Fully-automatic line production type multi-griddle pancake machine

A flow-through, fully automatic technology, applied in the field of machinery, can solve the problems of additive residue, operator fatigue, and low production efficiency, and achieve the effects of coordinated mechanical rotation, high degree of automation, and low mechanical failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

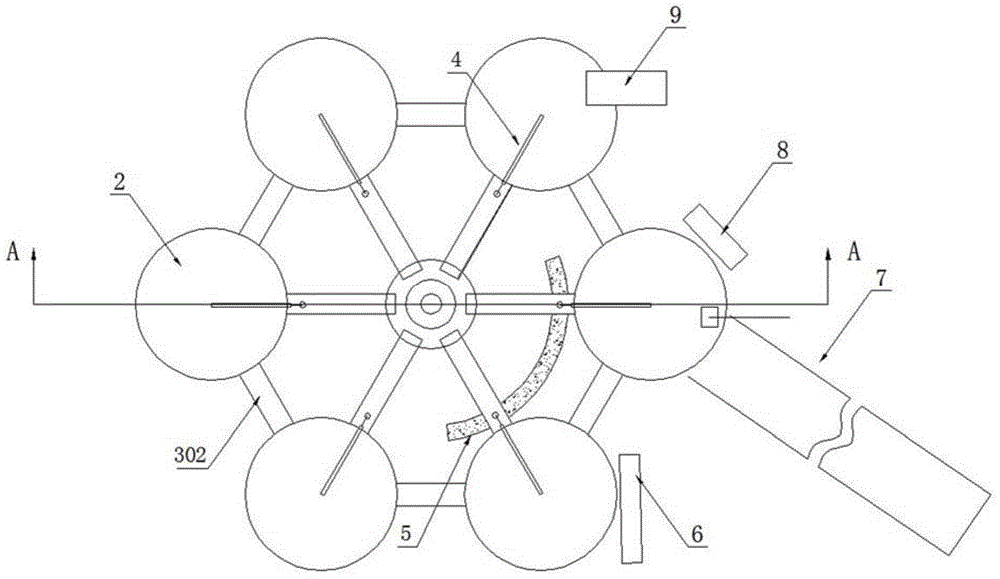

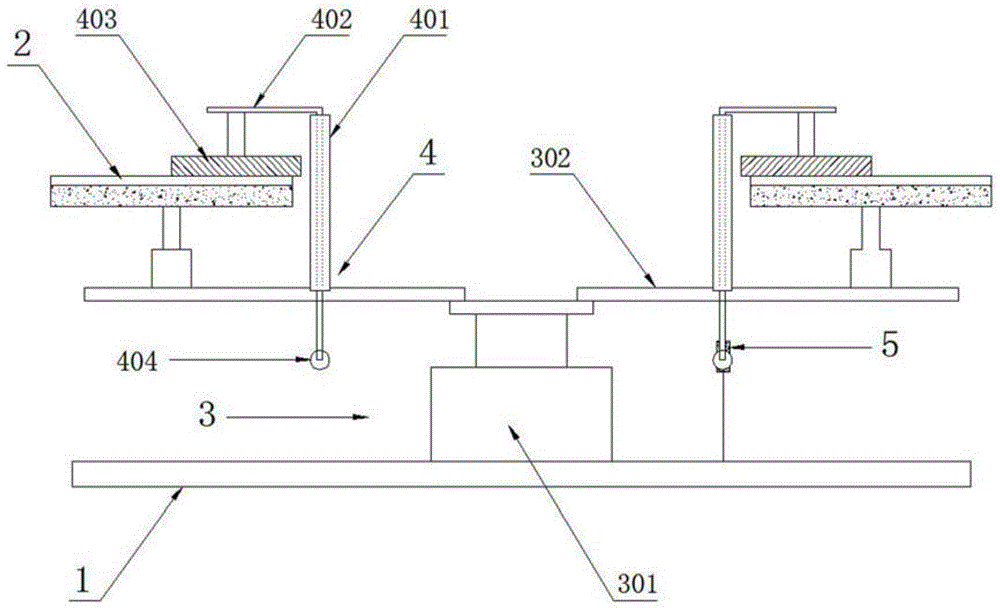

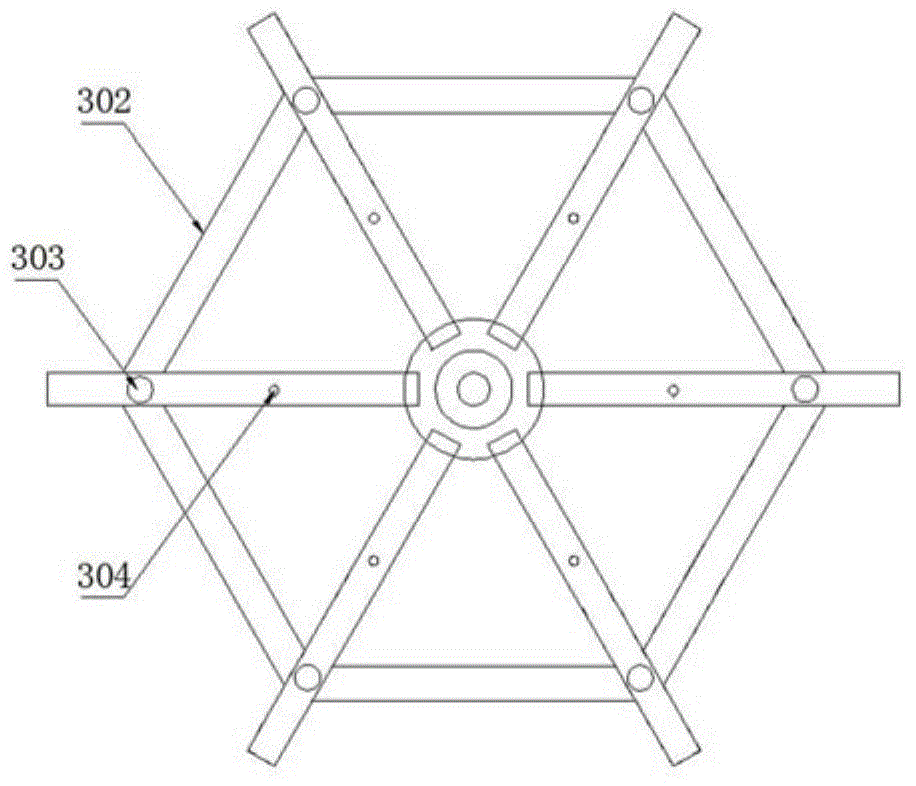

[0041] refer to figure 1 with figure 2 , the fully automatic flow-type multi-pan pancake machine of the present invention includes: pancake rotating device 3, multiple pans 2, multiple batter scraping devices 4, multiple batter mixing mechanisms 10, fixed-point lifting platform 5, scraper and propulsion device 6. Pancake grasping and conveying device 7, oil rubbing device 8 and paste spraying device 9, wherein, ladle rotating device 3, fixed-point lifting platform 5, scraper and propulsion device 6, pancake grasping and conveying device 7, oil rubbing device 8 and paste spraying device 9 are installed on the base 1, pan 2, batter scraping device 4 and batter mixing mechanism 10 are installed on pan rotating device 3, each pan 2 is equipped with a batter scraping device 4, each A batter scraping device 4 is equipped with a batter mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com