A chestnut automatic cutting device

A chestnut, automatic technology, applied in the field of kitchen utensils, can solve problems such as affecting work efficiency, high consumption, hidden safety hazards, etc., to achieve the effect of solving low efficiency, ensuring normal work, and preventing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

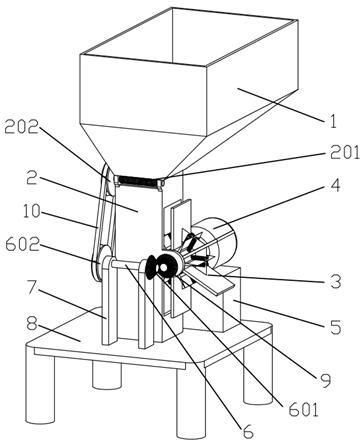

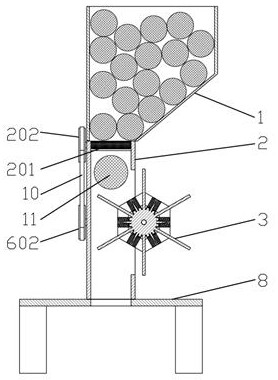

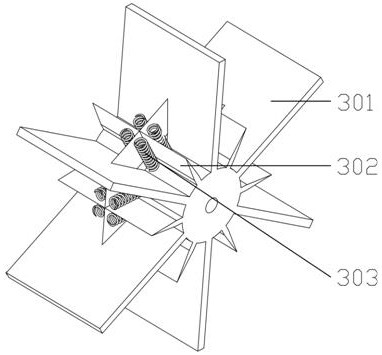

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: It should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

[0019] Such as Figures 1 to 4 Shown, a kind of chestnut automatic cutting device comprises power transmission mechanism and automatic blanking mechanism, is provided with motor 4, impeller 3, the first reversing gear 9, power transmission shaft 6, the second reversing gear in the described power transmission mechanism 601, the second pulley 602, the belt 10, the first pulley 202; the first pulley 202 and the second pulley 602 are connected through the belt 10, and the left end of the transmission shaft 6 is equipped with the second pulley 602 , the second reversing gear 601 is installed on the right side, the motor 4 is connected to one end of the impeller 3, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com