An Integrated Main Support Backplane for Lightweight Space Cameras

A space camera and main support technology, applied in the field of space optical remote sensing, to achieve excellent thermal stability, ensure surface shape accuracy, and good surface shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

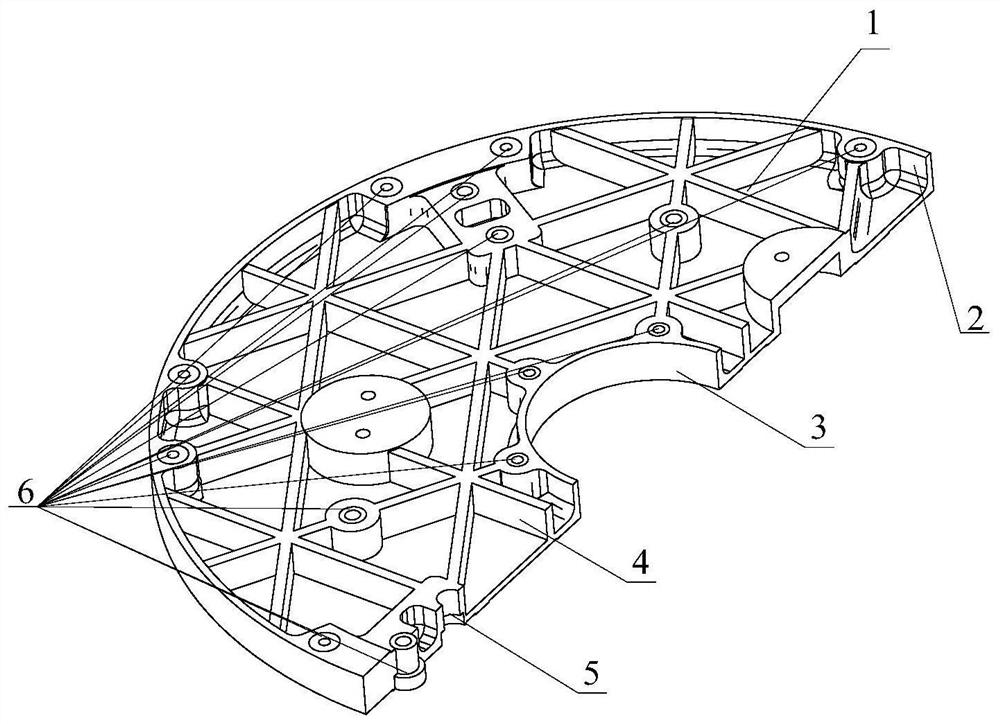

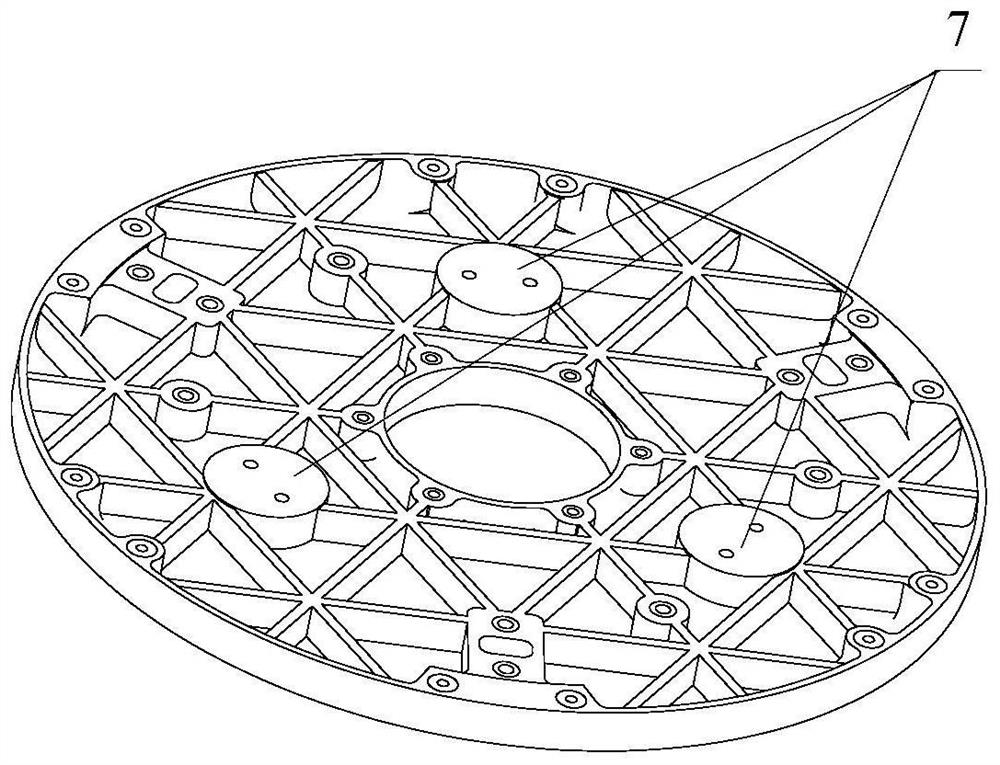

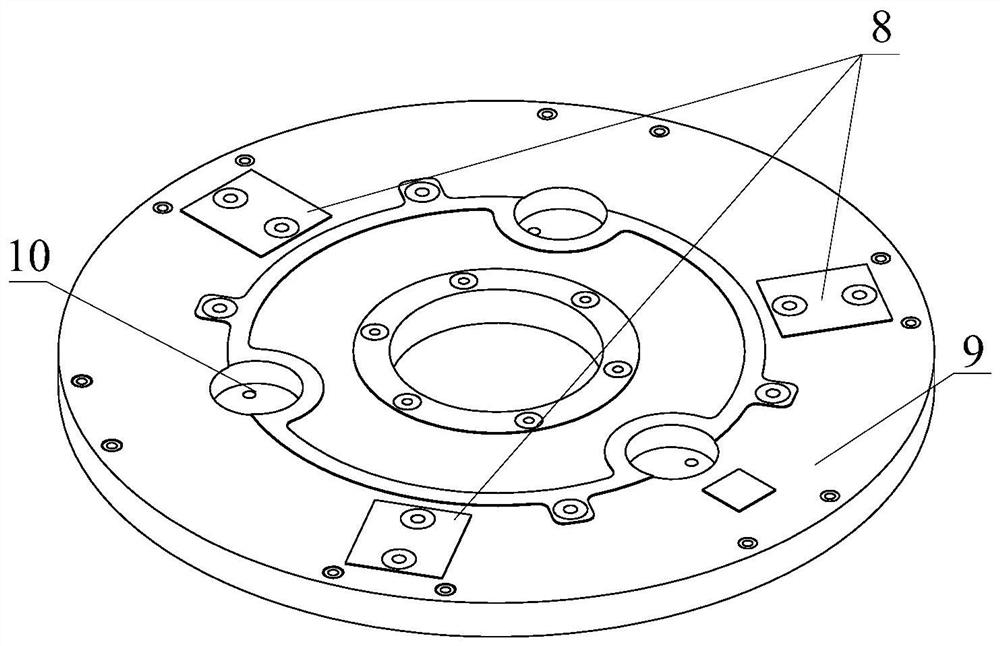

[0029] Such as figure 1 As shown, a comprehensive main support backboard suitable for light-duty space cameras, the backboard includes: ribs 4, embedded parts 6, main reflector mounts 7, camera leg mounts 8 and panels 9; The panel 9 has a ring structure, with a ring rib II3 on the circumference of the inner ring, and a ring rib I2 on the circumference of the outer ring; the panel 9, the ring rib I2 and the ring rib II3 form a silicon carbide substrate 1 . The embedded part 6 is arranged in the installation step hole 5 on the panel 9, and fits through gluing, wherein the installation step hole 5 is stepped, which can provide positioning constraints for the gluing of the embedded part 6, And it bears the axial tension of the embedded part 6, and there is a gap of 0.01mm-0.05mm between them for storing the adhesive. Such as figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com