Full-automatic pancake machine

A pancake machine, fully automatic technology, applied in the direction of baking pancakes, oil/fat baking, etc., can solve the problems of pancakes with low density, not very popular, bad taste, etc., and achieve the effect of reducing labor intensity and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

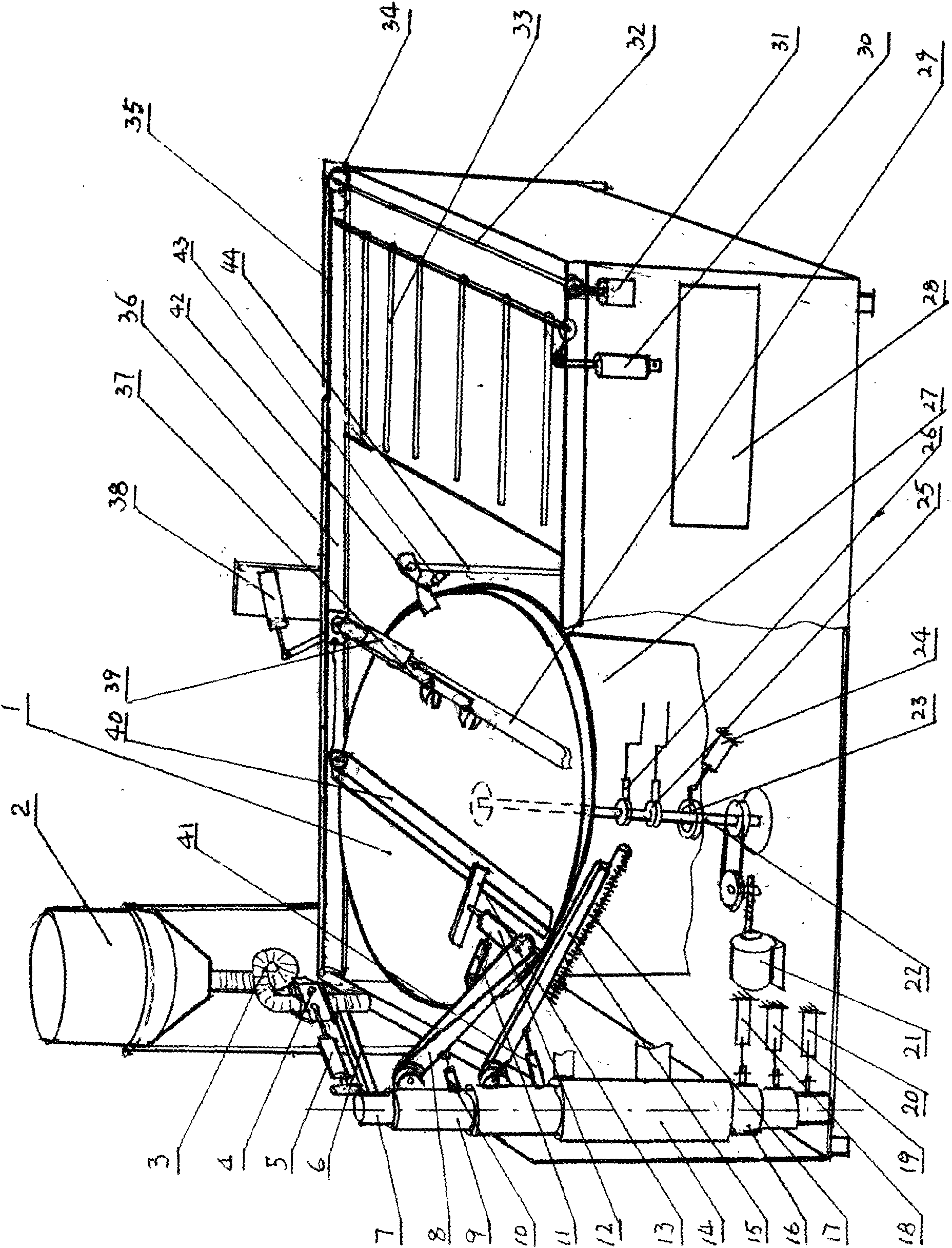

[0032] Referring to the accompanying drawings, the embodiments of the present invention will be described in detail.

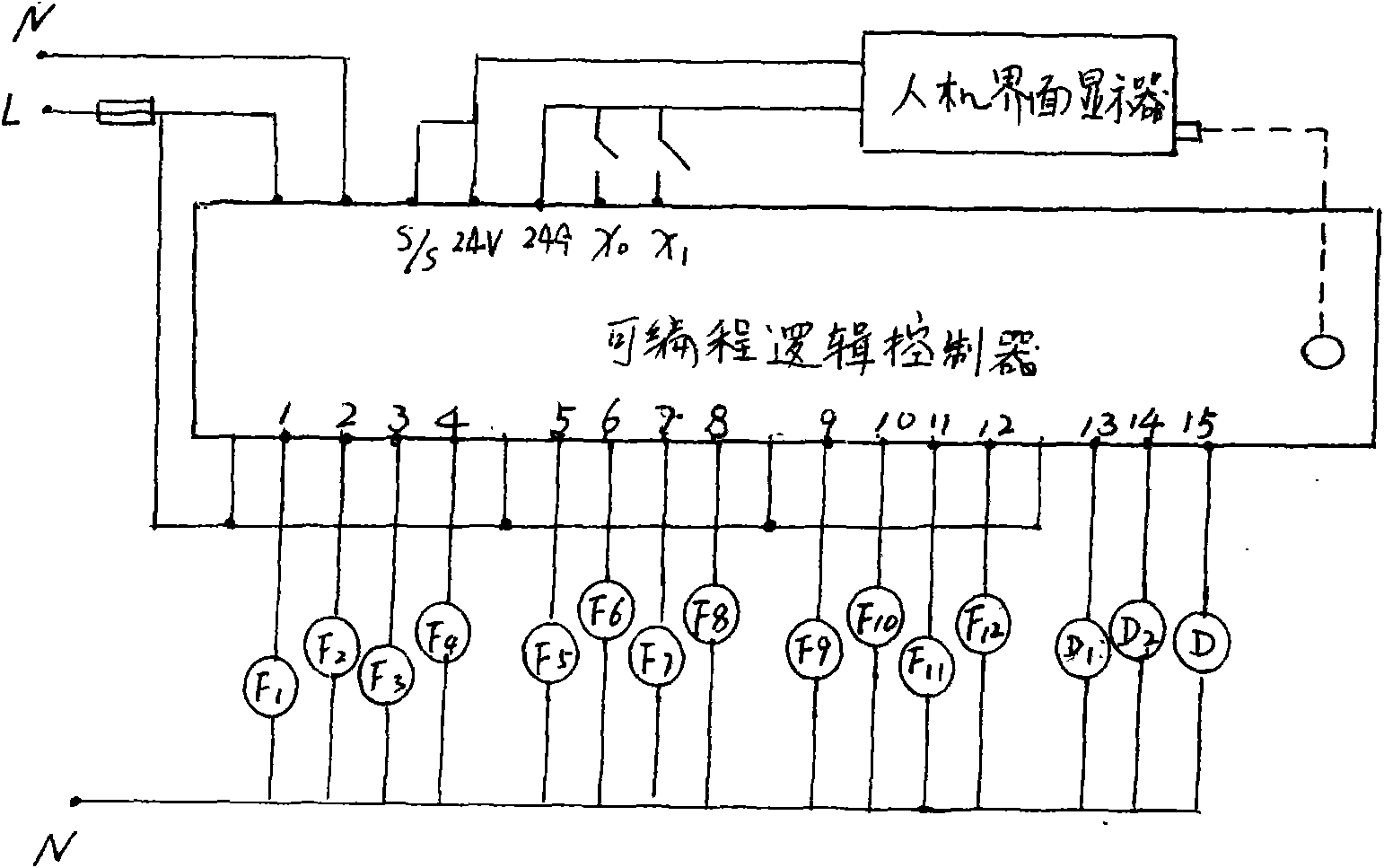

[0033] The mechanical structure of the embodiment is as figure 1 As shown, it includes a griddle 1 heated by a rotating electric heating element 27 driven by a rotating motor 21, a frame arranged on the side of the griddle 1, a stocker installed on the rack for automatic feeding, and a simulator for making pancakes. The various manipulators and automatic controllers of the action are composed together. The stocker is a hopper 2 arranged above the height of the griddle 1, and a discharge hose 3 is arranged at the bottom of the hopper 2. Described each manipulator is successively oil wiping manipulator, puts paste manipulator, spreading manipulator, lifting manipulator, uncovering manipulator, scraping manipulator and overturning manipulator successively according to action program. The structure of each manipulator is:

[0034] 1. The oiling manipulator is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com