown, it includes frame 1, frame 2, slide rail 3, slider 4, charging box 5, handle 6, cover plate 7, pin 8, magnet 9, bracket 10, air pump 11, discharge pipe 12 , the universal suction pipe 13 and the suction head 14 are fixedly connected with the frame 2 on the top of the frame 1, and the slide rail 3 is fixed on the inside of the frame 2, and there are two sliding connections on the slide rail 3. The slider 4 is fixedly connected with a charging box 5 above the two sliders 4, and is fixedly connected with a handle 6 on the left side of the charging box 5, and the left side above the frame 2 moves through a pin 8 and a cover plate 7 Type connection, a bracket 10 is fixedly connected below the outer side of the right wall of the frame 2, an air pump 11 is arranged above the bracket 10, and a discharge pipe 12 is connected above the air pump 11, and the discharge pipe 12 is fixed on the frame 2 A ...

Embodiment 3

[0026] A kind of waste paper waste collection equipment, such as Figure 1-3 As shown, it includes frame 1, frame 2, slide rail 3, slider 4, charging box 5, handle 6, cover plate 7, pin 8, magnet 9, bracket 10, air pump 11, discharge pipe 12 , the universal suction pipe 13 and the suction head 14 are fixedly connected with the frame 2 on the top of the frame 1, and the slide rail 3 is fixed on the inside of the frame 2, and there are two sliding connections on the slide rail 3. The slider 4 is fixedly connected with a charging box 5 above the two sliders 4, and is fixedly connected with a handle 6 on the left side of the charging box 5, and the left side above the frame 2 moves through a pin 8 and a cover plate 7 Type connection, a bracket 10 is fixedly connected below the outer side of the right wall of the frame 2, an air pump 11 is arranged above the bracket 10, and a discharge pipe 12 is connected above the air pump 11, and the discharge pipe 12 is fixed on the frame 2 A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com