Airtight oil tank

A technology for sealing fuel tanks and fuel tanks, which is applied to the fuel tanks of power plants, substructures, and vehicle components, and can solve problems such as complex aluminum alloys, easy cracks, and poor elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

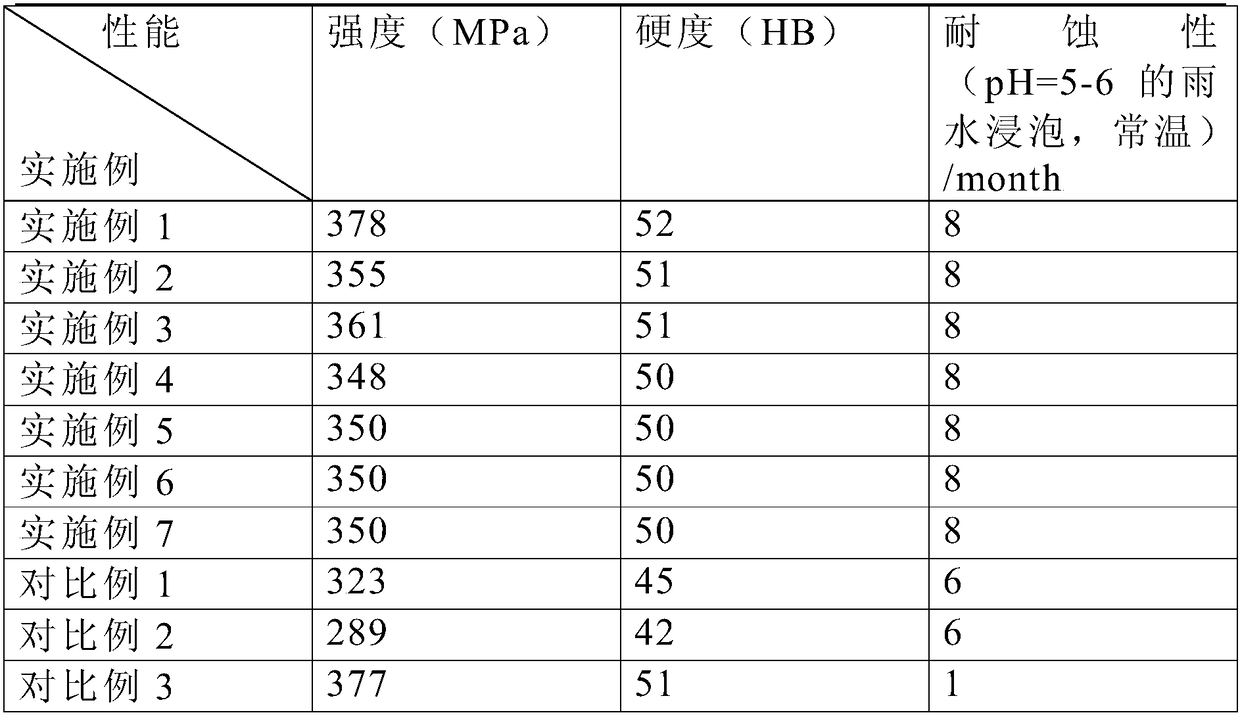

Examples

Embodiment 1

[0036] Ingredients: Weigh raw materials according to the composition and mass percentage of aluminum alloy, including: Si: 0.25%, Mn: 0.1%, Cr: 0.2%, Ni: 0.3%, Mo: 0.2%, Ti: 0.08%, C: 0.3 %, the balance is Al and impurities, wherein Si, Ti, C are weighed in the form of SiC, TiC granular compounds, impurities include H<0.001%, S<0.001%, N<0.001%, O<0.001%, Mn , Cr, Ni, Mo, Al are smelted directly into alloy liquid 1.

[0037] Purification: raise the temperature of alloy liquid 1 to 900°C, stir with a silicon rod, add SiC and TiC particles with a particle size of 8 μm while stirring, and simultaneously inject helium gas to obtain alloy liquid 2.

[0038] Sand core preparation: Mix and roll the original sand, binder and additives to form sand powder, in which the binder is calcium chloride and magnesium chloride, then fill the sand powder into the mold, and fill the mold with argon gas until the pressure is The semi-finished oil tank sand core is obtained at 3 atmospheres, and t...

Embodiment 2

[0042] Ingredients: Weigh raw materials according to the composition and mass percentage of aluminum alloy, including: Si: 0.2%, Mn: 0.05%, Cr: 0.1%, Ni: 0.2%, Mo: 0.1%, Ti: 0.05%, C: 0.1 %, the balance is Al and impurities, wherein Si, Ti, C are weighed in the form of SiC, TiC granular compounds, impurities include H<0.001%, S<0.001%, N<0.001%, O<0.001%, Mn , Cr, Ni, Mo, Al are smelted directly into alloy liquid 1.

[0043]Purification: raise the temperature of alloy liquid 1 to 900°C, stir with a silicon rod, add SiC and TiC particles with a particle size of 8 μm while stirring, and simultaneously inject helium gas to obtain alloy liquid 2.

[0044] Sand core preparation: mix and roll the original sand, binder and additives to form sand powder, in which the binder is calcium chloride and magnesium chloride, then fill the sand powder into the mold, and fill the mold with argon until the pressure is The semi-finished oil tank sand core is obtained at 3 atmospheres, and then t...

Embodiment 3

[0048] Ingredients: Weigh raw materials according to the composition and mass percentage of aluminum alloy, including: Si: 0.3%, Mn: 0.15%, Cr: 0.3%, Ni: 0.4%, Mo: 0.3%, Ti: 0.1%, C: 0.5 %, the balance is Al and impurities, wherein Si, Ti, C are weighed in the form of SiC, TiC granular compounds, impurities include H<0.001%, S<0.001%, N<0.001%, O<0.001%, Mn , Cr, Ni, Mo, Al are smelted directly into alloy liquid 1.

[0049] Purification: raise the temperature of alloy liquid 1 to 900°C, stir with a silicon rod, add SiC and TiC particles with a particle size of 8 μm while stirring, and simultaneously inject helium gas to obtain alloy liquid 2.

[0050] Sand core preparation: mix and roll the original sand, binder and additives to form sand powder, in which the binder is calcium chloride and magnesium chloride, then fill the sand powder into the mold, and fill the mold with argon until the pressure is The semi-finished oil tank sand core is obtained at 3 atmospheres, and then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com