Reflecting mirror and preparation method thereof

A mirror and glass plate technology, applied in the field of optics, can solve the problems of easy deformation of components, increase in the weight of mirrors, and reduce reflective components, and achieve the effects of extending service life, high lightweight rate, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for preparing a reflecting mirror, comprising the steps of:

[0051] Material preparation: select the expansion coefficient as 5×10 -9 Quartz glass at / ℃ is used as the blank, with a diameter of 1200mm;

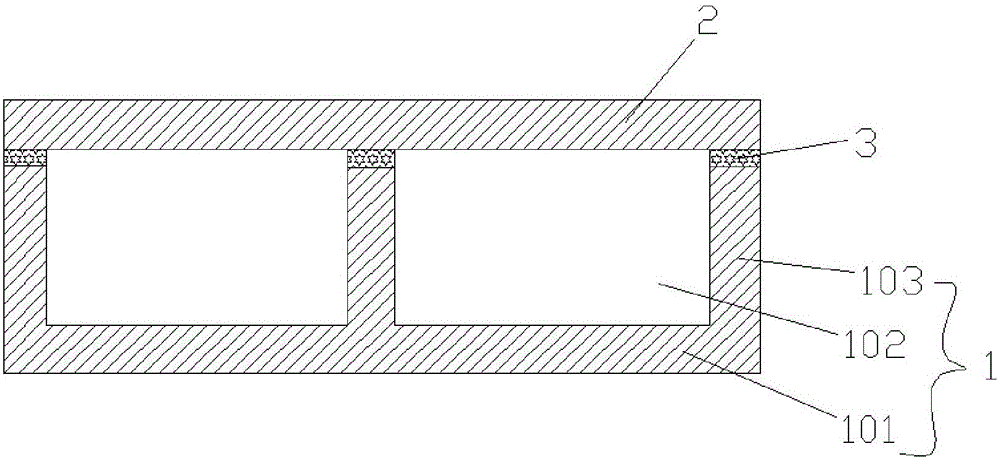

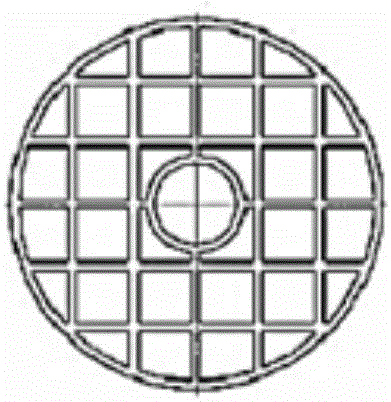

[0052] Preparation of lightweight structural layer: the blank is processed by numerical control to obtain the first glass plate with a support frame, specifically cutting or milling with a diamond tool according to the set shape, and the feed rate is 0.1 mm. The support frame and the first glass plate form a groove of a preset shape, the preset shape is a pentagon, and the grooves are connected to each other by punching holes in the groove wall; the thickness of the first glass plate is 20mm , the thickness of the support frame is 60mm, and the first glass plate is aspherical;

[0053] Preparation of the second glass plate: the blank is cold-processed to obtain a planar second glass plate, specifically, the quartz glass plate is cut in layers by means of mi...

Embodiment 2

[0057] A method for preparing a reflecting mirror, comprising the steps of:

[0058] Material preparation: select the expansion coefficient as 5×10 -7 Quartz glass at / ℃ is used as the blank, with a diameter of 500mm;

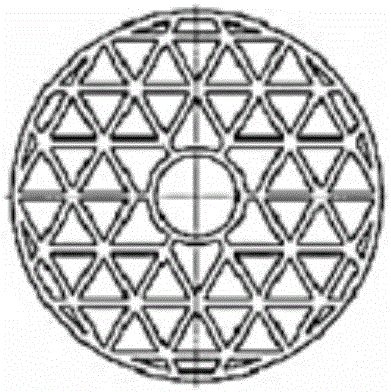

[0059] Preparation of the lightweight structural layer: cold processing the blank to obtain the first glass plate with a support frame, specifically cutting or milling with a diamond tool according to the set shape, and the cutting amount is 0.2 mm. The support frame and the first glass plate form a groove of a preset shape, the preset shape is a triangle, and the grooves are connected to each other by punching holes in the groove wall; the thickness of the first glass plate is 15 mm, and the supporting The frame thickness is 50mm, and the first glass plate is flat;

[0060] Preparation of the second glass plate: the blank is cold processed, specifically, the quartz glass plate is obtained by cutting the quartz glass plate in layers with a diamond grinding wh...

Embodiment 3

[0064] A method for preparing a reflecting mirror, comprising the steps of:

[0065] Material preparation: select the expansion coefficient as 1×10 -7 Quartz glass at / ℃ is used as the blank, with a diameter of 1000mm;

[0066] Preparation of a lightweight structural layer: cold processing the blank to obtain the first glass plate with a support frame, specifically cutting or milling with a diamond tool according to the set shape, with a feed rate of 0.3mm. The support frame and the first glass plate form a groove of a preset shape, the preset shape is fan-shaped; the thickness of the first glass plate is 28mm, the thickness of the support frame is 80mm, and the first glass plate is spherical;

[0067] Preparation of the second glass plate: the blank is subjected to cold processing to obtain a planar second glass plate, specifically, the quartz glass plate is obtained by cutting the quartz glass plate in a layered manner with a diamond grinding wheel by means of milling and g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com