Automatic pancake machine

A pancake machine, fully automatic technology, applied in the direction of baking pancakes, oil/fat baking, etc., can solve the problems of low efficiency, inapplicability, uneven thickness of pancakes, etc., and achieve economic benefits, convenient operation, and convenient disassembly and cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

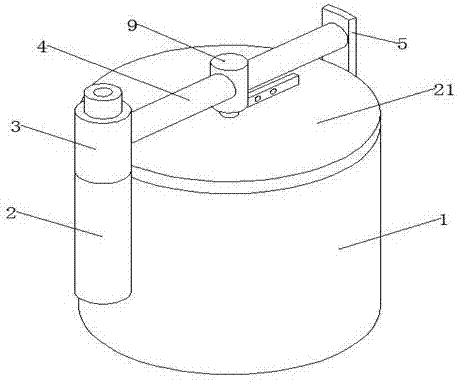

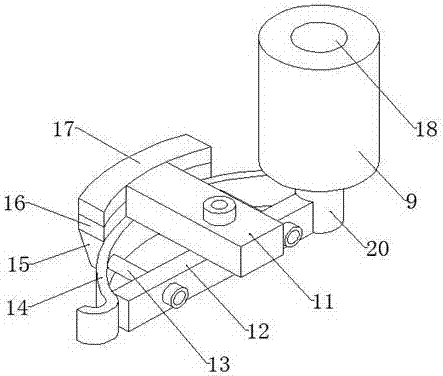

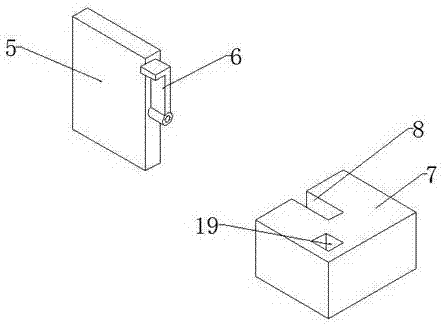

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

[0017] A fully automatic pancake machine, comprising a furnace 1, a fixed shaft 2, a shaft sleeve 3, a support arm 4, a fixed plate 5, a fixed pin 6, a fixed seat 7, a groove 8, a sleeve 9, a shaft sleeve 10, and a support shaft 11 , horizontal axis 12, adjusting screw 13, arc-shaped shovel 14, arc-shaped funnel 15, feeding pump 16, batter box 17, motor 18, pin groove 19, bearing 20 and griddle 21, and fixed shaft 2 is welded on the bottom of stove 1 On the side wall, the shaft sleeve 3 is fixed on the fixed shaft 2 and fixed by a nut, and the shaft sleeve 3 rotates around the fixed shaft 2, the support arm 4 is welded on the shaft sleeve 10, and the end is connected with the sleeve 9, and the sleeve 9 passes through the support arm 4 Connect the fixed plate 5, the fixed pin 6 is installed on the side wall of the fixed plate 5, and the fixed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com