Method for the cold rolling of metallic rolled stock

A technology for rolling materials and metals, applied in the field of cold-rolled metal rolling materials, can solve problems such as health problems and corrosion, and achieve the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

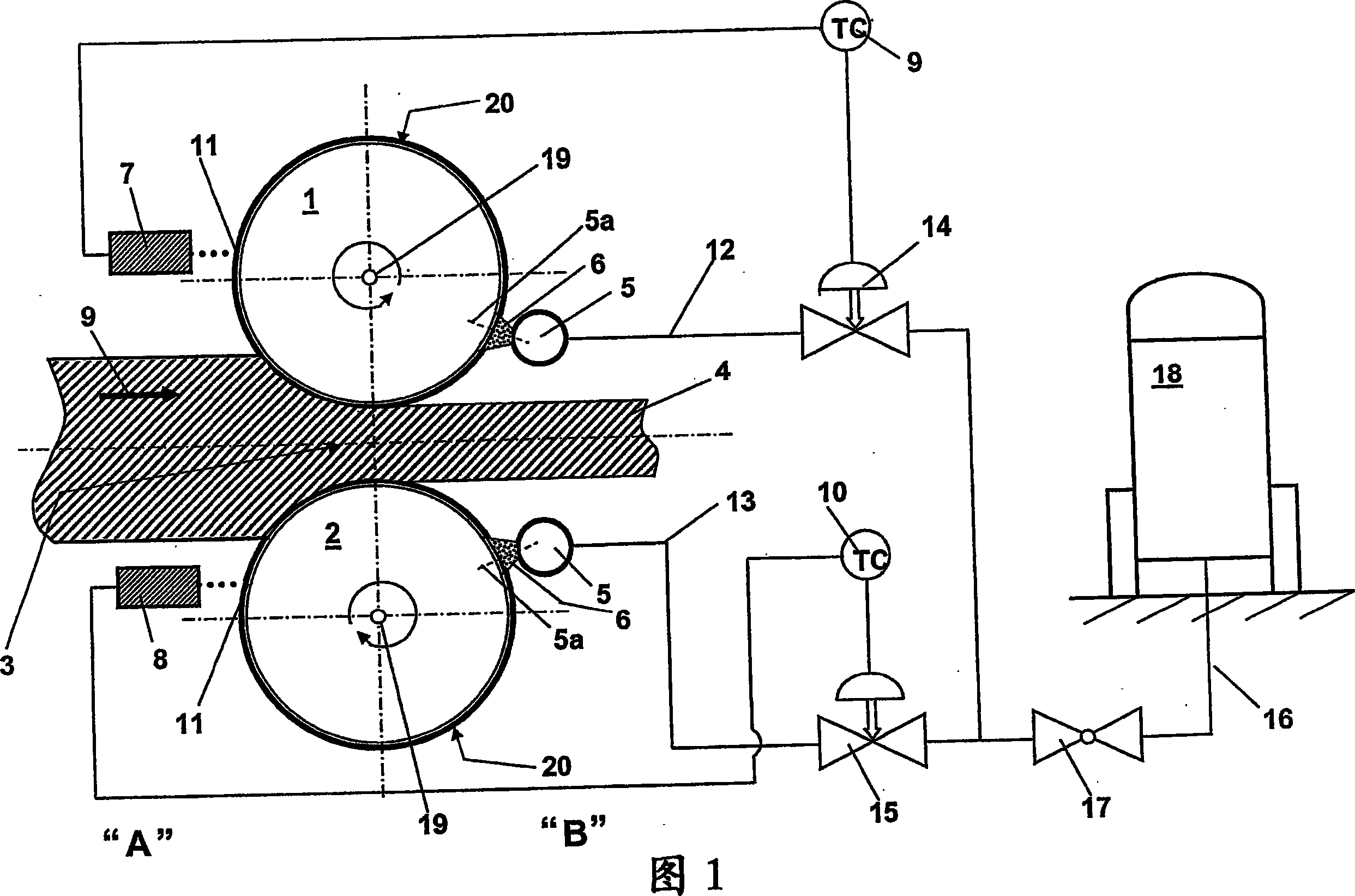

[0040]FIG. 1 schematically shows a cooling stand with two rolls 1 , 2 arranged vertically one above the other, forming a roll gap 3 between them. The rolling stock in the form of a metal strip 4 is drawn through this nip 3 in the direction of the arrow 9 .

[0041] On the strip delivery side "B" of the roll stand there are nozzles 5 which supply the coolant in liquid form onto the surfaces of the rolls. The nozzle 5 is formed as a tubular nozzle extending along the entire length of the two rolls 1 , 2 . Liquid jets 6 emerging from the nozzles 5 are directed onto the surfaces of the rolls 1 , 2 , the main direction of propagation of the jets 6 - indicated by the dashed line 5a - extending perpendicularly with respect to the outer cylindrical surface 20 of the respective roll 1 , 2 .

[0042] The surface temperature of rolls 1 and 2 is recorded with pyrometers 7 and 8 at measuring point 11 on the strip entry side "A". The pyrometers 7 and 8 are each connected to a temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com