Slurry lifting machine for building construction

A technology of building construction and lifting seats, which is applied in the direction of lifting devices, recycling technology, cleaning methods and appliances, etc., can solve the problems of low work efficiency and waste of manpower, and achieve the effects of saving labor, improving work efficiency and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

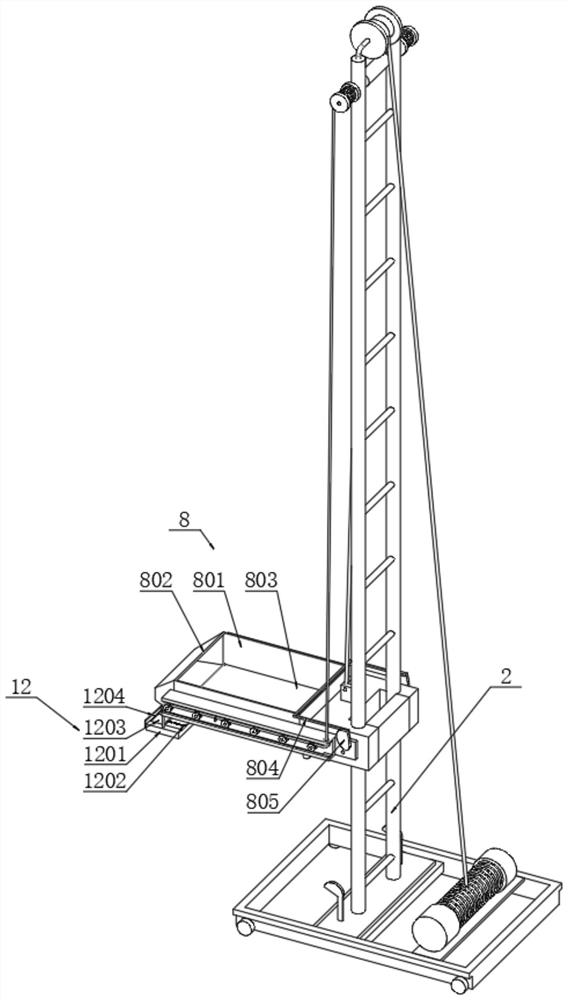

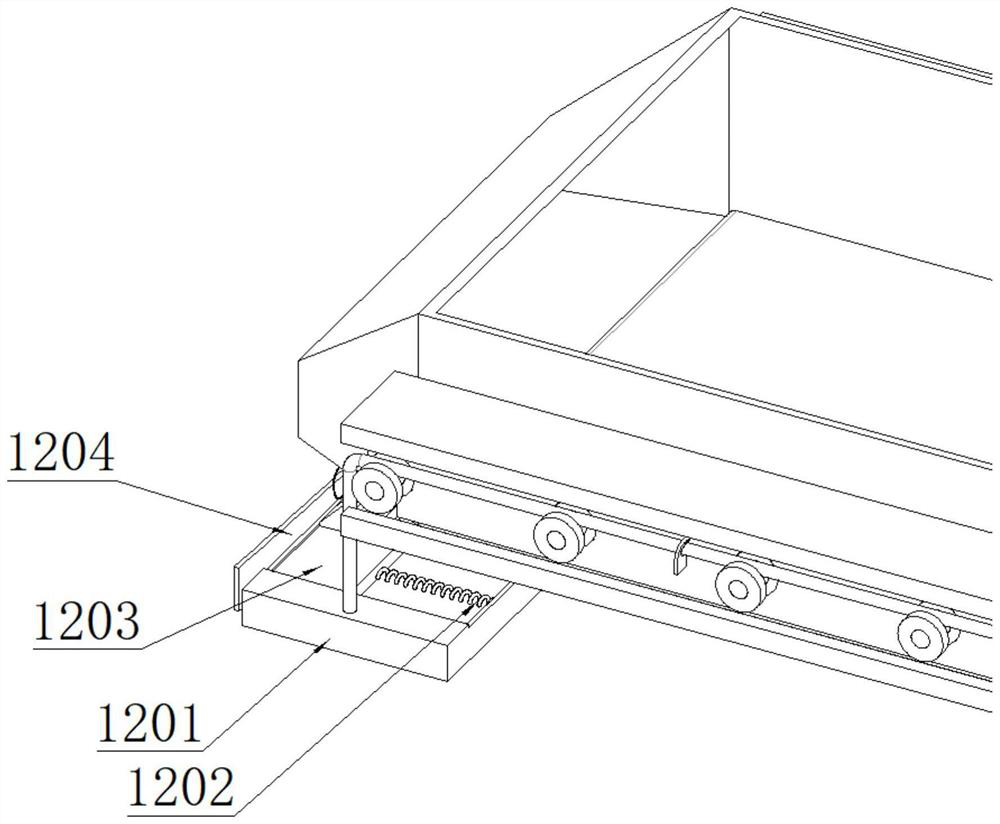

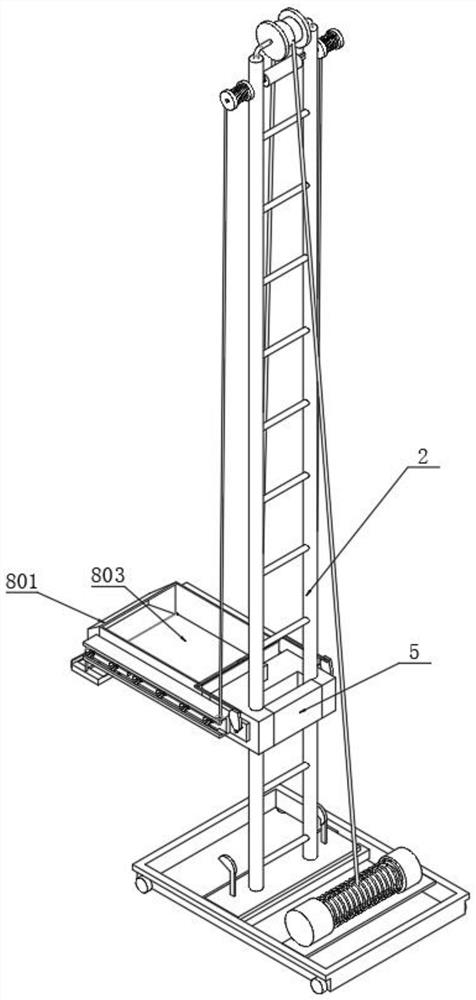

[0033] The following is attached figure 1 - Figure 11 , the specific implementation manner of the present invention will be further described in detail, so as to make the technical solution of the present invention easier to understand and grasp.

[0034] The pulp lifter for building construction includes a moving seat 1, a hopper mechanism 8, a guide seat mechanism 11 and a feeding mechanism 12: the front end of the lifting seat 5 is welded with a support frame 6, and the support frame 6 is hinged with a hopper mechanism 8 and a lifting frame 2 A top pulley 9 and a double-axis motor 10 are installed on the top of the top pulley 9. There is a first sling 901 connected between the electric hoist 4 and the lifting seat 5 over the top pulley 9. When the electric hoist 4 is powered on, the first sling 901 Pulling the lifting seat 5 drives the hopper mechanism 8 to slide up and down along the lifting frame 2 to meet the filling of mud inside the reinforcement cage of various heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com