Titanium alloy dot matrix reinforced aluminum matrix composite and preparation method thereof

A technology for strengthening aluminum-based and composite materials, which is applied in the direction of additive processing and additive manufacturing, etc., to achieve the effects of increased specific stiffness, short process and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

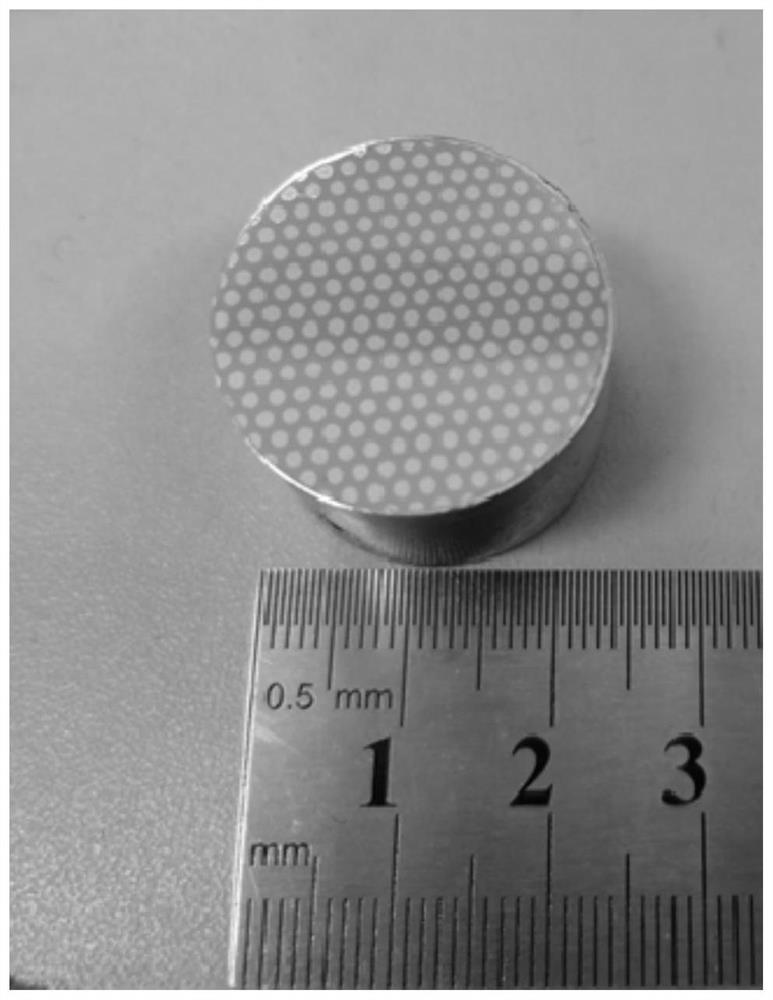

[0036] In this embodiment, the raw materials used in the preparation of the titanium alloy lattice structure reinforced aluminum matrix composite material are: Ti-6Al-4V powder with an average particle size of 20 μm, and a cylindrical 7075 aluminum alloy block. The specific preparation process is as follows:

[0037] (1) Using the three-dimensional modeling software Solidworks to design a Ti-6Al-4V titanium alloy lattice with a circular pore structure, and establish a three-dimensional model of the lattice. The Ti-6Al-4V titanium alloy lattice structure was printed by EOSINT M280 metal 3D printer. The size of the skeleton is Ф26×15mm, the porosity is 40%, the pore diameter is about 1mm, and the inner wall thickness of the lattice is 0.5mm;

[0038] (2) subjecting the Ti-6Al-4V titanium alloy lattice obtained by printing in step (1) to abrasive flow treatment, the abrasive is SiC, the pressure is 50Kg, and the time is 0.5h;

[0039] (3) put the Ti-6Al-4V titanium alloy lattice...

Embodiment 2

[0045] In this embodiment, the raw materials used in the preparation of the titanium alloy lattice structure reinforced aluminum matrix composite material are: Ti-6Al-4V powder with an average particle size of 20 μm, and a cylindrical 7075 aluminum alloy block. The specific preparation process is as follows:

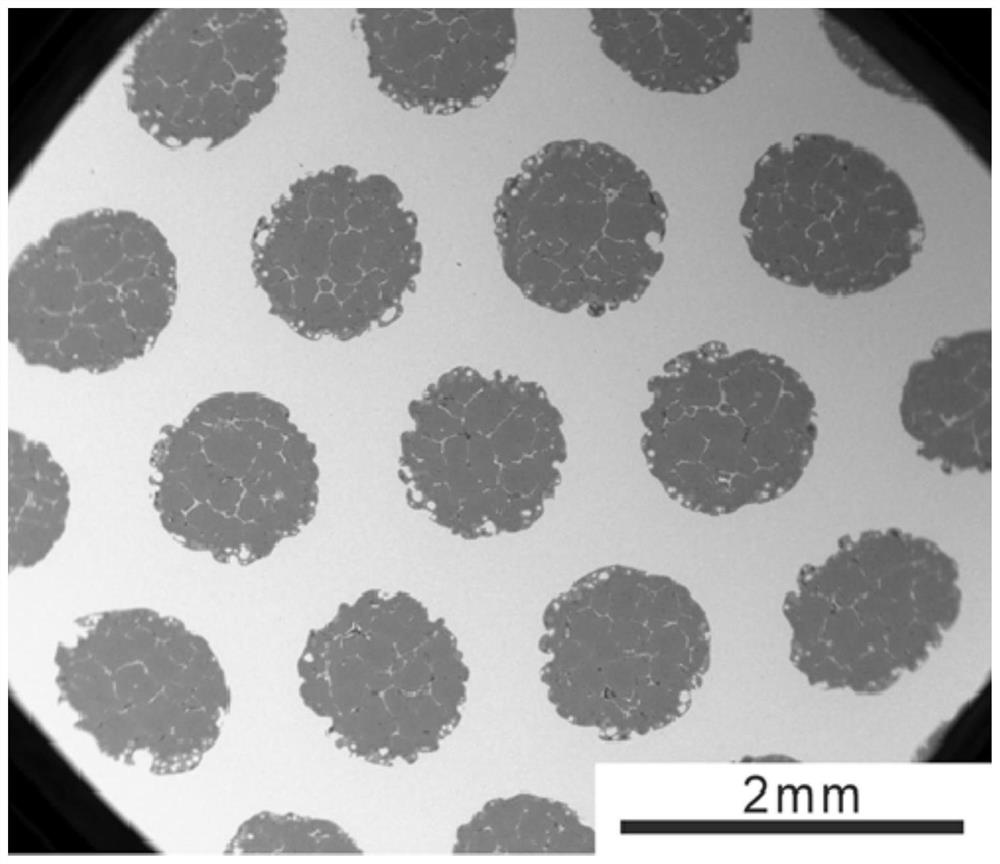

[0046] (1) This step is similar to step (1) in Example 1, except that the skeleton is a honeycomb structure, the size of the skeleton is Ф12×15mm, the porosity is 40%, and the corresponding hexagon side length is 1mm , the wall thickness is 0.5mm;

[0047] (2) this step is identical with step (2) in embodiment 1;

[0048] (3) this step is similar to the step (3) in embodiment 1, and the difference is that the diameter of the crucible used is 16mm;

[0049] (4) this step is identical with step (4) in embodiment 1;

[0050] (5) this step is identical with step (5) in embodiment 1;

[0051] (6) this step is identical with step (6) in embodiment 1;

[0052] Tested titan...

Embodiment 3

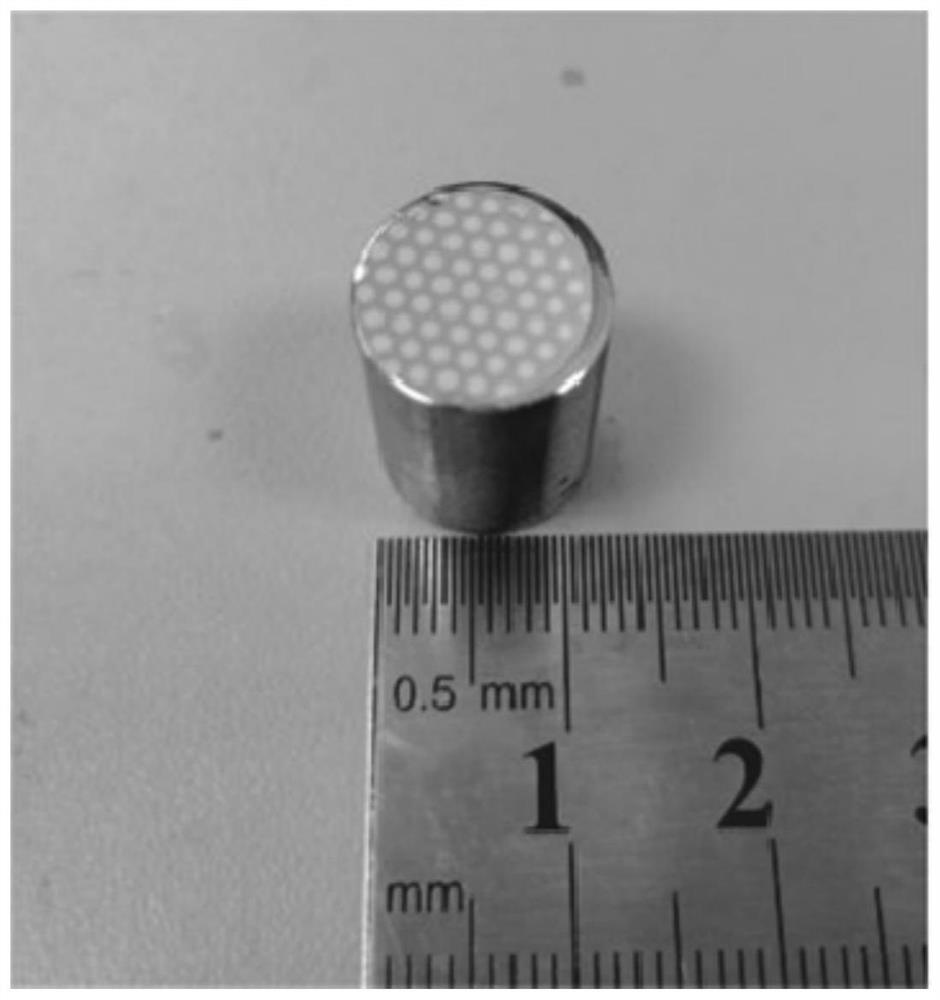

[0054] In this embodiment, the raw materials used in the preparation of the titanium alloy lattice structure reinforced aluminum matrix composite material are: Ti-6Al-4V powder with an average particle size of 20 μm, and a cylindrical 7075 aluminum alloy block. The specific preparation process is as follows:

[0055] (1) This step is similar to step (1) in Example 2, except that the porosity of the skeleton is 60%, the corresponding hexagonal side length is 2 mm, and the wall thickness is 0.2 mm;

[0056] (2) this step is identical with step (2) in embodiment 2;

[0057] (3) this step is identical with step (3) in embodiment 2;

[0058] (4) this step is identical with step (4) in embodiment 2;

[0059] (5) this step is identical with step (5) in embodiment 2;

[0060] (6) this step is identical with step (6) in embodiment 2;

[0061] After testing, the compressive strength of the titanium alloy lattice reinforced aluminum matrix composite material reaches 930MPa, and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com