Reflector and preparation method thereof

A mirror and glass plate technology, applied in the optical field, can solve the problems of increasing the cost and difficulty of aerial detection, being unable to bear its own weight, reducing reflective components, etc., and achieving the effect of high lightweight rate, high strength, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

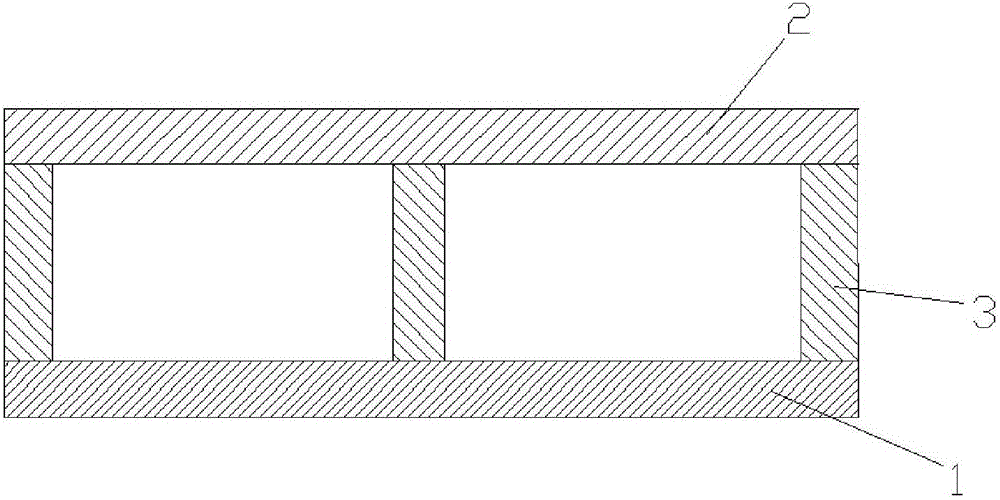

[0047] A method for preparing a reflecting mirror, comprising the steps of:

[0048] Material preparation: select the expansion coefficient as 5×10 -9 Quartz glass at / ℃ is used as the blank, with a diameter of 1200mm;

[0049] Preparation of the first glass plate and the second glass plate: the blank is subjected to cold processing to obtain a planar second glass plate, specifically, the quartz glass plate is obtained by cutting the quartz glass plate in layers with a diamond grinding wheel by means of milling, and the cutting amount is 2mm, the thickness of the first glass plate is 18mm, and the first glass plate is aspherical; the thickness of the second glass plate is 20mm, and the shape is planar;

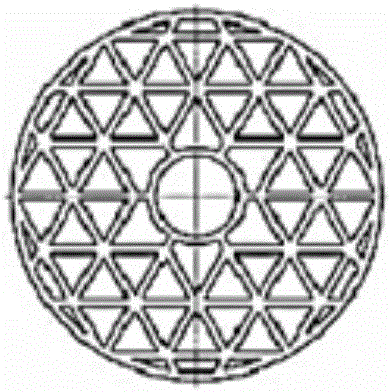

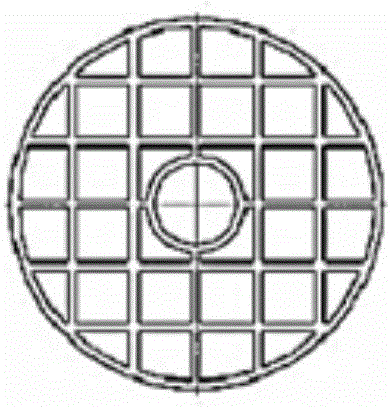

[0050] Preparation of lightweight interlayer: the blank is processed by numerical control to obtain a lightweight interlayer with weight-reducing holes. Specifically, diamond tools are used to cut or mill according to the set shape, and the feed rate is 0.1mm . The shape of t...

Embodiment 2

[0054] A method for preparing a reflecting mirror, comprising the steps of:

[0055] Material preparation: select the expansion coefficient as 5×10 -7 Quartz glass at / ℃ is used as the blank, with a diameter of 500mm;

[0056] Preparation of the first glass plate and the second glass plate: the blank is subjected to cold processing to obtain a planar second glass plate, specifically, the quartz glass plate is obtained by cutting the quartz glass plate in layers with a diamond grinding wheel by means of milling, and the cutting amount is 2mm, the thickness of the first glass plate is 8mm, and the first glass plate is spherical; the thickness of the second glass plate is 15mm, and the shape is planar;

[0057] Preparation of lightweight interlayer: the blank is processed by numerical control to obtain a lightweight interlayer with weight-reducing holes. Specifically, diamond tools are used to cut or mill according to the set shape, and the feed rate is 0.1mm . The shape of th...

Embodiment 3

[0061] A method for preparing a reflecting mirror, comprising the steps of:

[0062] Material preparation: select the expansion coefficient as 1×10 -7 Quartz glass at / ℃ is used as the blank, with a diameter of 1000mm;

[0063] Preparation of the first glass plate and the second glass plate: the blank is subjected to cold processing to obtain a planar second glass plate, specifically, the quartz glass plate is obtained by cutting the quartz glass plate in layers with a diamond grinding wheel by means of milling, and the cutting amount is 2mm, the thickness of the first glass plate is 15mm, and the first glass plate is planar; the thickness of the second glass plate is 22mm, and the shape is spherical;

[0064] Preparation of lightweight interlayer: the blank is processed by numerical control to obtain a lightweight interlayer with weight-reducing holes. Specifically, diamond tools are used to cut or mill according to the set shape, and the feed rate is 0.1mm . The shape of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com