Fully-automatic pancake maker capable of realizing single-piece production and customization

A single-piece production and fully automatic technology, which is applied in the direction of baking pancakes, baking workshops, baking, etc., can solve problems such as difficulty, many requirements, uneven dough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

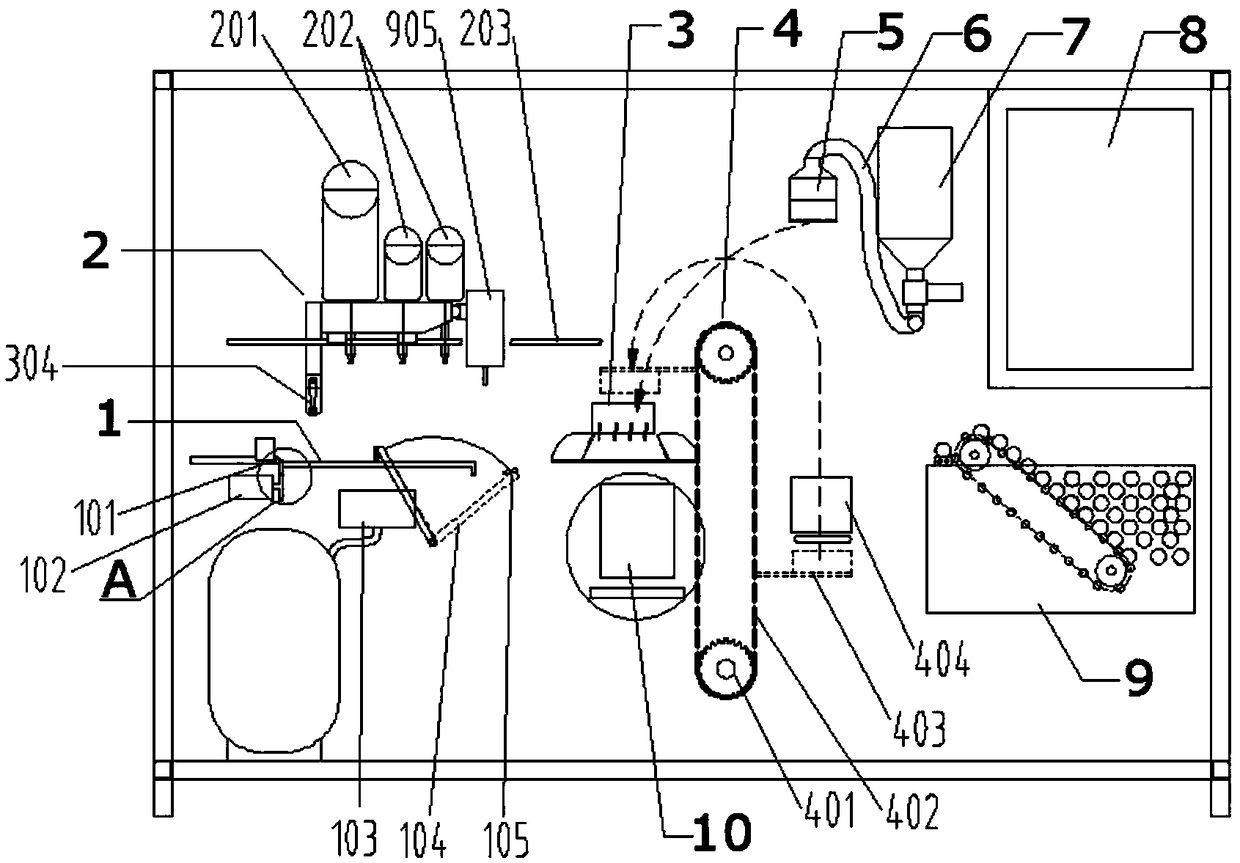

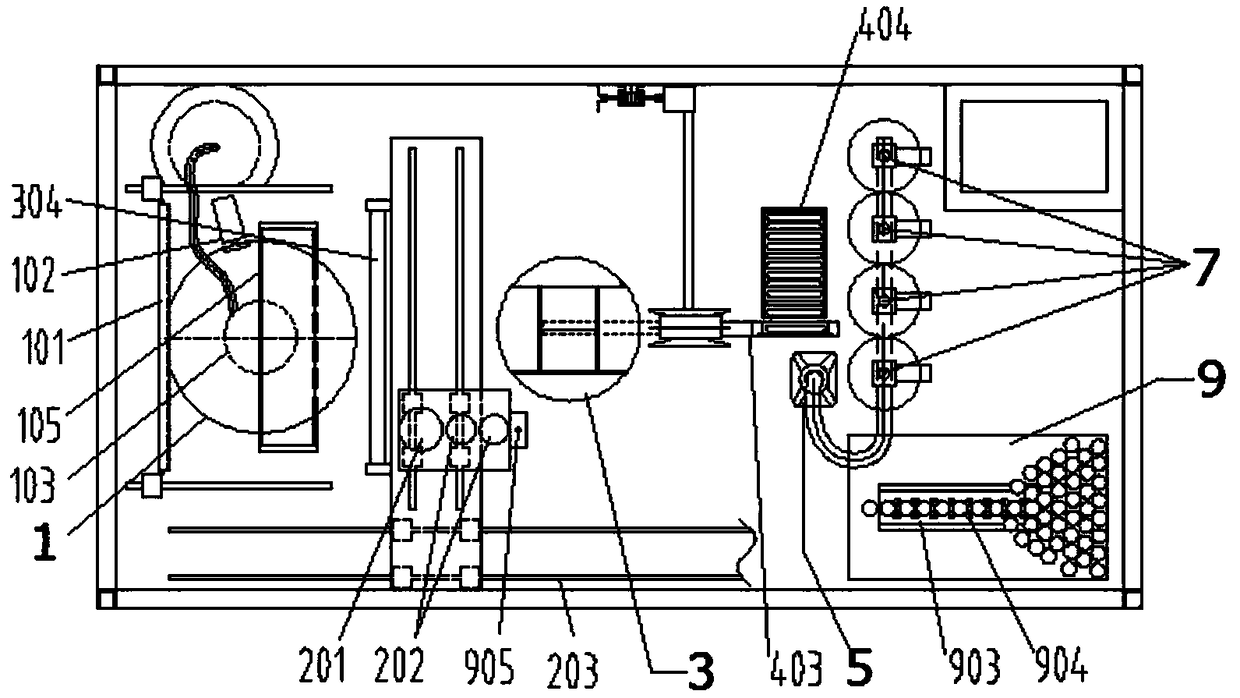

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the left and right positions mentioned in this article are the positions shown in the drawings, which are not intended to limit the actual structure of the pancake machine for the convenience of description. Such as figure 1 , 2 As shown, a fully automatic single-piece production of customized pancake machine, including grid plate 1, hopper 2, folding table 3, sausage adding device 4, vegetable box 5, egg adding device 9, bagging device 10.

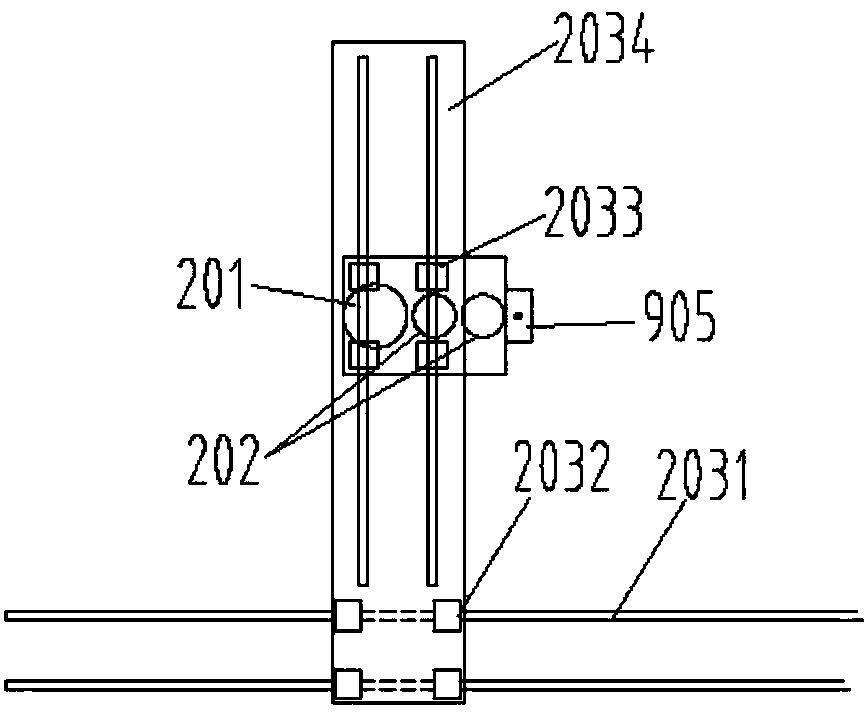

[0031] combine image 3 , the hopper 2 includes a noodle paste hopper 201 and a sauce hopper 202, each hopper is assembled together and integrally installed on the assembly beam 203 on the upper part of the machine body. The assembly beam 203 includes an X-axis translation beam 2031 and a Y-axis translation beam 2034. The Y-axis translation beam 2034 is installed on the X-axis translation beam 2031 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com