Polishing device for film color-changing sheet

A color-changing lens and film layer technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve problems such as difficult to meet people's needs, low grinding efficiency, and poor consistency of the two lenses, so as to reduce the temperature , high grinding consistency, reduce the effect of spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

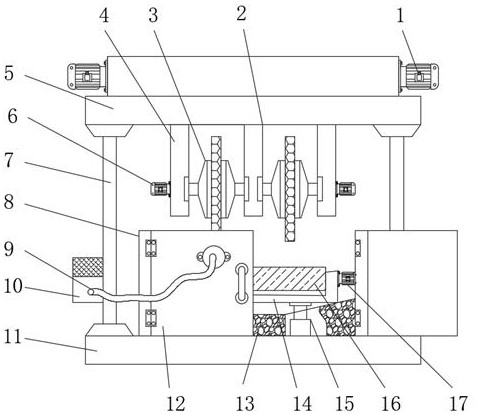

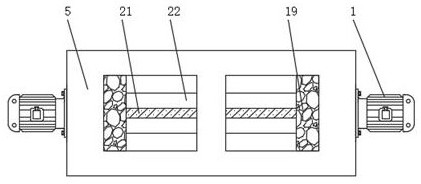

[0023] This embodiment provides a specific structure of a polishing device for a film layer color-changing sheet, such as Figure 1-3 As shown, it includes a top plate 5 and a bottom plate 11, and the top plate 5 and the bottom plate 11 are connected by a stand 7. A clamping mechanism for clamping the film layer color-changing sheet is installed under the top plate 5, and a clamping mechanism for clamping the film layer is installed above the bottom plate 11. A polishing mechanism for polishing the layer color film, wherein,

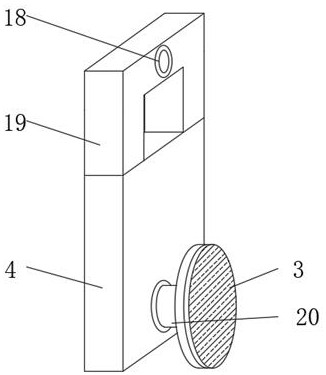

[0024] The clamping mechanism includes a fixed plate 2 and a movable plate 4. The fixed plate 2 is located on the center line below the top plate 5. There are two movable plates 2. The two movable plates 2 are symmetrically arranged on both sides of the fixed plate 2. The fixed plate 2 A splint 3 is arranged on the side opposite to the movable plate 4;

[0025] Grinding mechanism comprises lifting roller frame 14 and grinding roller shaft 16, and liftin...

Embodiment 2

[0033] This embodiment provides a specific structure of a polishing device for a film layer color-changing sheet, such as Figure 1-3 As shown, it includes a top plate 5 and a bottom plate 11, and the top plate 5 and the bottom plate 11 are connected by a stand 7. A clamping mechanism for clamping the film layer color-changing sheet is installed under the top plate 5, and a clamping mechanism for clamping the film layer is installed above the bottom plate 11. A polishing mechanism for polishing the layer color film, wherein,

[0034] The clamping mechanism includes a fixed plate 2 and a movable plate 4. The fixed plate 2 is located on the center line below the top plate 5. There are two movable plates 2. The two movable plates 2 are symmetrically arranged on both sides of the fixed plate 2. The fixed plate 2 A splint 3 is arranged on the side opposite to the movable plate 4;

[0035] Grinding mechanism comprises lifting roller frame 14 and grinding roller shaft 16, and liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com