Plastic product pneumatic automatic cutting machine

A technology for automatic cutting and plastic products, which is applied in metal processing and other directions, and can solve the problems of low cutting efficiency, slow production efficiency, and easy to cause work injuries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

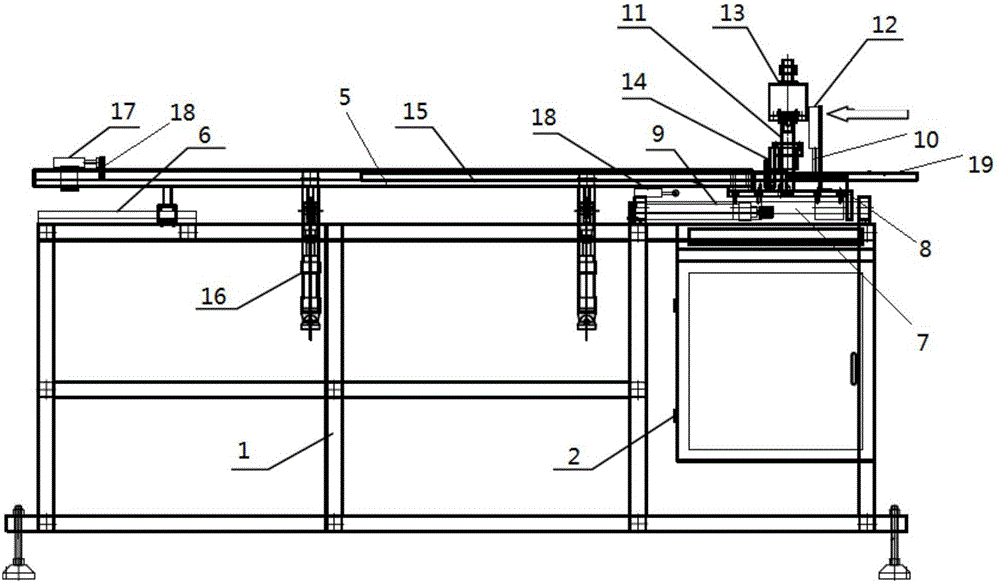

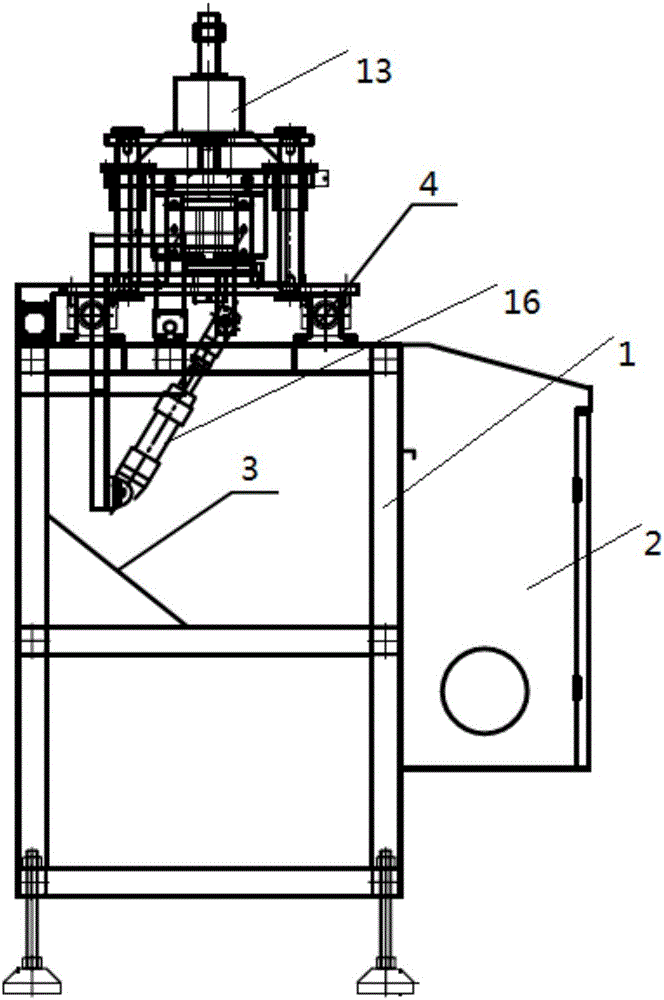

[0015] Referring to the accompanying drawings, a pneumatic automatic cutting machine for plastic products includes a frame 1, an electric control box 2, a collecting tank 3 is arranged on the upper part of the frame 1, and a front and rear traveling device 4 is installed on the upper end of the frame 1, and the front and rear traveling device 4 includes There are walking bracket 5 and slide rails 6 and linear guide rails 7 respectively installed at both ends of frame 1. The rear end of walking bracket 5 is slidably matched with slide rail 6 through guide seat. The two sides of the seat 8 are respectively equipped with a push-back cylinder 9 parallel to the linear guide rail 7, a compression bracket 10 and a cutting bracket 11 are installed on the walking slide 8, and a downward compression cylinder 12 is installed on the upper end of the compression bracket 10. Tight cylinder 12 lower ends are equipped with compaction block, cut off support 11 upper ends and cut off cylinder 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com