Mechanical automation processing device for chain

A processing device and mechanical technology, which is applied to the attachment of shearing machines, feeding devices, shearing devices, etc., can solve the problems of chains that are difficult to reuse, chains that are difficult to handle, and chains that do not realize mechanical automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

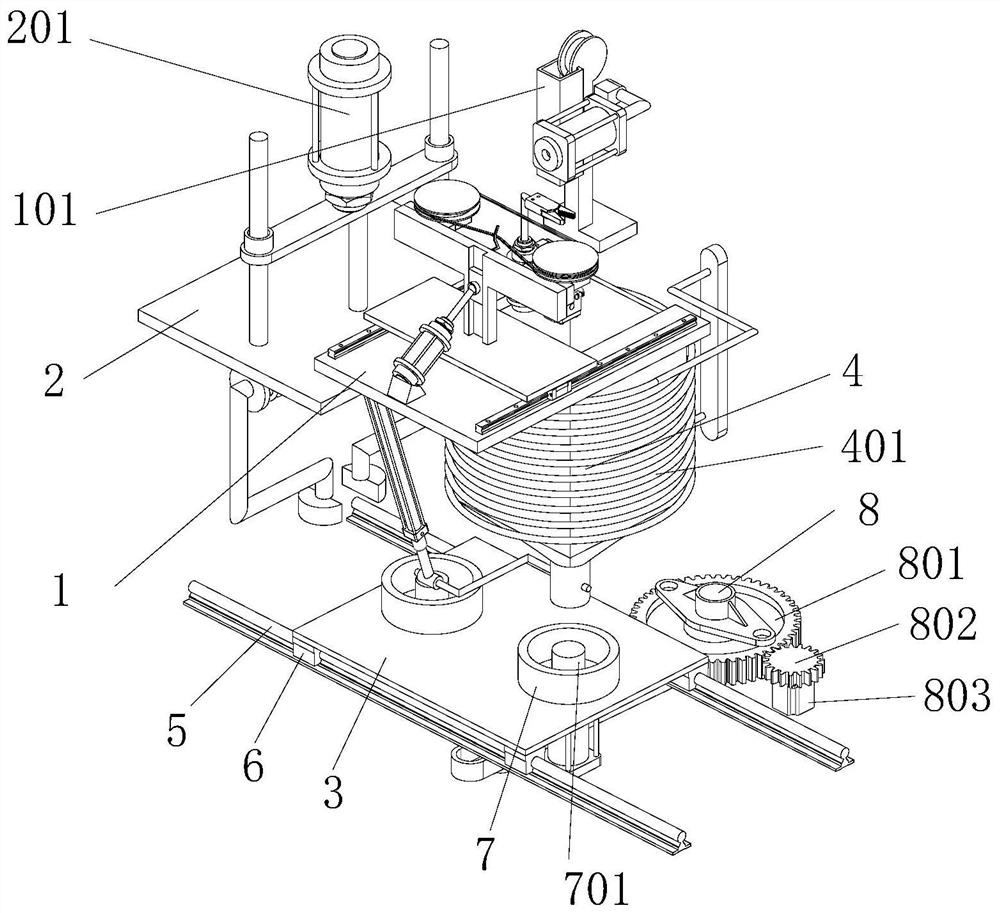

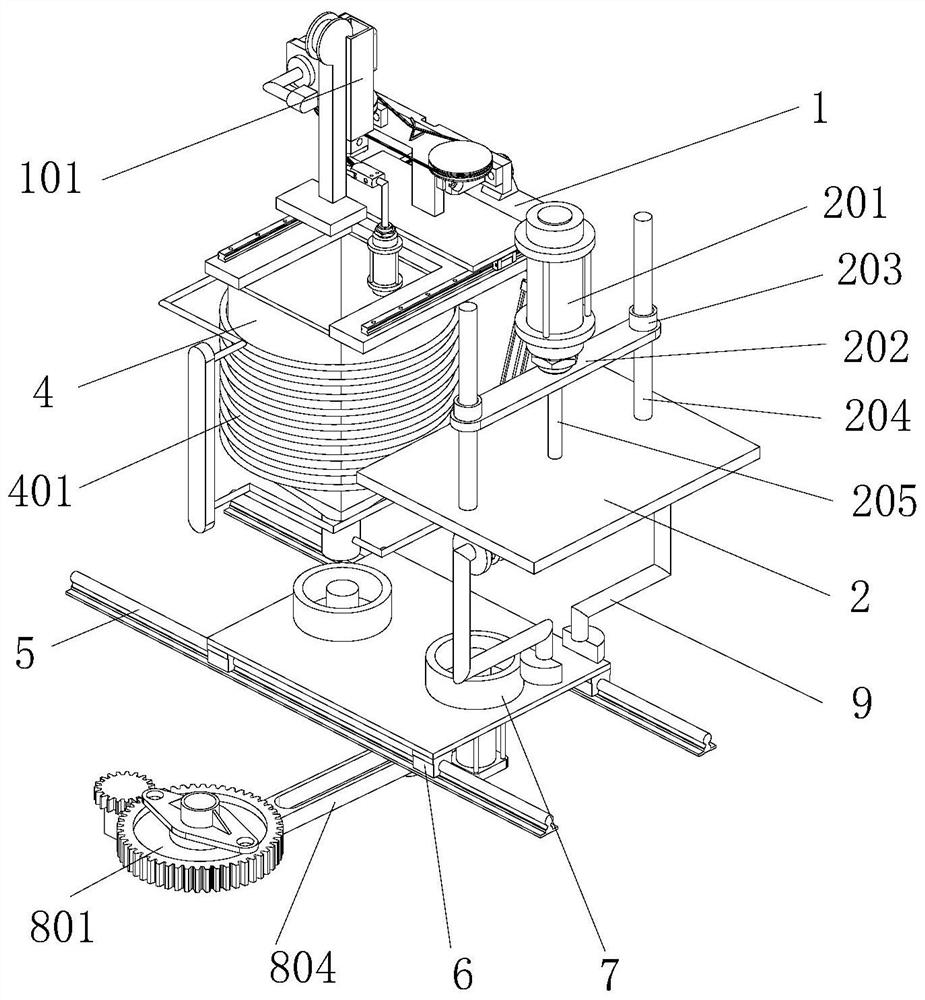

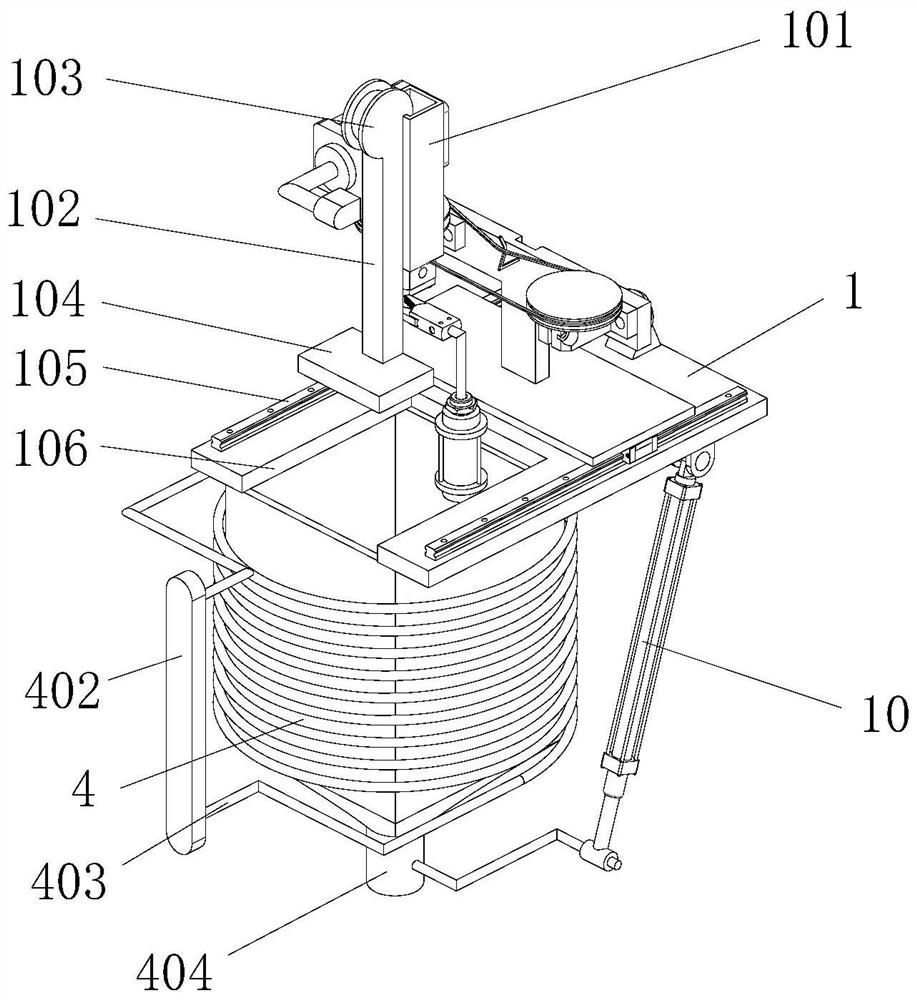

[0025] refer to Figures 1 to 8 The shown mechanical automatic processing device for a chain, for example, is a mechanical automatic processing device for waste chains, which includes a cutting table 1, and two pusher guide rails 105 are fixedly installed on the top of the cutting table 1, and each A sliding block 111 is installed on the propelling guide rail 105, and the sliding block 111 is slidably connected with the advancing guide rail 105. The tops of the two sliding blocks 111 are jointly fixedly installed with a sliding platform 112, and the top of the sliding platform 112 is fixedly installed with a vertical plate 11, and the vertical plate 11 Two shaft seats 14 are fixedly installed on one side of the shaft seat 14, and the two shaft seats 14 are respectively located at opposite ends of the vertical plate 11, and a cutting disc 16 is installed on the top of each shaft seat 14, and the cutting disc 16 and the shaft seat 14 are rotatably connected. , the two cutting di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com