Fully automatic pancake cooking machine

A pancake machine, fully automatic technology, applied in the direction of baking pancakes, baking, household utensils, etc., can solve problems such as delays in time, affect operations, and reduce production efficiency, so as to ensure taste and quality, save manpower, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

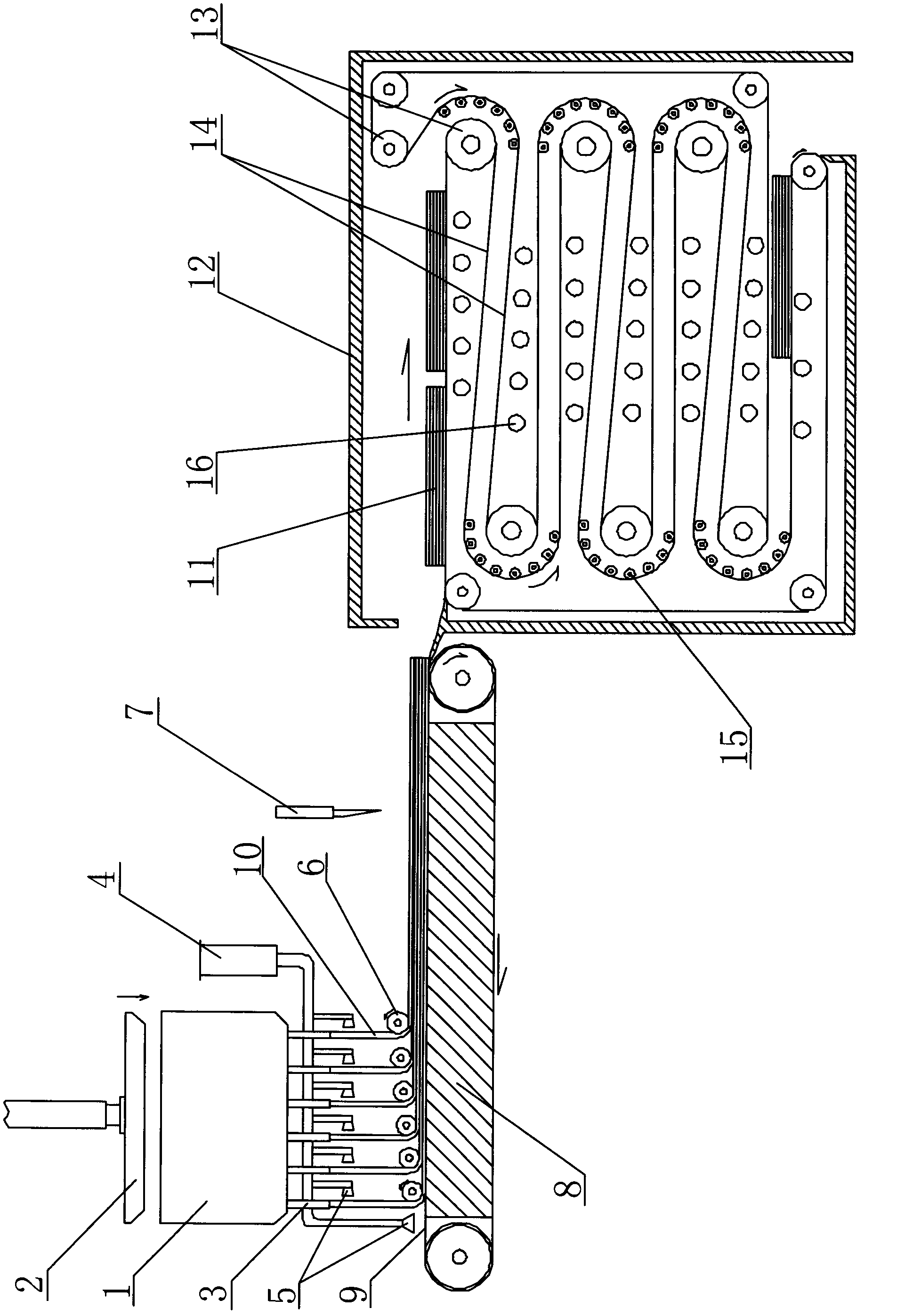

[0013] A fully automatic pancake machine, such as figure 1 As shown, it is mainly composed of cake making mechanism and pancake box. It includes a noodle bin 1 and an extruding panel 2 driven by a hydraulic device matched with the noodle bin 1. A number of sheet outlets 3 are arranged at the bottom of the noodle bin 1. Each sheet outlet 3 is flat, evenly spaced and parallel to each other. The sheet oil injection mechanism includes an oil storage tank 4, an oil delivery pipe, and several spray nozzles 5 arranged on the oil delivery pipe. The dough sheet pressure guide device includes a number of pressure guide rollers 6, and the dough cake fixed cutting device includes a fixed cutter 7. The table includes a matching pallet 8 and a guide conveyor belt 9, and a spray nozzle 5 is arranged on the lower side of each sheet outlet 3, and another spray nozzle 5 is aimed at the upper surface of the guide conveyor belt 9, and each pressure guide The rollers 6 are arranged in parallel at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com