Double-sided heating type pancake machine

A double-sided heating and pancake machine technology, which is applied in the direction of baking pancakes, oil/fat baking, etc., can solve the problems of limited application range and inability to realize double-sided three-dimensional, etc., and achieve the effect of wide application range, beautiful appearance, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

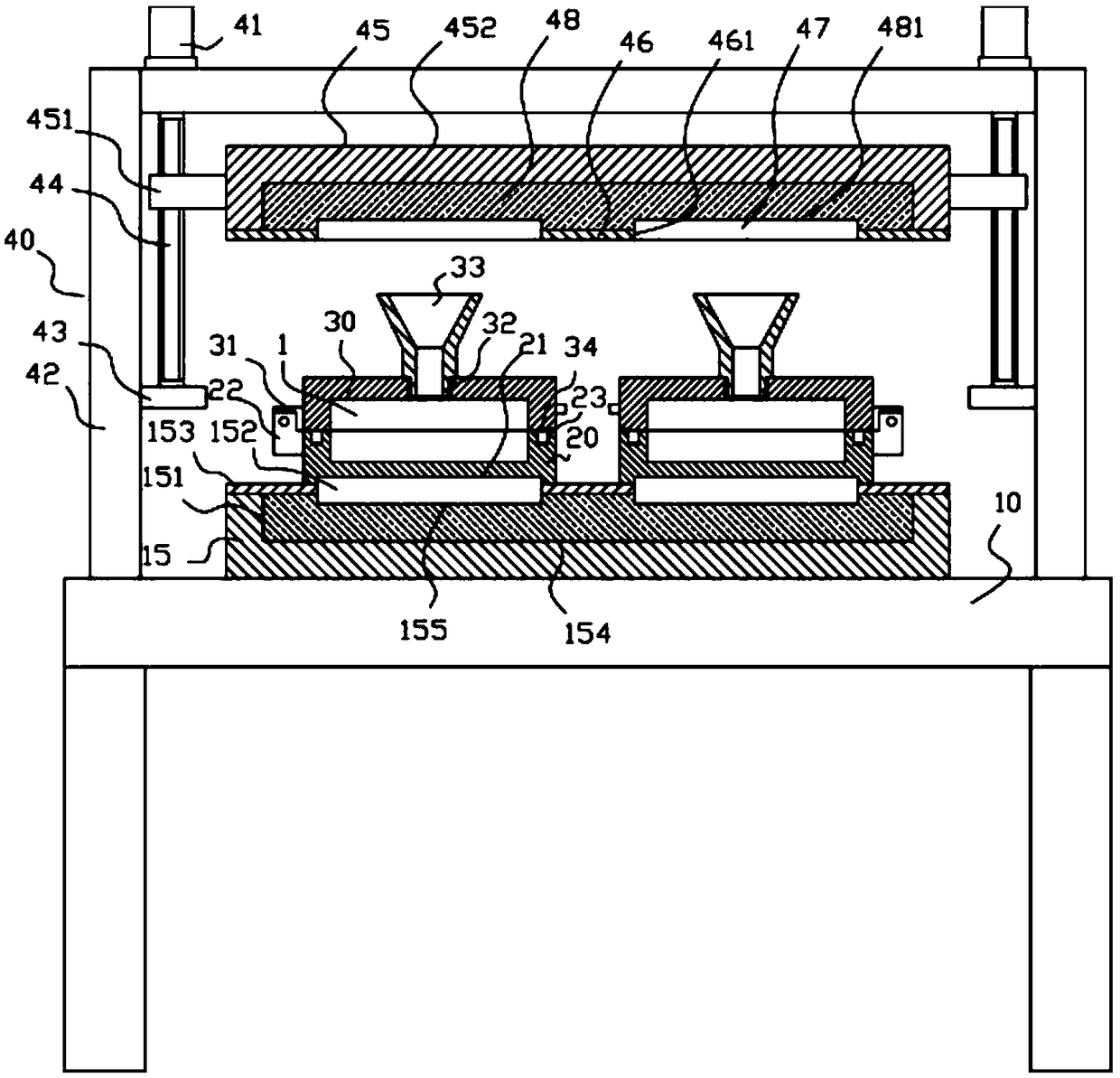

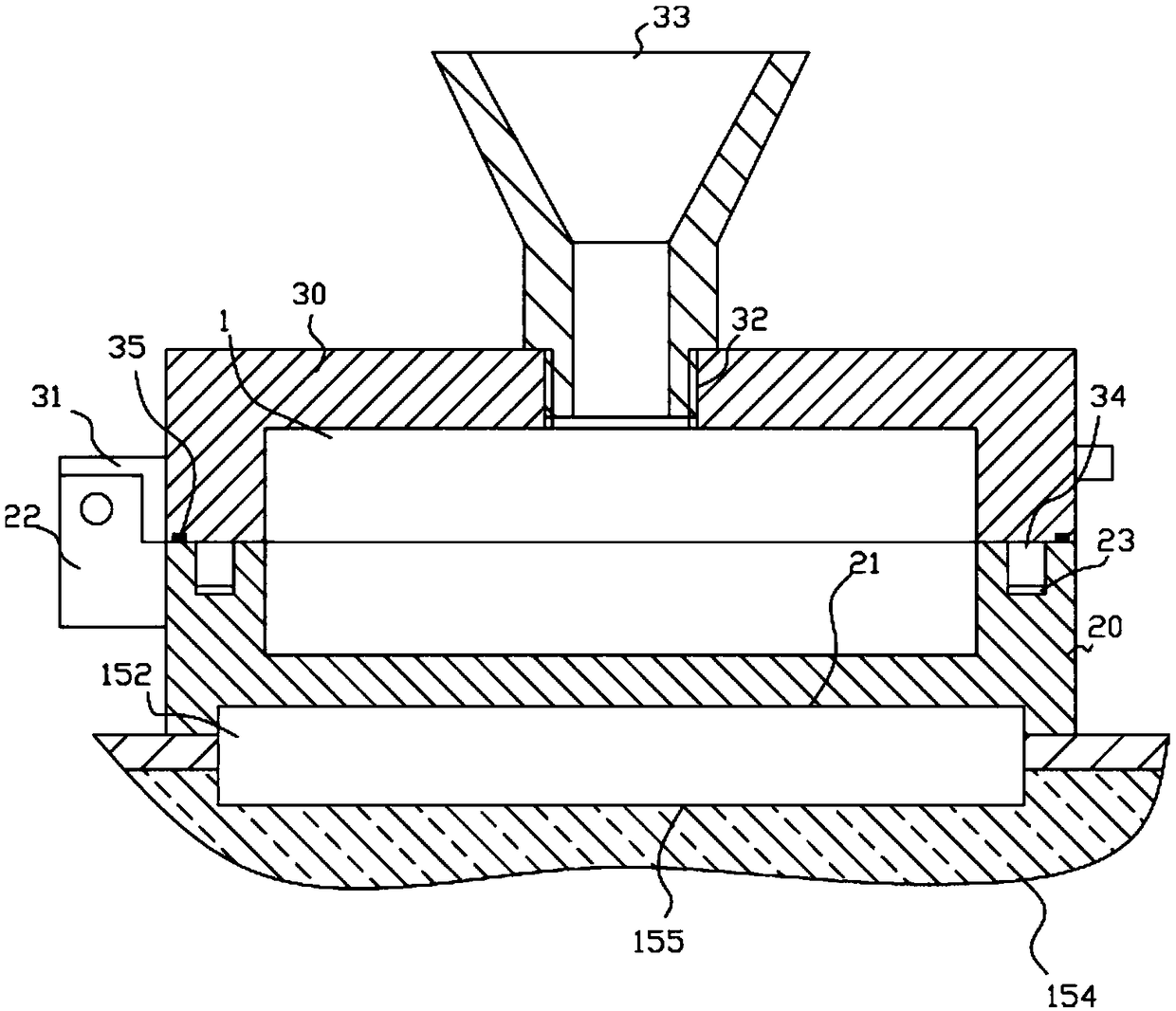

[0019] Example: see Figure 1 to Figure 2 As shown, a double-sided heating type pancake machine includes a frame 10, the top surface of the top plate of the frame 10 is fixed with a main bottom plate 15, and the middle part of the top surface of the main bottom frame 15 has a mounting groove 151, and the mounting groove 151 is fixed with a heating block 152, the top surface of the main chassis 15 is fixed with an upper support plate 153, the top of the heating block 152 stretches out from the installation channel of the upper support plate 153, and the pancake bottom plate 20 is fixed on the top surface of the upper support plate 153 Above, the bottom surface of the pancake bottom plate 20 has a heating groove 21, and the upper part of the heating block 152 is inserted and locked in the heating groove 21. The pancake bottom plate 20 is hinged with a pancake top plate 30. The top surface has corresponding processing grooves 1 up and down, and the two processing grooves 1 form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com