Automatic spreading and selling system for pancakes rolled with crisp fritters

An automatic technology for pancakes and pancakes, which is applied in the field of automatic pancake and pancake making and selling systems, can solve problems such as the inability to spread the dough, the inability to effectively pierce the egg shell, and the difference in size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following examples are used to further illustrate the present invention. The following examples are illustrative and not restrictive. The following examples cannot be used to limit the scope of protection of the present invention.

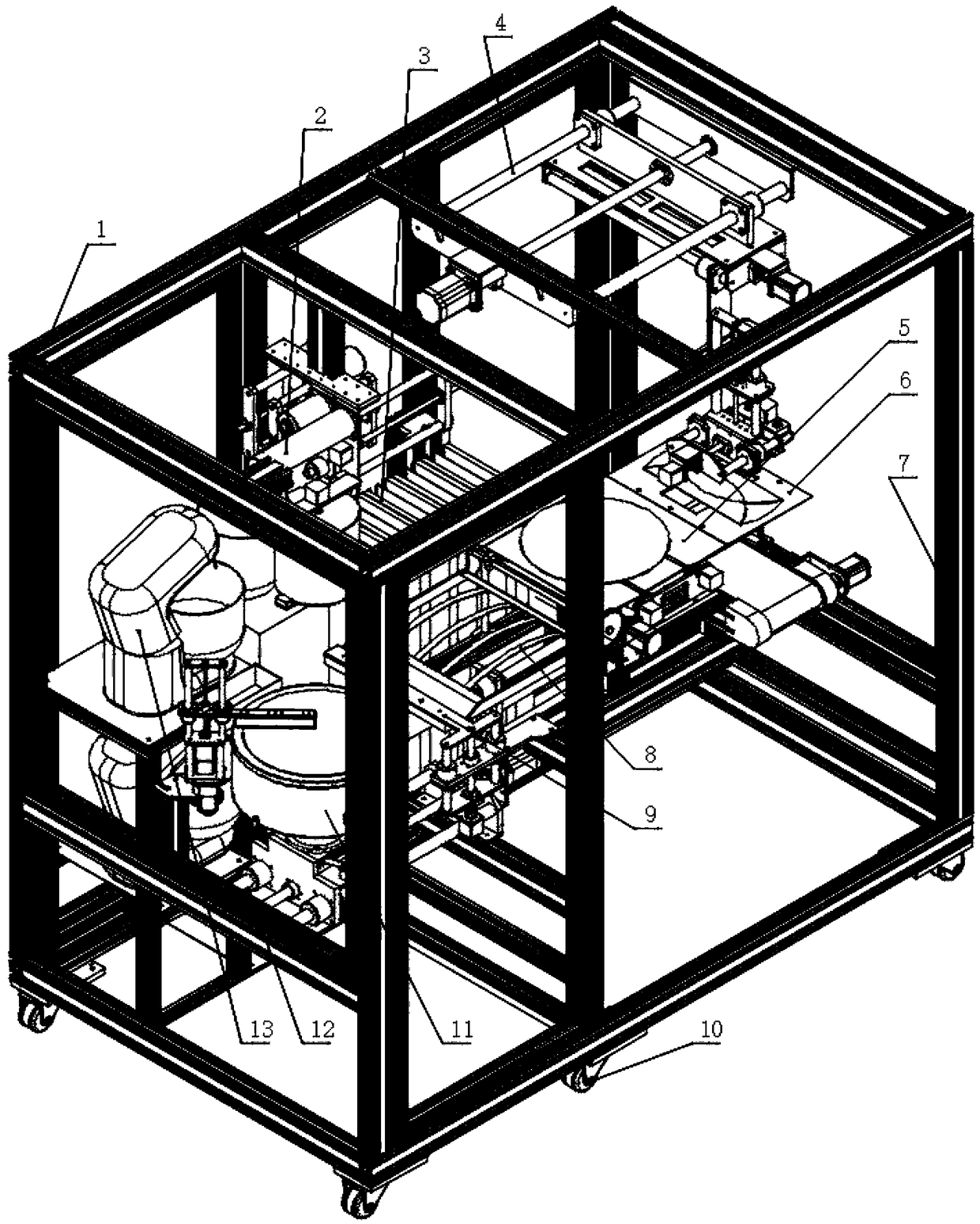

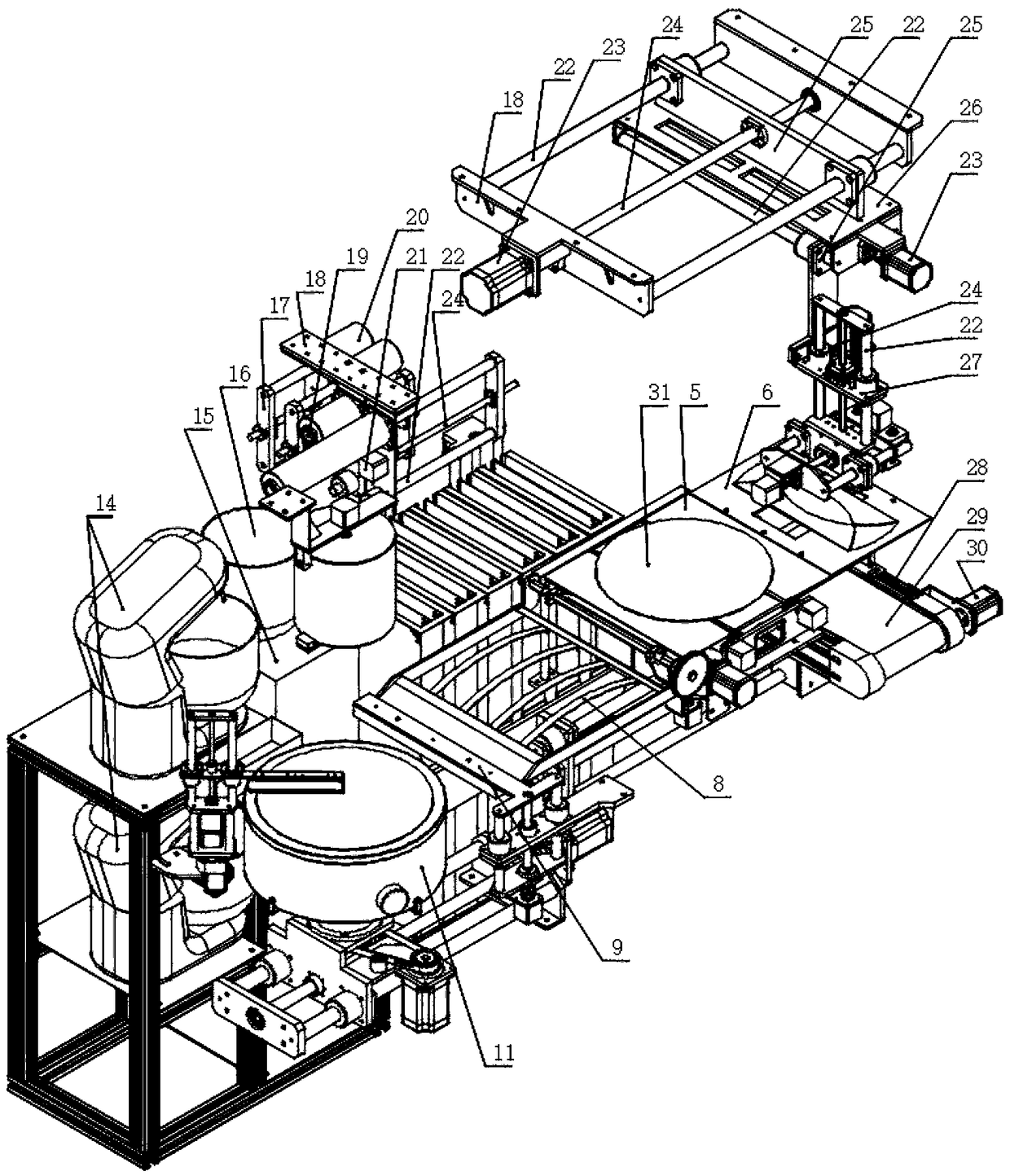

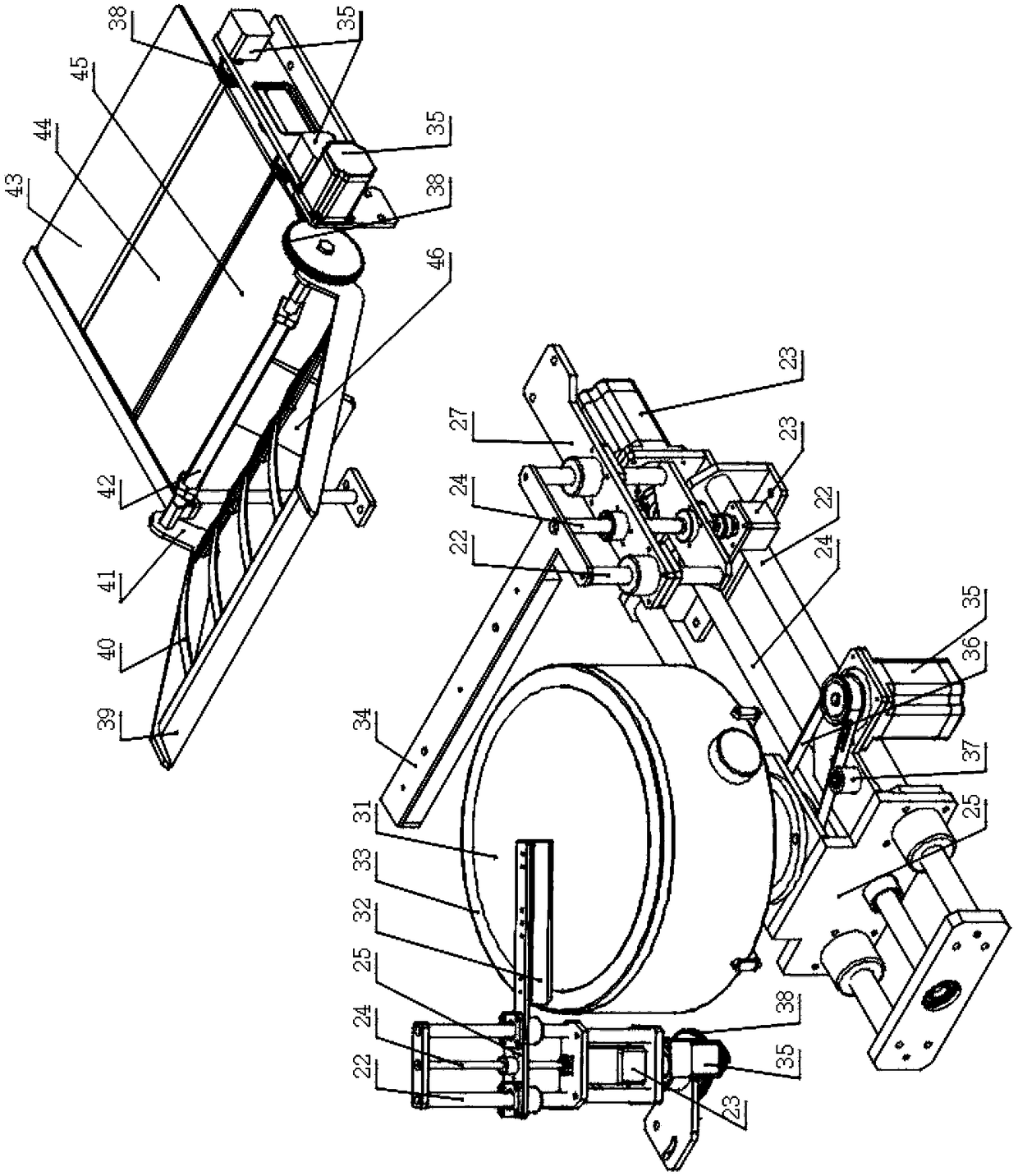

[0056] A kind of pancake lizi automatic selling system, such as Figure 1-12 As shown, it includes a casing, a raw material unit 13, a spreading unit 11, a slurry unit 2, a turning unit 5, a lizi storage unit 3, and a pick-and-place unit 4. The raw material unit, spreading unit, and slurry are arranged in the casing. Unit, turning unit and pick-and-place unit, the innovation of the present invention is: the raw material unit is used to process the batter, the slurry unit is used to supply the batter, egg liquid and seasoning, and the spreading unit is used to mix the batter and egg liquid. Any one or two kinds of spreads are made into pie crust, the turning unit is used to turn the pie crust, the lizi storage unit is used to store the lizi,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com