Method for preparing carbon fiber composite material reflector and carbon fiber composite material reflector

A composite material and mirror technology, applied in the direction of mirrors, etc., can solve the problems of large longitudinal deformation of the mirror, poor shear resistance, inconsistent thermal expansion coefficient, etc., to achieve good thermal expansion coefficient consistency, high bearing efficiency, high light weight rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

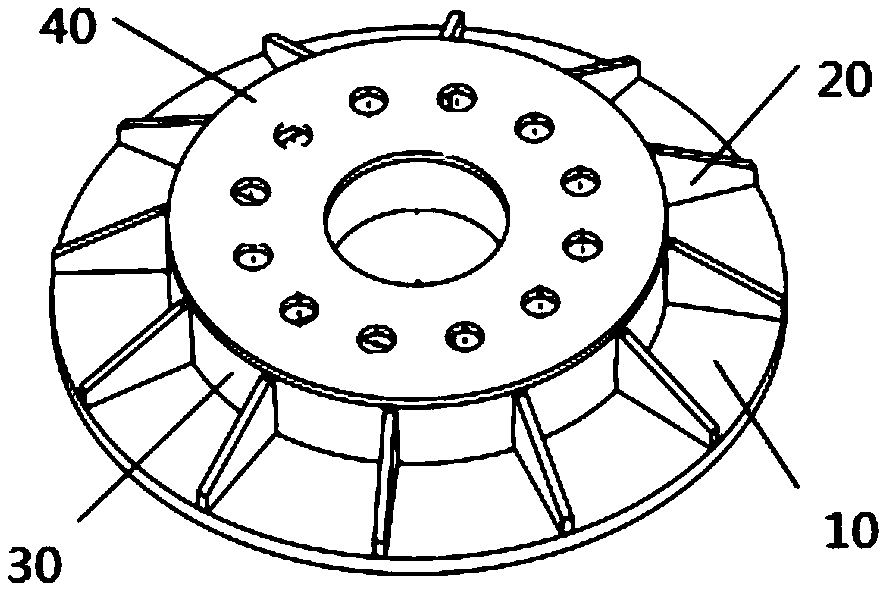

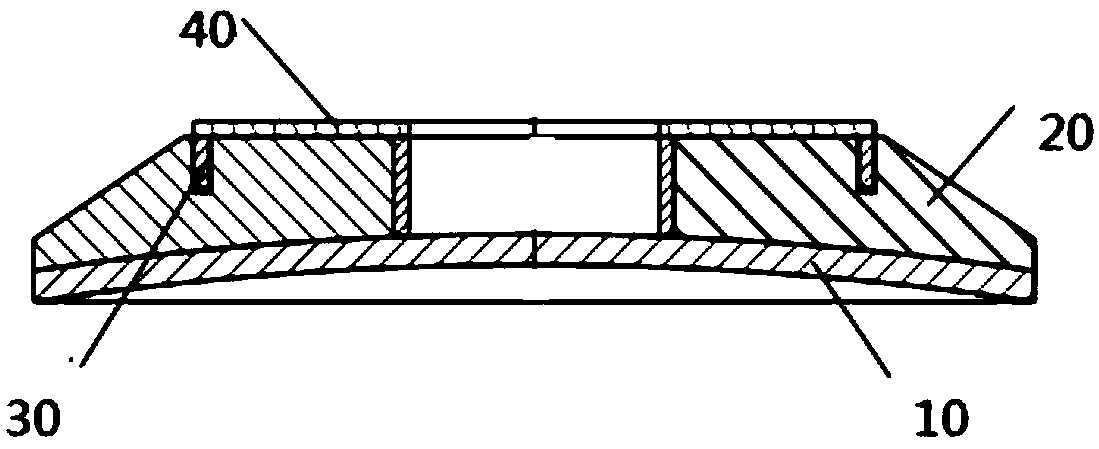

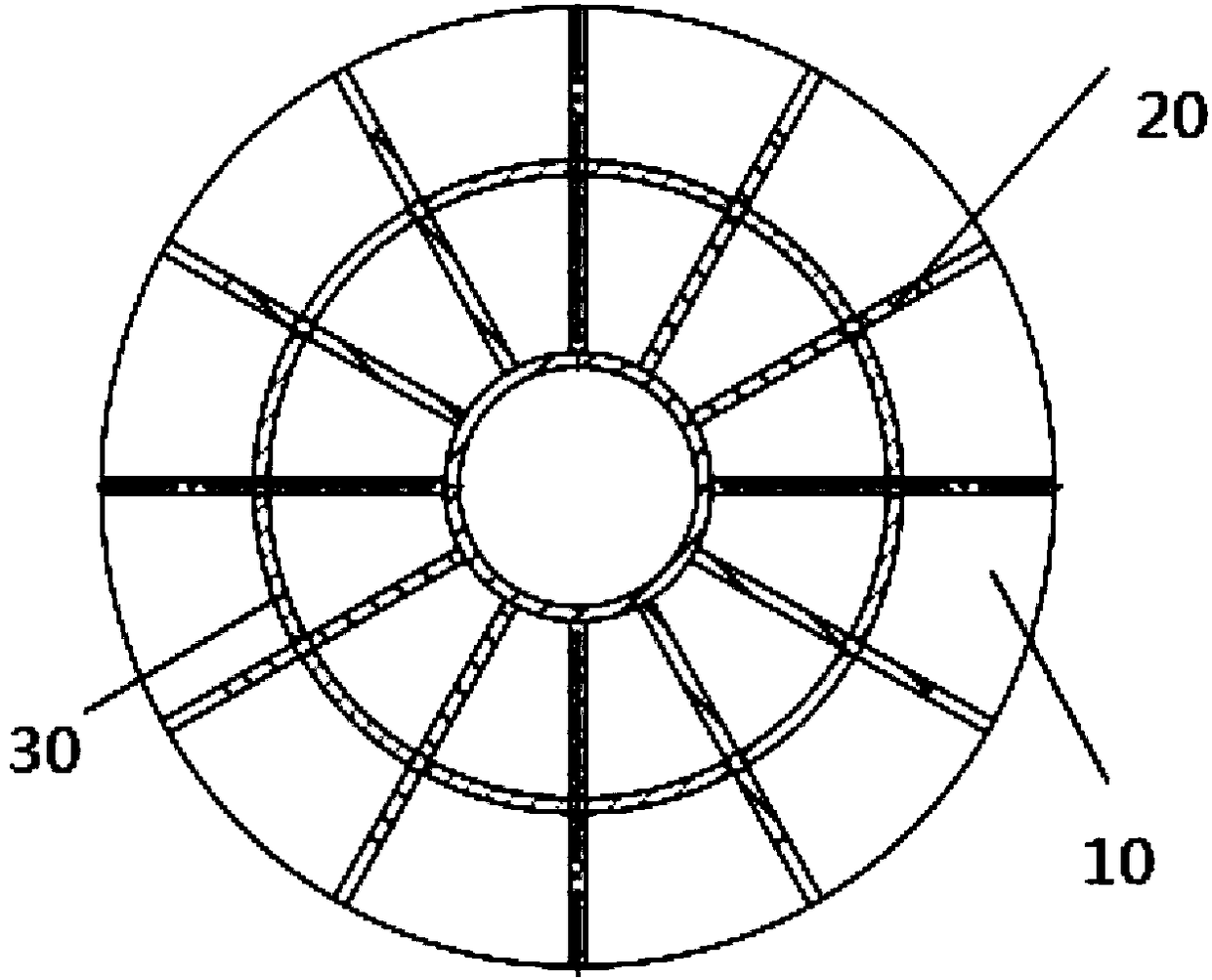

[0038] The invention provides a method for preparing a carbon fiber composite mirror, comprising:

[0039] Step 1, preparing the reflector panel 10: laying carbon fiber composite material prepreg on the mold of the reflector panel 10, and vacuum curing and forming;

[0040] Step 2. Prepare radial ribs 20 of the reflector: spread the carbon fiber composite material prepreg on the plane mold, and vacuum solidify to obtain a carbon fiber composite material flat plate, and process the carbon fiber composite material flat plate by cutting to obtain a shape matching the reflector panel. Mirror radial ribs 20;

[0041] Step 3. Preparing the reinforcing rib 30 in the circumferential direction of the reflector: laying the carbon fiber material prepreg on the cylinder mold, curing in a vacuum to obtain a cylinder of carbon fiber composite material, and processing the cylinder by cutting to obtain the reinforcing rib 30 in the circumferential direction of the reflector;

[0042] Step 4,...

Embodiment 1

[0059] The preparation steps of the carbon fiber composite mirror in the present invention are as follows:

[0060] In the first step, the mirror panel 10 is prepared. The high-modulus carbon fiber composite material prepreg is applied to the high-precision mold, and the lay-up adopts quasi-isotropic lay-up. Then put it into a vacuum bag and put it into a vacuum tank to solidify and form. According to different resin types, the range of curing temperature is 120-180°C, and the range of curing pressure is 0.1-1.0Mpa.

[0061] In this embodiment, M40JB is selected as the carbon fiber composite material, and the Young's modulus of the carbon fiber along the fiber direction is about 384Gpa; while for ordinary T700 carbon fiber composite material, the Young's modulus of the carbon fiber along the fiber direction is about 235Gpa.

[0062] The selection of curing parameters is affected by various factors. In this embodiment, the high temperature curing epoxy resin has a curing temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com